BDE BDI-2006 User manual

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

1

CHAPTER 1 INTRODUCTION

§

1-1 Welcome

The BDI-2006 weighing indicator is a model of breakthrough high resolution.

The purpose of designing BDI-2006 is to perform quick and accurate controls

Please contact us immediately for further services if needed.

§

1-2 Features

BDI-2006 Weighing Indicator & Controller Features:

1/16,000 displayed resolution (Max. 1/ 60,000 depending on load cell quality &

performance). Internal Resolution 1,000,000, A/D Conversion rate 120 times/

Sec.

Watchdog virtually eliminates malfunctions that associated with

computerized equipment or software failure.

Full Digital Calibration makes setting ZERO and SPAN Calibration an easy

task.

Drives up to 8 parallel connecting load cells.

8k bytes SRAM with Li-battery backup. Information will not disappear even

power failure.

The settings of function and weighing parameters are all stored in the EEPROM,

with storage duration over 40 years.

Important values and parameters can have storage backup.

Users can adjust the intensity of digits filter to avoid mechanical vibration that

caused by external environments to achieve high-speed and accurate

measurement.

Set point codes can store up to 100 sets of: Final, SP1, SP2, Free Fall, HI, LO.

Automatic Free Fall Compensation provides closer tolerance and precise

weighing.

8 Set of control Input: ZERO Input, TARE Input, Tare reset, Start

batch,Abort batch, Print Accumulator, Print Input, Clear, ACC. &

COUNT.

8 Set of control Output: ZERO Band output, SP1 output, SP2 Output, (Final-Free

Fall) output, HI output, LO output, Final Output, MD/Error output.

Standard Serial Output (20mA Current Loop) for remote display.

Optional printer interface can automatically print or output data includes: date,

time, set point code, serial number, weight, and unit.

§

1-3 Items In Carton

The carton in which the BDI-2002 is delivered contains: 1. Indicator. 2. Accessory pack (In

bag). 3. Electric Cord. 4. This manual.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

2

CHAPTER 2 INSTALLATION

§

2-1 Best Conditions For Use

When installing and wire connecting on BDI-2006, please follow the

points and guide for preventing any abnormal situation occurred.

1.Before connecting the Electric Power Supply, please identify the input

Electric voltage type is AC 110V or AC 220V.

2.The Grounding Wire shall be properly connected.

3.The Operation Temperature shall range within 0℃~ 45℃, please DO not

install in any place of direct sun-light.

5.Due to the minute output signal from Load Cell, please use isolated cables.

Also, separate the Load Cell cable from the power supply cable and control

I/O cables.

6.The input power shall be AC 110V or AC 220V±10%, if the Electric Power

Supply is not stable or the interference signal exists, that may cause

uncertain actuation or reaction, even damages.

Therefore, please utilize Electric Power Supply Stabilizer of adequate

capacity.

§

2-2 Power Supply Connecting

§

2-3 Connecting the Load Cell

Do not plug in your power cable until you have completely connected the load cell.

To connect your load cell to the weighing Indicator use a six-wire cable with

shield-connect the wires as indicated above. If the BDI-2006 is located near the Load

Cells (Within five meters or a few yards) you may use a 4-wire cable with shield, but first

connect screws 1&2 and 3&4 with independent jumper leads.

Screw Signal

1 Positive Excitation Voltage, (EXC+)

2 Positive Sense Voltage, (SEN+)

3 Negative Sense Voltage, (SEN-)

4 Negative Excitation Voltage, (EXC-)

5 Positive Signal Voltage, (SIG+)

6 Negative Signal Voltage, (SIG-)

7 Shield, (SHD)

Open the case, there

is a jumper﹝S1﹞

near the transformer,

please insert a

short-circuit pin to the

available side.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

3

The analogue output from the Load Cell and input/output signals are sensitive to

electrical noise. Do not bind these cables together as it could result in cross-talk interface.

Please also keep them away from AC power cables.

§

2-4 Front and Rear Panel Dimensions

Front Panel of BDI-2006

Rear Panel of BDI-2006

Side View of BDI-2006

Mounting Cut for BDI-2006

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

4

CHAPTER 3 SPECIFICATIONS

§

3-1 Analog Input and A/D Conversion

◎Analog Input and A/D Conversion

Type BDI-2006

Input Sensitivity ≧0.3uV/D

ZERO Adjustment Range 0 ~20mV

Load Cell Excitation DC10V±1%,230mA, Remote Sensing. Can be

connected up to 8 350ΩLoad Cells.

Non-Linearity 0.01 % F.S.

A/D Conversion Method △Σ

A/D Resolution ≒1/1,000,000

A/D Conversion Rate Approx. 120 Times∕Sec.

Max. Load Cell Input Voltage 32mV

ZERO Temperature Comp. ±(0.2μV + 0.001% of Dead Load)/℃TYP

SPAN Temperature Comp. ±0.001% ℃TYP

Max. Resolution 1/16,000 (BDI-2006 Resolution can reach 1/60,000 depending on

load cell quality & performance).

