9 10777 - GB-CZ-HU-PL-RO-RU - 0 - 04 / 07

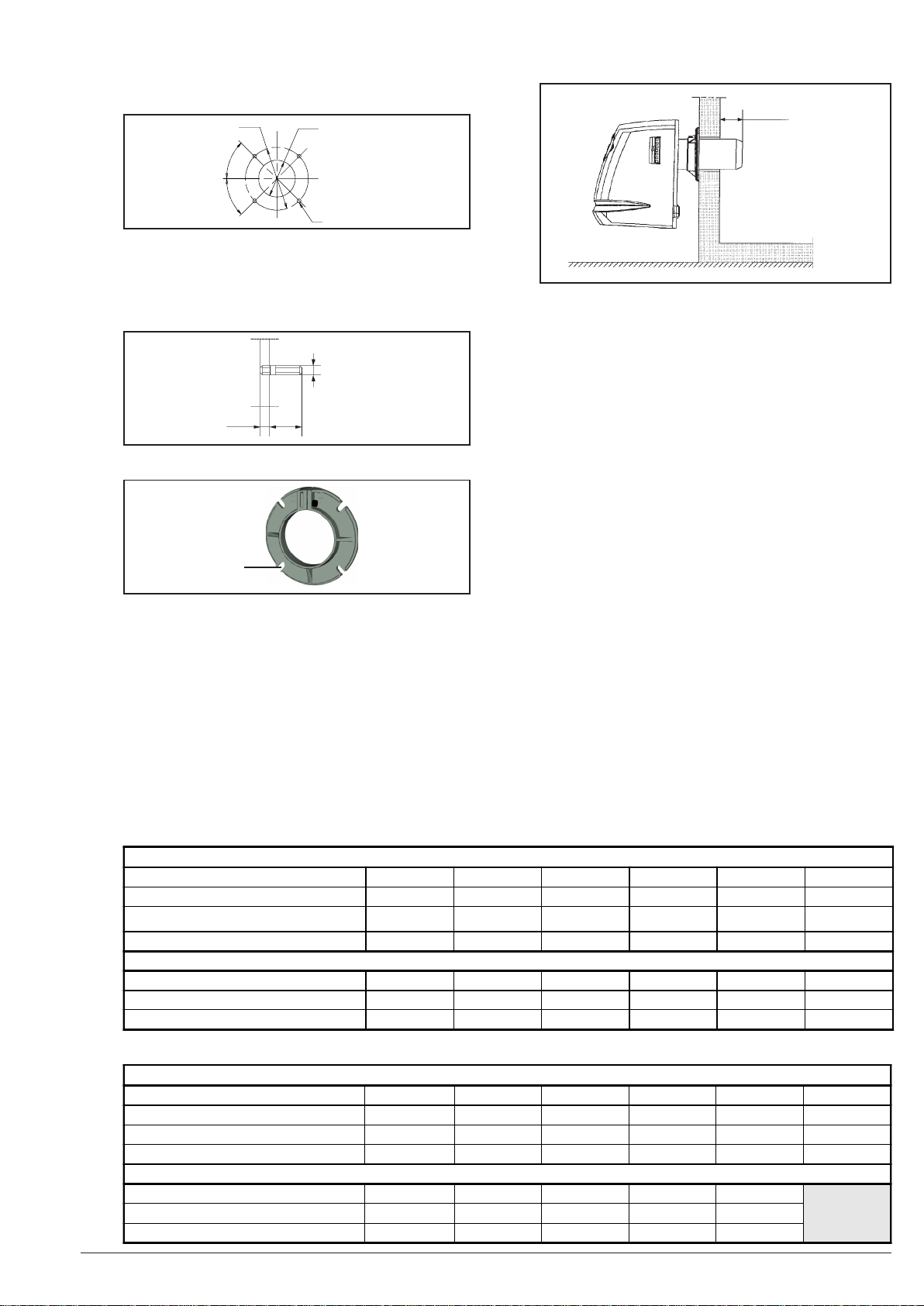

Two stage burner

- Adjusting the backflow air (flap)

- Servo moteur SQN 71 description:

1 red cam (I), 2nd rate cam,

2 blue cam (II) closing cam at stoppage,

3 orange cam (III) 1st rate cam,

4 black cam (IV) valve opening cam,

5 cam position angular marking,

6 shaft release button,

7 red and black cam adjustment key.

