BayWa novotegra closed II User manual

I

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

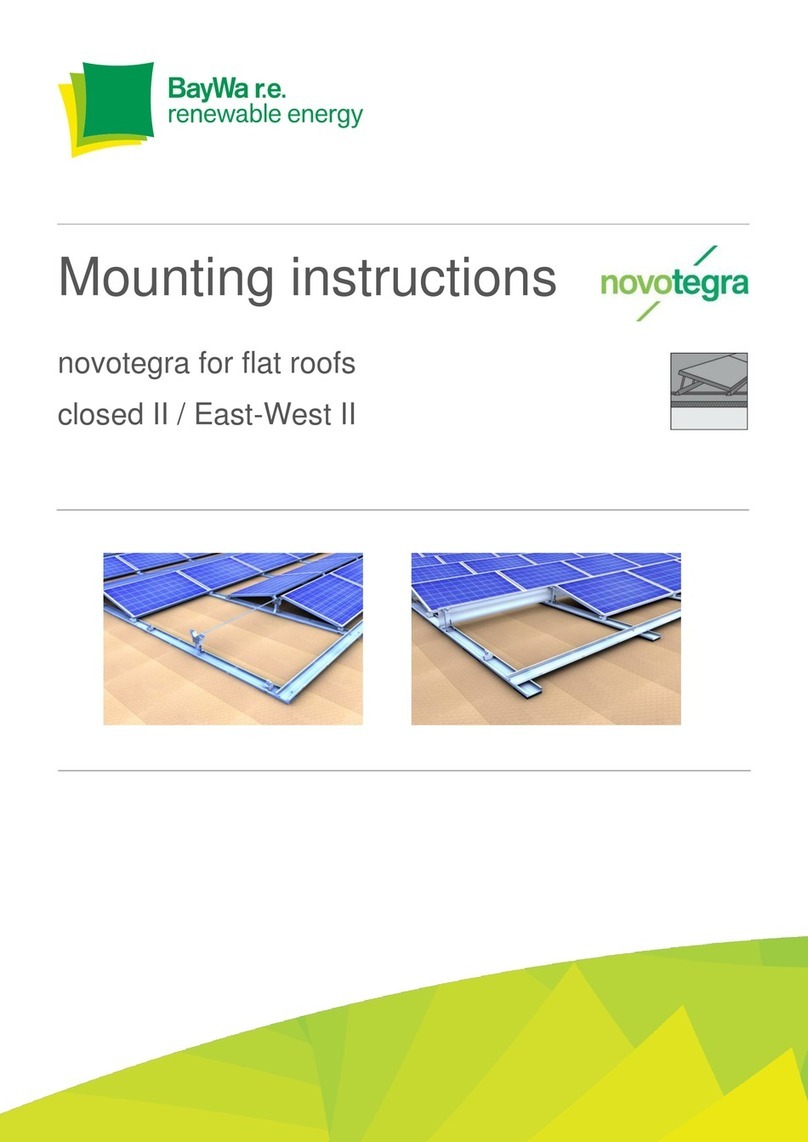

Mounting instructions

novotegra for flat roof

closed II / east-west II

II

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

TABLE OF CONTENTS

1Notes .................................................................................................................... 1

2Maintenance of the mounting system ............................................................... 3

3novotegra for facade........................................................................................... 4

4System components, tools and equipment ...................................................... 5

4.1 What is required for mounting.......................................................................... 5

4.2 Mounting system components – mounting versions ........................................ 6

4.3 Mounting system components – optional......................................................... 7

5Installing the mounting system ......................................................................... 8

5.1 Installing the base troughs and support components....................................... 8

5.2 Module installation, load redistribution and ballast........................................... 9

5.3 Mounting variations........................................................................................ 11

6Warranty / product liability (exclusion) ........................................................... 16

1

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

1 Notes

The following instructions are generally valid for our mounting system novotegra and are to be applied or

interpreted accordingly regardless of the respective roof and mounting system type.

Safety information

Mounting tasks may only be carried out by qualified and competent persons. During the work protective

clothing in accordance with the relevant national regulations and guidelines must be worn.

Mounting must be carried out by at least two persons to ensure help in case of an accident.

All relevant national and locally applicable health and safety regulations, accident prevention regulations,

standards, construction standards and environmental protection regulations as well as all regulations of the

employers’ liability insurance associations must be complied with.

The national regulations for working at height / on the roof must be complied with.

