Dosing Device Foamdos V6

Index: 00 Date modified: 18/05/2021 OI No.: BA DW 025-00 Foamdos V6 EN.DOCX Page 2 of 37

Table of contents

1About these instructions / general...........................................................................................................4

1.1 Scope of applicability...................................................................................................................................4

1.2 Target group...............................................................................................................................................4

1.3 Symbols used ..............................................................................................................................................4

1.4 Warranty....................................................................................................................................................5

1.5 Further information ....................................................................................................................................5

2Safety.......................................................................................................................................................6

2.1 Intended use ...............................................................................................................................................6

2.2 Safety notices..............................................................................................................................................6

2.2.1 Handling of chemicals, risks to humans and the environment .....................................................................6

2.2.2 Protective measures and rules of conduct...................................................................................................6

3Product description - scope of delivery....................................................................................................7

3.1 Scope of delivery / accessories ...................................................................................................................7

3.2 Product description.....................................................................................................................................7

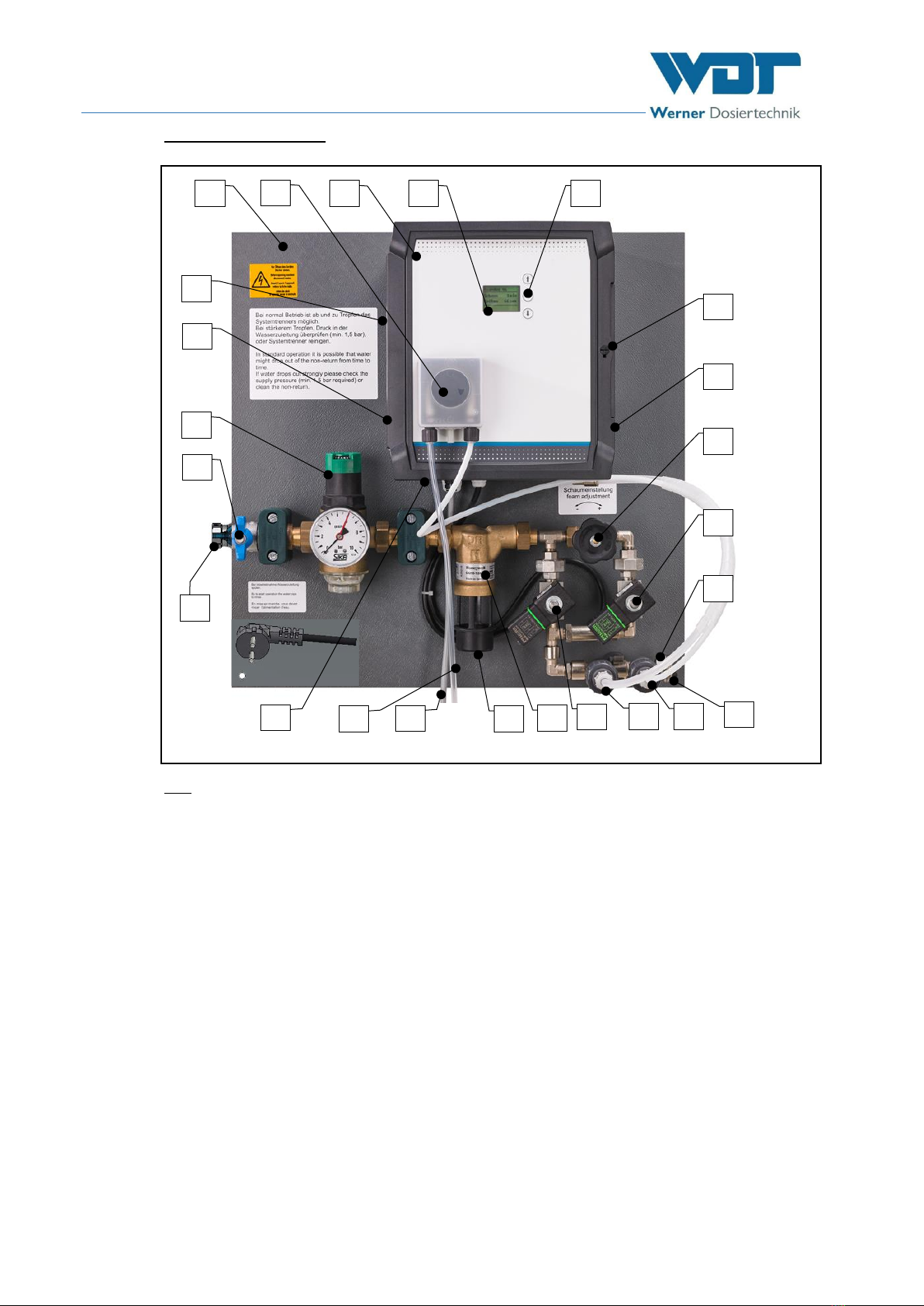

3.2.1 Dosing Unit.................................................................................................................................................9

3.2.2 Control unit ................................................................................................................................................9

3.2.3 Compressor................................................................................................................................................9

3.2.4 System separator ........................................................................................................................................9

3.2.5 Button plate ................................................................................................................................................9

3.2.6 Suction lance.............................................................................................................................................10

3.2.7 Drain valve (accessory) .............................................................................................................................10

