TABLE of CONTENTS

1. INTRODUCTION ...................................................................................................................................................1

1.1 THEORY OF OPERATION.......................................................................................................................................1

2. INSTALLATION ....................................................................................................................................................2

2.1 PRELIMINARY TESTS............................................................................................................................................2

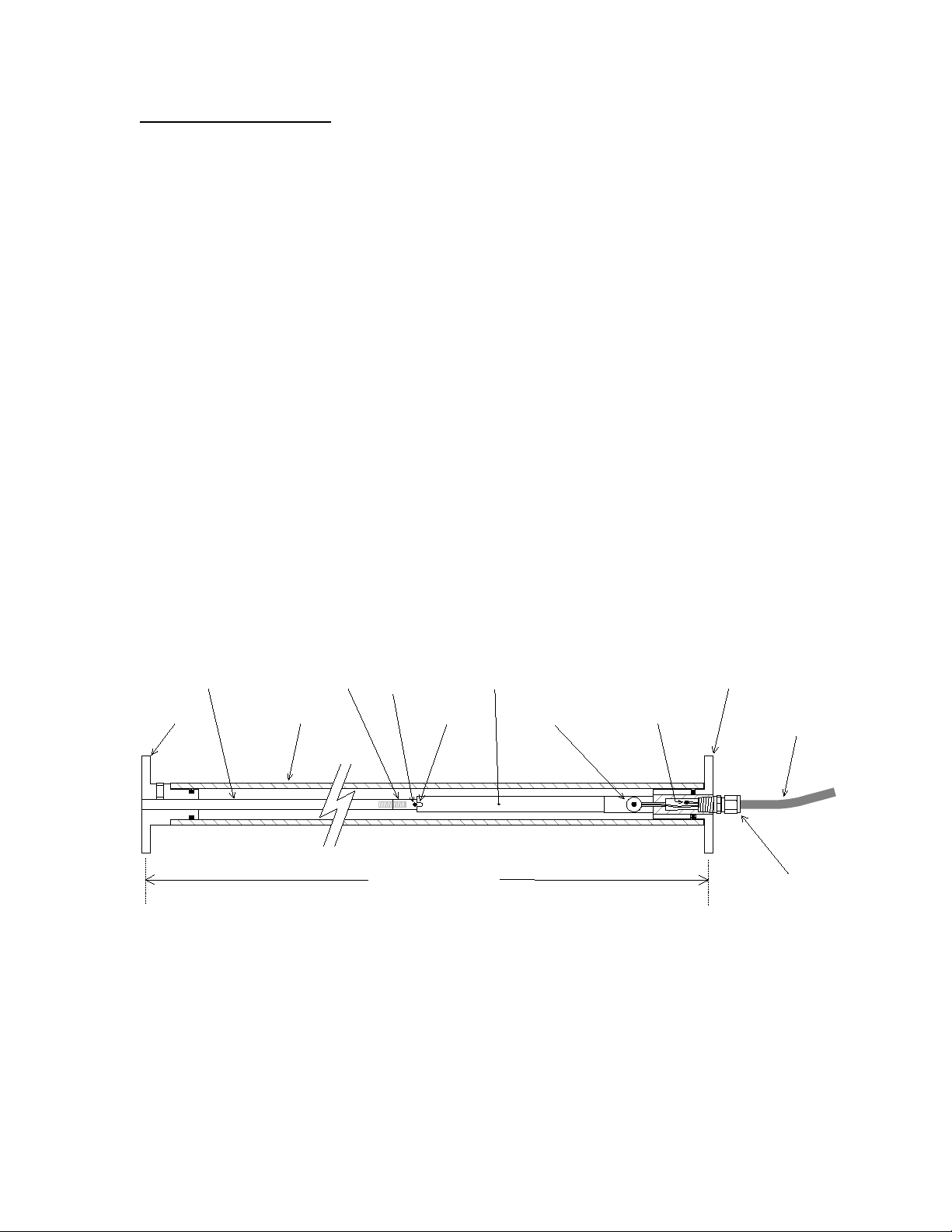

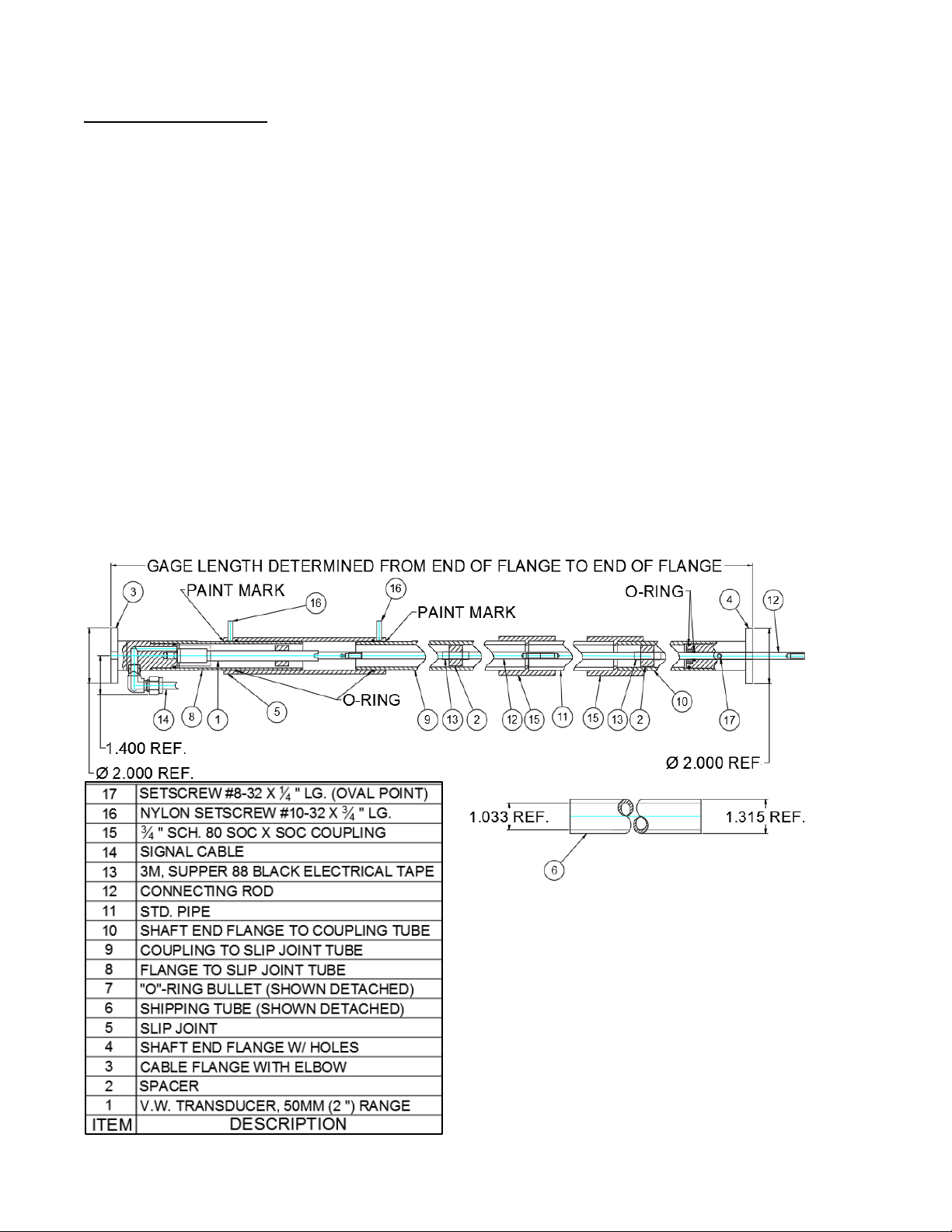

2.2 SENSOR ASSEMBLY ..............................................................................................................................................2

2.3 DEFORMATION METER INSTALLATION ................................................................................................................4