§

3-2 General

◎General

Type BDI-2006

Power Requirements AC 110V or AC 220V ±10%,50∕60Hz, Approx. 17VA

Net weight Approx. 3.2 kg﹝7.054 lb﹞

Operation Temperature -10℃〜 45℃

Maximum Humidity 85%﹝non-condensing﹞

Physical Dimensions 240 (D) ×190 (W) ×104(H) mm

§

3-3 Front Panel Description

*3-3-1 Rear Panel of BDI-2006

Section Description

1 I / O Input & Output

2 Power Switch

3 Fuse(Includes fuse set 0.5A/125V)

4 SET Switch

5 Power Supply Screw

6 Code Input (00-99)

7 20mA Current Loop

8 Screws for Load Cell

9 For Optional Interfaces

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

5

*3-3-2 BDI-2006 Front Panel Description

◎DIGIT / LED LIGHT SECTION BDI-2006

Main Display﹝Green Tube﹞3 Column, 7-segment,8-digit displays the weight,

with dots.

Minimum Division ×1、×2、×5、×10、×20、×50

Maximum Display +800450

Under ZERO Indicator 〝—〞minus sign

〝ZERO〞●LED Light Center of Zero

〝MD〞●LED Light Motion Detected = Unstable

〝GROSS〞●LED Light Gross Weight displayed

〝NET〞●LED Light Net Weight displayed

〝TARE〞●LED Light TARE weight when stable-in Net, display ZERO

〝START〞●LED Light Initial programmed control / STOP

〝〞●LED Light “ ” displays the custom weight unit.

〝kg 〞● LED Light Kilograms Displayed

〝ZERO BAND〞● LED Light Zero band in which indicator will read as zero

〝SP1 〞●LED Light Set -point 1 output.

〝SP2 〞●LED Light Set -point 2 output.

〝FF 〞●LED Light Free Fall output.(Final minus Automatic Free Fall

Value)

〝HI 〞●LED Light Hi limit output. (Over limit)

〝LO 〞●LED Light Lo limit output. (Under limit)

〝FINISH 〞●LED Light Final output.

〝MD / ERROR 〞●LED Light Motion Detected / Error occurred.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

6

◎KEYSECTION

BDI-2006

KEY SET MODE Accumulation

Mode WEIGHT

MODE WHEN

SETTING

Final / F1 / 1 Set Finish Weight Set pre-tare Unused Number “1”

SP1 / F2 / 2 Set set-point one value Print

Accumulated

Value

Unused Number “2”

SP2 / F3 / 3 Set set-point two value Unused Unused Number “3”

FF/ F4 / 4 Set Free Fall Value Unused Unused Number “4”

HI / F5 / 5 Set Hi limit Unused Unused Number “5”

LO / F6 / 6 Set Lo limit Unused Unused Number “6”

ZERO / 7 Display center of

Ze0ro Display center

of Zero Display

center of

Zero

Number “7”

TARE / 8 Zero display & stores

the TARE weight. Zero display &

stores the

TARE weight.

Zero display

& stores the

TARE

weight.

Number “8”

G/N / 9 Gross/Net Gross/Net Gross/Net Number “9”

TARE CLR / 0Tare Cleared Tare Cleared Tare Cleared Number “0”

CODE / ESC CODE Setup (00-99) CODE Setup

(00-99) Unused Cancel

PRINT / CLR Print once Print Once Print Once Clear Weight

START╱STOP╱

+/-/. Start Setup / Stop

operate Start Setup /

Stop operate Start Setup /

Stop operate

±key

DISP MODE /

▲

Display Mode Display Mode Display

Mode Increase 1

╱ ╱Standby / Operate Standby /

Operate Standby /

Operate Minus 1

〝ENTER 〞

KEY Confirm Confirm Unused Confirm

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

7

§

3-4 Quick Function Table

◎WEIGHT FUNCTION TABLE

F 000 Decimal Point

Adjustment No Decimal, 1 Decimal, 2 Decimal, 3 Decimal , 4

Decimal

F 001 Weighing Unit Selection None, Kilogram, Pound, gram, ton, Oz

F 002 Display Update rate 10 times/Sec, 20 times/Sec, 40 times/Sec

F 003 Digital Filter 0 〜7 step digital filter

F 004 Set Zero Range ±5% , ±10% , ±20% , or ±30% of Max. Capacity

F 005 Motion Detection 0.5 SEC 1 DIV〜1 SEC 18 DIV 16 Steps (00 Stable)

F 006 Automatic ZERO

Tracking Compensation 1 SEC 0.5 DIV〜2 SEC 4.0 DIV 16 Steps (00 OFF)

F 007 ZERO & TARE keys

Availability ZERO & TARE keys always work or, only work when

display is STABLE

F 008 TARE Key Availability TARE key always work / If the GROSS is Negative

(-), TARE key does not work

F 009 Accumulation Availability OFF, Stable, Manual , or Control Input Command then

Accumulated.

