Solargen solar PV 3

Index.........................................................................................................................

Table Index................................................................................................................

Figure Index..............................................................................................................

Safety information.....................................................................................................

1.INTRODUCTION...................................................................................................

1.1.Preface...............................................................................................................

1.2.Supply and Packaging........................................................................................

1.3.Security Warnings...............................................................................................

1.4.Installation Standards.........................................................................................

1.4.1. Safety and Care..............................................................................................

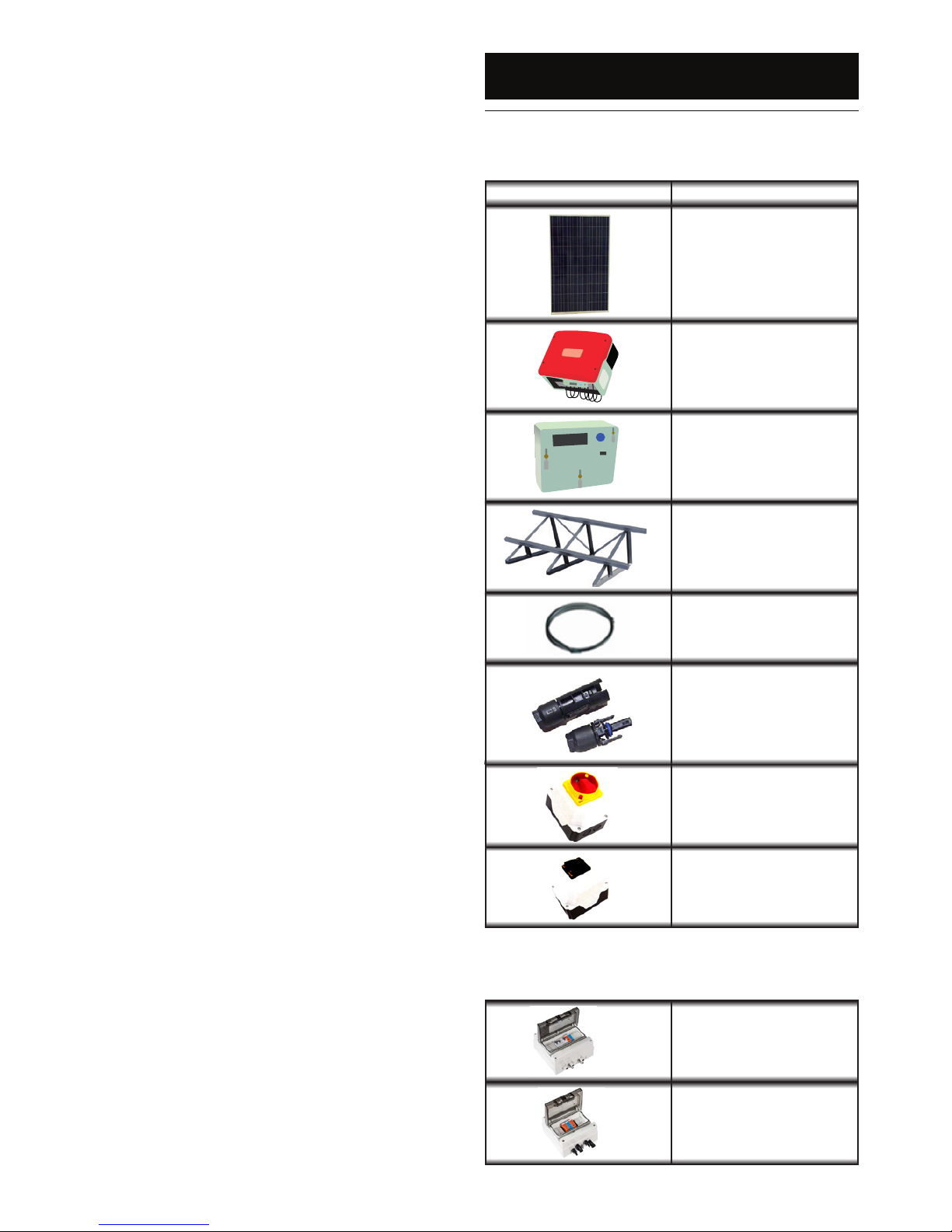

2.KIT CONTENTS..................................................................................................

