WWW.BBKPERFORMANCE.COM

FOLLOW THESE INSTRUCTIONS CAREFULLY TO ENSURE CORRECT FITMENT AND OPERATION

UPDATED LAST: April 2018

27427 BOSTIK COURT

TEMECULA, CA 92590

For any questions, email us:

IMPORTANT: All appropriate safety equipment and gear must be used during the installation of this or any BBK Performance products or any time you work on a vehicle.

BBK Performance Inc. accepts no responsibility for injuries or damage caused by or during the installation of this product.

MADE IN U.S.A.

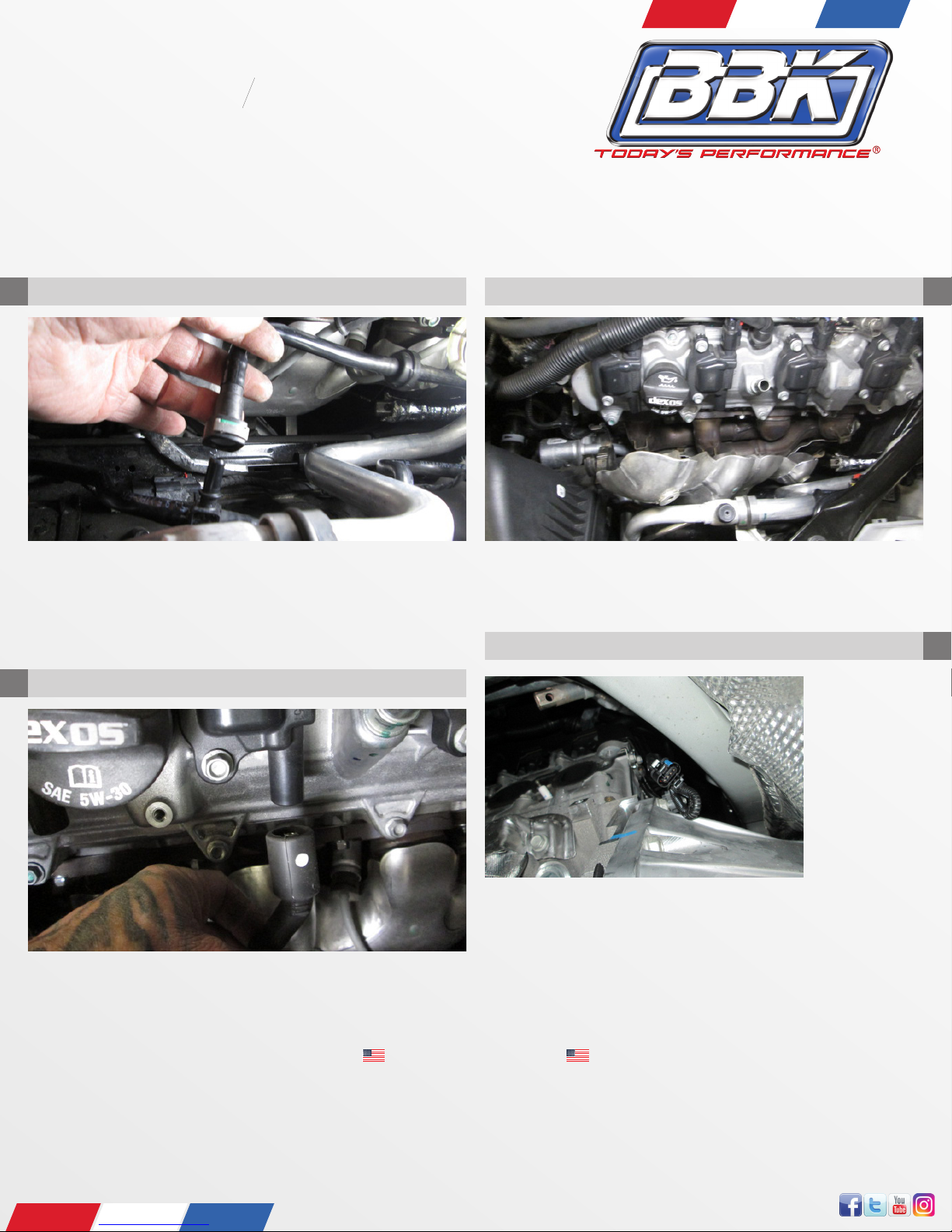

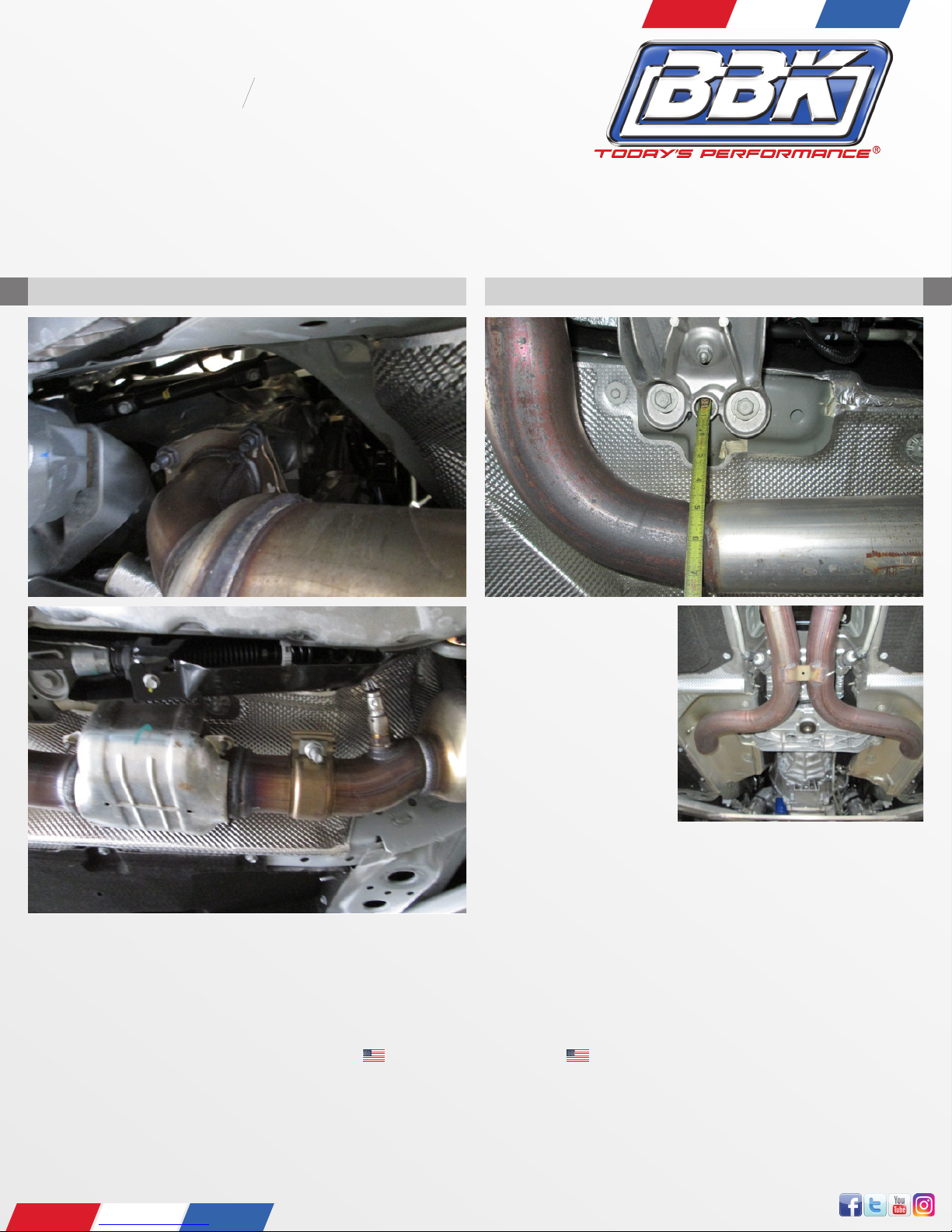

STEP 16

With both head pipes in place lift the exhaust system upwards and connect

the head pipes to the collector on the headers only snug the bolts up. Be

sure to level out the exhaust and adjust it to have clearance. Push the exhaust

system forward as much as possible while still having clearance everywhere.

Tack weld the BBK head pipes to the stock exhaust once tacked into place

check for any clearance issues and address them immediately. Now weld the

lower portion of the head pipes to the stock exhaust completely once both

sides are done unbolt the exhaust from the headers and drop it down and

nish welding the head pipes to the stock exhaust system.

Lift exhaust system into place and tighten down the anges on the head pipes

to the anges on the header collectors these bolts do not have to be crazy

tight as it may result in bending of the anges.