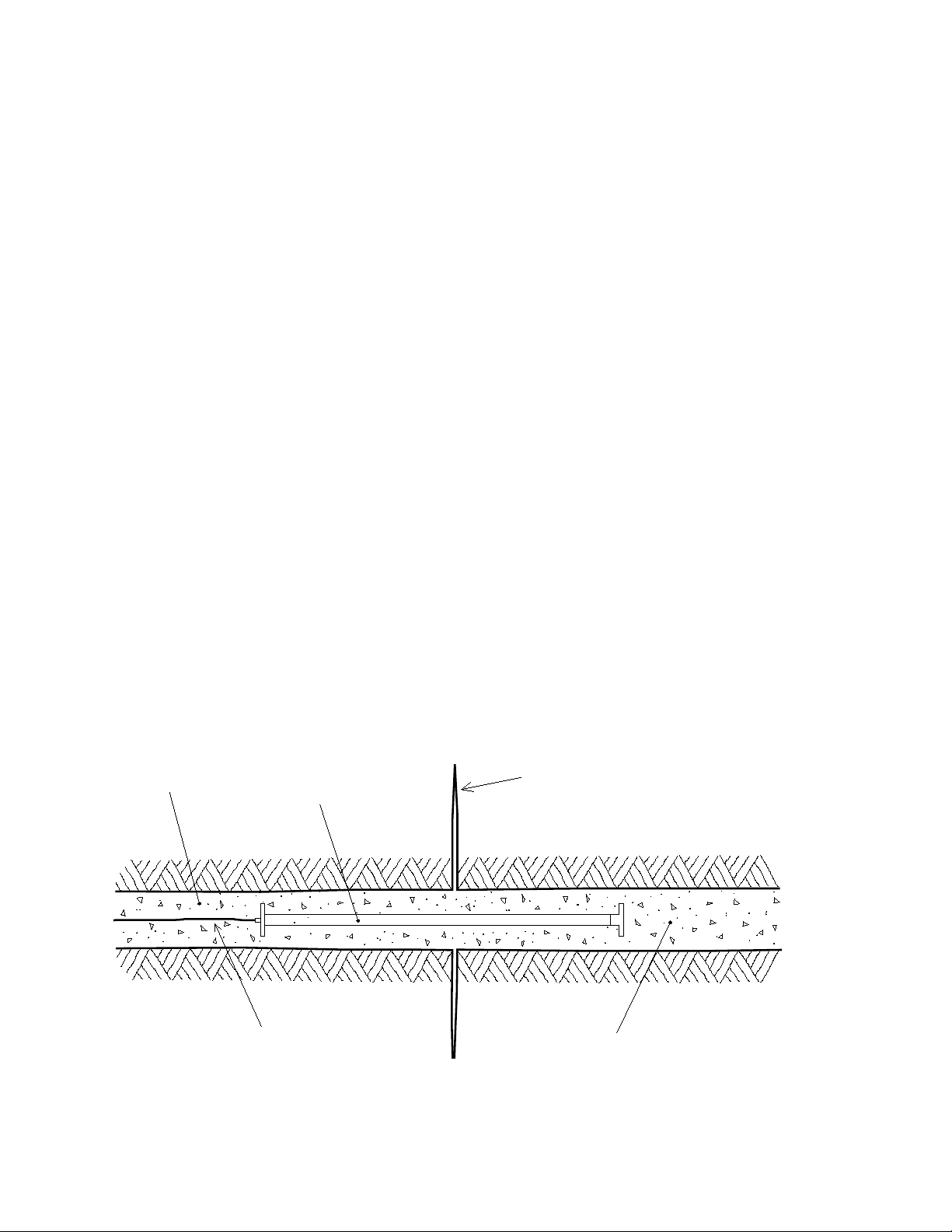

2.3.1 Installation in Boreholes.............................................................................................................................4

2.3.2 Installation in Mass Concrete .....................................................................................................................5

2.3.3 Installation in Fills and Embankments – Soil Strain Gauges......................................................................5

2.4 CABLE INSTALLATION AND SPLICING ..................................................................................................................6

2.5 INITIAL READINGS ...............................................................................................................................................6

2.6 ELECTRICAL NOISE..............................................................................................................................................6

2.7 LIGHTNING PROTECTION .....................................................................................................................................7

3. TAKING READINGS.............................................................................................................................................8

3.1 GK-404 READOUT BOX.......................................................................................................................................8

3.1.1 Operating the GK-404 ................................................................................................................................8

3.2 GK-405 READOUT BOX.......................................................................................................................................9

3.2.1 Connecting Sensors with 10-pin Bulkhead Connectors Attached ...............................................................9

3.2.2 Connecting Sensors with Bare Leads..........................................................................................................9

3.2.3 Operating the GK-405 ................................................................................................................................9

3.3 GK-403 READOUT BOX (OBSOLETE MODEL)....................................................................................................10

3.3.1 Connecting Sensors with 10-pin Bulkhead Connectors Attached .............................................................10

3.3.2 Connecting Sensors with Bare Leads........................................................................................................10

3.3.3 Operating the GK-403 ..............................................................................................................................10

3.4 MEASURING TEMPERATURES.............................................................................................................................10

4. DATA REDUCTION ............................................................................................................................................11