Electrical work must be carried out in compliance with the national and locally applicable standards and

guidelines and the safety rules for electrical work.

Earthing / equipotential bonding of the mounting system must be carried out in accordance with the

national and locally applicable standards and guidelines.

Categorisation into hazard classes

To alert the user of potential danger situations the hazard classes analogous to ANSI Z 535 are used. The

hazard class describes the risk if the safety information is not observed.

Warning symbol with signal word

Hazard class analogous to ANSI Z 535

DANGER! describes an immediate danger. If it is not

avoided, death or serious injury will result.

WARNING! describes a potential danger. If it is not avoided,

death or serious injury might result.

CAUTION! describes a potential danger. If it is not avoided,

light or minor injury might result.

NOTE! describes a potentially harmful situation. If it is not

avoided, the plant or objects in its vicinity might be damaged.

General information

After receipt the goods must be inspected for completeness using the accompanying delivery note.

BayWa r.e. Solar Energy Systems GmbH does not accept the costs, nor can we guarantee subsequent

express deliveries if missing material is only noticed during mounting.

Since our mounting systems are subject to continuous development, mounting processes or components

may change. Therefore, please check the current status of the mounting instructions on our website prior to

mounting. We are also happy to send you current versions upon request.

The mounting system is suitable for the attachment of PV modules with standard market dimensions.

Please find more detailed information about this in chapter 3.

The usability of the mounting system for the respective project must be checked for each individual case on

the basis of the roof cover / roof construction / facade present.

2

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

The roof cover / roof construction / facade must meet the requirements of the mounting system with regard

to load bearing capacity, support structure and condition.

Requirements for the material of the roof construction / roof cover / facade:

Wooden components (rafters/purlins): min. strength class C24, no fungus infection or rot

Tensile strength Rm, min for trapezoidal metal: steel 360 N/mm²; aluminium 195 N/mm²

Wall construction material: concrete, brick or sand-lime brick in solid or hollow block design.

The load bearing capacity of the roof / roof construction (rafters, purlins, trapezoidal metal, concrete floors,

number of adhesive points, folded seams, etc.) or the facade (wall construction materials) must be checked

by the user or a check be commissioned.

Physical building aspects concerning insulation penetrations (e.g. condensation) must be taken into

account by the user.

Notes on mounting

The components of the novotegra mounting system are intended exclusively for the attachment of PV

modules. Dependent on the roof type of the building the designated mounting system components must be

used.

A condition for the intended use of the novotegra mounting system is the mandatory compliance with the

specifications in these instructions regarding safety information and mounting.

In case of unintended use and non-compliance with the safety information and mounting instructions and

non-utilisation of the corresponding mounting components or use of third party components not belonging

to the mounting system any warranty and liability claims against the manufacturer are voided. The user is

liable for damage and resulting consequential damage to other components, such as PV modules, or the

building as well as personal injury.

The user must read the mounting instructions prior to mounting. Unresolved issues must be clarified with

the manufacturer prior to mounting. The mounting sequence in these instructions must be adhered to.

It must be ensured that a copy of the mounting instructions is accessible in the immediate vicinity of the

work on site.

The mounting specifications (module load, attachment, clamping areas etc.) of the module manufacturer

must be observed and complied with.

Prior to mounting the mounting system must be statically calculated with the loads to be assumed for the

building project in accordance with the national standards. Information relevant to mounting (e.g. roof hook

distance, lengths of bolts, overhang and protrusions or distance of base trough and required ballast) must

be determined by the static calculation using the design software www.solar-planit.

The permissible roof inclination for using the mounting system according to these installation instructions is

0 to 60 degrees for roof-parallel installation on a pitched roof and 0 to 5 degrees for elevated installation on

a flat roof. Facade systems must be mounted parallel to the facade.

For roof-parallel installation with the clamping system, two module support rails per module must be

mounted symmetrically under the modules for equal load transfer into the substructure. Alternatively, the

roof-parallel installation can also be installed with insertion rails.

The specified tightening torques must be adhered to and checked randomly on site.

Notes on static calculations

The mounting system must generally be statically calculated for each individual project using the design

software Solar-Planit. Excluding façade systems, the calculation for this will be carried out by the company

BayWa r.e. Solar Energy Systems GmbH.

The static calculation only determines the load bearing capacity of the novotegra mounting system and also

takes account of the attachment to the building (rafters, purlins, trapezoidal metal, facade etc.). The load

transfer within the building is not considered (customer static calculations).

