DIS Sensors CAN User manual

Page 2 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

Table of Contents

1Introduction................................................................................................................................................3

2Quick Reference Guide..............................................................................................................................3

3Safety, Installation, use & maintenance.....................................................................................................4

4Certification...............................................................................................................................................5

5Inclination sensor explained ......................................................................................................................5

6Safety function...........................................................................................................................................5

7Hardware setup..........................................................................................................................................5

8Signal processing.......................................................................................................................................6

8.1 Sample rate:....................................................................................................................................6

8.2 Averaging:......................................................................................................................................6

8.3 Output filter:...................................................................................................................................6

8.4 Peak Suppression Filter:.................................................................................................................7

8.5 Pre-set/zero adjustment: .................................................................................................................7

8.6 Accelerator element tolerance ........................................................................................................8

8.7 Output invalid.................................................................................................................................8

8.8 Writing objects ...............................................................................................................................8

8.9 Changing SRDO1 settings..............................................................................................................8

9Internal diagnostic tests .............................................................................................................................9

10 CAN Predefined Connection Object ID’s................................................................................................10

11 CAN Object Dictionary Entries (Communication Profile section)..........................................................11

12 CAN Object Dictionary Entries 360v device (Application Specific Profile section) ..............................13

13 CAN Object Dictionary Entries ±30h and ±90h devices (Application Specific Profile section)............15

14 EDS files..................................................................................................................................................17

15 Document revision control.......................................................................................................................17

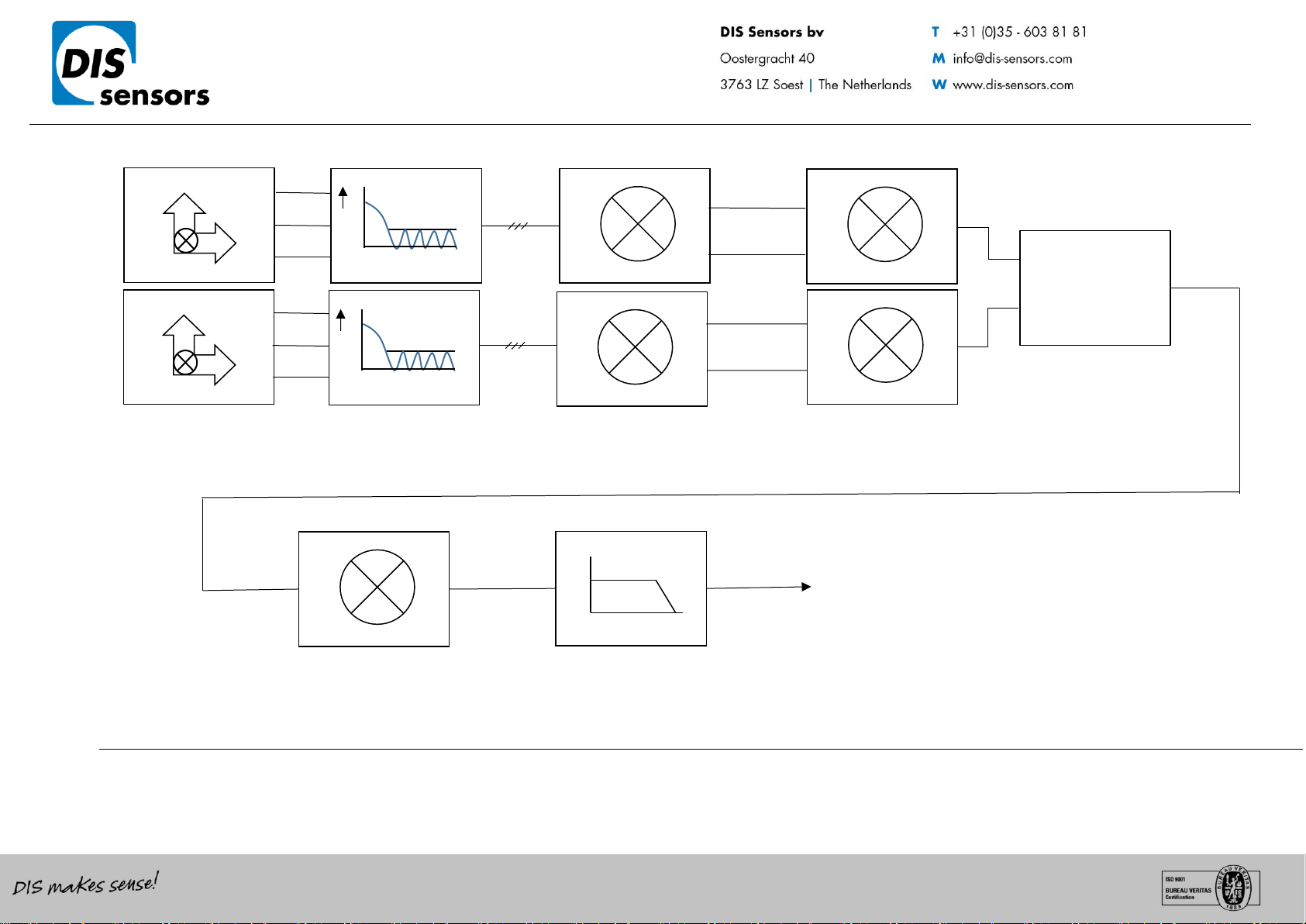

A. Appendixes1 Schematic overview inclination measurement...................................................................18

List of Figures

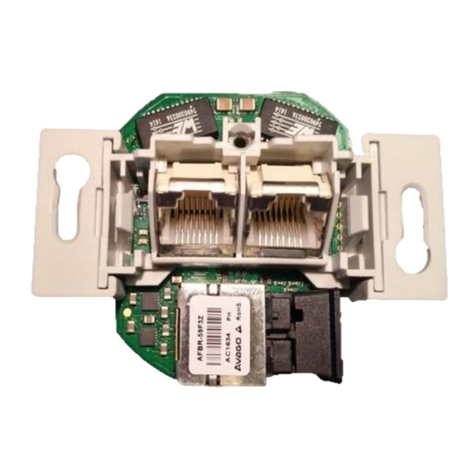

Figure 1: Layout CAN bus connector.......................................................................................................................... 5

Figure 2: Schematic overview inclination measurement......................................................................................... 18

List of Tables

Table 1 Object fields for zero value (pre-set) CRC calculation ................................................................................... 7

Table 2: Emergency code ........................................................................................................................................... 9

Table 3: COB id’s ...................................................................................................................................................... 10

