BDS S-6307 User manual

Service Manual

S-6307

3 HP Automatic Euro Top Post Mount

Doctor’s System with Flex Arm

Rev 5 - 1-10-20 900-021M

800.237.2303 ◆503.538.8756 ◆503.538.2845 Fax ◆www.beaverstatedental.com 1

S-6307

Installation 1. Install the chair adapter as per instructions provided with the chair adapter.

2. Place the shipping carton in the desired location. Remove the unit with arm system

and unit from the shipping carton.

3. Insert the unit post into the chair adapter hub. Level, then tighten the set screws to

secure the post in place.

4. Place the adapter in the unit post and insert the umbilical into the unit post, pulling

it out through the bottom. Slide the arm knuckle into the adapter.

5. Cut the safety tie strap and carefully release the arm system.

6. Rotatetheexarm1800in a counter-clockwise direction so that the umbilical tubings

do not become crimped or twisted.

7. Remove the rigid arm end cap and tighten the cap screw to set the stop limits for

theexarm.Replacetheendcap.

8. Installmastervalveassemblies,withlterandregulator,ontothemanualshut-off

valves.(Pressuresarepresetatthefactory:80psiair,40psiwater).

9. Feed the supply tubings from the umbilical through the 3/4" hole in the utility center

housing. Screw in the spiral tubing to act as a strain relief.

10.ConnectthesupplytubingsasshownintheUtilityCenterTemplate&Guide.

Checkairpressure,adjustto80psiifnecessary.

Checkwaterpressure,adjustto40psiifnecessary.

Testhandpiecesforproperfunction.

Testsyringeforproperpressureandfunction.

Adjustexarmtension,ifnecessary.

Final

Adjustments

WARNING

The arm system is spring loaded. Before removing

thesafetytiestrap,rmlygrasptheexarmandhold

Arm Stop Cap Screw

800.237.2303 ◆503.538.8756 ◆503.538.2845 Fax ◆www.beaverstatedental.com

2

S-6307

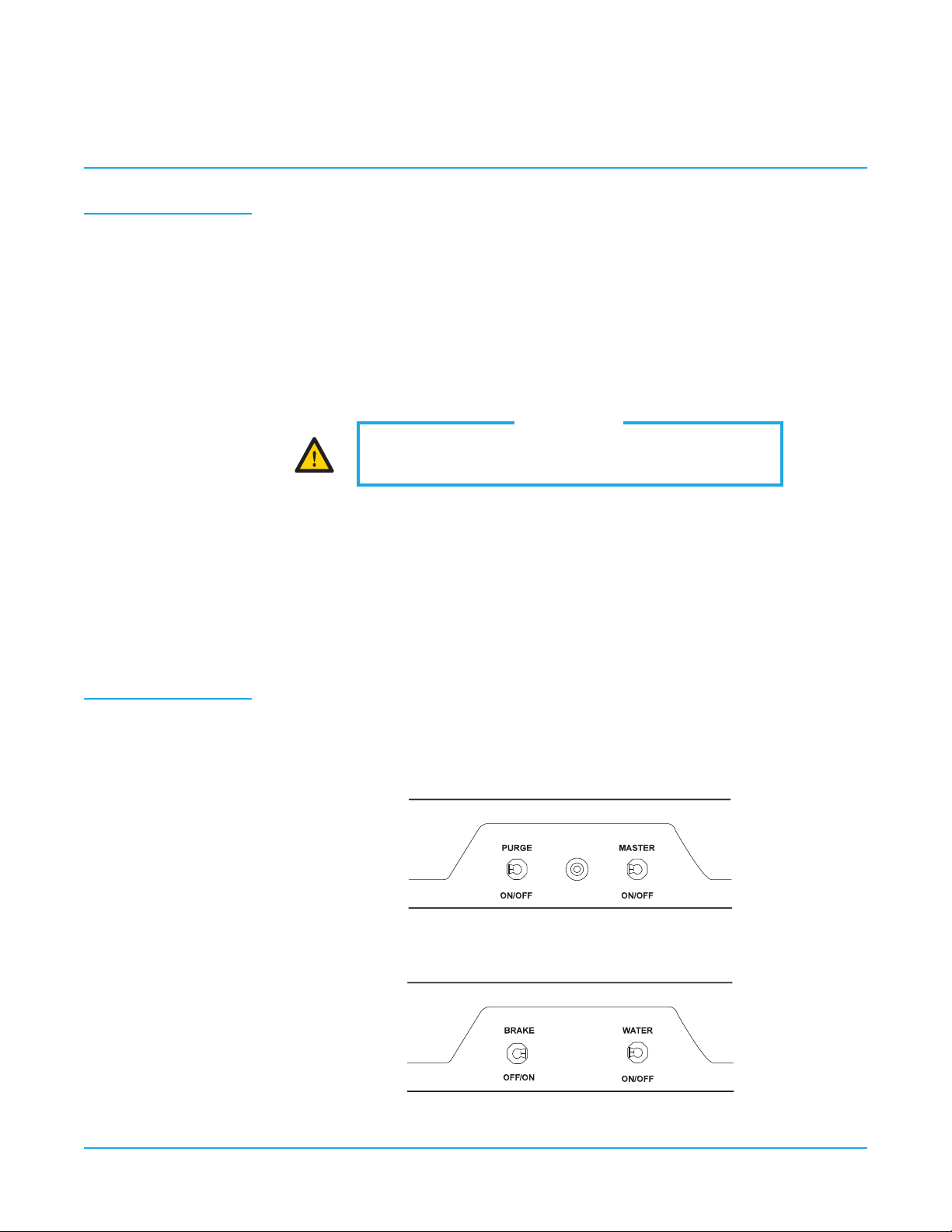

Operation 1. Turnonthemasterswitchlocatedontheleftsideofthecontrolhead.

2. Thehandpieceisautomaticallyactivatedwhenthewandispulledforward.

3. Depress the foot control to activate each handpiece. Pressure is shown on the gauge for

the handpiece being used.

4. Individual handpiece pressure adjustments are located on the autoblock inside the

controlhead.Toadjustthepressuretoeachhandpiece:

a. Turnadjustmentscrewclockwise to decrease the handpiece pressure.

b. Turnadjustmentscrewcounter-clockwise to increase the handpiece pressure.

5. Activatethewaterspraytothehandpiecebyippingthetoggleforthewaterlocatedon

the right side of the control head.

6. Watercoolantowadjustmentsarelocatedunderneaththecontrolhead.

7. Armbrakeswitchislocatedontherightsideofthecontrolhead.Thebrakeisonwhen

thetoggleispositionedtowardstherear(rightposition).Pulltheleverforward(leftposi-

tion)toreleasethearmbrake,adjustarmtodesiredlocationandmovelevertothe

rear(rightposition)toreapplythebrake.