The load bearing capacity of the mounting system components is determined on basis of the planned

module layout and the underlying building information (project data recording). Deviations from the

planning on site may lead to different results.

3

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

The load assumptions (load and roof division) are country-specific in accordance with the specifications of

the Eurocode load standards. The determination of the loads to be assumed for Switzerland is in

accordance with SIA 261.

At pitched roof, the modules may not be fitted above the gable end, ridge and eaves or the facade

(increased wind load). At the ridge the modules may be fitted up to max. a theoretical horizontal line with

the ridge tile and perfectly flush with the gable end. In the eaves area the modules may reach to max. the

end of the roof cover due to loads.

In case of an exposed building position (with wind load e.g. at the edge of a slope) or snow accumulation

(e.g. dormer or catchment grill or roof structures like domelights etc) the specifications of the Eurocode load

standards or SIA 261 (Switzerland) must be taken into account by the user within his own responsibility.

The design software does not consider these cases.

The static calculation of the mounting system is based on the symmetrical placement of the modules on the

mounting rails at the longitudinal side of the modules (roof-parallel clamping systems) or on the support

components (elevation) for equal load transfer into the substructure. For the insertion system a cross rail

arrangement is expected for equal load transfer.

The results calculated with the design software, such as distances of the fasteners (e.g. roof hooks, stock

screws, saddle clamps etc.), rail lengths and number of fasteners (e.g. direct attachment on the trapezoidal

metal), overhang (e.g. rail and roof hook protrusions) or distances between the base troughs and number

of fixing materials (e.g. rail joint)and the other calculation notes must be considered and complied with.

novotegra has been tested and certified by TÜV Rheinland:

2 Maintenance of the mounting system

The mounting system must be checked for stability and operation at regular intervals during the system

maintenance.

In addition to the visual inspection of the components, we recommend a random check of the connections

and the safe and correct position of the ballast on the base rails and ballast troughs.

Removal is possible in reverse order in the work steps mentioned below.

The maintenance work must be carried out by a specialist company with proven experience in electrical

systems and work on mounting systems.

4

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

3 novotegra for flat roof

The contents of this installation manual describe the installation of the substructure on roofs with sheet or

bitumen waterproofing, with or without gravel respectively substratum.

Depending on the roof seal material, separation and/or protection membranes may need to be added

between the roof seal and the substructure. This must be agreed upon directly between the company

installing the PV system, the building owner and the specialist roof sealing company.

The substructure is installed without penetrating the roof. The PV system is secured against wind suction

by providing ballast (e.g. suitable stones), based on the results of the wind tunnel tests for the system. The

required ballast is determined by BayWa r.e. Solar Energy Systems GmbH based on the project data

provided by the installation company. The ballast applies to the planned system; on-site deviations from

planning may lead to different results.

Protection against system sliding is verified based on a coefficient of friction of µ = 0.5. This value must be

checked by the installation company prior to installation. If the coefficient of friction is determined by the

installation company in advance, protection can be verified during planning using the determined value.

The system must be secured on site to prevent it from "creeping" due to expansion caused by temperature.

This can be achieved by installing suitable stop points on the roof surface or by anchoring to the parapet,

for example. The connection points on the building and building parts must be able to bear the forces

exerted.

General conditions to be observed in accordance with the wind tunnel test results:

- Roof incline 0 – 5 degrees

- Flat roofs with and without parapet

- Distance from system to roof edge (without parapet) = 0.50 m

- Distance from system to parapet (inside edge) = 0.50 m

- Module width = min. 0,92 m; max. 1,08 m

- Module length = max. 2,08 m

- Angle of installation (fixed) = 13°

- Distance between rows = 1.30 – 2.40 m (closed II) respectively 2.15 – 2.40 m (East-West II)

The installation system is designed for loads of up to 2.4 kN/m² (2,400 Pa). The modules are clamped on

the short frame side or, alternatively, on the long frame side in the corners (clamp surface 11 x 52 mm).

This requires approval from the module manufacturer for clamping on the short frame side or on the corner

of the long frame side. Any drainage openings on the module frame may not be blocked. This also applies

to the features provided for this purpose on the support components.