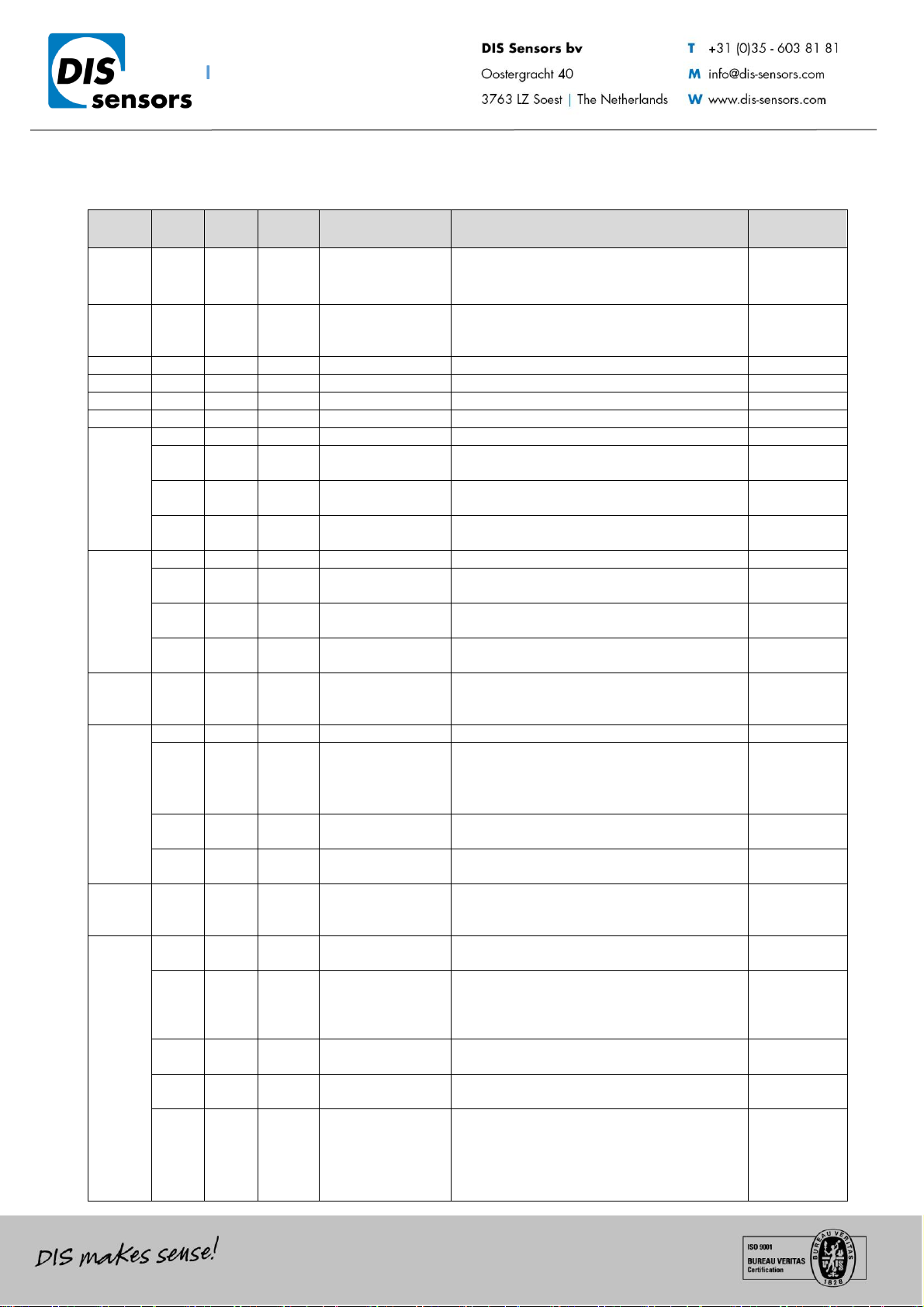

Table 4: Communication profile section .................................................................................................................. 11

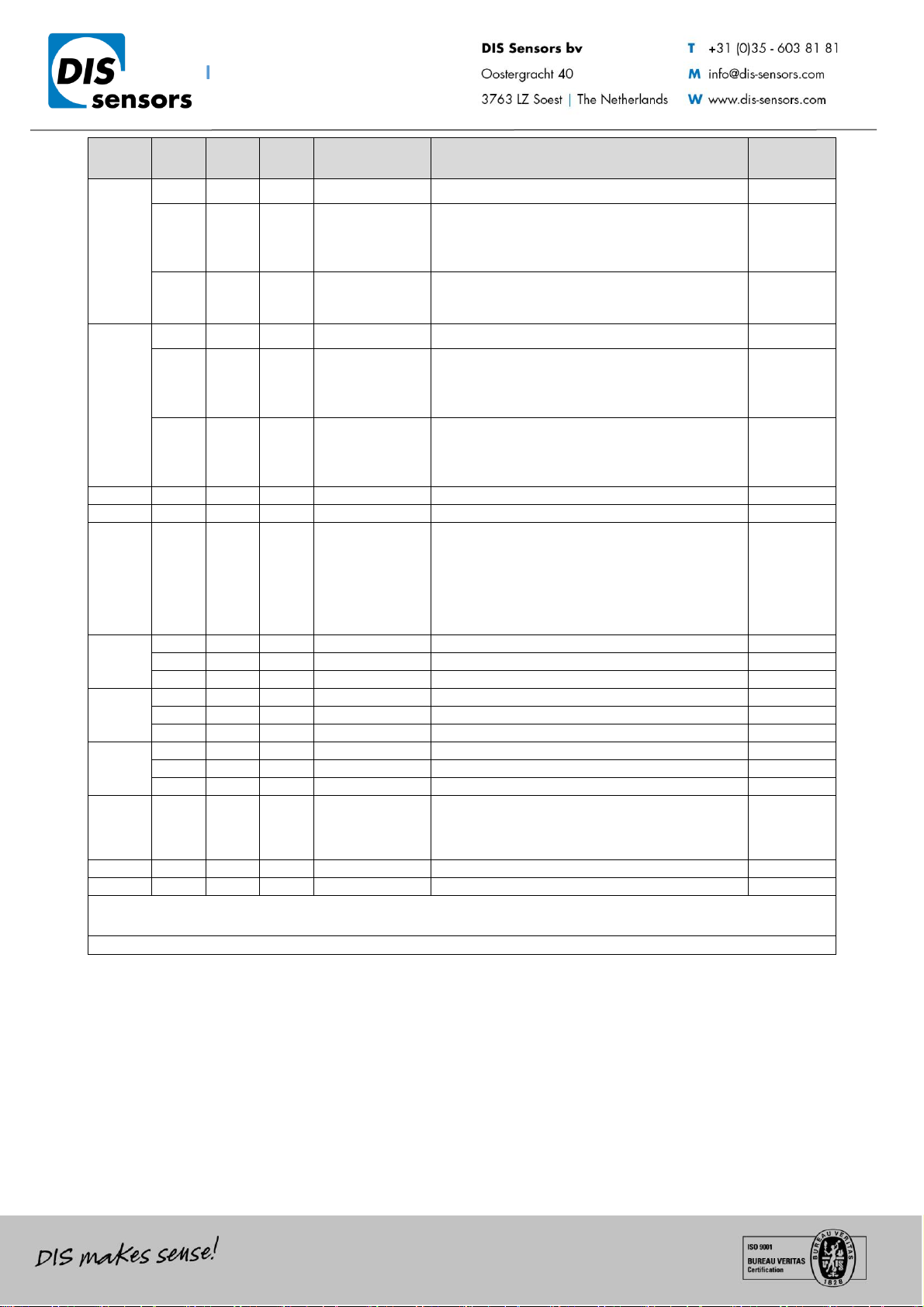

Table 5 Application specific profile section for 360 degree device.......................................................................... 13