Thepurgeswitch,locatedontheleftsideofthecontrolhead,ushesfreshwaterthroughthe

watercoolantsystem.GuidelinesfromtheCenterforDiseaseControl(CDC)recommendsthat

eachhandpiecebeushed(purged)20to30secondsbetweenpatientsandseveralminutes

at the beginning of each day. Handpieces must be removed from the holder to activate the

purge system.

CAUTION

When adjusting the handpiece pressure, do not over-

tighten the screws. Damage may result.

Handpiece Purge

Control Panel–Left Side

Control Panel–Right Side

800.237.2303 ◆503.538.8756 ◆503.538.2845 Fax ◆www.beaverstatedental.com 3

Troubleshooting

Symptom

Possible Causes

Symptom

Possible Causes

Symptom

Possible Causes

Handpiece lacks power.

A. Impropersupplypressurefromcompressor(80psi).

B. Checkhandpiecepressureadjustmentonunit.

C. Airltermaybeplugged.

D. Pinched supply tubing.

E. Defective handpiece gasket at connection with tubing.

F. Defective handpiece.

Water coolant does not shut off when foot control is released.

A. Adjustairpressureto80psi—waterpressureto40psi.

B. Footcontrolisnotexhausting.

C. Defective water relay valve.

More than one handpiece is operating.

A. Handpiece is not all the way in the holder.

B. Improperadjustmentonpilotvalveinthehandpieceholder.

C. Defective shuttle valve to gauge.

Insufcientwatercoolant.

A. Adjustcoolantowvalve.

B. Waterltermaybeplugged.

C. Handpiece may be plugged.

D. Pinched supply tubing.

E. Improper adjustment of water relay valve.

Water coolant is running from handpiece while in the holder.

A. Water pressure too high.

B. Airpressuretoolow.

C. Handpiece holder out of adjustment.

Water coolant is running continuously.

A. Purgeswitchison(onapplicablesystems).

B. Waterpressuretohigh.

C. Handpiece holder out of adjustment.

D. Defective water relay valve.

Symptom

Possible Causes

Symptom

Possible Causes

Symptom

Possible Causes

44

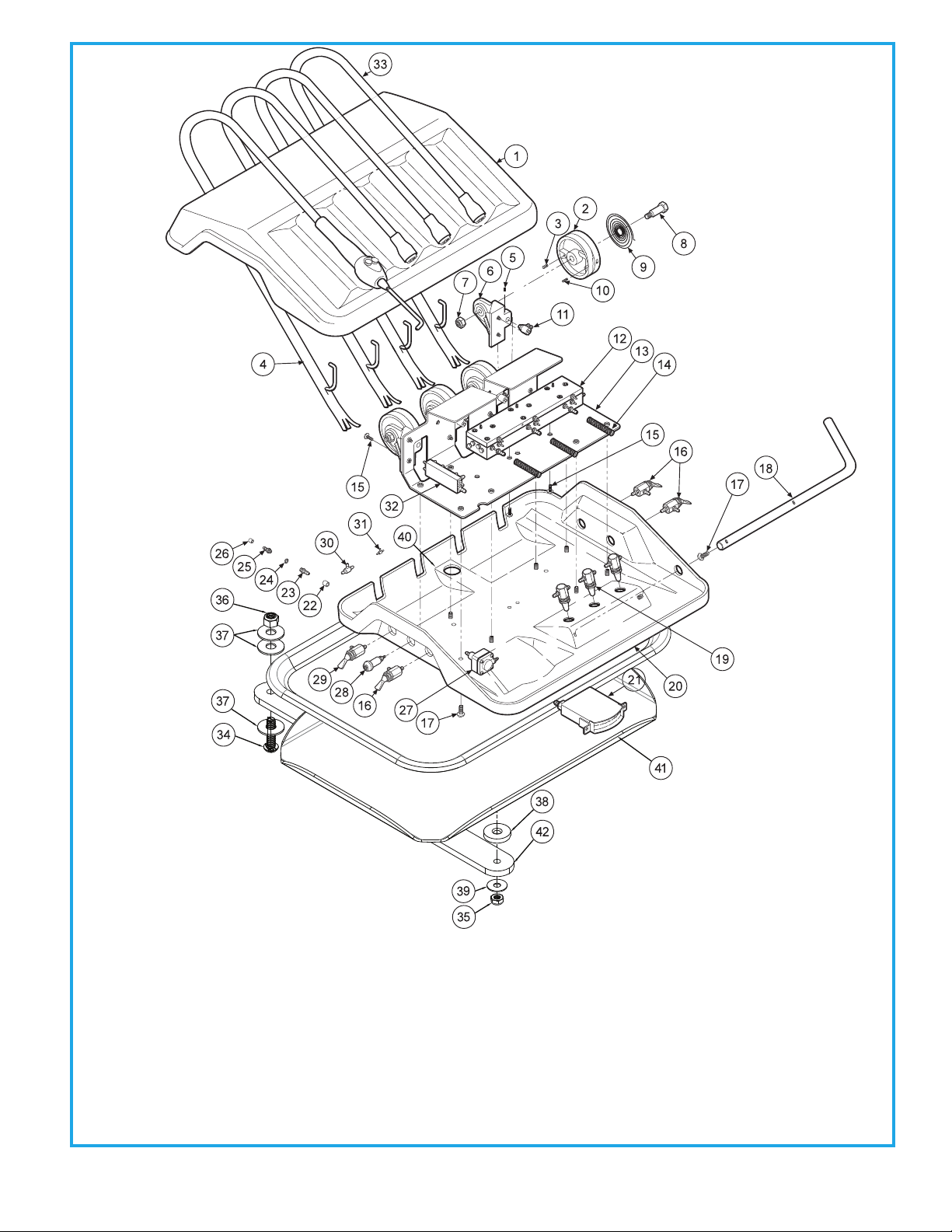

AUTOMATIC HANDPIECE CONTROL

S-6307

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PART DESCRIPTION

Cover................................................................

Euro Cam ........................................................

Pin, 1/8”x 1/2“ ...............................................

Euro Wand Assembly ................................

Set Screw, 4-40 x 3/16”...............................

Euro Cam Bracket........................................

Nylon Locknut, 10-32 .................................

Euro Pivot Shaft............................................

Euro Cam Spring..........................................

Set Screw, 6-32 x 3/8”.................................

Automatic Holder Valve ............................

Automatic Handpiece Block....................

Chasis...............................................................

Spring, Euro ...................................................

PART NUMBER

107-092

116-001

009-029

116-008

005-001

116-002

002-027

116-005

008-033

005-012

122-044

125-130

107-090

008-035

ITEM

15

16

17

18

19

20

21

22

23

24

25

26

27

28

ITEM

29

30

31

32

33

34

35

36

37

38

39

40

41

42

PART DESCRIPTION

Screw, 6-32 x 3/8”...........................

3-way Toggle Valve .......................

Screw, 10-32 x 3/8”........................

Holder Bar........................................