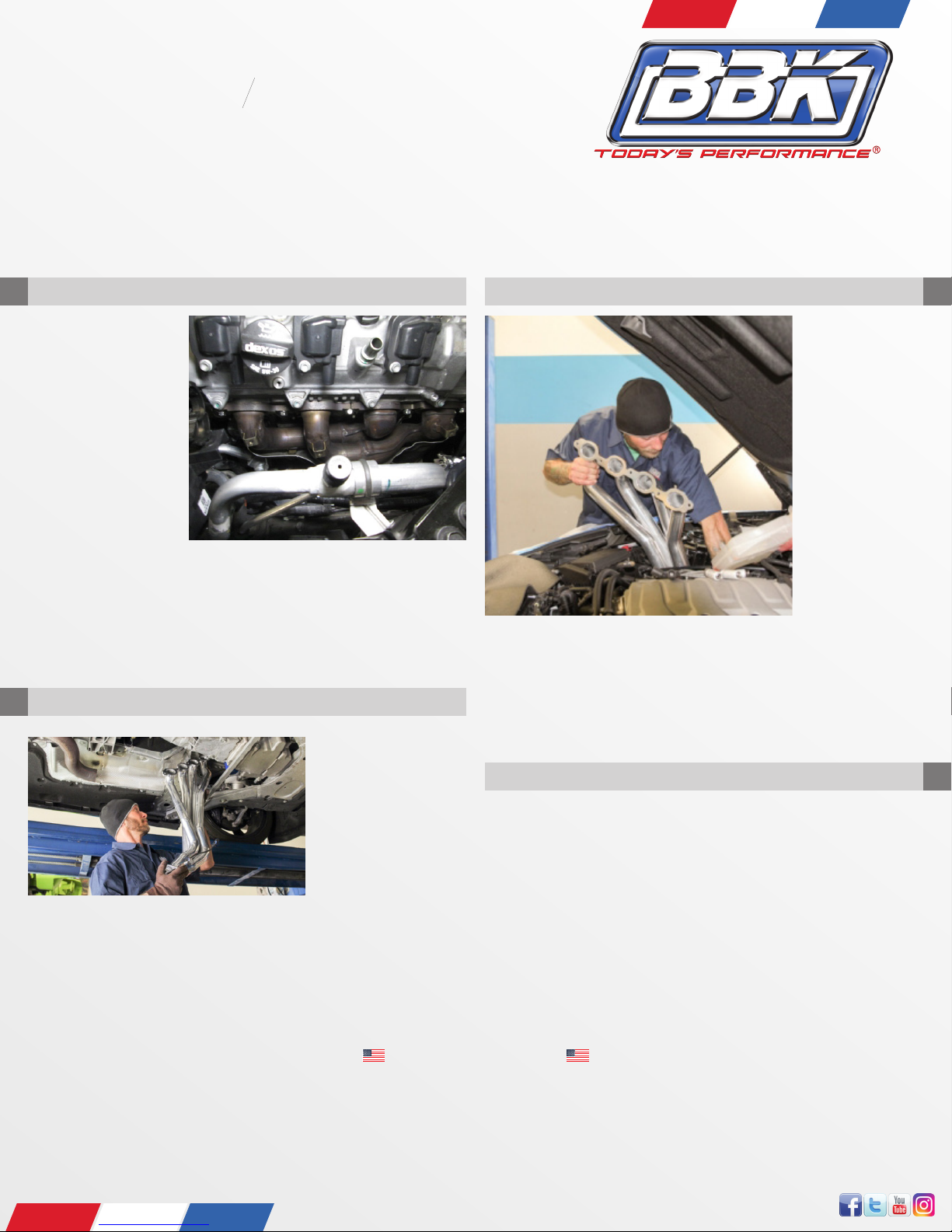

STEP 17

Install all (4) oxygen

sensors and connect

the wiring harnesses.

Reconnect the

negative battery

terminal and enjoy

the sound and power

of the BBK full length

headers “REMINDER”

check coolant levels

after start up and

engine is at operating temperature if any coolant was lost. After 500 miles

of driving re-torque all exhaust hardware to ensure the exhaust system is

properly sealed.

for added clearance. Now install header with supplied

gasket then install dipstick when header is loose in engine compartment. Now

torque header bolts to 30 FT/LB then reinstall,valve cover,spark plugs, wires

and then starter heat-shield from underneath the vehicle when installing

head-pipes. Now re-connect radiator hoses and put coolant bottle back in

place

NOTE: Make sure to check coolant level and use remaining zip-ties to keep

any hoses from resting on header and do not over tighten zip-ties cutting o

coolant ow.