Table 6: Application specific profile section for ±30h and ±90h devices ................................................................. 15

Page 3 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

1Introduction

This manual is only valid for CAN Open safety inclination sensor (D-type inclination sensors)

DIS CAN Open safety inclination sensor (D-type) family overview:

•Three housing types: 60x50mm plastic or aluminium (QG65), 70x60 stainless steel (QG76)

•Three inclination devices: Inclination 1-axis (vertical plane) 1x ±180°

•Inclination 2 axis (horizontal plane) 2x ±30°

•Inclination 2 axis (horizontal plane) 2x ±90°

•Various CAN settings can be configured according to the CAN Open standard

•Various Sensor-settings can be configured via CAN Open

•CAN Device Profile CIA410 V2.0.0 is supported

•EDS files are available

•CRC calculation tool is available (2 different CRC calculations available, check your firmware version first)

2Quick Reference Guide

•Hexadecimal figures will have suffix “h” in this manual

•CAN hardware interface: CAN2.0 A and B (complies to ISO11898-1&2)

•CAN communication profile: CAN Open (complies to CiA301 version 4.2.0 & EN50325-4)

•CAN device profile: CiA410 DSP 2.0.0 for inclinometers

•Baud-rate: default 125 kbit/s (can be set to 10, 20, 50, 125, 250, 500, 1000 kbit/s)

•Node-ID: default 01h (possible range 01h –7Fh, so max. 127 nodes)

•Event time: default 50ms for TPDO1 and TPDO2 (range 10ms –5000ms)

•TPDO1 output: 180h + node-ID (181h for node-ID 1). Default ‘off’

•TPDO2 output: 280h + node-ID (281h for node-ID 1). Default ‘off’

•SRDO1 normal: 0FFh + 2*node-ID (101h for node-ID 1).

•SRDO1 inverse: 100h + 2*node-ID (102h for node-ID 1).

•Byte-sequence on CAN-bus: little-endian (least significant byte first)

•Negative values: two’s complement

•Two modes of operation: Event-mode (periodically autonomous messages) & Sync-mode

•Sync-mode: default disabled for TPDO1 and TPDO2

•Heartbeat: default off.

•Vendor-ID DIS: 000001BDh (index 1018h sub index 01h)

•Firmware-version available via CAN Object Dictionary (index 1018h sub index 03h)

•Serial number available via CAN Object Dictionary (index 1018h sub index 04h)

•Pre-set/zero adjustment available via CAN Object Dictionary (index 300Fh sub index 01h)

•Sample rate g-sensor-chip: 1600 Hz. Averaging during event-time TPDO1

•Input filter: Fixed 32 taps 45dB suppression (low-pass cut off freq. 20 Hz).

•Output filter: adjustable high- or low-pass filter 1st order. Controlled by CAN object 300Eh.

•Document data-types definition:

U8 Unsigned 8-bits number (0 - 255)

U16 Unsigned 16-bit number (0 - 65535)

U32 Unsigned 32-bit number (0 - 4294967295)

S8 Signed 8-bits number (-128 - +127) (also known as ‘Integer 8’)

S16 Signed 16-bits number (-32768 - +32767) (also known as ‘Integer 16’)

S32 Signed 32-bits number (-2147483648 - +2147483647) (also known as ‘Integer 32’)

Page 4 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

3Safety, Installation, use & maintenance

•By ignoring the safety instructions the manufacturer cannot be hold responsible for any damage or

hazard.

•If any damage is noticed (M12 connector(s) and/or the enclosure) the device must be replaced by a new

one in order to avoid hazard.

•Never move the sensor by pulling the cable.

•The device should only be used in situations covered by the datasheet.

•Only a SELV power supply should be used.

•Only the CANopen Safety interface according to EN50325-5 should be used.

•As this device is accelerometer-based the sensor is inherent sensitive for accelerations/vibrations.

Application specific testing must be carried out to check whether this sensor will fulfil customer

requirements.

•The family of sensors involved will have a variety of types due to different outputs, measuring ranges,

enclosures and connection options. Datasheets are available for each specific type. Customer must select

and read the datasheet for the product he is using.

•The Safety Related Fault Response Time (SRFRT) of this device is defined as the maximum time the sensor

will report a non-safe situation to the outside world, after detecting an internal safety error. Actual value

is specified in the datasheet

•Configuration of the device like changing Node-ID, COB-ID’s and centring (sensor-offset) can only be done

after a new CRC-code is generated separately and written to the device.

•The sensor should be mounted on a stable flat surface with all screws tightened.

•Use only double twisted double shielded CAN cables.

•The proof test interval for this sensor is 20 years. After this interval the sensor should be replaced or

checked by comparing the output to a reference sensor or checked / recalibrated by the manufacturer.

This is to check for any non-detectable faults and/or degradation. This check / recalibration is not included

in the price.

•The calculated MTTFd of the sensor is specified in the datasheet.

•This sensor does not require any maintenance between proof-test intervals.

The user of this safety device shall only use this device when:

•he is educated to design in / use functional safety sensors.

•he has taken knowledge of both the datasheet and the user manual.

•the zeroing / centering function is only performed in the right position by an authorized person.

•the redundancy compare parameters (both Redundancy Compare Time and Redundancy Compare Angle)

are set by the customer according to the application demands. The actual values used by the customer

should fit the application involved. Before using this sensor and with the settings chosen the customer

should evaluate risks in order to check whether the chosen settings satisfy his safety requirements.

Manufacturer is not responsible for any damage caused by these customer-setting, even when the

manufacturer defaults are used.

•the bandwidth settings are according to the application demand

•the device is used inside the specified environmental situation

The user of this safety device shall consider its output as ‘defective’ in the following situations:

•the device is not responding

•the device is not running in operational state

•the device is not running in the desired mode of operation. To be checked at installation/start-up.