Needle Flow Valve.........................

Base ....................................................

Gauge ................................................

Ferrule, 1/4”......................................

Barb, 10-32 x 1/8”...........................

Plastic Washer, 1/4”........................

Barb, 10-32 x 1/16”.........................

Ferrule, 1/8”......................................

Water Relay......................................

Indicator............................................

PART DESCRIPTION

Momentary Valve ............................

Shuttle Valve......................................

Plastic Tee, 1/16”...............................

Handpiece Manifold.......................

Euro Wand Assembly .....................

Screw, 5/16-18 x 1-1/4”..................

Nut 1/4-20..........................................

Lock Nut, 5/16-18.............................

3/8 Nylon Washer............................

Tray Mount Spacer Washer ..........

Tray Mount Friction Washer..... ....

Tray, 9-3/4 x 13-1/4..........................

Tray Holder.........................................

Euro Tray Arm....................................

PART NUMBER

001-041

120-000

001-070

107-093

121-000

107-091

026-003

117-008

022-010

003-001

022-009

117-007

123-000

026-020

PART NUMBER

120-005

014-012

022-033

023-001

116-009

001-184

002-023

002-033

003-010

003-022

003-023

010-001

107-047

107-094

QTY

1

4

4

1

4

4

4

4

4

4

3

1

1

3

QTY

10

3

4

1

4

1

1

5

4

14

11

48

3

1

QTY

1

1

2

1

4

1

1

1

3

1

1

1

1

1

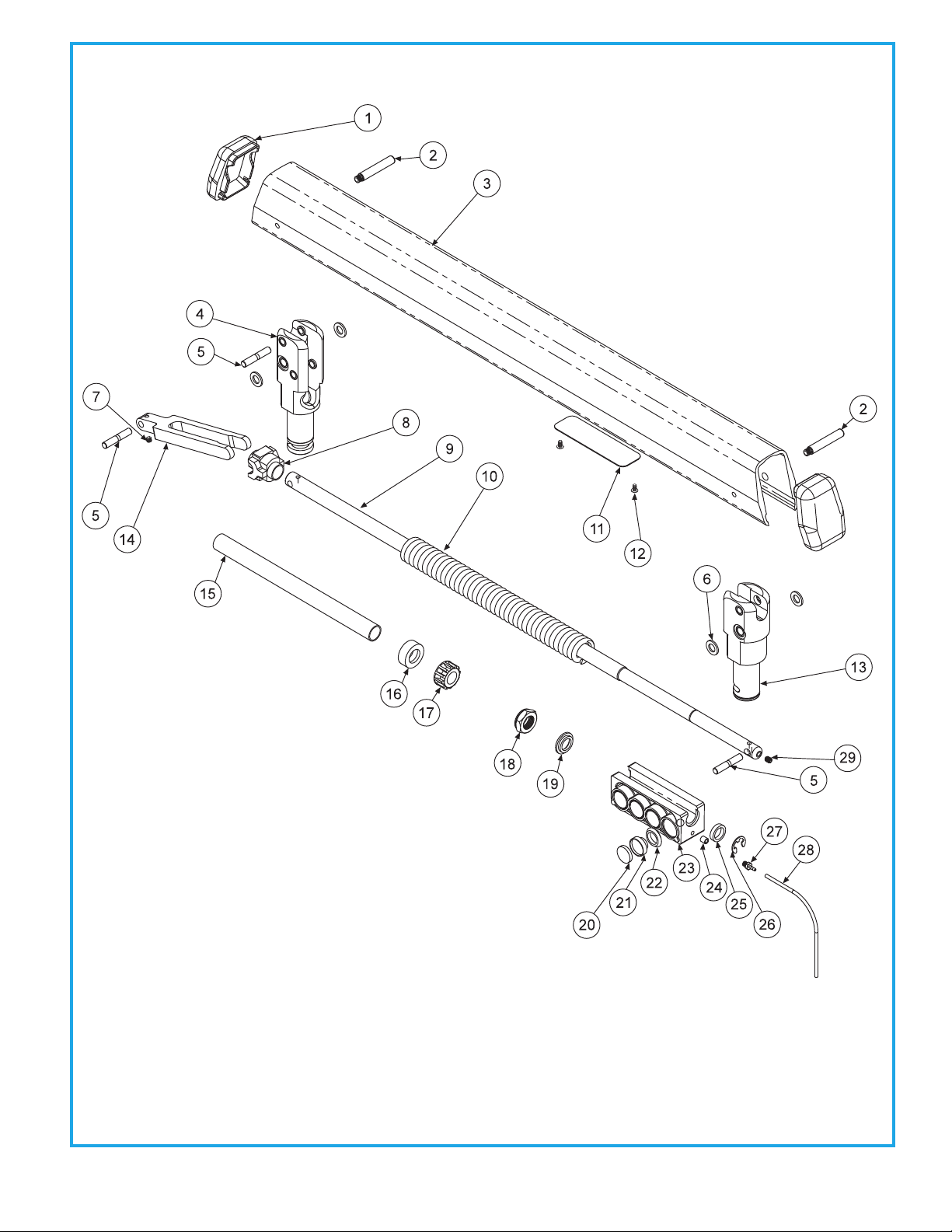

55 FLEX ARM WITH PNEUMATIC BRAKE

106-336

ITEM

1

2

3

4

5

6

7

8

9

10

PART DESCRIPTION

End Cap...................................................

Pin, Arm Housing.................................

Arm Housing.........................................

Arm Knuckle..........................................

Pin Rod....................................................

Plastic Washer.......................................

Set Screw, 10-32 x 3/16" ....................

Spring Slider..........................................

Rod............................................................

Spring ......................................................

PART NUMBER

106-319

009-030

106-314

106-322

009-031

003-040

005-037

106-311

106-327

008-019

ITEM

11

12

13

14

15

16

17

18

19

20

ITEM

21

22

23

24

25

26

27

28

29

PART DESCRIPTION

Plug Adjustment.......................................

Screw, 6-32 x 1/4"......................................

Head Knuckle.............................................

Arm Fork Link.............................................

Sleeve............................................................

Seat, Flex Arm Spring..............................

Adjustment Nut ........................................

Nut, Hex, Jam 9/16-18, Nylon Insert ...

Collar, w/Shoulder, Brake, Flex. .............

Brake Pad.....................................................

PART DESCRIPTION

Piston, Brake.............................................

U-Cup. .........................................................

Brake Housing..........................................

Ferrule, Delrin, 1/8".................................

Brake Collar, Threaded .........................

Ring,Truarc, 5133-43..............................

Barb 10-32 x 1/16"..................................

1/8" Supply Line, Black..........................

Socket Set Screw, 10-32 x 1/4"...........