5

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

4 System components, tools and equipment

4.1 What is required for mounting

Figure

Tool

Component*

Product group

Base trough 150-30

Material: Aluminium Profile rails

Base trough connector 150-30 I

Material: Aluminium

Tool: Socket bit AF 8 mm

Rail connectors and

expansion joints

Base trough expansion joint 150-30

Material: Aluminium and stainless

steel

Tool: Socket bit AF 8 mm

Rail connectors and

expansion joints

Base foot set

Material: Aluminium Module elevation

Module support set 13°

Material: Aluminium Module elevation

Flat roof mid clamp

Material: Aluminium and stainless

steel

Tool: Socket bit AF 8 mm

Module elevation

Flat roof end clamp

Material: Aluminium and stainless

steel

Tool: Socket bit AF 8 mm

Module elevation

Flat roof end clamp (short side)

Material: Aluminium and stainless

steel

Tool: Socket bit AF 8 mm

Module elevation

Wind deflector 13°

Material: Aluminium

Tool: Socket bit AF 8 mm

Module elevation

Flat roof mounting screw chipless

Material: stainless steel

Tool: Socket bit AF 8 mm

Fastening equipment

Aluminium edge protector self-

adhesive

Material: Aluminium

Sealing parts and

protective devices

* The components vary depending on the requirements of the roof, the structural analysis and the choice of

components and may deviate from the images above.

6

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

Figure

Equipment

Use for tool

Application

Cordless

screwdriver

Bit Torx TX 40

Socket bit AF 8 mm

Component

connections, clamp

assembly

Torque key up

to at least

12 Nm

Socket bit AF 8 mm Clamp assembly

Chopsaw --- Cutting rails

Place / replace

tool base

trough 150-30

For place / replace of base foot and

module supports set in the base

trough 150-30

Correct installation

4.2 Mounting system components – mounting versions

Figure

Tool

Component**

Product group

Module support set 13° e/w

Material: Aluminium Module elevation

Support brace 20x20x1.5

Material: Aluminium Profile rails

Wind deflector 13° e/w

Material: Aluminium

Tool: Socket bit AF 8 mm

Module elevation

C-rail (base profile, base trough)

Material: Aluminium Profile rails

Rail connector set

Material: Aluminium and stainless

steel

Tool: Special lock nut AF 18 deep

Profile rails

PE pad 140 x 390 x 20 mm

Material: PE foam

** Required components for ballast distribution at system edge, depending on substructure construction.

7

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

4.3 Mounting system components – optional

Image

Tool

Component***

Product group

Ballast trough

Material: Aluminium Module elevation

Coupling profile C47 385 mm

Material: Aluminium

Tool: Socket bit AF 8 mm

Profile rails

Base trough cable bracket

Material: Plastic

Cable management

Top cover base trough 150-30

3.00 m

Material: Aluminium

Module protection

and rail top cover

Cable-tie clip for profile flange Cable fixing

Cable clip d = 10 mm Cable fixing

Grounding connector set AF 18

Material: stainless steel

Tool: Special lock nut AF 18 deep

Accessories and

optional components

Perforated Alu-tape 10,000 x 20 x 1

Material: Aluminium

Tool: Socket bit AF 8 mm

Accessories and

optional components

Mounting-Set Optimizer FR Accessories and

optional components

Contact latch module clamp Accessories and

optional components

*** Optionally available installation system components, e.g. for improving the aesthetics of the system,

cable management or grounding of the installation system.

8

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

5 Installing the mounting system

Prior to installation, the module array must be measured out on the roof and the position of the modules

determined, taking into account any obstacles such as light domes or strips, fans or drains.

The individual installation steps of the system variant closed II (south facing) are described below.

References are made to mounting versions (MV) for the various design possibilities respectively to the

system variant east-west II. The associated work steps are described at the end.

5.1 Installing the base troughs and support components

Arranging the base troughs

Install the base troughs centrally beneath the

module joint (MV 1).

Maximum module field size without measurements

(MV 4) for compensation of temperature-related

length expansions 17 x 17 m (Module field 10 x 10

with approx. 1.70 m row distance).

Distance to adjacent module field: min. 50 mm

System edge / module joint:

eM= module length + 12 mm

Observe the accident prevention regulations when

sawing.

Base trough variations

1 2 3

Selection of the base trough depends on the

respective project with recognition to the roof

characteristics.

1. base trough 150-30 w/cross drainage

2. base trough 150-30 w/protection layer

3. base trough 150-30 (bare)

Connecting the base troughs

Push the ends of the base troughs tightly together,

put the connectors under the ridge of the base

troughs and fix them by using two screws for each

connector.