◎20 mA Current Loop STANDARD

F C00 Data type Same as display / Gross Weight / NET Weight / TARE Weight /

Gross Weight, NET Weight, TARE Weight

F C01 Output Mode Stream / Stable and auto print / Manual print mode

/ Accumulate and print

F C02 Output Format Sending without set point Code / Sending with set point Code

◎Batch & Loss-in weight Weighing

F 100 Zero Band 6 digit Zero band value (Initial ”000.000”)

F 101 Batching Mode

Customer Programmed Control Mode :

Normal Batching, Loss-in-Weight Batching

Built-in Automatic Program Mode :

Normal Batching , Built-in Automatic Program

Mode :Loss-in-Weight Batching

F 102 Timer-Comparator Inhibitor Set between 0.0 to 2.0 Sec (Initial 0.0 Sec)

F 103 Timer-Finish Signal Set between 0.0 to 9.9 Sec (Initial 0.0 Sec)

F 104 Pulse Width of Finish Signal Set between 0.0 to 2.0 Sec (Initial 0.5 Sec)

F 105 COM 8 Unstable, Error

F 106 Input Mode By Panel key, BCD Input, or Serial Input

F 107 Free Fall compensation Please enter 6 digit free fall compensation value

within effective range (Initial “000.000”---Free Fall

OFF)

F108 Memory of Automatic Free

Fall Compensation value Not memory / memory

◎SERIAL ﹝RS-232﹞OP-02

F 200 Baud Rate 1200 BPS / 2400 BPS / 4800 BPS,/ 9600 BPS / 19200BPS

F 201 Parity Non-parity / Even Parity / Odd Parity

F 202 Output Data Same as display / Gross Weight / NET Weight / TARE Weight /

Gross Weight, NET Weight, TARE Weight

F 203 Output Mode Stream / Stable and auto print / Manual Print Mode /

Accumulate and Print / Command Mode

F 204 Output Format Sending without Set point Code / Sending with set point Code

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

8

◎PRINTER OP-03

F 300 Setting Date, Time Setting Year. Month, day, hour, minute, second

F 301 Data Format

Date Not print / Only print above the latest data / Print on all

Time Not print / Only print above the latest data / Print on all

Set Not print / Only print above the latest data / Print on all

Serial Number Not print / Print

Weight Same as display / Gross Weight / NET Weight / TARE

Weight / Gross Weight, NET Weight, TARE Weight

/ Gross Weight, TARE Weight, NET Weight

Unit

Not print / Only print above the latest data according to F001

/

Only print the latest data “g” / Only print above the latest

data ”t” / Print on all according to F001/ Print on all “g” / Print

on all “t”

F302 Accumulation

Date Not print / Print once

Time Not print / Print once

Count Not print / Print once

F 303 Output Mode Stable and auto print / Manual Print Mode

/ Accumulate and Print

F 304 Select Printer MINI Printer / Normal Printer

◎BCD OP-04

F 400 Data type Same as display / Gross data / NET data / TARE data

F 401 Output Mode Stream / Stable and print / Manual print mode

/ Accumulate and print

F 402 Output Logic Positive Logic / Negative Logic

◎AnalogOutput OP-05

F 500 Analog Output Data Output 4~20 mA / Output 0~+10 V

F 501 Output Mode Same as display / Gross data / NET data

F 502 Loss-in-weight Absolute

Value Not readAbsolute Value / BDI-2006 reads Absolute

Value

F 503 Output current when

display ZERO 0.0mA through 9.99mA (Initial 0.40mA)

F 504 Output current at Full

Capacity 0.0mAthrough 9.99mA (Initial 20.0mA)

F 505 Output Volt when display

ZERO -2.5V through +59.9V (Initial 00.0 V)

F 506 Output Volt at Full

Capacity -2.5V through +59.9V (Initial 10.0 V)

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

9

§

3-5 Panel Key Function Table

Act Accordance Status

Panel Key ZERO

Control I / O Pin 25 +(Pin 16 /17)

ZERO OP-02(Command Mode)Z Cr Lf

BDI - 2002 returns to the center

of ZERO if the weight value

within F004 range.

Panel Key TARE

Control I / O Pin 24+ (Pin 16/ 17)

TARE OP-02(Command Mode)T Cr Lf

BDI – 2002 switches to NET

mode, ZERO’s the display and

stores the TARE weight in

Memory.

Panel Key TARE CLEAR

TARE

CLEAR Control I / O Pin23 + (Pin 16/ 17) Clear TARE Value

Panel Key GROSS / NET

GROSS OP-02(Command Mode)G Cr Lf Shift to GROSS Mode

Panel Key GROSS / NET

NET OP-02(Command Key)N Cr Lf Shift to NET mode

Panel Key PRINT

PRINT Control I / O Pin19 + (Pin 16/ 17)

Print or Output latest Data

Panel Key PRINT /ACC

ACC Control I / O Pin20 + (Pin 16/ 17) Print Accumulator Value

ACC Panel Key DISPLAY MODE

KEY Display accumulator and Count

Panel Key Clear Accumulator

and Count (5-2-1)

CLEAR Control I / O Pin18 + (Pin 16/ 17) Clear Accumulator and Count

Panel Key SET POINT/CODE

Code Input CODE INPUT

CODE OP-02(Command Key)CCXX Cr Lf Display current Code number

Standby Panel Key ╱Terminate operation

Operate Panel Key ╱Start operation

Panel Key SET POINT/CODE

Set

Point OP-02 S Cr Lf, SS Cr Lf

Setting Final, SP1, SP2, Free

Fall, Hi, Lo

CANCEL Panel Key ESC Quit current mode

MODE Panel key DISP MODE / ▲CHANGE MODE

Act Accordance Status

Key 0 to 9 Panel Key Key 0 to 9 Input Number

Display Finish weight Panel Key Finial Display Finish weight

Display Set-Point 1 Panel Key SP1 Display Set-Point 1

Display Set-Point 2 Panel Key SP2 Display Set-Point 2

Display Free Fall Value Panel Key FF Display Free Fall Value

Display Hi

limit Value Panel Key HI Display Hi limit Value

Display Lo limit Value Panel Key LO Display Lo limit Value

※Please refer to chapter 7 about Control I/O and OP-02

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

10

CHAPTER 4 SYSTEM FUNCTIONS

§

4-1 System Check

A system check should be run: after initial installation, after moving your

BDI-2006, after connecting or disconnecting an attachment from the Rear Panel and

as means of locating any unexplained system error. An occasional self-check to make

sure everything is working properly is a good maintenance practice as well.