PART NUMBER

106-329

001-133

106-337

106-318

106-321

106-320

106-325

002-011

106-338

106-313

PART NUMBER

106-317

017-204

106-316

117-007

106-324

006-004

022-059

115-028

005-035

QTY

2

2

1

1

3

4

1

1

1

1

QTY

1

2

1

1

1

1

1

1

1

8

QTY

8

8

1

1

1

1

1

11

1

66

FLEX ARM SYSTEM WITH PNEUMATIC BRAKE, TOP POST MOUNT

106-307

ITEM

1

2

3

4

5

6

7

8

9

PART DESCRIPTION

Flex Arm..................................................

Thrust Washer, Small...........................

End Cap...................................................

Set Screw, Half Dog.............................

Rigid Arm................................................

Pivot Mount...........................................

Snap Ring ...............................................

Plug Square, 3/4" ..................................

Bronz Bushing........................................

PART NUMBER

106-336

003-038

106-326

005-007

106-360

106-355

006-002

010-042

013-019

QTY

1

2

1

2

1

1

1

1

1

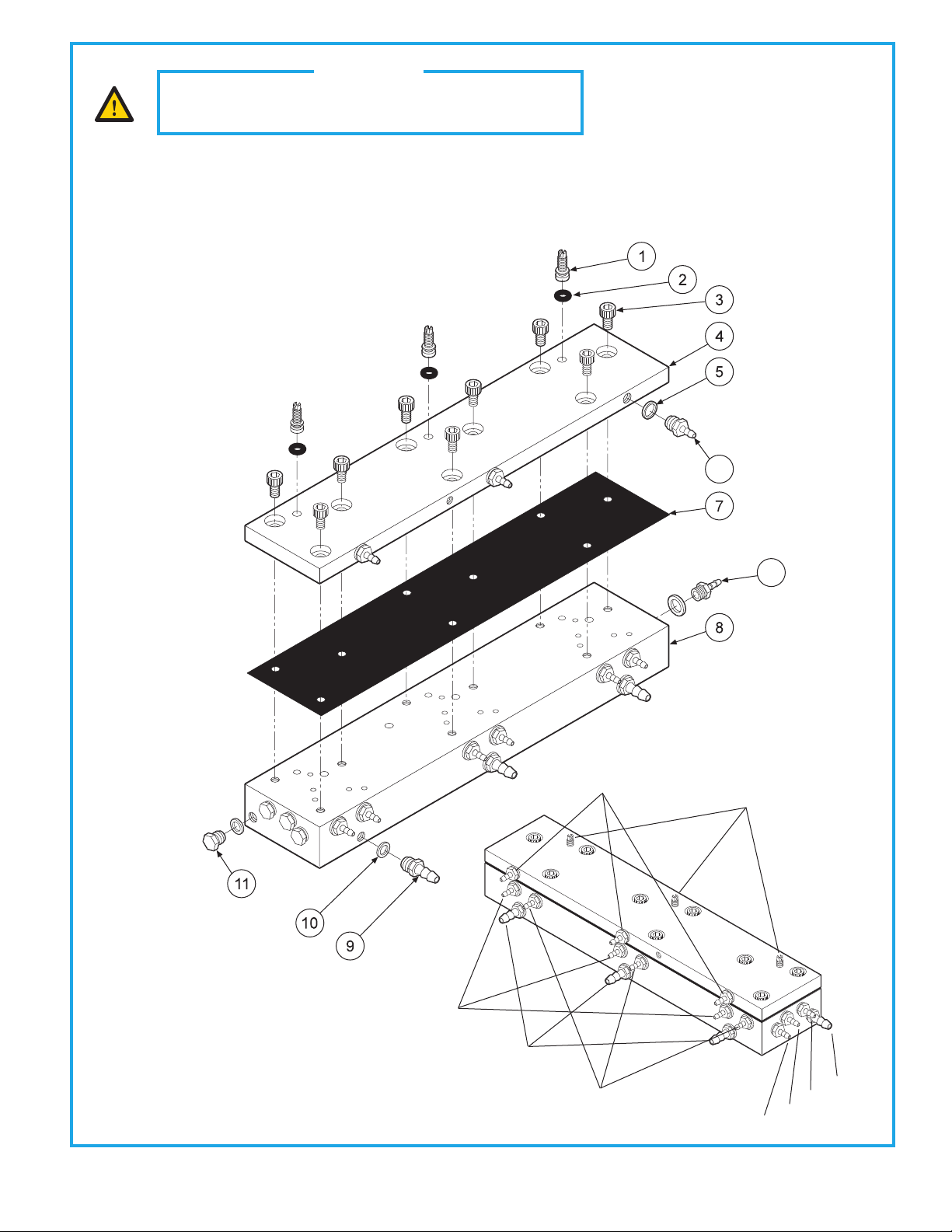

77 UTILITY CENTER

144-018

ITEM

1

2

3

4

PART DESCRIPTION

Utility Center Lid...........................

Manual Shut-off Valves...............

Master Shut-off Valve Kit............

Utility Center Housing................

Utility Center Kit............................

Plug ,10-32.............................

Screw, #6 x 3/4" ....................

Plastic Washer, 1/4".............

Plug, 3/4" ................................

Plug, 1-3/8" ............................

Plug, 1/2" ................................

Plug, 1-1/2" ............................

Plug, 2-1/4" ............................

Plug, 13/16”............................

Barb, 10-32 x 1/16"..............

Barb, 10-32 x 1/8" ................

Ferrule, 1/8" ...........................