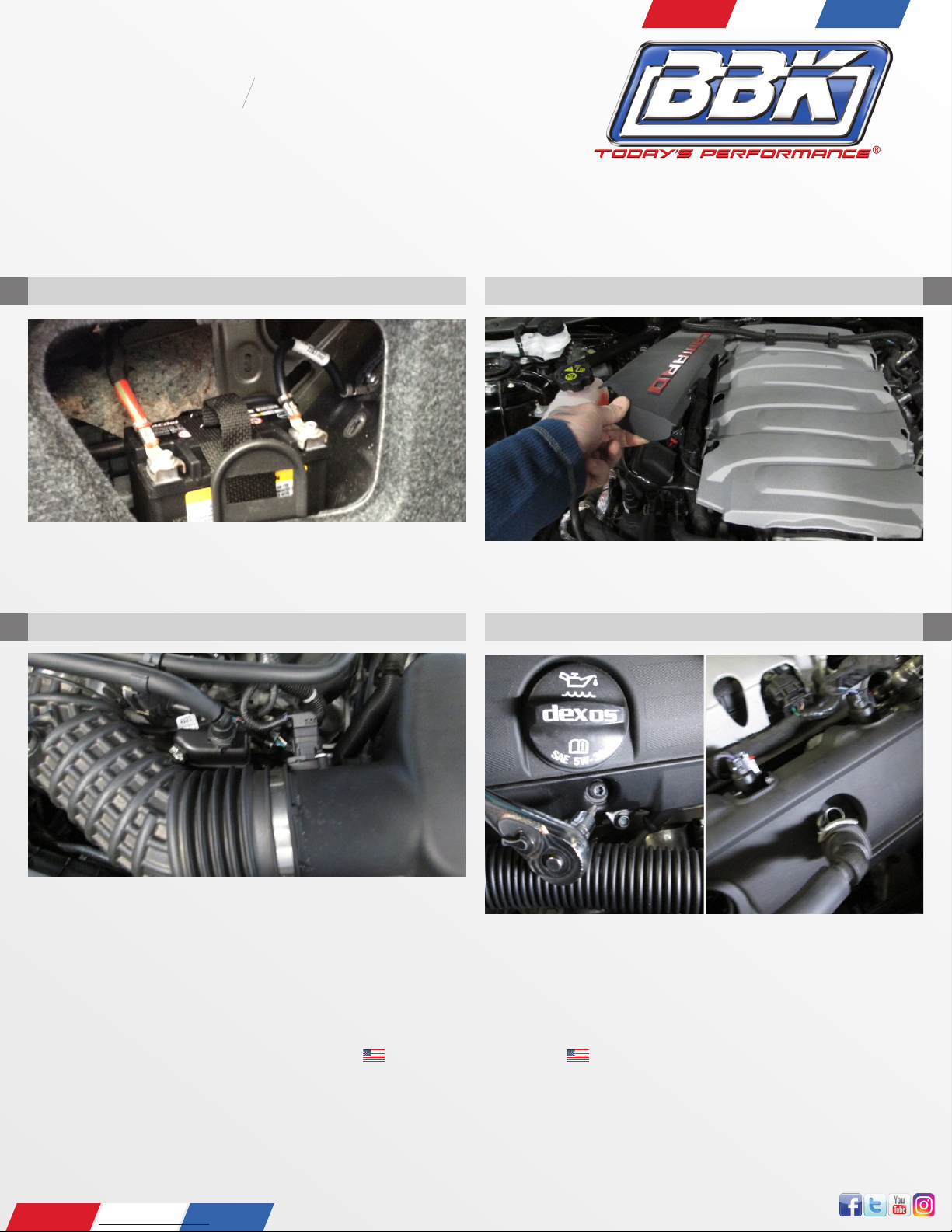

STEP 15

Head pipe adapter installation there is a driver and passenger side head pipe.

The driver side head pipe is the longer of the (2). Install the supplied hardware

studs into the anges on the BBK full length headers. Slide the end of the head

pipe over the stock exhaust pipe where it was cut o in (step 11.) 0nce in place

rotate the head pipe so that the oxygen sensor bung is facing towards the

center of the car. Repeat this step for the passenger side.

Cont. step 14.

NOTE! ON MANUAL TRANSMISSION CARS YOU WILL NOT NEED 02 SENSOR EXTENSION AS FACTORY HARNESS

EXTENDS TO CORRECT LENGTH. FOR AUTOMATICS YOU WILL NEED TO PURCHASE DR-SD EXTENSIONS

!