STEP 1: Turn the Power Switch OFF on the Rear Panel. Slide the SET switch to the

set side.

STEP 2: Turn the power supply ON, the display will show blinking SELECT.

STEP 3: Press the Final/F1/1 key and screen will show blinking CHEC, and press

key to start system check.

STEP 4: The system will check Green Tube and LED in sequence.

STEP 5: Check MEMORY﹝EEPROM、SRAM﹞

When the screen shows SRAN, please press key. The screen will

subsequently show a series blinking dots ……… indicating system checking

in process. If the screen shows PASS, it means checking passed. If the

screen shows FAIL, it means system error.

STEP 6: EEPRON 1 checking. The screen will show EE-1. Please press key and the

screen will subsequently show a series blinking dots ……… indicating system

checking in process. If the screen shows PASS, it means checking passed. If

the screen shows FAIL, it means system error.

STEP 7: EEPRON 2 checking. The screen will show EE-2. Please press key and the

screen will subsequently show a series blinking dots ……… indicating system

checking in process. If the screen shows PASS, it means checking passed. If

the screen shows FAIL, it means system error.

STEP 8: 1.BCD checking. The screen will show CODE ----. Please make

SHORT-CIRCUIT test on 9-Pin Dshape Code Input on the rear panel. When

short-circuiting COM9 with other pins, the short-circuit pin will show the

accordance value on the screen. If not, there suggests an error occurred.

2. Input/Output checking. When the screen show I-O , please enter key.

Subsequently, the screen will show INPUT 0 with the 0 blinking. Please make

SHORT-CIRCUIT test on 25-Pin Dshape Code Input on the rear panel. When

short-circuiting COM17 or COM16 with pin25〜pin18, the short-circuit pin will

light up a specific LED on the screen. If not, there suggests an error occurred.

3.When short-circuiting COM17.COM16 with pin13〜pin16 , the short-circuit

pin will light up a specific LED on the front panel. If two or more LED light up

or turned off at the same time, there suggests an error occurred.

STEP 9: When press a key, the key number will show in the middle of the screen.

01 02 03 15

04 05 06 14

07 08 09 13

11 00 10 12

If the key number does not match, it suggests an error occurred. Please contact us.

STEP 10: Finish checking, display END .Slide the SET switch to the original side.

Above testing if any FAIL or error shows on the screen, please contact us.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

11

§

4-2 Functions

STEP 1: Turn the Power Switch OFF, Slide the SET switch to the set side.

STEP 2: Turn the power supply ON, the display will show blinking SELECT.

STEP 3: Press SP1/F2/2 key and screen will show as follows:

Func

F000

STEP 4: Please press ▲or ▼key to move through the function category (F000,

FC00, F200, F300, F400 or F500). Then press the Key to enter the category.

Use the▲or ▼key to choose specific function (F000 ~ FC02, F100 ~

F107, F200 ~ 204, F400 ~ F402 or F500 ~ F506). In each function, please

use number key to set function value. If you want to return to previous

function category, please press ESC key, or press key to enter.

If any errors occurred, please check if each setting value within effective range.

note:● Indicates initial factory setting.

STEP 5:When you finished changing the Function setting, slide SET Switch to the

original side. The screen will show END.