PART NUMBER

144-005

020-022

127-012

144-004

010-055

001-001

001-063

003-001

010-005

010-008

010-013

010-015

010-017

010-016

022-009

022-010

117-007

QTY

1

2

1

1

1

1

6

2

2

1

1

1

1

2

1

1

4

88

UTILITY CENTER INSTALLATION

144-018

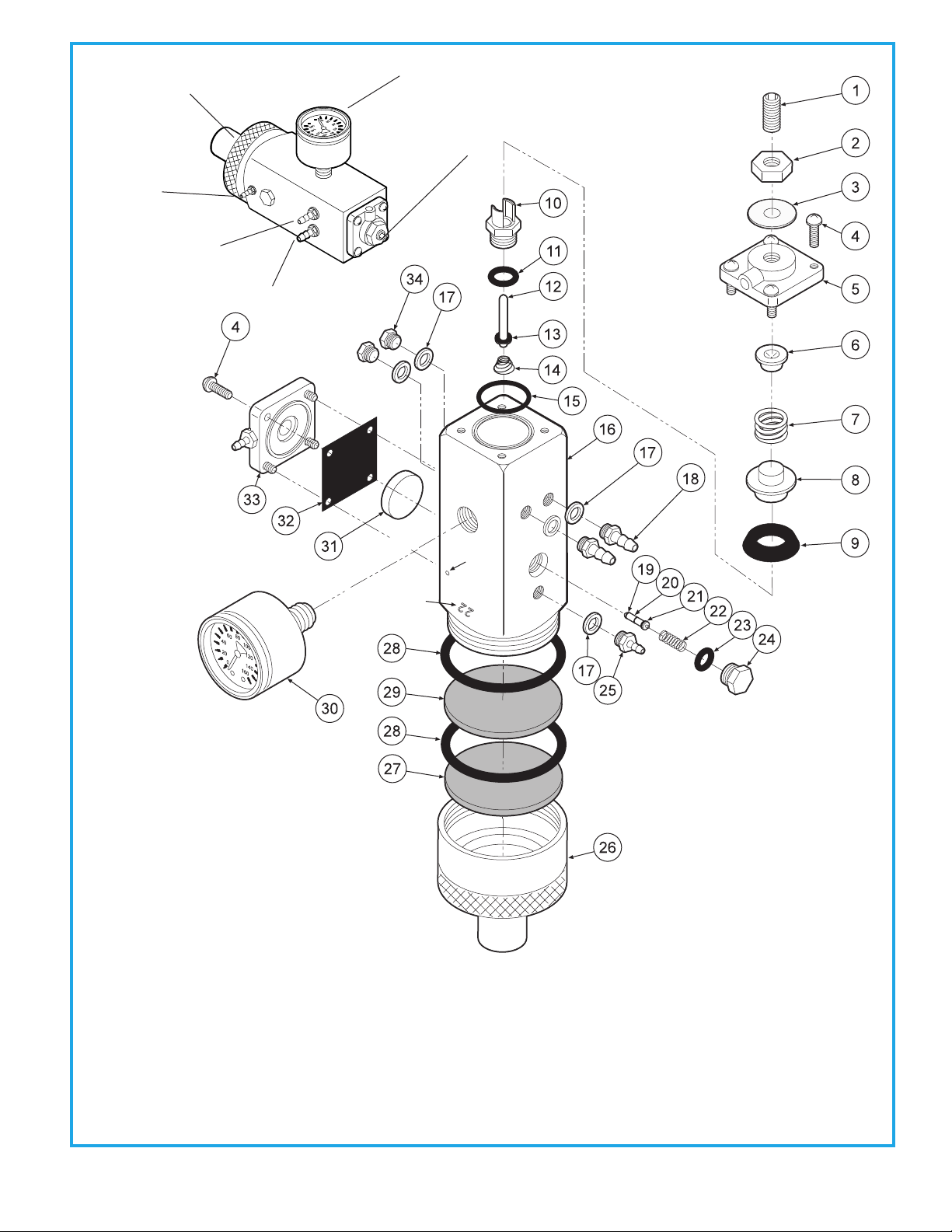

99 MASTER VALVE

127-010 AIR

Batch Stamp

Located Here

Vent Hole

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

PART DESCRIPTION

Set Screw, 1/4-20 x 5/8”.........................

Jam Nut, 1/4-20.......................................

Washer........................................................

Screw, 6-32 x 3/8”....................................

Cap...............................................................

Spring Seat...............................................

Spring.........................................................

Cup Seat.....................................................

Cup Seal......................................................

Seat..............................................................

O-Ring, 008................................................

Stem.............................................................

PART NUMBER

005-024

002-006

003-015

001-041

127-033

127-043

008-008

127-044

017-200

127-026

017-008

127-024

ITEM

13

14

15

16

17

18

19

20

21

22

23

ITEM

24

25

26

27

28

29

30

31

32

33

34

PART DESCRIPTION

O-Ring, 004........................................

Spring..................................................

O-Ring.................................................

Body.....................................................

Plastic Washer, 1/4”........................

Barb, 10-32 x 1/8”............................

O-Ring, 001........................................

Stem....................................................

O-Ring, 003........................................

Spring..................................................

O-Ring, 007.................................. .....

PART DESCRIPTION

Plug...................................................................

Barb, 10-32 x 1/16”......................................

Cap Inlet..........................................................

Filter Element, 100 Micron........................

O-Ring, 018.....................................................

Filter Element, 35 Micron..........................

Gauge...............................................................

Piston................................................................

Gasket..............................................................

Cap....................................................................

Plug...................................................................

