precisionplus L10 User manual

USER MANUAL

DENTAL LOW SPEED HANDPIECE

1. Indication for Use

2. Precautions for Handling and Operation

For your safety and the safety of your patients please read this user manual

carefully before use and file for future reference.

This manual is published by Precision Plus.

Precision Plus does not guarantee its contents and reserves the right to amend

without prior notice. Amendments will be published in new editions of this manual.

L10 Straight Handpiece

●This low speed straight handpiece is intended for the purposes of dental

treatment and prophylaxis.

●It is to be used for dental treatment by trained dental professionals.

●All precautions should be read and understood before use.

●Devices are only to be used for its specified intended use.

●Safety instructions are provided in order to prevent the risk of personal

injury or damage to the dental handpiece.

3. Contraindications

Should be used with caution on infants, pregnant women, hemophiliacs and

patients with heart problems.

4. Adverse Reactions

●Patients may feel tense, uncomfortable or experience pain during use of the device.

●Patients hearing may be affected during use of the device.

P. 1

P. 2

P. 3

WARNING: Indicates a hazard that may result in serious injury/device

damage if instructions are not correctly followed.

CAUTION: Indicates a hazard that may result in mild to moderate

injury/device damage if instructions are not correctly followed.

CAUTION

●Users are required to protect themselves, the patient and third parties from danger.

●Users are responsible for correct and intended use, regular maintenance and

continual inspection of the handpiece.

●Avoid impact or contamination of handpiece.

●Do not disassemble or alter the handpiece except as recommended in our user

instructions.

●Correct eye, face and personal protection must be used by operator, assisting staff

and patient whilst handpiece is being used.

●If the handpiece begins operating abnormally, immediately stop use and contact

your authorized Precision Plus dealer.

●Handpiece is supplied in a non-sterile state and must be autoclaved before use.

●Handpiece should be carefully tested for vibration, noise or overheating prior to use,

if it has not been used for a long time.

L10 Rev. V2.1 © Precision Plus

L10-1

WARNING

● Immediately after each and every treatment, the handpiece should be inspected,

cleaned, lubricated and sterilized. Failure to correctly maintain the handpiece

may lead to overheating, injury to user/patient or damage to handpiece.

● Debris inside the gear mechanism can lead to overheating and burn injuries.

Do not allow foreign materials into the gear mechanism or chuck.

6. Connection & Disconnection of Handpieces to Motor

1. Connect handpiece to motor until it locks

into place. (Fig.1)

2. Pull on handpiece to make sure it is securely

attached to motor.

1. Hold motor and handpiece separately and pull the handpiece off in an axial

direction using a slight rotation (Fig.1).

6.1 Connection

6.2 Disconnection

P. 4

P. 6

P. 5

P. 7

CAUTION: Motor must have completely stopped rotating before

connecting/disconnecting. Connect only to E type motors

[ ISO 3964 ]. Do not exceed the Max Rotational Speed as

shown in '5. Specifications'.

Fig. 1

● Always inspect bur to confirm it is free of debris before inserting into handpiece.

Debris inside chuck may cause rotation slip or allow the bur to become

disengaged during use.

● Do not exceed the maximum length or speed of bur for the handpiece as

recommend by Precision Plus. See “5. Specifications” of this manual for

information on correct bur choice.

● Do not apply excess pressure to the bur during use, this can lead to bur bending

or breaking causing injury to user/patient or the handpiece.

● Do not use burs that are bent, rusted, worn, cracked, deformed or have non ISO

standard conforming shanks, Burs with these issues may disengage or break

during use.

● Always engage bur correctly into handpiece head. Failure to correctly insert burs

may cause damage to bearings leading to injury or premature failure of handpiece.

● Before use always inspect handpiece for excessive vibration, noise or overheating.

If there are abnormalities stop use and contact authorized Precision Plus Dealer.

(refer to 8 . Test prior to use)

7. Inserting & Removing the Bur

1. Turn the Bur Locking Ring

towards the mark until

a “click” is heard.(Fig. 2)

2. Insert the bur fully into the

chuck and then turn the Bur

Locking Ring towards

the mark until a “click” is heard (Fig. 2).

7.1 Inserting the Bur

Fig. 2

3. The bur should now be engaged in the chuck. Test the Bur is secured by holding

the handpiece and gently pulling the bur outwards.