•the device is sending an emergency message

•the device switches to NMT stop state

•the safeguard cycle time (SCT) exceeds the limit

•the safety related validation time (SRVT) exceeds the limit

•the angle output is 200°

Page 5 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

4Certification

EC Type examination by:

Name: DEKRA testing and Certification GmbH

Adress: Handwerkstraße 15, D-70565, Stuttgart, Germany

Identification Nr.: 0158

EC Type-Examination Certificate no. 4821024.21001

Certificate valid until June 14th 2026

Certified level: SIL CL2 (claim limit 2 according to IEC 62061) & PLd (according to EN ISO 13849)

Architecture: HFT=1 (according to IEC 62061) & CAT3 (according to EN ISO 13849)

5Inclination sensor explained

An inclinometer measures the angle(s) of the device with respect to earth gravity, using earth gravity vector as

external reference. The inclinometer involved is based on an accelerometer. The acceleration values are used to

calculate the angle(s). The device takes both the static component (100%) and the dynamic component (partial,

depending on frequency and bandwidth-setting) into account. The device will periodically send a CAN message

on the CAN-bus containing the angle(s) in degrees.

6Safety function

The safety function of the inclinometer sensor is to generate angle information based on acceleration values

(caused by gravitation) measured by a MEMS acceleration sensor chip. Based on this angle information the safety

controller of the application can switch the machine to safe-mode in order to prevent for a dangerous situation.

Example: a crane having a maximum tilt angle of the chassis. If the tilt angle of the chassis exceeds a certain

critical value, the crane will fall over. To prevent for this an inclinometer can be mounted on the chassis,

measuring the X- and Y tilt of the chassis. The safety controller of the application should monitor the X- and Y tilt

angles and should switch the crane to safe-mode as soon as a certain tilt angle for X and/or Y exceeds the limits

for the application. This will significantly reduce the risk of a dangerous situation to happen.

7Hardware setup

Connection:

Default: 2x 5-pins M12 connector (A-coding), female & male, loop-through.

According to CiA303 V1.8.0

Figure 1: Layout CAN bus connector

Optional: 1x 5-pins M12 connector (A-coding) male only

CAN-Cable with 5-pins M12 connector (A-coding) male

CAN-Cable 5-wire

CAN-bus termination 120Ω

Default: no CAN-bus termination inside

Optional: CAN-bus termination inside

Tip: the last CAN-device in the chain should be terminated. For this purpose you can use the

M12 male 5-pin termination resistor’ (DIS article number 10217) or the

M12 female 5-pin termination resistor’ (DIS article number 10194).

Page 6 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

8Signal processing

The Safety sensor transmits SRDO messages. These message must be used to check the data and timing. In this

SRDO message the angle information is available in normal and in inverse format. Customer should compare

these messages in order to check the sensor output is safe. It is also possible to send the data via the TPDO

message according to CiA410 but in this case the sensor should be treated as a non-safety sensor. An output

filter is available for a stable signal. To compensate for mounting tolerances a pre-set/zero adjustment option is

available. When pre-set/zero values are changed a CRC must be calculated off-line (CRC calculate tool available)

and written to the sensor. The settings of the SRDO messages are also protected with a CRC code. When these

are changed also new CRC code must be determined. When the sensor detects a failure an emergency message

is generated and a safe state is activated. In the safe state no communication is possible (No SRDO, TPDO and

Heartbeat).

8.1 Sample rate:

The internal g-sensor chip is sampled every 10ms. Each sample of the element consists of 16 samples for each

axis. Resulting in sample rate of 1600 Hz. These samples are input for a 32 tabs FIR input low pass filter. Each

10ms new data is available for the CAN bus.

8.2 Averaging:

The FIR filtered values are averaged during the TPDO1 cycle time set by the customer. A longer TPDO cycle time

results is a smaller bandwidth and therefore a more stable output signal (less noise), but also more phase delay.

e.g. if Event time TPDO1 is 10 ms (fastest time) à a filtered value of 16 samples is available.

e.g. if Event time TPDO1 is 100 ms à an average value of 10*16 samples is available.

8.3 Output filter:

The output of the sensor can be extra filtered by a 1st order low-pass filter. Default this output filter is disabled.

Via the CAN object dictionary (index 300Eh) this filter can be controlled, by setting the time-constant in ms, with

a maximum of the redundancy compare time (set by index 4006h sub-index 02h) .

The time constant is defined as the time in which the output changes to 70% of the step after a step response.

The -3dB frequency can be calculated by the formula f = 1 / (2*pi*time-constant). This -3dB frequency is

independent of a change in TPDO1 event time and the SRDO refresh time. But when the output filter time-

constant is set < min. [TPDO1 event time, the SRDO refresh time], the output filter is disabled. With the factory

default, the filter time-constant can be set within 50ms –2000ms, other value will disable the filter.

Page 7 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

8.4 Peak Suppression Filter:

Two Peak Suppression Filters (PSF) are implemented to reduce unwanted disturbances in the inclination

measurement caused by acceleration peaks.

Filter principle: as inclination normally changes relative slow, a sudden peak in the inclination signal indicates an

acceleration peak instead of a real inclination angle change. In this case, the filter can make the sensor ignore

this peak for a certain time.

PSF in the redundancy compare chain (object 4007h):

The redundancy compare chain checks the difference between the two redundant MEMS chips. The filter helps

to prevent for false safety alarms.

PSF in the inclination output chain (object 4008h):

The filter in the output chain makes the inclination output more stable and more realistic

PSF can be adjusted with 2 parameters:

•Angle (°): This parameter sets the threshold for the peak. Only peaks above this threshold will be

filtered. Setting this angle parameter to 0° will disable the PSF

•Time (ms): After the peak suppression filter becomes active, it will hold the inclination signal for a

certain period of time, set by this parameter.

Default values for Object 4007h: on, 3°, 40ms

Default values for Object 4008h: on, 9°, 50ms

8.5 Pre-set/zero adjustment:

To eliminate mechanical offsets a pre-set/ zero value can be added. This can be done with the pre-set/zero

adjustment method, so introducing a permanent offset on the output of the sensor (centre point = middle of

measuring range). The current position will be regarded as the new pre-set/zero position. This can be done

limited to 100.000x. (The value is written in EEPROM. The write actions for EEPROM is limited to 100.000x)

Via CAN object 300Fh (see sensor specific part) the centering/zeroing can be done for each axis separate or for

both axis at the same time. Status information of the result is available from the same object 300Fh

Since the offset has direct influence on the output angle, the pre-set/zero value is protected with a CRC code.

This CRC code must be set via object 63FFh. When the CRC code is written it must be validated with object 63FE

sub id 0 writing data A5h.

The polynomial of the CRC code is:

Table 1 Object fields for zero value (pre-set) CRC calculation

Order

Index

Sub index

Value

Size

Data

1

6200h

00h

Highest sub index supported

1 octet

2

01h

Sub index number

1 octet

3

Safety slope longitudinal offset (pre-set) value

2 octets

4

02h

Sub index number

1 octet

5

Safety slope lateral offset(pre-set) value

2 octets

For CRC calculation a PC tool is developed and can be found on the DIS web site www.dis-sensors.com

We have implemented two different CRC-calculations. Please check your firmware version number first, and then

select the right Firmware version when using the PC-tool.