PART NUMBER

017-104

008-028

017-018

127-040

003-001

022-010

017-501

127-045

017-103

008-040

017-007

PART NUMBER

020-026

022-009

127-041

119-005

017-022

119-004

026-001

123-014

127-031

123-030

001-001

QTY

1

1

1

8

1

1

2

1

4

3

2

1

QTY

1

1

1

1

5

2

2

1

1

1

1

QTY

1

1

1

1

2

1

1

1

1

1

2

Constant Air Out

Out to Foot Control

ToMaster

On/Off Switch

Regulator Pressure

Adjustment

PressureGauge

Air—80psi

Water—40psi

RemoveBrassKnurledCap

to Replace Filter Element

1010

WaterRelayValve123-000

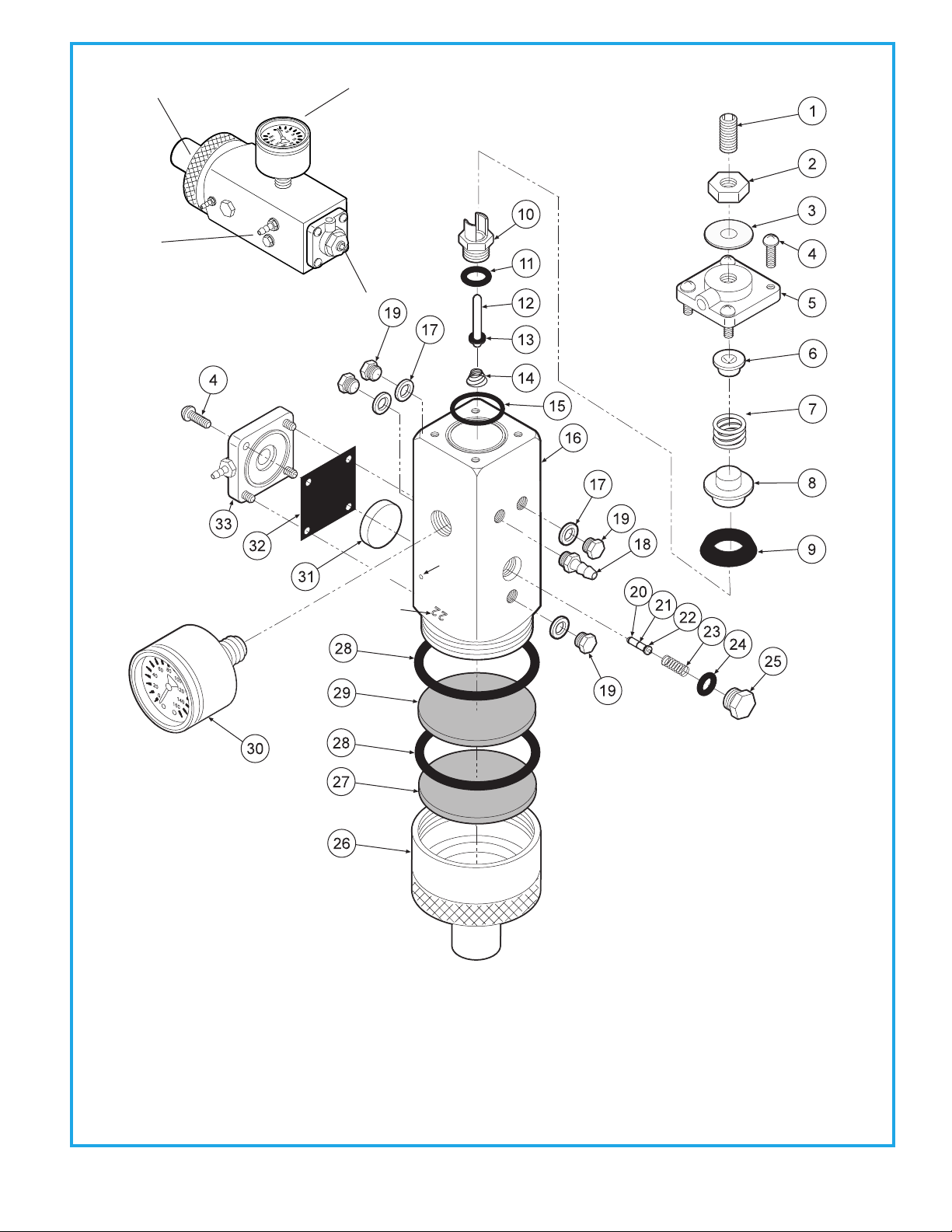

MASTER VALVE

127-010 WATER

Vent Hole

Batch Stamp

Located Here

ITEM

1

2

3

4

5

6

7

8

9

10

11

PART DESCRIPTION

Set Screw, 1/4”-20 x 5/8”.......................

Jam Nut, 1/4”-20......................................

Washer........................................................

Screw, 6-32 x 3/8”....................................

Cap...............................................................

Spring Seat...............................................

Spring.........................................................

Cup Seat.....................................................

Cup Seal......................................................

Seat..............................................................

O-Ring, 008................................................

PART NUMBER

005-024

002-006

003-015

001-041

127-023

127-043

008-008

127-044

017-200

127-026

017-008

ITEM

12

13

14

15

16

17

18

19

20

21

22

ITEM

23

24

25

26

27

28

29

30

31

32

33

PART DESCRIPTION

Stem....................................................

O-Ring, 004........................................

Spring..................................................

O-Ring.................................................

Body.....................................................

Plastic Washer, 1/4”........................

Barb, 10-32 x 1/8”............................

Plug......................................................

O-Ring, 001........................................

Stem....................................................

O-Ring, 003........................................

PART DESCRIPTION

Spring........................................................

O-Ring, 007......................................... .....

Plug............................................................

Cap Inlet.....................................................

Filter Element, 100 Micron..................

O-Ring, 018...............................................

Filter Element, 35 Micron.....................

Gauge.........................................................

Piston..........................................................

Gasket.........................................................

Cap...............................................................

PART NUMBER

127-024

017-104

008-028

017-018

127-040

003-001

022-010

001-001

017-501

127-045

017-103

PART NUMBER

008-040

017-007

020-026

127-041

119-005

017-022

119-004

126-001

123-014

127-031

123-012

QTY

1

1

1

8

1

1

1

1

1

1

1

QTY

1

1

1

1

1

1

1

4

2

1

1

QTY

1

1

1

1

1

2

1

1

1

1

1

Water Out

Regulator Pressure

Adjustment

PressureGauge

Air—80psi

Water—40psi

RemoveBrassKnurledCap

to Replace Filter Element

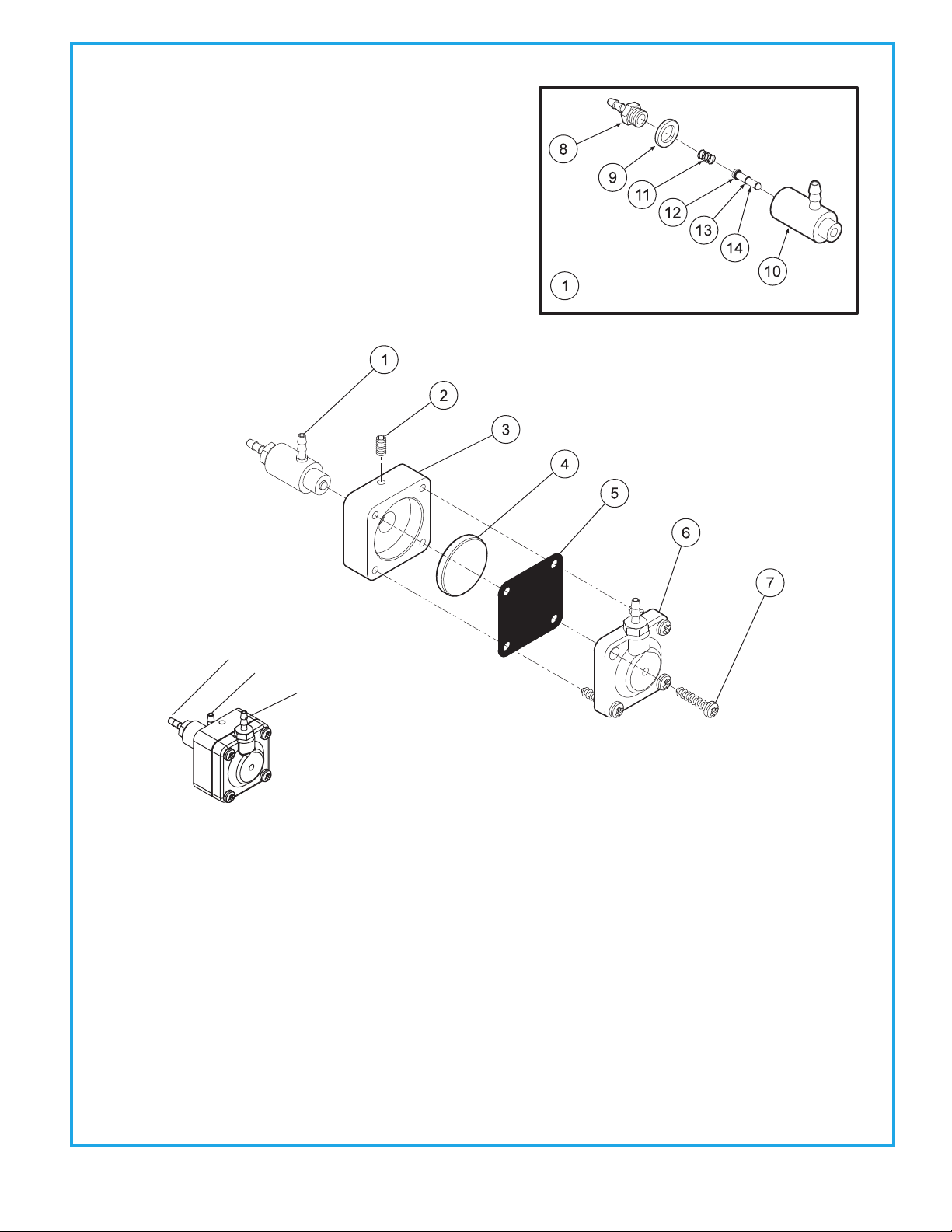

1111 NON-RETRACTION WATER RELAY VALVE

123-000

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PART DESCRIPTION

Cartridge Body Assembly.............

