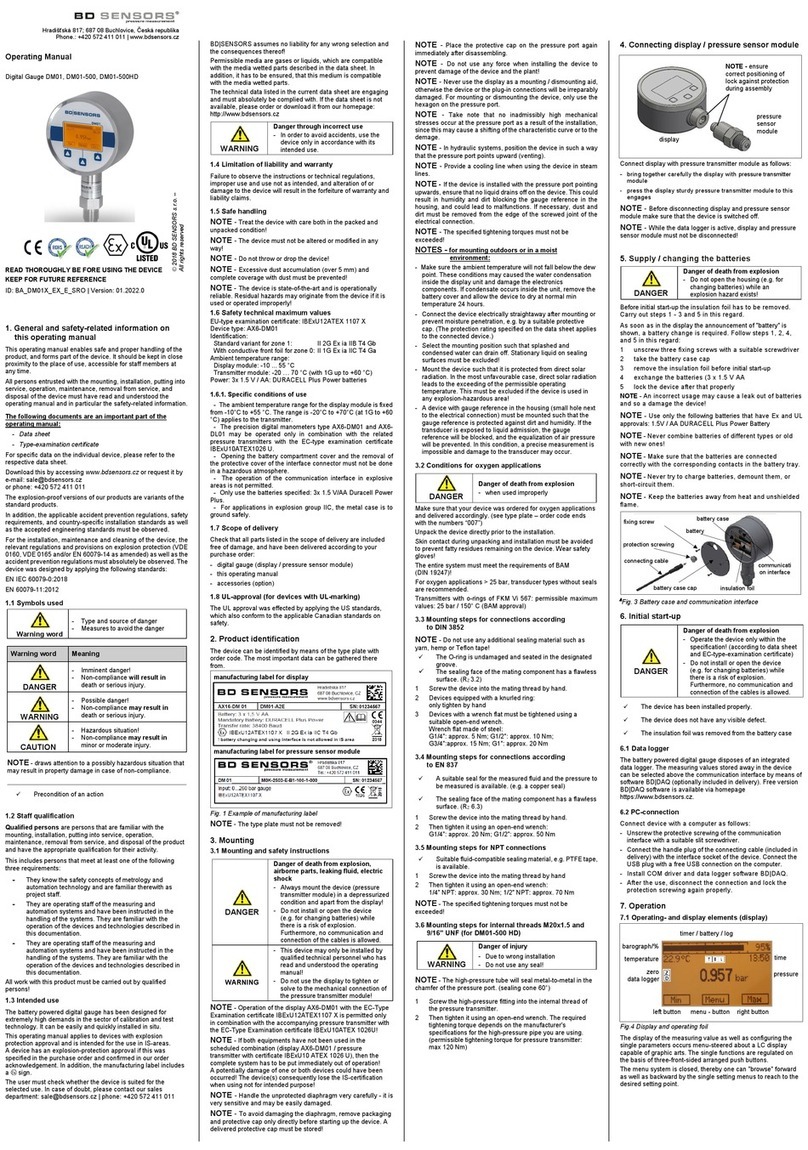

Adjustment of the access security - secured status

If the password is activated, the user is asked to enter the

unlock code after pressing both the control buttons to make

settings in the menu system.

Adjustment of the password security - unsecured status

If not activate, the password can be activated by pressing

both the buttons simultaneously and entering

a predetermined secret number. In settings of the

mechanism, 5 is the secret number. To change this number,

both the buttons should be pressed simultaneously in this

menu. Then, the number 0835 should be adjusted by the

cursor. Afterwards, both the buttons should be pressed

simultaneously again, and the secret number within 0 and

9999 should be adjusted by cursor buttons. The number is

confirmed by pressing the cursor buttons simultaneously.

That way, the new password is adjusted. To activate the

password protection, instructions given in the PAon menu

should be followed.

Adjustment of decimal point

After pressing of both the buttons simultaneously, position

of the decimal point can be adjusted. The desired position

can be selected using "▲" or "▼" buttons. Pressing both

the buttons simultaneously, the settings are closed.

Adjustment of zero

Pressing both the buttons simultaneously, zero can be

adjusted. The adjusted value is shown when the electrical

output signal of the pressure sensor corresponds to 4 mA

(zero). Pressing both the buttons simultaneously, the

settings are closed.

Adjustment of the ending value

After pressing both the buttons simultaneously, the ending

point can be adjusted. The programmed value is shown

when the electrical output signal of the pressure sensor

corresponds to 20 mA (the ending point). Pressing both the

buttons simultaneously, the settings are closed.

Adjustment of attenuation (filter)

After pressing both the buttons simultaneously, the time

interval for updating the displayed value can be adjusted.

The range of the adjustment is from 0.3 to 30 seconds. To

close the configuration, both the buttons should be pressed

simultaneously.

Activation of report about exceeding the range

After pressing both the buttons simultaneously, the report

about exceeding or failing to meet the display range can be

activated. Only the "ON" status or the "OFF" status can be

selected. Pressing both the buttons simultaneously, the

settings are closed.

High-Pressure

After pressing both the buttons simultaneously, the

maximum pressure saved during the measurement is

displayed. If both the buttons are within one-second interval

pressed again, the saved value is deleted. Please note that

the value does not stay saved when the power supply is

interrupted (current loop).

Low-Pressure

After pressing both the buttons simultaneously, the

minimum pressure saved during the measurement is

displayed. If both the buttons are within one-second interval

pressed again, the saved value is deleted. Please note that

the value does not stay saved when the power supply is

interrupted (current loop).

Transport and storage

The range of storage temperatures: -10°C to +50°C

When transporting, make sure that both the inputs of differential pressure sensors are open.

Calibration instructions

Required equipment: pressure gauge: (e.g., high-precision digital pressure gauge)

pressure source: (e.g., a pump, a bag)

power supply: according to the design of the pressure gauge

measuring device: mA-meter for measuring the output signal.

Output settings

1) The sensor should be connected to the corresponding power supply (see operating instructions). Instead of

a load resistor and a voltmeter, a suitable mA-meter of the accuracy class at least 2 times better than the sensor

should be connected.

2) After switching on, the starting time should be let to pass (see operating instructions).

3) Adjusting zero (trimmers RP2 or RP101)

When adjusting zero, both the pressure inputs have to be open. The output current is adjusted to 4 mA by the

RP2 trimmer or the RP101 trimmer (only one of them is available).

4) Adjusting range (trimmers RP1 or RP102)

The nominal pressure is set on the pressure source. This pressure is connected to the inlet "+" (at over-pressure)

or to the inlet "-" (at under-pressure). The output current is adjusted to 20mA by the RP2 trimmer or the RP101

trimmer (only one of them is available). If necessary, the procedure according to points 3) and 4) is repeated.