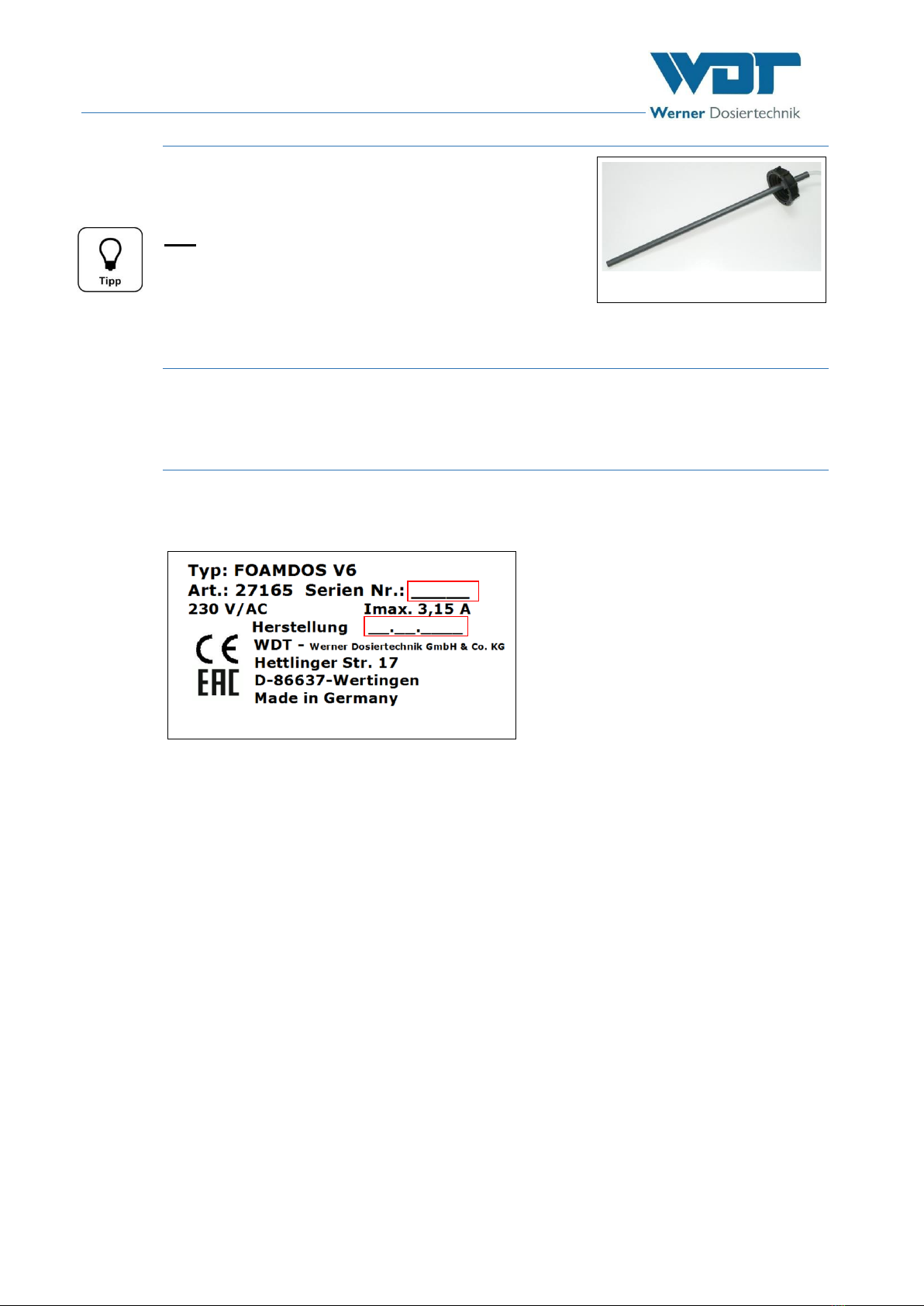

3.3 Device identification / identification plate .................................................................................................10

3.4 Technical data ...........................................................................................................................................11

3.5 Transport / storage ..................................................................................................................................12

3.5.1 Storage of foam concentrate.....................................................................................................................12

4Installation..............................................................................................................................................13

4.1 Select the installation site ..........................................................................................................................13

4.2 Installation instructions (suggested installation) .........................................................................................13

4.3 Mechanical installation...............................................................................................................................13

4.3.1 Install mounting plate with control unit .....................................................................................................13

4.3.2 Install the button plate ..............................................................................................................................13

4.4 Hydraulic installation.................................................................................................................................14

4.5 Electrical installation..................................................................................................................................16

4.5.1 Open/ close the housing...........................................................................................................................16

4.5.2 Establish electrical connection ...................................................................................................................16

5Commissioning.......................................................................................................................................17

5.1 Commissioning - remarks .........................................................................................................................17

5.2 Commissioning works...............................................................................................................................17

5.2.1 Prepare the foam concentrate ..................................................................................................................17

5.2.2 Insert the roller carrier at the fragrance pump..........................................................................................17

5.2.3 Establish power supply..............................................................................................................................18

6Operation / service ...............................................................................................................................19

6.1 General.....................................................................................................................................................19

6.2 Control unit - Software .............................................................................................................................19

6.3 Switch on Foamdos V6 .............................................................................................................................20

6.4 Button plate function ................................................................................................................................20

6.5 Control unit menus ...................................................................................................................................21

6.5.1 Foam time.................................................................................................................................................21

6.5.2 Flush time .................................................................................................................................................21

6.5.3 Pressure reduction....................................................................................................................................21

6.5.4 Test foam..................................................................................................................................................22

6.5.5 Test compressor .......................................................................................................................................22

6.5.6 Test SV flush .............................................................................................................................................22

6.5.7 Test SV foam ............................................................................................................................................22

6.5.8 Test emptying (accessory drain valve).......................................................................................................22

6.5.9 Test pump.................................................................................................................................................22

6.5.10 Test fault (not conducted by the factory) ..................................................................................................23

6.5.11 Emptying foam line (accessory) .................................................................................................................23

6.5.12 Emptying time (accessory emptying foam line)..........................................................................................23

6.5.13 Emptying type (accessory emptying foam line)..........................................................................................23