Set Screw, 4-40 x 5/8".....................

Body....................................................

Piston..................................................

Diaphragm........................................

Cap.......................................................

Screw, #6 x 1/2"................................

Barb, 10-32 x 1/16".........................

Plastic Washer, 1/4"........................

Valve Body..........................................

Spring.................................................

O-Ring, 002.......................................

O-Ring, 001......................................

Stem...................................................

PART NUMBER

123-018

005-028

123-013

123-014

127-031

123-012

001-267

022-009

003-001

123-017

008-011

017-502

017-501

123-015

QTY

1

1

1

1

1

1

4

1

1

1

1

1

2

1

WaterRelayValve123-000

Air In

Water In

Water Out

1212

AUTOMATIC HANDPIECE CONTROL BLOCK

125-130

Theautomaticcontrolblockisthecontrolcenterforyourdentalunit.

Individualhandpiecepressureadjustmentsarelocatedontheautoblock.Toadjustthe

pressure to each handpiece:

a. Turnadjustmentscrewclockwise to decrease the handpiece pressure.

b. Turnadjustmentscrewcounter-clockwise to increase the handpiece pressure.

CAUTION

When adjusting the handpiece pressure, do not over-

tighten the screws. Damage may result.

Drive Air In

OuttoGauge

Coolant Air In

Coolant Water In

Coolant Air Out

Drive Air Out

Coolant Water Out

Signal Air In Handpiece Pressure

Adjustment

12

6

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

PART DESCRIPTION

Adjusting Stem...............................

O-Ring, 021 ......................................

Screw, 6-32 x 1/4”...........................

Cap. ....................................................

Plastic Washer. ...............................

Barb, 10-32 x 1/16”.........................

Diaphram ........................................

Body ..................................................

Barb, 10-32 x 1/8”...........................

Plastic Washer, 1/4”.........................

Plug, 10-32 ......................................

Barb, 8-32 x 1/16”...........................

PART NUMBER

125-023

017-021

001-131

125-132

003-030

022-009

125-116

125-131

022-010

003-001

001-001

022-040

QTY

3

3

9

1

3

9

1

1

4

13

4

3

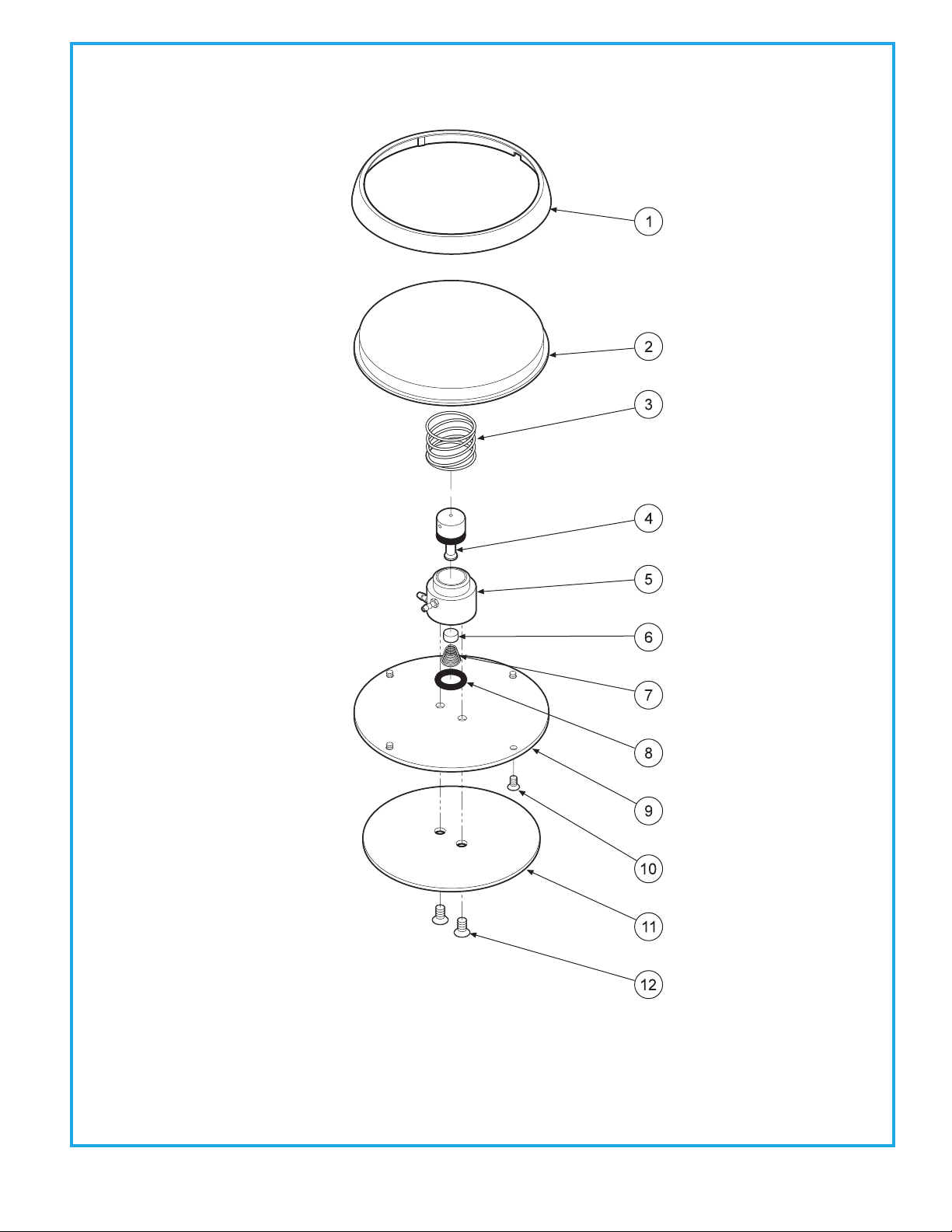

1313 FOOT CONTROL

126-200

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

PART DESCRIPTION

Ring......................................................

Cover....................................................

Spring.................................................

Stem (Includes 017-012 o-ring).....

Body....................................................

Poppet................................................

Spring..................................................

O-Ring, 013........................................

Baseplate...........................................

Screw, 4-40 x 1/4"...........................