Maximum uninterrupted rail length approx.17 m,

then install expansion joint or disconnect the rail

(MV 4).

The base trough joints and base trough ends must

be covered using the self-adhesive edge protection

provided.

The distance between the base troughs in the joint

may not exceed 100 mm.

eM

eM

Edge e

M

joint

e

M

joint

9

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

Installing the base foot

Insert the component into the base trough on one

side as shown and then click into the base trough. If

a base foot is located above an elongated hole, it

must always be secured with a screw.

Prior to installation, the position (installation axis) of

the components must be determined on the base

trough.

Depending on the conditions on site, it’s

recommended to use the mounting and removal

tool.

Installing module supports

Insert the component into the base trough on one

side as shown and then click into the base trough.

Installation module support east-west regarding MV

6.

Prior to installation, the position (installation axis) of

the components must be determined on the base

trough.

Depending on the conditions on site, it’s

recommended to use the mounting and removal

tool.

5.2 Module installation, load redistribution and ballast

Installing the module

Place the module landscape on the base feet and

put it on the module support set afterwards.

Please see MV 7 for further information regarding

module installation for east-west II.

Connect the cables of adjacent modules while

installing them.

Place the string cables first.

10

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

Fastening the modules on the row end

Secure modules at the end of a row or at a

interruption in the row (light domes, fans, etc.) using

the flat roof end clamp (short side).

Push the clamping block of the module fastener

beneath the module, place the fastener on the

module and fix the drilling screw through the

borehole.

Tightening torque max. 6 Nm.

The screw must not be overtightened!

Clamping takes place on the short frame side.

Please observe the mounting instructions of the

module manufacturer.

Fastening the module to the module joint

Place the subsequent module on the base foot or

module support. Determine the gap between the

modules (12 mm) by inserting the flat roof mid

clamp. Insert the module fasteners so that the

drilling screw is positioned in the borehole on the

base foot or module support.

Tightening torque max. 6 Nm.

The screw must not be overtightened!

Clamping takes place on the short frame side.

Connection rail

To reduce ballast on the southern (East-West) edge

or at interruptions in the system (e.g. along light

domes or maintenance walkways), place a base

trough 150-30 rectangular on the base troughs as a

connection rail and each with two screws per base

trough. Extension using base trough connectors or

expansion joints at system interruptions. Arrange

the expansion joints identically to the expansion

joints of the module supports. Cut the base troughs

to length if required.

The connection rail can be used to place the string

cable or to insert / put on the required ballast.

Further rails can be used to redistribute load:

C-rail 47, 71 and 95, support brace

11

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

Ballast

Place the required ballast in accordance to the

ballast planning inside or on top of the base troughs

after installing the modules. The required ballast

depends on the system area and is specified in the

ballast plan in kg and/or number of stones. The

ballast can be laid out under, in front of or behind

the module to place all the required ballast. The

selection of the ballast stone is up to the customer,

the dimensions are to be adapted to the weight of

the ballast indicated at each point.

For ballast installations using large amounts of

ballast, ballast troughs (MV 9) or additional base

troughs under the module are recommended

(MV 5).

Installing the wind deflector

Guide the wind deflector over the round part of the

module supports and place it on the base trough.

Install the adjacent wind deflector for the following

module with an overlap of at least 150 mm to the

first wind deflector.

Secure the wind deflectors to the base troughs with

two screws for each base trough and to the round

part of the module support with one screw.

The screw must not be overtightened!

5.3 Mounting variations

Explanation of the installation variants depending on the roof construction or design variants.

MV 1 – Flush base troughs on system edge

Alternatively, the first base trough at the system

edge / expansion joint must be installed flush with

the modules, the subsequent troughs must be

positioned centrally beneath the module joint.

Prerequisite:

Flat roof end clamp (MV 2)

Approval module manufacturer for module clamping

required

System edge / expansion joint:

eA= module length – 69 mm

Module joint:

eM= module length + 12 mm

> 150

eM

eA

5 kg

10 kg

23 kg

5 kg

10 kg

23 kg

Edge e

A

joint

e

M

joint

12

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

MV 2 – Module fastening long side

Place the drilling screw from the flat roof end

clamp centred over the screw channel of the base

foot or module support and screw in.

Tightening torque max. 6 Nm.

The screw must not be overtightened!

Approval from manufacturer required for clamping

in the corner section of the long frame side.