Model L10-1

Maximum Speed 24,000 r.p.m. ±10%

Applicable Bur Φ2.35(+0,-0.016) mm

Maximum Overall Length of Applicable Bur 44.6 mm (type 2 of ISO 14457)

Max. Working Dia of the Rotary Instruments Φ4 mm

Minimum Fitting Length of Shank Type 2: 15 mm

Gear Reduction Ratio 1:1

5. Specifications

Type of Connector ISO 3964

9. Post-use Maintenance

8. Test prior to Use

Once handpiece is correctly connected to motor, check for unusual vibration,

noise or overheating. If there are any abnormalities, stop using and contact your

authorized Precision Plus dealer.

2. Insert the Spray Nozzle into the rear of the handpiece.

Hold the handpiece firmly and spray lubricant for 2-3

seconds. Apply lubricant until it has been expelled from

handpiece head for 2 seconds (Fig. 3).

Handpiece should be sterilized after each and every treatment.

1. Handpiece should be lubricated as per user manual.

2. Insert into an autoclave pouch and seal pouch correctly.

3. Sterilize at 134°C(273°F) for 5 mins.

4. Handpiece should be stored in a sealed pouch in a dry place out of direct

sunlight until required for use.

9.4 Sterilization

1. Use correct eye, face and personal protection to avoid possible infection.

2. Remove the bur.

3. Disconnect handpiece from the Motor.

9.1 Preparation

1.Remove dirt and debris from handpiece using a soft bristle brush. Do not use a

wire brush.

2. Automated Cleaning and Disinfection: Use a thermo-disinfector according to

ISO 15883. For programme settings as well as cleansers and disinfectants to be

used, please refer to the user manual of the thermo- disinfector.

3. Automated Drying The drying procedure is normally part of the cleaning programme

of the thermo-disinfector. Refer to the user manual of the thermo- disinfector.

9.2 Cleaning

Lubricant must be applied after use and before autoclaving.

1. Attach the Spray Nozzle onto the Spray Port of the can.

(not included with this device)

9.3 Lubricating

P.10

P. 11

P. 8

P. 9

CAUTION

CAUTION: Do not use the following fluids to wipe, immerse or clean the

handpiece: strong/highly acidic water, strong acid/alkaline

chemicals, chlorine containing solutions or solvents such as

benzine or thinner.

Do not use ultrasonic bath during the cleaning process.

CAUTION

7.2 Removing the Bur

WARNING

1. Turn the Bur Locking Ring towards the mark until a “click” is heard.(Fig. 2)

Gently pull the bur outwards to remove from chuck.

●After engaging bur in chuck, check the ●mark is correctly aligned with the mark.

If the marks are not correctly aligned, the bur will not be securely or safely engaged

and overheating may occur. This may lead to handpiece damage or patient burn

injuries.

●Remove the bur only after the handpiece has completely stopped rotating.

●Always keep hands clear of bur during rotation to avoid injury.

●Do not run the handpiece without a bur inserted or when a bur is inserted but the

Bur Locking Ring is in an open position.

Fig. 3

●Always follow lubricant manufacturers instructions.

●Always hold lubricant can in an upright position.

●Hold handpiece firmly to avoid it being dislodged due to lubricant spray pressure.

If the handpiece will not work correctly after following above troubleshooting solutions,

please contact Precision Plus or an authorized maintenance centre.

Malfunction Cause Solution

High pitched or unusual noise,

reduced cutting power or

failure to rotate

Debris in handpiece

or gear mechanism Clean and lubricate handpiece

Reduction in speed Motor problem Check motor speed

Handpiece will not engage

bur or hold bur in chuck Damaged chuck Send device to Precision Plus

authorized repairer

Abnormal bur rotation or

failure to cut Bearing damage Replace damaged components

11. Troubleshooting

10. Symbol

P.12

P.13

P.14

P.15

CAUTION

●Do not use an ultrasonic bath during the cleaning process.

●Always follow the instructions provided by lubricant manufacturer. Be aware of all

precautions and warnings.

●Handpiece must be cleaned and lubricated before sterilization.

●Any remaining blood on outer surface may become clotted and cause operational

failure.

●Do not overheat or cool Handpiece too quickly. Rapid change in temperature may

cause damage to the product.

●Do not use autoclaves exceeding 137°C during sterilization.