A CRC code is also oblige for SRDO1 messages. For detailed information about generating see EN 50325-5. This

CRC code can also be calculated with the same PC tool.

Page 8 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

8.6 Accelerator element tolerance

The sensor consists of two accelerator elements. The acceleration values of these elements are converted to

angles. These angles are compared and a safe state is set when the elements differ too much. To prevent for

false alarms, a tolerance can be configured. The tolerance consists of allowing an angle deviation during a certain

time.

These values are adjustable via object 4006h sub- index 01h and 02h. The default values are 300d and 200d ( 3°

during 2000 ms). The actual values used by the customer should fit the application involved. Before using this

sensor and with the settings chosen the customer should evaluate risks in order to check whether the chosen

settings satisfies his safety requirements. Manufacturer is not responsible for any damage caused by these

customer-setting, even when the manufacturer defaults are used.

Definitions for the Redundancy error:

‘Redundancy Compare time’ (user programmable, default 2000ms)

‘Redundancy Compare angle’ (user programmable, default 3°)

8.7 Output invalid

A vertical device measures the angle relative to the gravity. When a device is tilted towards the horizontal plane

for more than 45°, the angle can’t be accurately measure because the gravitation vectors become shorter. In this

case the output is set to 200°. This value indicates that the output is invalid.

For horizontal devices the same principle is valid. When the longitudinal axis is greater than 45 degree the output

for lateral axis is set to 200°. When the lateral axis is greater than 45° the longitudinal is set to 200°. The output is

also invalid when the range limits are reached. Example when angle is 32° for a ±30 device the output is limit to

±30°. For a ±90 device the angle is limited to ±90°.

8.8 Writing objects

When writing an object it can have a major influence on the output. To prevent unauthorized changes most write

action can only be executed when the device is in pre-operational state. According to EN 50325-5

8.9 Changing SRDO1 settings

When changing an SRDO1 setting the sensor must be in pre-operating state.

The direction 1301h sub id 01h must be disabled by writing 00h to object 1301h sub id 01h.

When the SRDO setting is changed the CRC code must also be changed and activated. Finally the data must be

stored in EEPROM

Example to change SRDO1 refresh time

Load object: 1301h sub id 01h with: 00h disable SRDO1 communication.

Load object: 1301h sub id 02h with: 0064h new SRDO1 refresh time.

Load object: 1301h sub id 01h with: 01h enable transmit SRDO1 communication.

Load object: 13FFh sub id 01h with: xxxxh code from CRC calculation tool.

Load object: 13FEh sub id 00h with: A5h validate new CRC.

Load object: 1010h sub id 01h with: “save” or 65766173h write new SRDO1 refresh time, CRC and

validation to EEPROM.

After a power reset and when the device is set to operational, the transmission time is equal to the desired time.

Page 9 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

9Internal diagnostic tests

To ensure safety the hard- and software of the safety sensor is continue checked. When a failure is detected, an

emergency message is sent. After sending this message, the device goes to a safe state, in which no

communication is possible (No SRDO, TPDO and Heartbeat). In this state, a NMT reset will not restart the sensor.

Failure should be analyzed by reading out the emergency message. If the error can be fixed, give the sensor a

new power cycle will restart the communication. If it is a ‘sensor element error (redundancy error), you

might consider to update ‘redundancy compare time’ and/or ‘redundancy compare angle. If the error cannot be

fixed, please contact your distributor.

The receiving application should detect that no communication is possible and shall set the system to a safe

state.

Table 2: Emergency code

CAN Connection Object ID: 080h+NODE_ID (emergency message)

Byte number

Type

Description

01h and 00h

U16

Error-code:

0000h: no error

FF00h: CAN Open device specific error code

02h

U8

Error-register:

00h: no error

01h: error register object 1001h

04h and 03h

U8

Diagnose error CAN stack:

0000h: No error

0001h: Reset state

0002h: Can driver has to be reset

0004h: Safety cycle is ready

0008h: reserved

0010h: Timeout by watchdog diagnose

0020h: Overvoltage

0040h: Unknown interrupt occurs

0080h: CSC stack has entered safety stop

0100h: Initialization error

0200h: Can error

0400h: CAN NMT state error

0800h: Diagnose error

1000h: Safety cycle error

2000h: SRDO error

4001h: RAM error

8000h: Unknown error

-multiple errors can be indicated (bitwise OR-ed) simultaneously.

-when an overvoltage occur the device stays permanent in safe state

05h

reserved

06h

00h

01h

02h

03h

04h

05h

06h

07h

09h

Diagnose error

Start CRC calculation ROM

Check register

Check stack

Check addressing part unit 1

Check addressing part unit 2

Check conditional jumps

Check opcode

Check CRC for SRDO’s

Check time stamp

Page 10 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

0Ah

0Bh

0Ch

0Dh

0Eh

0Fh

10h

11h

12h

19h

7Fh

Wait for end of CRC calculation for CSC main

Start CRC calculation ROM for application

Wait for end of CRC calculation for application

Start CRC calculation ROM for start-up monitor

Wait for end of CRC calculation for start-up monitor

Check RAM with GALPAT algorithm

Check software interrupt

Check software interrupt was ok

Check undefined instruction interrupt

Check undefined instruction interrupt was ok

Idle state

07h

00h

01h

02h

04h

08h

10h

20h

40h

80h

Application error

No application error

Unknown interrupt occurs

Safety RAM error

SRDO error

3V3 monitor error

Sensor element error (Redundancy Error)

RAM error

EEPROM error

Watchdog or 5V under voltage error

multiple errors can be indicated (bitwise OR-ed) simultaneously.

Sensor goes to safe state (stop state) when an error is reported. Sensor must be power cycled to restart.