4.1 DEFORMATION CALCULATION...........................................................................................................................11

4.2 TEMPERATURE CORRECTION .............................................................................................................................13

4.3ENVIRONMENTAL FACTORS ...............................................................................................................................14

5. TROUBLESHOOTING........................................................................................................................................15

APPENDIX A. SPECIFICATIONS.........................................................................................................................17

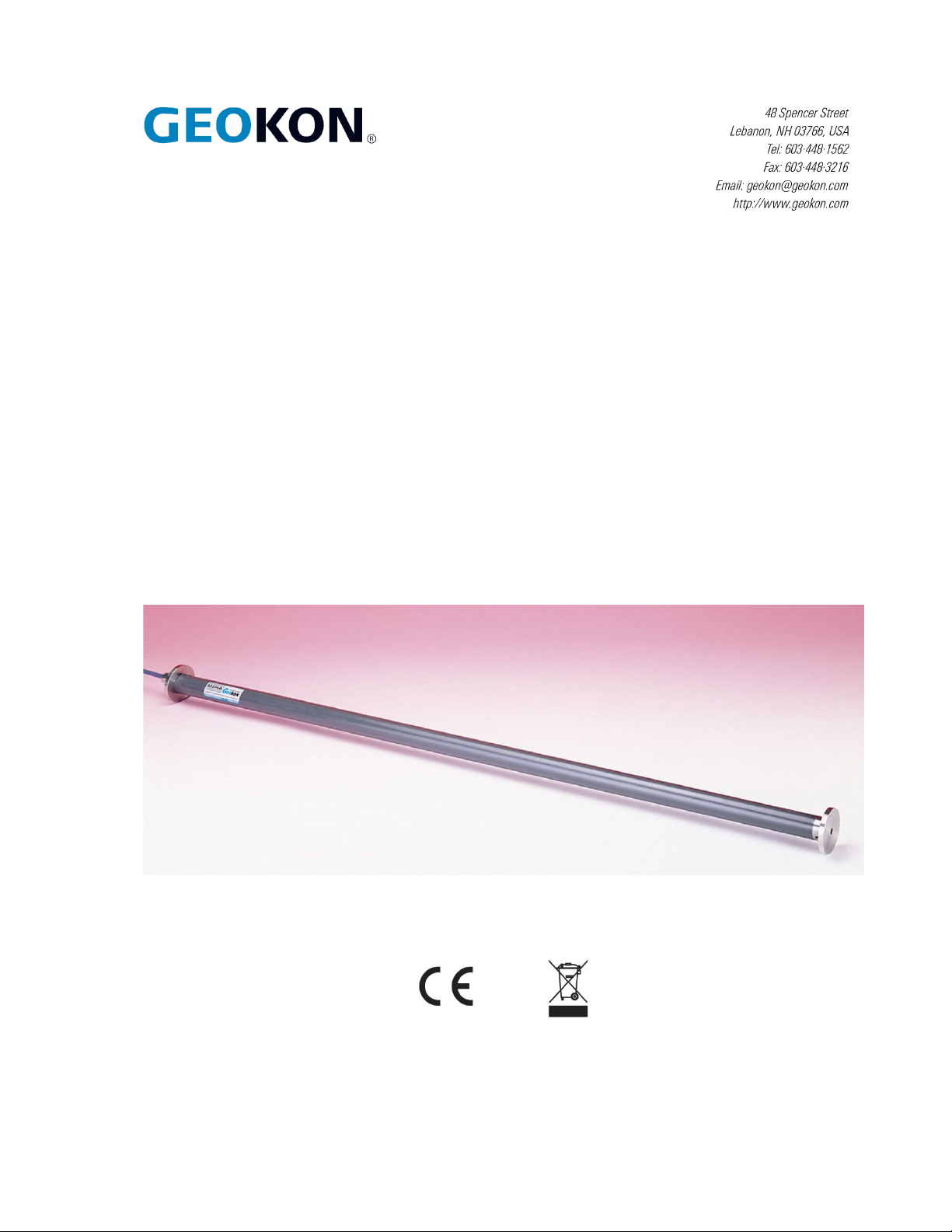

A.1 MODEL 4430 DEFORMATION METER ................................................................................................................17

A.2 THERMISTOR (SEE APPENDIX BALSO) ..............................................................................................................17

APPENDIX B. THERMISTOR TEMPERATURE DERIVATION.....................................................................18