MV 3 – Base troughs for cross drainage

If the base trough 150-30 w/cross drainige has to

be cut to size on site and then starts/ends without

a PE-pad, then a PE pad must also be applied on.

Distance between PE pads: max. 610 mm

Shorten PE-pad to the required length if

necessary.

The base trough has always to start/end with a

PE-pad.

MV 4 – Installation of expansion joints in the base troughs

Push the base trough expansion joint centrally into

the adjacent base troughs. A gap of 50 mm must

remain between the ends of the base troughs. Fix

the expansion joints to the base troughs. On the

movable side, the two screws must be screwed

into the base trough so that they are centred in the

elongated holes.

Do not install the expansion joint below a module.

Max. base trough length without base trough

expansion joint approx.. 17 m, with the base

trough expansion joint approx. 34 m, plan for

proper expansion joints after this.

50 mm

13

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

MV 5 – Mounting 3rd base trough

Depending on the ballast, a 3rd base trough may

be required for additional storage space. It should

be positioned centrally between two base troughs

according to the ballast plan. Secure the module

in addition to the clamps at the corners using the

flat roof end clamp on the long side (1).

The installation of a 3rd base trough may also be

necessary if the module support set or the base

foot is overloaded.

Secure the wind deflectors to the base troughs

with two screws for each base trough and to the

round part of the module support with one screw.

MV 6 – Module supports east-west

Regarding the occurring loads the module support

set of the east-west II system variant must be

installed with a single or a double leg.

Prior to installation, the position (installation axis)

of the components must be determined on the

base trough.

Depending on the conditions on site, it’s

recommended to use the mounting and removal

tool.

MV 7 – Installing the module – system variant east-west II

Place the module landscape on base feet and

then put it on the module support set. Install the

modules of one axis of a double row first.

Place the required ballast in accordance to the

ballast planning inside or on top of the base

troughs after installing the modules.

After fixing the modules place the support brace

on the module support set and fit them together

with one screw each. Support brace joint

overlapping above the module support brace.

Place ballast and install the modules on the other

side of the double row on the module support set.

Wire adjacent modules when installing them.

Install the string cable first.

1

1

14

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

MV 8 – Wind deflector east-west II

Support wind deflector to module (1):

Place wind deflector under module, fasten module

and wind deflector with module fastener E-K on

support and with two further screws on the base

trough.

Support wind deflector to wind deflector or edge

(2):

Mount the east-west wind deflector on the module

support set 2S as described in the section

Mounting the wind deflector, on the base trough

with two screws and on the module support with

one screw.

Place the weight of the replaced module with

ballast stones into the east-west wind deflector.

MV 9 – Ballast troughs

Using ballast troughs allows small and large

ballast which can be securely inserted or laid on if

required. The ballast troughs must be mounted

sideways to the base troughs.

MV 10 – Installation of the coupling

profiles for ballast reduction

Connect parallel module fields with two coupling

profiles. Secure the first profile (1) with two screws

on the left base trough and then secure the

second profile (2) on the right base trough. Leave

the loose end of the coupling profile protruding

over the edge of the second base trough (3).

The coupling profile is only firmly secured to one

base trough.

Distance between base troughs 50 mm.

10 kg

35 kg

10 kg

35kg

3

1

2

1

2

15

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

MV 11 – equipotential bonding and

lightning current carrying capacity

MV 11.1 – Attaching grounding connectors

Ground wire (∅according to national

specifications):

Disassemble grounding connector, remove

clamping disk. Push component through

elongated hole in the base trough. Push ground

wire through the opening (suitable for ∅ 6-10 mm)

and attach the component with the self-locking

nut.

Ground wire tightening torque 20 Nm.

The applicable standards and guidelines, e.g.

lightning protection standard, must be observed.

MV 11.2 – Attaching contact latch module clamp

Slide the contact latch on the sliding bracket over

the longitudinal bars of the middle clamp push it

up the screw. Tightening torque as described

above. The contact plate is used for equipotential

bonding and lightning current carrying capacity

of the system.

16

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

6 Warranty / product liability (exclusion)

In addition to the above-mentioned regulations and safety notices the applicable regulations and rules of

technology must be observed by the installing specialist company.

The installer is responsible for the dimensioning of the mounting system.

The installer is responsible for the connection of the interfaces between the mounting system and the

building. This also includes the tightness of the building envelope.