Example:

Receive COB-id 81h with data 00h FFh 01h 80h 00h 00h 0Eh 08h

81 emergency message of node id 01h

00h FFh-> FF00h CAN Open device specific error code

01h-> error register object 1001h

80h 00h ->0080h CSC stack has entered safety stop

00h reserved

0Eh Wait for end of CRC calculation for start-up monitor

08h. 3V3 monitor error

10 CAN Predefined Connection Object ID’s

Table 3: COB id’s

Standard CAN Connection Object ID’s (Most used)

CAN-ID

Data

Description (client = CAN master, server = sensor)

000h

NMT Network Management

080h

Sync command to sensor

080h + node-ID

Emergency message from sensor

0FFh + 2 * node-ID

SRDO1 normal message

100h + 2 * node-ID

SRDO1 inverse message

180h + node-ID

TPDO1 message from sensor

280h + node-ID

TPDO2 message from sensor

580h + node-ID

SDO Download Request: Feedback from sensor (server to client)

600h + node-ID

SDO Upload Request: Write to sensor (client to server)

700h + node-ID

00h

04h

05h

7Fh

heartbeat from sensor, boot-up mode

heartbeat from sensor, stopped mode

heartbeat from sensor, operational mode

heartbeat from sensor, pre-operational mode

Page 11 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

11 CAN Object Dictionary Entries (Communication Profile section)

Table 4: Communication profile section

Index

Sub-

index

Type

Read/

Write

Data

Description

Pre-

operational

1000h

00h

U32

R

3001019Ah

3002019Ah

Device Type

= Inclination, C1 (360°) normal TPDO

= Inclination, C2 (±90° or ±30°) normal TPDO

No

1001h

00h

U8

R

e.g. 00h

e.g. 81h

Error Register

= Normal operation

= Device error

No

1003h

00h

U32

R

Predefined error field

No

1005h

00h

U32

R+W

COB-ID SYNC

No

100Ch

00h

U16

R

Guard time

No

100Dh

00h

U8

R

Life time factor

No

1010h

00h

U8

R

3

Number of entrees

No

01h

U32

R+W

“save” in ASCII

Or “65766173h”

Save all parameters in EEPROM

Yes

02h

U32

R+W

“save” in ASCII

Or “65766173h”

Save communication parameters in EEPROM

Yes

03h

U32

R+W

“save” in ASCII

Or “65766173h”

Save application parameters in EEPROM

Yes

1011h

00h

U8

R

3

Number of entrees

No

01h

U32

R+W

“load” in ASCII

Or “64616F6Ch”

Restore all parameters from EEPROM

Yes

02h

U32

R+W

“load” in ASCII

Or “64616F6Ch”

Restore communication parameters from

EEPROM

Yes

03h

U32

R+W

“load” in ASCII

Or “64616F6C h”

Restore application parameters from EEPROM

Yes

1017h

00h

U16

R+W

e.g. 07D0h/2000d

e.g. 0000h

Heartbeat time (ms)

= 2000 ms

= 0 ms (heartbeat switched off, default)

No

1018h

01h

U32

R

4

Vendor ID (000001BDh)

No

02h

U32

R

e.g.04000001h

e.g.04000002h

e.g.04000003h

Product Code

= Inclination 1-axis (vertical plane): 360°

= Inclination 2-axis (horizontal plane): 2x ±90°

= Inclination 2-axis (horizontal plane): 2x ±30°

No

03h

U32

R

e.g. 00020001h

Firmware version sensor (000x000yh)

= v2.1

No

04h

U32

R

e.g. 00000000h

up to FFFFFFFFh

Serial number sensor (32 bit, unique)

No

1300h

00h

U8

R+W

e.g. 00h

e.g. 01h

GFC parameter

= Invalid

= Valid

No

1301h

00h

U8

R

6

Number of entrees SRDO1 communication

parameter

No

01h

U8

R+W

00h

01h

02h

SRDO1 direction

= Disabled

= Tx/SRDO producer (default)

= RX/SRDO consumer

Yes

02h

U16

R+W

e.g. 50h/80d

SRDO1 refresh time/SCT

= 80 ms default

Yes

03h

U8

R+W

e.g. 14h/20d

Safety-relevant validation time (SRVT)

= 20 ms default

Yes

04h

U8

R+W

e.g. FEh/254d

Transmission type

= Asynchronous (default)

Yes

Page 12 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

Index

Sub-

index

Type

Read/

Write

Data

Description

Pre-

operational

05h

U32

R+W

e.g. 101h

COB-ID1

0xFFh + Node ID *2 (default)

Yes

06h

U32

R+W

e.g. 102h

COB-ID2

0x100h + Node ID *2 (default)

Yes

13FEh

00h

U8

R+W

e.g. A5h

Other value

SRDO configuration

= SRDO configuration signature valid

= SRDO configuration signature not valid

Yes

13FFh

00h

U8

R

4

Number of entrees

No

01h

U16

R+W

CRC of SRDO1

Yes

1400h

00h

U8

R

2

Number of entrees Receive PDO 1

No

01h

U32

R+W

C0000201h

COB-ID used by RPDO1

= RPDO1 disabled

No

02h

U8

R+W

FFh

Transmission type

= event-driven (default)

No

1401h

00h

U8

R

2

Number of entrees Receive PDO 2

No

01h

U32

R+W

C0000301h

COB-ID used by RPDO2

= RPDO2 disabled

No

02h

U8

R+W

FFh

Transmission type

= event-driven (default)

No

1600h

00h

U8

R

00h

Receive PDO mapping

= Mapping disabled

No

01h-

08h

U32

R

00000000h

= Disabled

No

1601h

00h

U8

R

8

Number of entrees Receive PDO mapping

No

01h-

08h

U32

R

00000000h

= Disabled

No

1800h

00h

U8

R

5

Number of entrees

No

01h

U32

R+W

e.g. 40000181h

e.g. C0000181h

TPDO1 event-mode

= Enable

= Disable (default)

No

02h

U8

R+W

e.g. 01h

e.g. FFh

TPDO1 sync-mode

= Enable

= Disable (default)

No

05h

U16

R+W

e.g. 0032h/50d

e.g. 0000h

TPDO1 event-time (time in ms )

= 50 ms (default)

= 0 ms (disable TPDO1)

(Max. = 5000ms)

No

1801h

00h

U8

5

Number of entrees

No

01h

U32

R+W

e.g. 40000281h

e.g. C0000281h

TPDO2 event-mode

= Enable

= Disable (default)

No

02h

U8

R+W

e.g. 01h

e.g. FFh

TPDO2 sync-mode

= Enable

= Disable (default)

No

05h

U16

R+W

e.g. 0032h/50d

e.g. 0000h

TPDO2 event-time (time in ms)

= 50 ms (default)

= 0 ms (disable TPDO2)

(Max. = 5000ms)

No

To store communication specific parameters permanent into the EEPROM of the sensor CAN Object 1010h should be used,

otherwise the changes will be lost after a power cycle.

All not-specified indices and/or sub-indices are reserved for factory use only.