●Precision Plus recommends sterilization according to EN 13060/EN 285. Always

follow autoclave manufacturer’s instructions for use.

●Reprocessed products should be stored, protected from dust in a dry, dark and

cool place with minimum exposure to germs.

●Autoclave sterilization is the only agreed method to correctly sterilize this

handpiece.The validity of other sterilization methods is not confirmed or guaranteed.

Serial number

Conforms to CE European Directive of “Medical device directive 93/42/EEC”

Authorized representative in the European Community.

Batch code

Date of manufacture

Manufacturer

0197

Sterilizable in a steam sterilizer (autoclave) at the temperature 134°C(273°F)

The device has not been subjected to a sterilization process

Medical Device

Consult instructions for use

Washer-disinfector for thermal disinfection

P.16

12. Warranty

Precision Plus products are warranted against manufacturing and material defects.

Precision Plus reserves the right to analyze and determine the cause of any problem.

The warranty is voided should the product not be used in accordance to the user

manual, not for its intended purpose, has not been repaired by Precision Plus or an

authorized Precision Plus repairer, or has non genuine Precision Plus parts installed.

Replacement parts will be made available for seven years after the date of

discontinuation of the model.

13. Disposal of Product

In order to avoid the health risks to operators handling the disposal of medical

equipment, as well as the risks of environment contamination caused thereof,

a surgeon or a dentist is required to confirm the equipment is sterile. Ask specialist

firms who are licensed to dispose of specially controlled industrial wastes, to dispose

of the product for you. Always follow your country specific laws, directives, standards

and guidelines for disposal of medical devices.

made in China

Precision Plus China Limited

Flat 103, No. 122, Tianqiao Road,

Tutang, Changping, Dongguan,

Guangdong, China.

Tel: +86-769-82306233

Fax: +86-769-82301566

L10-12-2020

01234

THE ACTUAL SCALE

User Manual_L10-1 120 x 60 mm

2017-05Premiumplus international

K

ARTWORKS:

DOC. NO.

DIMENSIONS:

PRODUCT NO.

COLORS:

Version: Revise Content: Prepared By: Audited By: Approval:

DESIGNER: DATE:

WellKang Ltd

The Black Church

St. Mary's Place

Dublin 7, D07 P4AX

Ireland

Table of contents

Other precisionplus Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Orascoptic

Orascoptic EyeSpy Reprocessing Instructions

DentalEZ

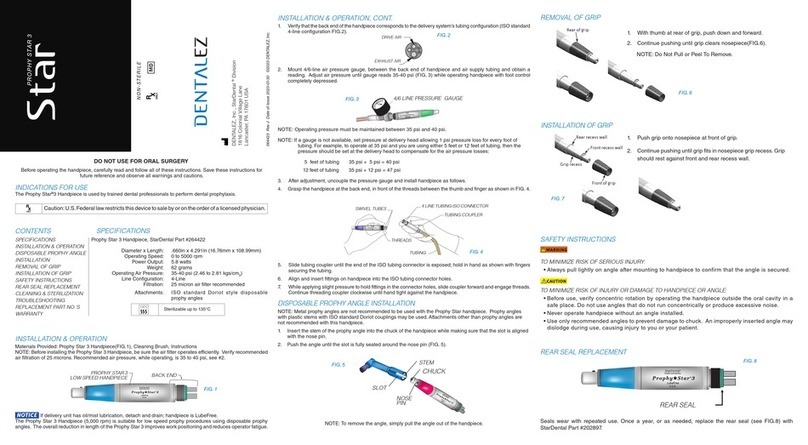

DentalEZ StarDental PROPHY STAR 3 instruction manual

GNATUS

GNATUS EasySonic owner's manual

K-LASER

K-LASER Blue Derma Operating instruction

Propel Trampolines

Propel Trampolines VPro+ quick start guide

Aseptico

Aseptico AMC-20CF Service manual & parts list

KaVo

KaVo ProXam Extraoral Installation quick guide

Heraeus

Heraeus iBond Total Etch Instructions for use

Ivoclar Vivadent

Ivoclar Vivadent Programat EP 5000 operating instructions

EMS

EMS PIEZON MASTER 700 operating instructions

septodont

septodont Biodentine Gun manual

Zyris

Zyris ISOVAC Instructions for use