www.bdsensors.com

EN

Operating Manual

Probe for Marine and Offshore

LMK 457, LMK 458, LMK 458H, LMK 487

Headquarters

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Germany

Tel.: +49 (0) 9235-9811-0

Fax: +49 (0) 9235-9811-11

The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certifi-

cates, as well.

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual

carefully before installing and starting up the pressure

measuring device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable

regulations regarding occupational safety, accident preven-

tion as well as national installation standards and engineer-

ing rules must be complied with!

This operating manual is part of the device, must be kept

nearest its location, always accessible to all employees.

This operating manual is copyrighted. The contents of this

operating manual reflect the version available at the time of

printing. It has been issued to our best knowledge.

BD SENSORS is not liable for any incorrect statements and

their effects.

– Technical modifications reserved –

1.2 Symbols used

DANGER! – dangerous situation, which may result in

death or serious injuries

WARNING! – potentially dangerous situation, which

may result in death or serious injuries

CAUTION! – potentially dangerous situation, which may

result in minor injuries

!CAUTION! – potentially dangerous situation, which may

result in physical damage

NOTE – tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropriate

use, modification or damage, no liability is assumed and

warranty claims will be excluded.

1.5 Intended use

- The hydrostatic probes LMK 457, LMK 458, LMK 458H

and LMK 487 have been designed especially for ship-

building and offshore applications with rough environ-

mental and operation conditions. The probes are suita-

ble for level measurement of fluids or pasty media (no

solids and frozen media) in open tanks, containers, or

reservoirs. As medium all fluids can be used which are

compatible with the materials of housing, sealing and

cable. Based on a rugged and reliable capacitive ceram-

ic sensor the probe is qualified for measuring small fill-

ing heights with high accuracy. Typical areas of use are

ballast tanks, fuel and oil tanks as well as ser-vice and

waste water tanks. The probes as standard complies

with the requirements of DNV▪GL (Det Norske Veri-

tas▪Germanischer Lloyd). The certificates are available

for download on our homepage:

http://www.bdsensors.com

- It is the operator's responsibility to check and verify the

suitability of the device for the intended application. If

any doubts remain, please contact our sales department

in order to ensure proper usage. BD SENSORS is not

liable for any incorrect selections and their effects!

- The hydrostatic probe has to be used according to the

area of application specified above! In addition it has to

be ensured, that this medium is compatible with the me-

dia wetted parts.

- The technical data listed in the current data sheet are

engaging. If the data sheet is not available, please order

or download it from our homepage.

(http://www.bdsensors.com)

WARNING! – Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your

order:

- hydrostatic probe

- mounting instructions

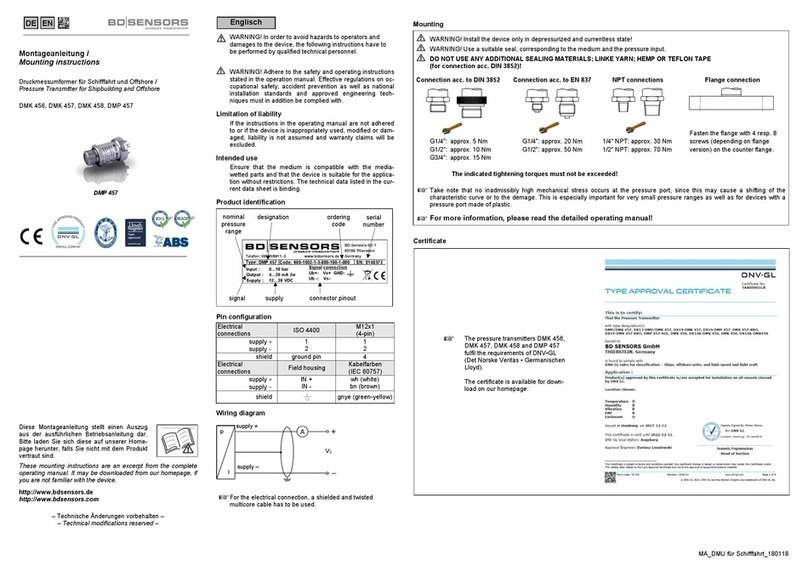

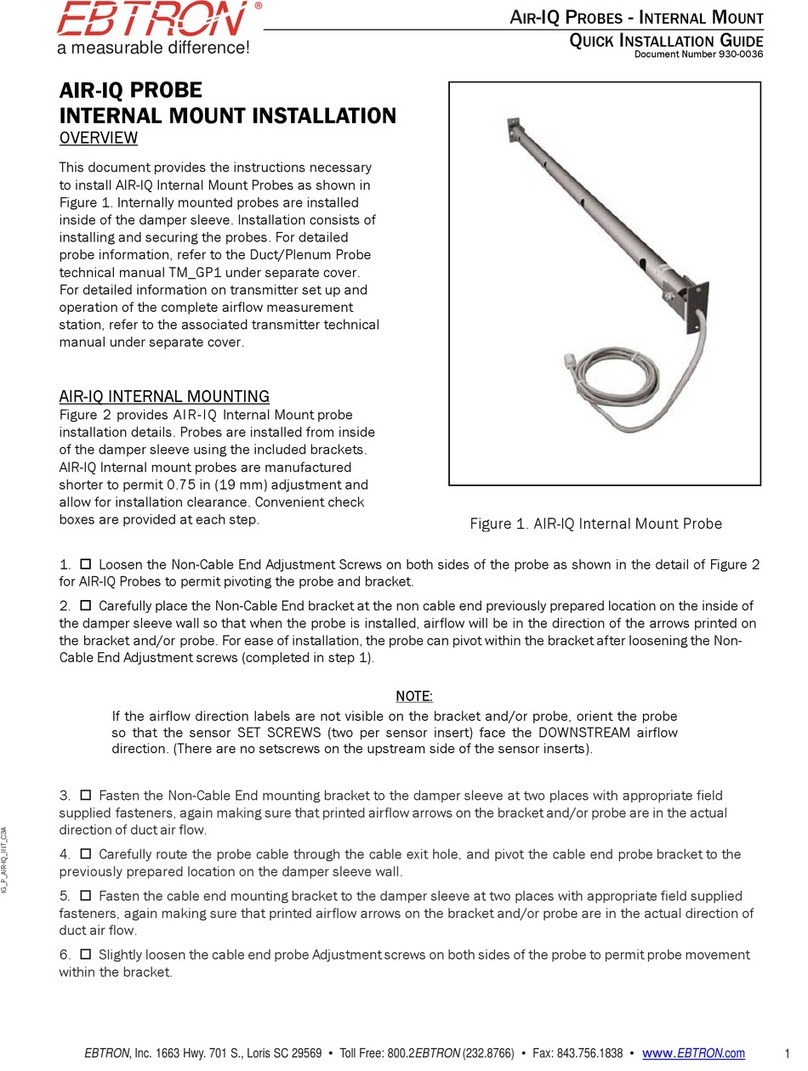

2. Product identification

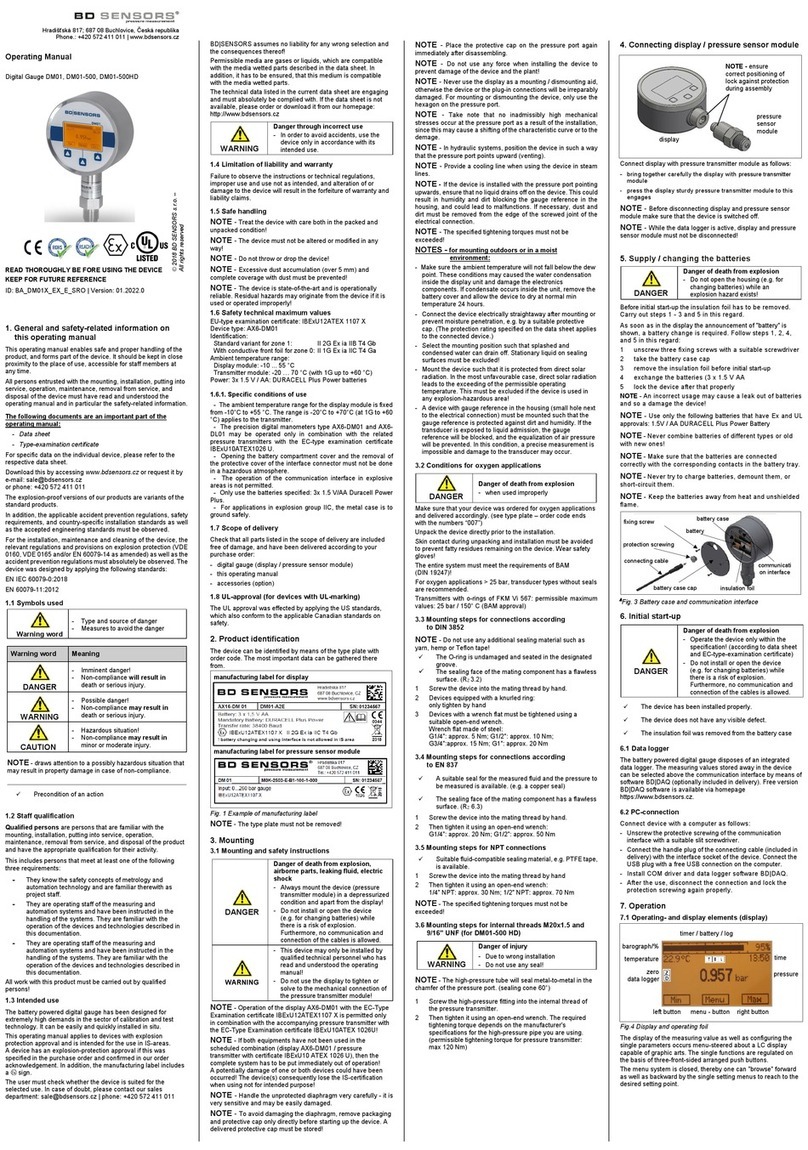

The device can be identified by its manufacturing label. It

provides the most important data. By the ordering code the

product can be clearly identified.

Fig. 1 manufacturing label

!The manufacturing label must not be removed from the

device!

3. Mechanical installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be installed by

qualified technical personnel who has read and under-

stood the operating manual!

!Handle this high-sensitive electronic precision

measuring device with care, both in packed and

unpacked condition!

!There are no modifications/changes to be made on the

device.

!Do not throw the package/device!

!To avoid damaging the diaphragm, remove packaging

and possibly protective cap directly before starting

assembly. The possibly delivered protective cap has to

be stored! Place this protective cap on the pressure port

again immediately after disassembling.

!Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!Do not use any force when installing the device to

prevent damage of the device and the plant!

!When placing the probe into operation or after mainte-

nance work, the probe has to be submerged slowly into

the medium! A rough immersion into the medium can

damage or destroy the diaphragm.

!For installations outdoor and in damp areas following

these instructions:

- Choose an assembly position, which allows the

flow-off of splashed water and condensation.

- Turn the outgoing cable downwards. If the cable

has to be turned upwards, then point it downward

so the moisture can drain.

- Install the device in such a way that it is protected

from direct solar irradiation. Direct solar irradiation

can lead to the permissible operating temperature

being overstepped in the worst case. By this the

operability of the device can be affected or dam-

aged. If the internal pressure increases due to so-

lar irradiation, measurement errors may be caused.

Take note for screw-in and flange transmitter that no

inadmissibly high mechanical stresses occur at the

pressure port as a result of the installation, since this

may cause a shifting of the characteristic curve or to the

demage.