Page 13 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

12 CAN Object Dictionary Entries 360v device

(Application Specific Profile section)

Table 5 Application specific profile section for 360 degree device

Index

Sub

index

Type

Read/

Write

Data

Description

Pre-

operational

1381h

00h

U8

R

4

Number of entrees

No

01h

U32

R

e.g. 62100108h

SR application data object 1 (normal)

= Normal longitudinal bit 0-7

No

02h

U32

R

e.g. 62110108h

SR application data object 1(inverse)

= Inverse longitudinal bit 0-7

No

03h

U32

R

e.g. 62100208h

SR application data object 2 (normal)

= Normal longitudinal bit 8-15

No

04h

U32

R

e.g. 62110208h

SR application data object 2 (inverse)

= Inverse longitudinal bit 8-15

No

3000h

00h

U8

R

1

Number of entrees

No

01h

U8

R+W

01h up to 7Fh

Node-ID

01h (default) up to 7Fh

(when Node-ID >3Fh non-standard COB-ID of SRDO1

must be used)

(changes are being affected after a power cycle only)

Yes

3001h

00h

U8

R

1

Number of entrees

No

01h

U8

R+W

e.g.06h

e.g.05h

e.g.04h

e.g.03h

e.g.02h

e.g.01h

e.g.00h

Baud rate (kbit/s)

= 50

= 100

= 125 (default)

= 250

= 500

= 800

= 1000

(changes are being affected after a power cycle only)

Yes

300Eh

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

Time in ms

e.g. 0000h

e.g. 0064h/100d

Output filter (1st order low pass filter):

= Disabled (default)

= Enabled, 100 ms (f=1.59 Hz)

(Max. = ‘redundancy compare time’)

Yes

300Fh

00h

U8

R

1

Number of entrees

No

01h

S8

R+W

e.g. 01h

Pre-set adjustment angle.

Write 01h: start zero longitudinal

Read 00h= zero successful,

Read FFh= zero unsuccessful

Yes

4006h

00h

U8

R

2

Number of entrees

No

01h

U16

R+W

e.g. 012Ch/300d

e.g. 001Eh/30d

Redundancy Compare Angle

(Maximal angle deviation between two elements)

= 3,00° (default)

= 0,3°

(Max. = 18°)

Yes

02h

U16

R+W

e.g. 00C8h/200d

Redundancy Compare Time [x10 ms]

(Time within maximal deviation is allowed)

= 2000 ms (default)

(Max. = 10 s)

Yes

Page 14 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

Index

Sub

index

Type

Read/

Write

Data

Description

Pre-

operational

4007h

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

e.g. 0000h

e.g. 012Ch/300d

Peak suppression redundancy angle

= Disabled

= 3° (default)

(Min. = 3°)

Yes

02h

U16

R+W

e.g. 0004h/4d

e.g. 03E8h/1000d

Peak suppression redundancy time [x10 ms].

= 40 ms (default)

(Max. = 10 s)

Yes

4008h

00h

U8

R

1

Number of entrees

01h

U16

R+W

e.g. 0000h

e.g. 0384h/900d

e.g. 012Ch/300d

Peak suppression output angle

= Disabled

= 9° (default)

(Min.= 3°)

02h

U16

R+W

e.g. 0005h

e.g. 0032h/50d

e.g. 03E8h/1000d

Peak suppression output time [x10 ms].

= 50 ms (default)

= 500 ms

(Max. = 10 s)

6000h

00h

U8

R

e.g. 000Ah/10d

Resolution = 0,01°

No

6010h

00h

S16

R

Longitudinal slope

No

6011h

00h

U8

R+W

e.g. Bit0 = 0

e.g. Bit0 = 1

e.g. Bit1 = 0

e.g. Bit1 = 1

Other bits

Operating parameter longitudinal slope

= Slope normal

= Slope inverse

= Pre-set disabled

= Pre-set enabled

= No function

Yes

6200h

00h

U8

R

2

Number of entrees

No

01h

S16

R+W

Pre-set value longitudinal

Yes

02h

S16

R+W

Pre-set value lateral

Yes

6210h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of normal SRDO longitudinal slope

No

02h

U8

R

Bit 8-15 of normal SRDO longitudinal slope

No

6211h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of inverse SRDO longitudinal slope

No

02h

U8

R

Bit 8-15 of inverse SRDO longitudinal slope

No

63FEh

00h

U8

R+W

e.g. A5h

e.g. 00h

Pre-set configuration field

= Signature valid

= Signature not valid

Yes

63FFh

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

Pre-set value signature

Yes

To store application specific parameters permanent into the EEPROM of the sensor CAN Object 1010h should be used, otherwise

the changes will be lost after a power cycle.

All not-specified indices and/or sub-indices are reserved for factory use only.

Page 15 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

13 CAN Object Dictionary Entries ±30h and ±90h devices

(Application Specific Profile section)

Table 6: Application specific profile section for ±30h and ±90h devices

Index

Sub

index

Type

Read/

Write

Data

Description

Pre-

operational

1381h

00h

U8

R

8

Number of entrees

No

01h

U32

R

e.g. 62100108h

SRDO1 mapping object 1 (normal)

= Normal longitudinal bit 0-7

No

02h

U32

R

e.g. 62110108h

SRDO1 mapping object 1 (inverse)

= Inverse longitudinal bit 0-7

No

03h

U32

R

e.g. 62100208h

SRDO1 mapping object 2 (normal)

= Normal longitudinal bit 8-15

No

04h

U32

R

e.g. 62110208h

SRDO1 mapping object 2 (inverse)

= Inverse longitudinal bit 8-15

No

05h

U32

R

e.g. 62200108h

SRDO1 mapping object 3 (normal)

= Normal lateral bit 0-7

No

06h

U32

R

e.g. 62210108h

SRDO1 mapping object 3 (inverse)

= Inverse lateral bit 0-7

No

07h

U32

R

e.g. 62200208h

SRDO1 mapping object 4 (normal)

= Normal lateral bit 8-15

No

08h

U32

R

e.g. 62210208h

SRDO1 mapping object 4 (inverse)

= Inverse lateral bit 8-15

No

3000h

00h

U8

R

1

Number of entrees

No

01h

U8

R+W

01h up to 7Fh

Node-ID

(When Node Id >3Fh non-standard COB-ID of SRDO1

must be used)

(Changes are being affected after a power cycle only)

Yes

3001h

00h

U8

R

1

Number of entrees

No

01h

U8

R+W

e.g. 06h

e.g. 05h

e.g. 04h

e.g. 03h

e.g. 02h

e.g. 01h

e.g. 00h

Baud rate (kbit/s)

= 50

= 100

= 125 (default)

= 250

= 500

= 800

= 1000

(Changes are being affected after a power cycle only)

Yes

300Eh

00h

U8

R

1

Number of entrees

No

01h

U8

R+W

Time in ms

e.g. 0000h

e.g. 0064h

Output filter (1st order low pass):

= Disabled (default)

= Enabled, 100 ms (f=1.59 Hz)

(Max. = ‘redundancy compare time’)

Yes

300Fh

00h

U8

R

1

Number of entrees

No

01h

S8

R+W

e.g. Write 01h

e.g. Write 02h

e.g. Write 03h

e.g. Read 00h

e.g. Read FFh

e.g. Read FEh

Pre-set adjustment

= start zero longitudinal

= start zero lateral

= start longitudinal and lateral

= zero successful,

= fail zero longitudinal

= fail zero lateral

Yes

4006h

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

e.g. 012Ch/300d

Redundancy Compare Angle

(Maximal angle deviation between two elements)

= 3,00° (default)

(Max = 3° (±30h) / 9° (±90h))

Yes

02h

U16

R+W

e.g. 00C8h/200d

Redundancy Compare Time [x10ms].