◎ General Functions

F000 Decimal Point Adjustment

0 No Decimal 1234567

1 1 Decimal 123456.7

2 2 Decimal 12345.67

●3 3 Decimal 1234.567

4 4 Decimal 123.4567

F003 Digital Filter

Filter

Environ-

mental

Vibration

Response

Speed

0 No stage Weak Bad Fast

11

st stage

2 2ed stage

33

rd stage ▲▲▲

●44

th stage ▼▼▼

55

th stage

66

th stage

77

th stage Strong Good Slow

F00

1 Weighing Unit Selection

0 None

●1 Kilogram

2 Pound

3 Gram

4 Ton

5 Oz

F004 Set ZERO Range

5

±5% of weighing platform Full Capacity

●10 ±10% of weighing platform Full

Capacity

20 ±20% of weighing platform Full

Capacity

30 ±30% of weighing platform Full

Capacity

F002 Display Update Rate

10 10 Times/Sec

●20 20 Times/Sec

40 40 Times/Sec

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

12

F008 TARE key Availability

●0 TARE key always work

1 If the GROSS is negative, TARE key does not work

F009 Accumulation Availability

0 OFF

1 Stable

2 Manual

●3 Control Input--Command Accumulation

◎ Standard 20 mA Current Loop

F005 Motion Detection

00 Stable

01 0.5 SEC 1 DIV

02 0.5 SEC 2 DIV

03 0.5 SEC 3 DIV

04 0.5 SEC 4 DIV

05 0.5 SEC 5 DIV

06 0.5 SEC 6 DIV

07 0.5 SEC 7 DIV

08 0.5 SEC 8 DIV

11 1 SEC 1 DIV

●12 1 SEC 2 DIV

13 1 SEC 3 DIV

14 1 SEC 4 DIV

15 1 SEC 5 DIV

16 1 SEC 6 DIV

17 1 SEC 7 DIV

18 1 SEC 8 DIV

F006 Automatic ZERO Tracking Compensation

00 OFF

11 1 SEC 0.5 DIV

12 1 SEC 1.0 DIV

13 1 SEC 1.5 DIV

●14 1 SEC 2.0 DIV

15 1 SEC 2.5 DIV

16 1 SEC 3.0 DIV

17 1 SEC 3.5 DIV

18 1 SEC 4.0 DIV

21 2 SEC 0.5 DIV

22 2 SEC 1.0 DIV

23 2 SEC 1.5 DIV

24 2 SEC 2.0 DIV

25 2 SEC 2.5 DIV

26 2 SEC 3.0 DIV

27 2 SEC 3.5 DIV

28 2 SEC 4.0 DIV

F007 ZERO & TARE keys Availability

●0 ZERO & TARE keys always work

1 ZERO & TARE keys only work when display is STABLE

FC00 Output Data

●1 Same as display

2 GROSS Weight

3 NET Weight

4 TARE Weight

5

GROSS Weight, NET

Weight, TARE Weight

FC02 Output Format

●0 Sending without set point

Code

1 Sending with set point Code

FC01 Output Mode

●1 Stream

2 Stable and auto print

3 Manual Print Mode

4 Accumulate and Print

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

13

◎Batching Weighing

F000 Set ZERO Range

6 digit Zero band value (●Initial ”000.000”)

F101 Batching Mode

●1 Customer Programmed Control Mode: Normal Batching

2 Customer Programmed Control Mode: Loss-in-Weight Batching

3 Built-in Automatic Program Mode: Normal Batching

4 Built-in Automatic Program Mode: Loss-in weight Batching

5 Built-in Automatic Program Mode: Normal Batching(Auto TARE)

6 Built-in Automatic Program Mode: Loss-in weight Batching (Auto TARE)

F102 Timer-Comparator Inhibitor

Set between 0.0 to 2.0 Sec (●Initial 0.0 Sec)

F103 Timer-Finish Signal

The finish signal timer can be Set between

0.0 to 9.9 Sec

※●Factory Initial 0.0 Sec

※Finish Signal sent ON at 0.0 Sec. And

stays ON until the next START Signal

F104 Pulse Width of Finish Signal

Set between 0.0 to 2.0 Sec

※●Initial 0.5 Sec

※Stable at 0.0 Sec. which is apply to F101

setting at 3 or 4.

F105 COM 8

0 Unstable

1 Error

F106 Input Mode

1 Panel key

2 BCD Input

3 Serial Input

F107 Automatic Free Fall Compensation

Please enter 6 digit free fall compensation

value within effective range

●Initial “000.000”--- Free Fall OFF

F108 Memory of Automatic Free

Fall Compensation value

0 Not memory

1 Memory

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

14

◎SERIAL (RS-232)