6.5 Oil pressure setting

- Switch on the burner. The programming unit indicator light (reference D) goes on, the fan starts (immediately if the burner

is “not reheated”) 50 seconds after switch on (if the burner is “reheated”). The burner ignites after 15 seconds of preliminary fanning.

- Using the setting screw (reference Q) set the fuel pressure by reading the value on the pressure gauge installed on the

pressure intake (reference K).

6.6 Combustion control

In principle this is controlled using an analyser with the burner cover on. If for convenience you have to work with the burner

cover off, the CO2measured should be 0.3 to 0.5% below the desired values (12 to 13% CO2).

- Shipping position: remove the servomotor cover. To

prevent damaging the air flap, the burner is

supplied with the servomotor set to position 0 (blue

cam).

- When powering on the burner, set the blue cam to

position 0 (screwdriver).

- Setting the 2nd air rate: after burner ignition, the

servomotor shifts to 2nd rate position. (setting

devices in demand). If required, fine tune this

setting by turning the red cam (130°) (adjustment

key).

- Setting the shift into 2nd rate: turn the black cam.

Set it upstream the 2nd rate cam (between the red

cam and orange cam, and very close to it) to

ensure the valve opens before full opening of the air

flap (adjustment key).

- Setting the 1st rate: fine tune this setting by turning

the orange cam (65° to 70°) (screwdriver).