Rubber Pad.......................................

Screw, 6-32 x 1/4"...........................

PART NUMBER

126-202

126-201

008-005

126-005

126-004

126-006

008-006

017-013

126-003

001-005

126-007

001-004

QTY

1

1

1

1

1

1

1

1

1

4

1

2

1/4" Clear - Constant Air In

1/8" Brown - On/Off (flow out) to M.V.

1/4" Blue - Water In

1/8" Yellow - On/Off (flow In) from M.V.

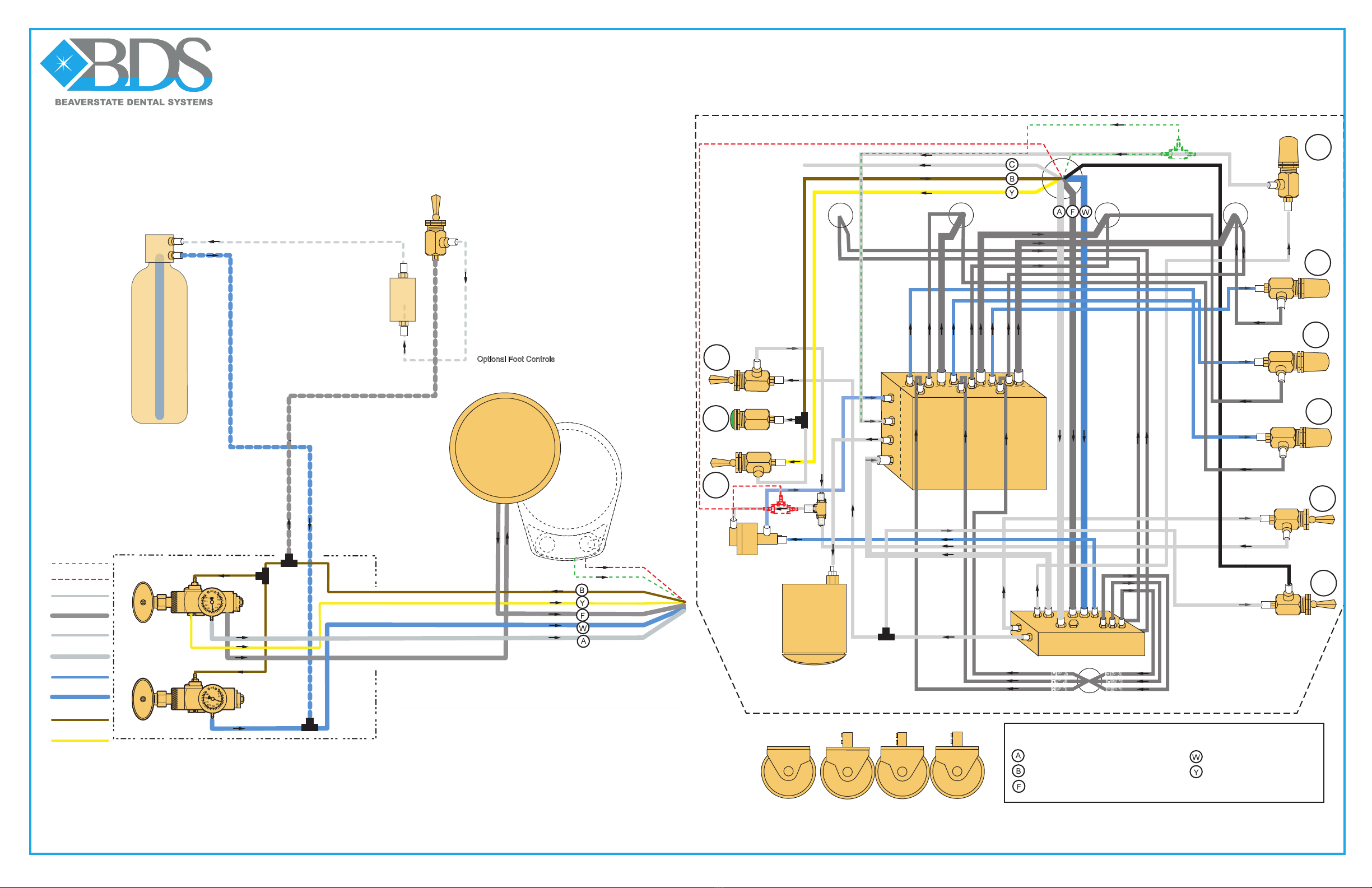

Circled letters indicate connection at Junction Box

Junction Box

Air 80 psi

1/4" Gray

1/4" Clear

1/8" Blue

1/8" Clear

1/8" Gray

1/8" Brown

1/8" Yellow

1/4" Blue

1/4" Gray - In From Foot Control

Wet Dry Option

Chip Air Option

Utility Center

S-6300 / S-6307 Unit Head

Water 40 psi

Optional

Water Bottle System

Mini

Regulator

128-016

On/Off

Toggle

120-000

Air Regulator

127-010-A

Water

Regulator

127-010-W

Syringe Handpiece 2 Handpiece 3

Handpiece 1

Unregulated

Foot Control

126-200

Optional Foot Controls

126-133 (Chip Blower)

126-260 (Wet/Dry)

126-203 (Wet/Dry Chip Blower)

Manifold

Block

023-001

HP Pressure

Gauge

026-003

Non-Retracting

Water Relay

Valve

123-000

Shuttle Valve

014-012

Auto Block

125-030

To Syringe To HP 1 To HP 2 To HP 3

HP 1

HP 2

HP 3

1

2

3

5

6

7

8

9

4

HP 1

HP 2

HP 3

Euro 3 Handpiece Automatic control

S-6307

WARRANTY

BDS warranties its product to be free of defects in material and workmanship for SEVEN FULL YEARS from the

date of purchase on all units. Auto-blocks and standard foot controls are covered by a LIFETIME warranty when

factory installed as part of a complete dental system. Upholstery has a TWO YEAR warrany and does not cover

normal wear, stains, cuts or tears. Our LED lights have a FIVE year Warranty and our halogen light has a ONE year

Warranty. Operatory chair motors feature a TEN year warranty. All warranty is limited to repair or replacement

by BDS. Products returned to the factory and determined to be defective will be repaired or replaced free of

charge at discretion of BDS. The warranty does not cover light bulbs, electrical components and trimmed or

installed tubing. BDS reserves the right to void all warranties if any product is installed by other than an authorized

technician. BDS' warranty does not cover damage to any surface finish, including but not limited to, discoloration

or abrasion from cleaners, disinfectants or light sources. No claim for labor or consequential damages will be

allowed. Return items must include a copy of the invoice or packing slip as proof of purchase.

Beaverstate Dental Inc.

115 S. Elliott Rd.

Newberg, OR 97132

800-237-2303

503-538-8756

503-538-2845 Fax

www.beaverstatedental.com

Table of contents

Other BDS Dental Equipment manuals