◎Printer

F300 Setting Date, Time

YY / MM / DD HH:MM:SS

F301 DataFormat *Atinitialsetting, the screen shows: 1 2 1 0 1 1

Date Time

Set point

code Serial

Number Weight Unit

Not Print Not Print Not Print Not Print Not Print

1 Only Print

above the

Latest data

Only Print

above the

Latest data

Only Print

above the

Latest data Print Same as

display

Only print above

the latest data

according to F101

2 Print on all Print on all Print on all GROSS

Weight Only Print above the

Latest data ” g “

3 NETWeight Only Print above the

Latest data “ t “

4

TARE

Weight Print on all ,

according to F001

5

GROSS

Weight, NET

Weight,

TARE

Weight

Print on all “ g “

6

GROSS

Weight, NET

Weight,

TARE

Weight

Print on all “ t “

Initial 1 2 1 0 1 1

F200 Band Rate

12 1200BPS

24 2400BPS

48 4800BPS

96 9600BPS

19 19200Bps

F203 Output Mode

1 Stream

2 Stable and auto print

3 Manual Print Mode

4 Accumulate and Print

5 Command Mode

F201 Parity

0 Non-parity

1 Even- Parity

2 Odd- Parity

F202 Parity

1 Same as display

2 GROSS Weight

3 NET Weight

4 TARE Weight

5 GROSS Weight, NET

Weight, TARE Weight

F204 Output Format

●0 Sending without set point

Code

1 Sending with set point Code

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

15

◎BCD

◎ Analog Output

F302 Accumulation

Date Time Count

0 Not print Not print Not print

1 Print

once Print once Print once

Initial 0 0 0

F304 Select Printer

1 MINI Printer

2 Normal Printer

F303 Output Mode

1 Stable and auto print

2 Manual print mode

3 Accumulate and print

F400 Data Type

1 Same as display

2 GROSS Weight

3 NET Weight

4 TARE Weight

F402 Output Logic

1 Positive Logic

2 Negative Logic

F401 Output Mode

1 Stream

2 Stable and auto print

3 Manual Print Mode

4 Accumulate and Print

F 500 Analog Output Data

1 Output 4~20 mA

2 Output 0~+10 V

F 504 Output current at Full Capacity

0.0mA through 9.99mA

●Initial 20.0mA

F 501 Output Mode

1 Same as display

2 GROSS Weight

3 NET Weight

F 505 Output Volt when display ZERO

-2.5V through +59.9V

●Initial 00.0 V

F 502 Loss-in-weight Absolute Value

0 Not read Absolute Value

1 BDI-2006 reads Absolute

Value

F 506 Output Volt at Full Capacity

-2.5V through +59.9V

●Initial 10.0 V

F 503 Output current when display

ZERO

0.0mA through 9.99mA

●Initial 4.0mA

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

16

§

4-3 CALIBRATION

1. ENTER CALIBRATION MODE:

STEP 1: Turn the Power Switch OFF. Slide the SET switch to the set side.

STEP 2: Turn the power switch ON. The screen will show blinking SELECT.

STEP 3: Please press SP2/F3/3 key and blinking F-A-CAL displayed.

STEP 4: Use ▲or▼key to choose either F-A-CAL or d-cal. Please press the

key.

4-3-1 FULL CALIBRATION (Normal)

﹝1﹞Setting Minimum Division

The display of di and 01 shows the smallest division. Use the ▲

or▼key to move through the available divisions.﹝1、2、5、10、20、50﹞. Press

the key to set the minimum division.

﹝2﹞Setting Decimal

(

F000 will change---see

§

4-2

)

The screen will show dp. A blinking decimal point will show on the screen.

Use the 1,2,3,or4 key to move through the available position of decimal

Point

. Press the key to set the decimal position.

﹝3﹞Setting Maximum Capacity

When setting maximum capacity, the screen will show CAP →

C000.000. Use the ▲,▼, or number keys to set numeric value. Press the

to finish the step.

﹝4﹞ZERO Adjust

The Screen will display ZERO . Please move the calibration mass and

objects away on the Weighing device then press key. . . . . . . . means

finishing of the Adjustment.

﹝5﹞SPAN Calibration

The screen will show SPAN . Press key and place your calibration mass

on the weighing device and input weight value. Use the ▲,▼, or number

keys to set the available value. Please press the key to finish the

calibration. The screen will show . . . . . . . .

STEP 5 : The screen will show END .

SlidetheSET switch to the original side.

2. Select Digital Calibration (Use load cell parameter.(An easy way to make

calibration by inputting Load Cell’s Full Scale Output voltage).

STEP 1: Turn the Power Switch OFF on the rear panel. Slide the SET switch to the set

side.

STEP 2: Turn the power switch ON. The screen will show blinking SELECT.

STEP 3: Please press SP2/F3/3 key and a blinking F-A-CAL will show on the

screen. Then press the key.

STEP 4: Use the ▲or▼key to choose d-CAL. Please press the key.

﹝1﹞Setting Minimum Division

The display of di 1 shows the smallest division. Use the ▲or ▼

key to move through the available divisions.﹝1、2、5、10、20、50﹞. Press

the key to set the minimum division.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

17

﹝2﹞Setting Decimal

(

F000 will change---see

§

4-2

)

The screen will show dp. A blinking decimal will show on the screen. Use the

1,2,3 or 4 key to move through the available position of decimal

Point

.

Press the key to set the decimal position.

﹝3﹞Setting Maximum Capacity

When setting maximum capacity, the screen will show CAP .

Use the ▲,▼, or number keys to input value. Press the key to finish the

step.

﹝4﹞Setting Full Scale Output Voltage of the Load Cell Sensors

When setting full scale output voltage of the load cell sensors, the

screen will show LC-CAP. Please use the ▲,▼, or number keys to input

value. Press the key to finish the step.

﹝5﹞ZERO Adjust

The Screen will display ZERO . Please move the calibration mass and

objects away on the Weighing device then press key. A display of . . . . . . .

means finishing the Adjustment.

﹝6﹞d-SPAN Calibration

The screen will show d-SPAN . Press key and place your calibration

mass on the weighing device and input weight value. Use the ▲,▼, or

number keys to enter Load Cell O/P Volt. Please press the key to finish

d-SPAN. The screen will show . . . . . . . .

STEP 5: The screen will show END . Please slide the SET switch to the original side.

※Example of selecting FULL CALIBRATION (Div 2, 3 decimal, Max cap.20)

Key Screen will display

Turn the Power Switch OFF

Slide Set switch to the ON side

Turn the power ON. Blinking SECECT

Press SP2/F3/3. Blinking F-A-CAL

Press key Blinking di-CAP

Press key di 01(Blinking at 01)

Press ▲key di 02(Blinking at 02)

Press key dp→000.000(Blinking at the Decimal Point----

F000 will subject to change if 1,2,3,or 4 key been

pressed)

Press key CAP →010.000(Blinking)

Press 2,0,0,0,0key 020.000(Blinking)

Press key ZERO

Press key

……

→SPAN

Press key 000.000(Blinking at the latest decimal)

Place 20kg Calibration Mass, 020.000

Press key

……

→

End

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

18

◎Calibration Errors

C.Err 1:The resolution exceeds 1:16,000.