- Suction air setting (intake): see the one stage burner

567

1234

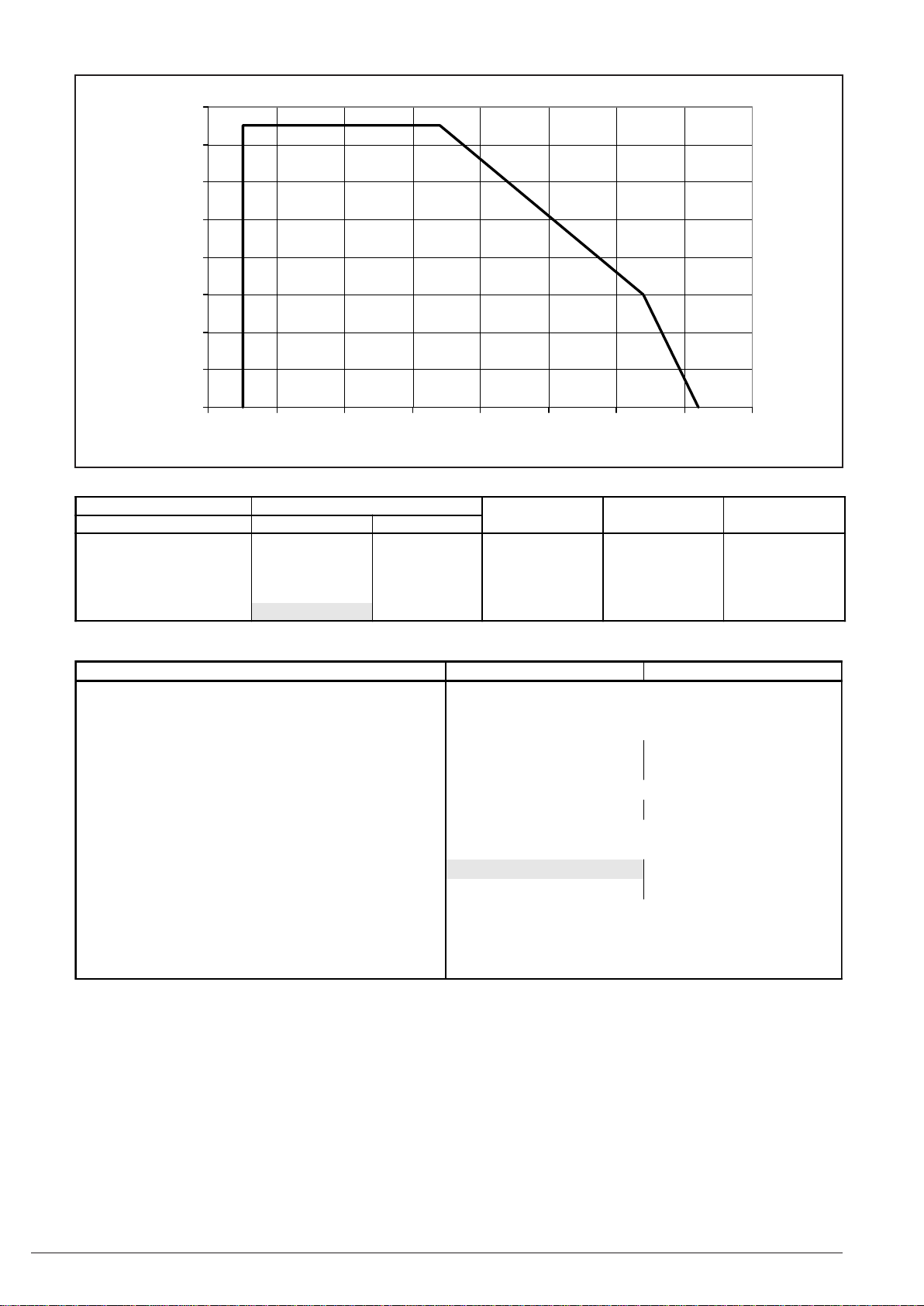

Case CO2Smoke Corrective action

One stage burner

0 12 to 13 ST = 0 No change

1 12 to 13 ST > 1 Check the settings parameters. Check the seal between the nozzle, boiler and chimney and

boiler door tigtness. Check the nozzle penetration in heating chamber. If the parameters are

correct, change the nozzle.

2CO

2>13 TTurn the button (reference V) to open the internal air flow regulator 1 or 2 notches (e.g. 3

to 4.5) to obtain CO2between 12 and 13%. Check the ST (if ST > case N° 1 return).

Check cold starting.

3CO

2< 12

Turn the button (reference V) to close the internal air regulmator 1 or 2 notches (e.g. 3 to 2).

If the CO2stays below 12 close the intake half a graduation (e.g. 8.5 to 8) and the refore

next to obtain CO2between 12 and 13%. Check the ST (if ST > 1 case N° 1 return).

Check cold starting.

Two stage burner

Adjusting the line (without touching the suction

intake) (2nd rate only) Air flap setting (without touching the line)

(1st rate only)

0 12 to 13 ST = 0 No change

1 12 to 13 ST > 1 Check the settings parameters. Check the seal between the nozzle, boiler and chimney and

boiler door tigtness. Check the nozzle penetration in heating chamber. If the parameters are

correct, change the nozzle.

2CO

2>13 Move the line backward by one increment,

by turning the ""L"" screw towards ""+"" and

check combustion.

Open the flap, by turning the orange cam on

the servomotor and check combustion.

3CO

2< 12 Move the line forward by one increment, by

turning the ""L"" screw towards ""-"" and

check combustion.

Close the flap, by turning the orange cam on

the servomotor and check combustion.

Boiler power (92% output) 80 90 95 100 105 110 115 120 125 130 135 140

One stage burner

DELAVAN 60° B nozzle 1.75 2.00 2.00 2.25 2.25 2.25 2.50 2.50 2.75 2.75 2.75 3.00

Pump pressure (bar) 11.0 10.8 12.0 10.6 11.7 12.8 11.3 12.3 11.1 12.0 12.9 11.6

Two stage burner

DELAVAN 60° W nozzle 1.25 1.35 1.50 1.50 1.75 1.75 1.75 2.00 2.00 2.00 2.25 2.25

Pump pressure (bar) 22.6 24.4 22.2 24.6 20.1 22.1 24.1 20.3 22.0 23.8 20.4 21.9