For flat roofs the roof insulation must be evaluated by the installer on site within his own responsibility

regarding the material of the sealing layer, resistance, ageing, compatibility with other materials, overall

condition of the roof insulation, need for a separating layer between the roof insulation and the mounting

system. The required and necessary measures or precautions for the protection of the roof insulation for

the mounting of the substructure of a PV system must be initiated by the installer with the aid of a specialist

tradesman where necessary. BayWa r.e. Solar Energy Systems GmbH does not accept liability for faulty or

inadequate measures and precautions for the protection of the roof insulation!

The installer must review the friction coefficient used in the calculation for the verification of the slip safety

of PV systems on flat roofs on site. Friction coefficients determined on site can be taken into account by

entering them in the Solar-Planit planning tool. BayWa r.e. Solar Energy Systems GmbH does not

guarantee the correctness of the assumed values and is not liable for damage due to the use of incorrect

values.

The specifications of the module, cable and inverter manufacturers must be observed. If these contradict

the mounting instructions, always consult the BayWa r.e. Solar Energy Systems GmbH sales team before

mounting the novotegra mounting system or – in the case of components not supplied by BayWa r.e. Solar

Energy Systems GmbH – the manufacturer concerned.

During the preparation of the offers for novotegra by our sales staff the local conditions are not always

sufficiently known, which is why changes to the offered quantities may result during installation. These

changes relate mainly to the number of fasteners for the building envelope (for example roof hooks). In this

case the additionally required components must always be installed in accordance with the dimensioning.

BayWa r.e. Solar Energy Systems GmbH is not liable for incorrect or incomplete data collection sheets.

Error-free and fully completed data collection sheets are essential for correct dimensioning.

The information in the mounting instructions, the warranty terms and the information about the liability

exclusion must be noted.

17

Subjects excepted. Illustrations are exemplary and may vary from the original.

V3.3 - April 2020/ASc,

Copyright BayWa r.e. Solar Energy Systems GmbH

BayWa r.e. Solar Energy Systems GmbH

Eisenbahnstraße 150

D-72072 Tübingen

Tel. +49 7071 98987-0

Fax +49 7071 98987-10

solarenergysystems@baywa-re.com

www.baywa-re.com

solar-distribution.baywa-re.de

novotegra.de

Other manuals for novotegra closed II

1

This manual suits for next models

1

Table of contents

Other BayWa Solar Panel manuals

Popular Solar Panel manuals by other brands

Sonnenkraft

Sonnenkraft GK5-HP manual

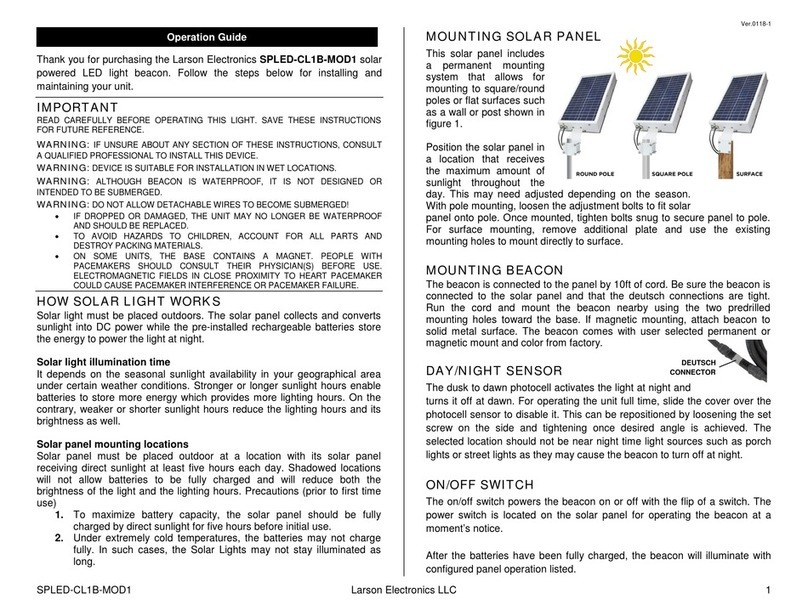

Larson Electronics

Larson Electronics SPLED-CL1B-MOD1 Operation guide

Lennox

Lennox SunSource installlation instructions

Qcells

Qcells Q.PEAK DUO ML-G9 Plus Installation and operation manual

ZepSolar

ZepSolar ZEP SYSTEM II installation manual

LEJ LINE

LEJ LINE LSK-JC-2V Installation and maintenance manual