Change the minimum division and maximum capacity within

1∕16,000.

Resolution ratio= Minimum division∕maximum capacity

C.Err 2:The load cell output is too large at ZERO calibration.

Add an additional resistor (50kΩ〜500KΩ) between EXC+

and SIG—. ※Refer to the Right Figure

C.Err 3:The load cell output is too small at ZERO calibration.

Add an additional resistor (50kΩ〜500KΩ) between

EXC+andSIG+. ※Refer to the Right Figure

C.Err 4:The calibration mass has been mistakenly entered as a

value greater than the maximum capacity.

Please reduce the weight of calibration mass, and re-enter the weight value.

C.Err 5: The calibration mass has been wrongly entered zero or it is smaller than the

minimum capacity.

Please increase the weight of calibration mass, and re-enter the weight value.

C.Err 6: The load cell output is too low.

Replace your load cell with a more sensitive one or adjust the minimum division.

C.Err 7: The load cell signal pins are reversed, or the load cell output voltage is too

low.

Check the load cell connections if reversed or load cell failure.

C.Err 8: The load cell output voltage at maximum capacity is too high.

Check the load cell specification or load cell failure.

C.Err 9: The maximum, capacity has been wrongly entered as a value smaller than

100.

Check Resolution Table.

C.Err 10 The maximum, capacity has been wrongly entered as a value greater than

800,000.

Check the load cell specification or load cell failure.

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

19

◎Display Resolution Table

Maximum Ca

p

acit

y

Resolution

1 Min. Div. 2 Min. Div. 5 Min. Div. 10 Min. Div. 20 Min. Div. 50 Min. Div.

300 1∕300 ------------ ------------ ------------ ------------ ------------

400 1∕400 ------------ ------------ ------------ ------------ ------------

500 1∕500 ------------ ------------ ------------ ------------ ------------

600 1∕600 1∕300 ------------ ------------ ------------ ------------

800 1∕800 1∕400 ------------ ------------ ------------ ------------

1,000 1∕1000 1∕500 ------------ ------------ ------------ ------------

1,200 1∕1200 1∕600 ------------ ------------ ------------ ------------

1,500 1∕1500 1∕800 1∕300 ------------ ------------ ------------

2,000 1∕2000 1∕1000 1∕400 ------------ ------------ ------------

2,500 1∕2500 1∕1200 1∕500 ------------ ------------ ------------

3,000 1∕3000 1∕1500 1∕600 1∕300 ------------ ------------

4,000 1∕4000 1∕2000 1∕800 1∕400 ------------ ------------

5,000 1∕5000 1∕2500 1∕1000 1∕500 ------------ ------------

6,000 1∕6000 1∕3000 1∕1200 1∕600 1∕300 ------------

8,000 1∕8000 1∕4000 1∕1500 1∕800 1∕400 ------------

10,000 1∕10000 1∕5000 1∕2000 1∕1000 1∕500 ------------

12,000 1∕12000 1∕6000 1∕2500 1∕1200 1∕600 ------------

15,000 1∕15000 1∕8000 1∕3000 1∕1500 1∕800 1∕300

20,000 ------------ 1∕10000 1∕4000 1∕2000 1∕1000 1∕400

25,000 ------------ 1∕12500 1∕5000 1∕2500 1∕1200 1∕500

30,000 ------------ 1∕15000 1∕6000 1∕3000 1∕1500 1∕600

40,000 ------------ ------------ 1∕8000 1∕4000 1∕2000 1∕800

50,000 ------------ ------------ 1∕10000 1∕5000 1∕2500 1∕1000

60,000 ------------ ------------ 1∕12000 1∕6000 1∕3000 1∕1200

80,000 ------------ ------------ 1 / 16,000 1∕8000 1∕4000 1∕1500

100,000 ------------ ------------ ------------ 1∕10000 1∕5000 1∕2000

120,000 ------------ ------------ ------------ 1∕12000 1∕6000 1∕2500

150,000 ------------ ------------ ------------ 1∕15000 1∕8000 1∕3000

200,000 ------------ ------------ ------------ ------------ 1∕10000 1∕4000

250,000 ------------ ------------ ------------ ------------ 1∕12500 1∕5000

300,000 ------------ ------------ ------------ ------------ 1∕15000 1∕6000

400,000 ------------ ------------ ------------ ------------ ------------ 1∕8000

500,000 ------------ ------------ ------------ ------------ ------------ 1∕10000

600,000 ------------ ------------ ------------ ------------ ------------ 1∕12000

700,000 ------------ ------------ ------------ ------------ ------------ 1∕14000

750,000 ------------ ------------ ------------ ------------ ------------ 1∕15000

800,000 ------------ ------------ ------------ ------------ ------------ 1 / 16,000

☆BDI-2006 Display Resolution may reach 1/60,000. (Depends on load cell quality

and performance).

BENEDICTION ENTERPRISE CO., LTD, TAIWAN

---------------------------------------------------------------------------------------------------------------------------------------------------------------

---------------------------------------------------------------------------------------------------------------------------------------------------------------

BDI-2006

20

§

4-4 PANEL KEY DISABLE

Disable unimportant or unused keys.

STEP 1: Turn the Power Switch OFF on the rear panel. Slide the SET switch to the set

side.