(Time within maximal deviation is allowed)

= 2000 ms (default)

(Max. = 10 s)

Yes

Page 16 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

Index

Sub

index

Type

Read/

Write

Data

Description

Pre-

operational

4007h

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

e.g. 0000h

Peak suppression redundancy angle

= Disabled

= 3° (default)

(Min. = 3°)

Yes

02h

U16

R+W

e.g. 0004h/04d

Peak suppression redundancy time [x10 ms].

= 40 ms (default)

(Max. = 10 s)

Yes

4008h

00h

U8

R

1

Number of entrees

01h

U16

R+W

e.g. 0000h

e.g. 0384h/900d

Peak suppression output angle

= Disabled

= 9° (default)

(Min. = 3°)

02h

U16

R+W

e.g. 0005h/5d

Peak suppression output time [x10 ms].

= 50 ms (default)

(Max. = 10 s)

6000h

00h

U8

R

e.g. 0Ah/10d

Resolution

= 0,01°

No

6010h

00h

S16

R

Longitudinal slope

No

6011h

00h

U8

R+W

e.g. Bit0 = 0

e.g. Bit0 = 1

e.g. Bit1 = 0

e.g. Bit1 = 1

e.g. Other bits

Operating parameter longitudinal slope

= Slope normal

= Slope inverted

= Pre-set disabled

= Pre-set enabled

= No function

Yes

6020h

00h

S16

R

Lateral slope

No

6021h

00h

U8

R+W

e.g. Bit0 = 0

e.g. Bit0 = 1

e.g. Bit1 = 0

e.g. Bit1 = 1

e.g. Other bits

Operating parameter lateral slope

= Slope normal

= Slope inverted

= Pre-set disabled

= Pre-set enabled

= No function

Yes

6200h

00h

U8

R

2

Pre-set value

No

01h

S16

R+W

Pre-set value longitudinal

Yes

02h

S16

R+W

Pre-set value lateral

Yes

6210h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of normal SRDO longitudinal slope

No

02h

U8

R

Bit 8-15 of normal SRDO longitudinal slope

No

6211h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of inverse SRDO longitudinal slope

No

02h

U8

R

Bit 8-15 of inverse SRDO longitudinal slope

No

6220h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of normal SRDO lateral slope

No

02h

U8

R

Bit 8-15 of normal SRDO lateral slope

No

6221h

00h

U8

R

2

Number of entrees

No

01h

U8

R

Bit 0-7 of inverse SRDO lateral slope

No

02h

U8

R

Bit 8-15 of inverse SRDO lateral slope

No

63FEh

00h

U8

R+W

A5h

00h

Pre-set configuration field

= Signature valid

= Signature not valid

Yes

63FFh

00h

U8

R

1

Number of entrees

No

01h

U16

R+W

Pre-set value signature

Yes

To store application specific parameters permanent into the EEPROM of the sensor CAN Object 1010h should be used, otherwise,

the changes will be lost after a power cycle.

All not-specified indices and/or sub-indices are reserved for factory use only.

Page 17 of 18

CAN User Manual

Inclination Safety Sensor

(Type D) V2.0

14 EDS files

The “Electronic Data Sheet” (EDS file) is a file format that describes the communication behavior and the object

dictionary entries of a device. In fact it’s a template. This allows tools such as CAN configuration tools to handle

the device properly. The file format is described in CiA306 V1.3.0

The EDS-file contains all possible settings and functions for the device by describing the CAN object dictionary

for the device to be set by CAN commands.

The EDS-file does not contain a customer specific configuration description (the values of the object dictionary,

like i.e. the chosen baud rate, TPDO1 event time, Node ID etc.). For this purpose the customer can generate a so

called DCF-file (Device Configuration File) with all customer specific settings out of the EDS-file. The DCF file is in

fact the incarnation of the EDS-file.

After loading the DCF-file into the device you have to store the settings into EEPROM by index 1010h sub index

01h to store permanently, see “CAN Object Dictionary Entries”.

The EDS-files available for sensors with embedded firmware version D-type described in this document should

have a version D-type also.

The next EDS-files are available at www.dis-sensors.com under ‘downloads’:

•QG_Dtype_1_axis_360v_v*.*

•QG_Dtype_2_axis_30h_v*.*

•QG_Dtype_2_axis_90h_v*.*

15 Document revision control

V1.0 first release

V1.1 Add SRD1 objects programming. Add Writing objects in pre-operating state. Major text additions

V1.2 Add commend after review JK

V1.3 Safety information added (MvA)

V1.4 Layout changed (RMo), safety chapters modified (MvA)

V1.5 Change mapping object 1381h for 1 axis and 2 axis according to profile (RMo)

V1.6 20190725 Various more accurate descriptions, some parameters maximized, see release notes firmware

v2.9 & v2.5.3

V1.7 20200831 Insert Peak suppression filter for MEMS elements and for inclination output (MvA)

V1.8 20210823 correct proof test period and pre-set disable/enable(SX).

V1.9 20210917 Re-certification / EC type examination by DEKRA successful. New certificate nr.

V2.0 20220321 Add max. redundancy compare angle.(SX)

CAN User Manual Inclination Safety Sensor

(Type D)V2.0

Page 18 of 18

A. Appendixes1 Schematic overview inclination measurement

Figure 2: Schematic overview inclination measurement.

800Hz

100Hz

0

-45

dB

800Hz

100Hz

0

-45

dB

∑

Fs = 1600 Hz

Sample rate 1600 Hz

32 taps FIR filter

45 dB suppression.

Sample rate 10 ms

Offset and gain

correction.

Calculate angle

Lookup correction.

Compare sensor

elements

Perform PSF in redundancy

chain and then

Average the two

sensor elements

Zero (pre-set) correction.

Output according profile

Perform PSF in output chain

1st order low pass

Fcut-off = 1 / (filter-time*2*pi)

(adjust response with object

300Eh)

X counts

Y counts

Z counts

X counts

Y counts

Z counts

X Y Z filtered

X Y Z filtered

Longitudinal

angle in degree

Lateral angle in

degree

Longitudinal

angle in degree

Lateral angle in

degree

Output angles

Corrected angles

in degree

Table of contents

Other DIS Sensors Accessories manuals

Popular Accessories manuals by other brands

Actelser

Actelser ACT1002 installation instructions

Homematic IP

Homematic IP HmIP-SWDM Mounting instruction and User manual

AFK

AFK EB-100.1D instruction manual

Amcrest

Amcrest SmartHome AD410 installation guide

Axminster

Axminster woodturning 310404 quick start guide

Bodet

Bodet HARMONYS Flash Installation and user manual