3.PV KIT INSTALLATION.......................................................................................

3.1.PV module........................................................................................................

3.1.1.Choosing the site...........................................................................................

3.1.2.Installation guidelines.....................................................................................

3.1.3.Mechanical characteristics..............................................................................

3.1.4 Mechanic Installation.....................................................................................

3.2.PV Generator....................................................................................................

3.2.1.PV series connection.....................................................................................

3.2.2.PV module fastening......................................................................................

3.3.DC Electric Box (available as an optional extra)...............................................

3.3.1.Components....................................................................................................

3.3.2.Location..........................................................................................................

3.3.3.Electric Scheme.............................................................................................

3.3.4.Crimp connectors...........................................................................................

3.4.Inverter..............................................................................................................

3.4.1.Installation requirements................................................................................

3.4.2.Clearances.....................................................................................................

3.4.3.Position..........................................................................................................

3.4.4.Mounting the inverter.....................................................................................

3.4.5.Connecting PV strings to the inverter.............................................................

3.5. AC electric box (available as an optional extra)...............................................

3.5.1.Description.....................................................................................................

3.5.2.Location..........................................................................................................

3.5.3.Single line diagram.........................................................................................

3.6.Connection to the grid.......................................................................................

3.6.1.AC cable size.................................................................................................

3.7.Energy meter.....................................................................................................

3.7.1.Warnings........................................................................................................

3.7.2.Environmental requirements..........................................................................

3.7.3.Cabling...........................................................................................................

3.7.4.Cable specication.........................................................................................

3.7.5.Installation data..............................................................................................

3.7.6.Dimensions and mounting..............................................................................

3.8.Electrical diagrams............................................................................................

4.PV SYSTEM PROTECTION................................................................................

4.1.Protection against lightening.............................................................................

4.1.1.Array Frame Earthing Decision Tree..............................................................

4.2.Protection against direct contact.......................................................................

4.3.Protection against indirect contact....................................................................

4.4.Warning and note signs.....................................................................................

4.4.1.Location of the safety labels...........................................................................

5.PV SYSTEM COMMISSIONING..........................................................................

5.1.Connect a PV system........................................................................................

5.2.Disconnect the PV system................................................................................

5.3.Security notes...................................................................................................

6.MAINTENANCE MANUAL.................................................................................

6.1.General information..........................................................................................

6.2.PV generator....................................................................................................

6.3.Inverter.............................................................................................................

6.3.1.Safety Warnings............................................................................................

6.3.2.Inverter operation conditions.........................................................................

7.SUPPORTING STRUCTURE ASSEMBLING MANUAL....................................

7.1.Flat roof............................................................................................................

7.2.Parallel to pitched roof......................................................................................

8.WARRANTY........................................................................................................

9.MAINTENANCE..................................................................................................30

10.NOTES..............................................................................................................31

Index

3

4

5

6

8

8

8

8

8

9

10

11

11

11

11

11

11

12

12

12

13

13

13

13

13

14

14

14

14

15

15

16

16

16

16

16

16

17

17

17

17

17

17

17

18

19

19

19

20

20

20

20

21

21

21

21

22

22

22

22

22

22

23

26

26

29

© Baxi Heating UK Ltd 2011. All rights reserved. No part of this publication may be reproduced or

transmitted in any form or by any means, or stored in any retrieval system of any nature (including

in any database), in each case whether electronic, mechanical, recording or otherwise, without

prior written permission of the copyright owner, except for permitted fair dealing under Copyrights,

Designs and Patents Act 1988.

Applications for the copyright owner’s permission to reproduce or make other use of any part of

this publication should be made, giving any details of the proposed use to the following address:

The Company Secretary, Baxi Heating UK Ltd, Brooks House, Coventry Road, Warwick CV34 4LL.

Full acknowledgement of author and source must be given.

WARNING: Any person who does any unauthorised act in relation to a copyright work may be

liable to criminal prosecution and civil claims for damages.