STEP 2: Turn the power switch ON. The screen will show blinking SELECT.

STEP 3: Please press FF/F4/4 key and a blinking LOC will show on the

screen. After enter key, a 〔〕will show on the screen. Please press the

key you wish to disable. The screen will show the key’s number. BDI-2006

will inquire if you want to lock or unlock the key: 〔00〕u or L (Key number

〔00〕: Unlock or Lock the key).

STEP 4: Use the ▲or ▼key to choose lock or unlock the key and press key for

confirmation.

STEP 5 : Slide the SET switch to the original side for finishing the step.

§

4-5 COPY SYSTEM PARAMETER

A backup can be stored to prevent data loss.

System Parameter: includes functions FXXX, Calibration parameters,

disable keys.

STEP 1: Turn the Power Switch OFF on the rear panel. Slide the SET switch to the set

side.

STEP 2: Turn the power switch ON. The screen will show blinking SELECT.

STEP 3: Please press HI/F5/5 key and a blinking COPY will show on the

screen. Please enter key.

STEP 4: Use the ▲or ▼key to choose NO or YES . If NO is entered, the screen

will show END. If YES is entered, the screen will show ……→END .

STEP 5 : Slide the SET switch to the original side for finishing the step.

§

4-6 RESTORE SYSTEM PARAMETERS

Restoration can be used when system failed or human operation error happens.

Restoration will not restore set-point parameters.

System Parameter: includes functions FXXX, Calibration parameters,

disable keys.

Set-point Parameter: includes Final, SP1, SP2, Free Fall, Hi, Lo.

STEP 1: Turn the Power Switch OFF on the rear panel. Slide the SET switch.

STEP 2: Turn the power switch ON. The screen will show blinking SELECT.

STEP 3: Please press Lo/F6/6 key and a blinking RESTORE will show on the

screen. Please enter key.

STEP 4: Use the ▲or ▼key to choose NO or YES . If NO is entered, the screen

will show END. If YES is entered, the screen will show ……→END .

STEP 5 : Slide the SET switch to the original side for finishing the step.

Popular Measuring Instrument manuals by other brands

audiophony

audiophony BM-Control user guide

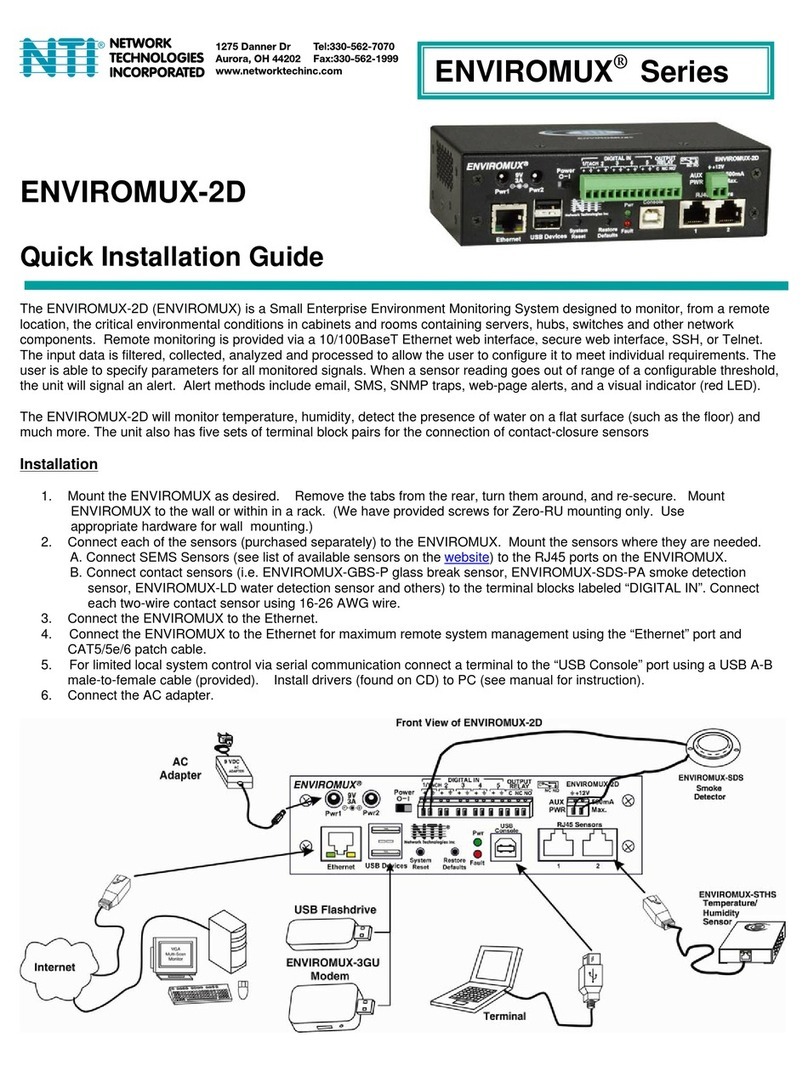

Network Technologies Incorporated

Network Technologies Incorporated ENVIROMUX-2D Quick installation guide

IKA

IKA IKA C 48 operating instructions

MerCs

MerCs Strider M4 V2 Series user manual

Elcomponent

Elcomponent PQPro user manual

Kemo Electronic

Kemo Electronic M167N quick start guide