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

Provide a cooling line when using the device in steam

piping.

If installing the device outdoor and there is any danger

of lightning or overpressure we suggest putting a

overpressure protection unit between the supply/switch

cabinet and the device to prevent damage.

3.2 General installation steps

- Carefully remove the pressure measuring device from

the package and dispose of the package properly.

- Go ahead as detailed in the specific instructions below.

3.3 Installation steps for probe

- Install the device according to your demands.

Usually, the probe is delivered without mounting acces-

sories. But BD SENSORS offers different accessories

on request e.g. mounting clamp, terminal clamp or

mounting flange.

Do not use freely suspended probes with an FEP cable

if effects due to highly charging processes are ex-

pected.

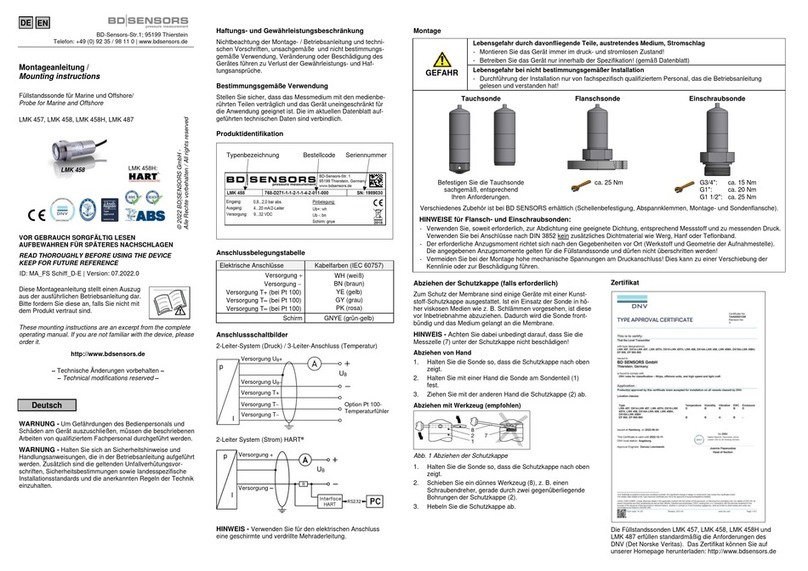

3.4 Installation steps for flange transmitter

- Please ensure that the mounting thread is clean and

free of damage.

- Check to ensure that the O-ring fits properly in the

groove.

- Screw in the mounting thread of the transmitter in the

transmitter flange, by hand.

- Next, tighten it by an open-end wrench. (approx. 25 Nm)

- Install the flange according to your demands.

If a new transmitter flange is needed, it can be ordered

from BD SENSORS.

3.5 Installation steps for screw-in transmitter

- Please ensure that the mounting thread is clean and

free of damage.

- Check to ensure that the O-ring fits properly in the

groove.

- Ensure that the sealing surface of the taking part e.g.

welding socket is perfectly smooth and clean.

- Screw the device in the corresponding thread by hand.

- Next, tighten it by an open-end wrench.

(G3/4": approx. 15 Nm; G1": approx. 25 Nm)

3.6 Removing the protection cap (for probe)

For the protection of the diaphragm, some of the probes

have a plugged-on protection cap. If the device shall be used

in high-viscosity media such as sludge, a removal of the cap

before start-up is necessary. Thus, the sensor becomes

flush and the medium will attain quickly to the diaphragm.

If it is necessary for your application to remove the

protection cap, this has to be done with utmost care. To

prevent a damage of the diaphragm, please follow the

instructions below.

Removal by hand

- Hold the probe in a way that the protection cap points

upwards.

- Hold the probe with one hand on the sensor section (1).

- Remove the protection cap (2) with the other hand.

LMK 458H:

LMK 45

ordering

code

nominal

pressure range

type

designation

connector pinoutsupply

signal

serial

number