BE Ag & Industrial BE-TS Series Application guide

PURCHASE DATE MODEL NO. SERIAL NUMBER

DEALER

ROTARY TILLER

BE-TSXXX

OPERATIONS & PARTS MANUAL

FOR MODELS:

• BE-TS120

• BE-TS140

• BE-TS160

• BE-TS180

• BE-TS200

TABLE OF CONTENTS

3INTRODUCTION & SAFETY

6OPERATION

8MAINTENANCE

9EXPLODED VIEW & PARTS LIST

BE-TSXXX USER MANUAL 3

SAFETY SIGNAL WORDS

Note the use of the signal words DANGER, WARNING and CAUTION with the safety messages. The

appropriate signal word for each has been selected using the following guidelines:

DANGER!:

Indicates an imminently hazardous situation that, if not avoided, will result in death

or serious injury. This signal word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

WARNING!:

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury, and

includes hazards that are exposed when guards are removed. It may also be used to alert against unsafe

practices.

CAUTION!:

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

GENERAL SAFETY GUIDELINES

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build as many safety features as possible. However, every year many accidents

occur which could have been avoided by a few seconds of thought and more careful approach to handling

equipment. You, the operator, can avoid many accidents by observing the following precautions in this

section. To avoid personal injury, study the following precautions and insist those working with you, or for

you, follow them.

Replace any CAUTION, WARNING, DANGER or instruction safety decal that is not readable or is missing.

Location of such decals are indicated in this booklet.

Do not attempt to operate this equipment under the influence of drugs or alcohol. Review the safety

instructions with all users annually.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations.

Do not allow persons to operate or assemble this unit until they have read this manual and have developed a

thorough understanding of the safety precautions and of how it works.

To prevent injury or death, use a tractor equipped with a Roll Over Protective System (ROPS).

Do not paint over, remove or deface any safety signs or warning decals on your equipment. Observe all

safety signs and practice the instructions on them.

Never exceed the limits of a piece of machinery. If its ability to a do a job, or to do so safely, is in question

DON’T TRY IT.

INTRODUCTION & SAFETY

Thank you for purchasing your Tiller. Your Rotary Tiller is designed to be used on 540 RPM tractors.

It is important to properly maintain and keep in place all safety guards and shields that came with your tiller.

SAFETY

Read and understand this manual and all safety signs before operating and maintaining. Review the safety

instructions and precautions annually.

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGH THIS MANUAL IS USED TO CALL YOUR

ATTENTION TO INSTRUCTIONS INVOLVING YOUR PERSONAL SAFETY AND THE SAFETY OF OTHERS.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED

4 BE-TSXXX USER MANUAL

SAFETY DECAL CARE

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

• Replaced parts that displayed a safety sign should also display the current sign. • Safety signs are available

from your Local Dealer.

HOW TO INSTALL SAFETY SIGNS

• Be sure that the installation area is clean and dry.

• Decide on the exact position before you remove the backing paper.

• Remove the smallest portion of the split backing paper.

• Align the decal over the specified area and carefully press the small portion with the exposed sticky

backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the decal in place. •

Small air pockets can be pierced with a pin and smoothed out using the piece of decal backing paper.

BEFORE OPERATION

• Carefully study and understand this manual.

• Do not wear loose-fitting clothing, which may catch in moving parts. Always wear protective clothing and

substantial shoes.

• Assure that all tires are inflated evenly.

• Give the unit a visual inspection for any loose bolts, worn parts or cracked welds and make necessary

repairs.

• Be sure there are no tools lying on or in the equipment.

• Do not use the unit until you are sure that the area is clear, especially of children and animals.

• Don’t hurry the learning process or take the unit for granted. Ease into it and become familiar with your

new equipment.

• Practice safe operation of your equipment and its attachments. Completely familiarize yourself and other

operators with its operation before using.

• Use a tractor equipped with a Roll Over Protective System (ROPS) and fasten your seat belt prior to

starting the engine. The manufacturer does not recommend usage of tractor with ROPS removed.

• Move tractor wheels to the widest recommended settings to increase stability.

• Securely attach to towing unit. Use a high strength, appropriately sized hitch pin with a mechanical retainer

and attach a safety chain.

• Do not allow anyone to stand between the tongue or hitch and the towing vehicle when backing up to the

equipment.

DURING OPERATION

• Children should not be allowed on the product.

• Clear the area of small children and bystanders before moving the feeder.

• If using a towing unit, securely attach feeder by using a hardened 3/4” pin, a metal retainer and safety

chains if required. Shift towing unit to a lower gear before going down steep downgrades, thus using the

engine as a retarding force. Keep towing vehicle in gear at all times. Slow down for corners and rough

terrain.

• Make sure you are in compliance with all local and state regulations regarding transporting equipment

on public roads and highways. Lights and slow moving signs must be clean and visible by overtaking or

oncoming trac when feeder is transported.

• Beware of bystanders, particularly children! Always look around to make sure that it is safe to start the

engine of the towing vehicle or move unit. This is particularly important with higher noise levels and quiet

cabs, as you may not hear people shouting.

• NO PASSENGERS ALLOWED! Do not carry passengers anywhere on, or in, the tractor or equipment,

expect as required for operation.

• Keep hands and clothing clear of moving parts.

BE-TSXXX USER MANUAL 5

• Do not clean, lubricate or adjust your equipment while it is moving.

• When halting operation, even periodically, set the tractor or towing vehicle brakes, disengage the PTO, shut

o the engine and remove the ignition key.

• Be especially observant of the operating area and terrain. Watch for holes, rocks or other hidden hazards. •

Always inspect the area prior to operation.

• DO NOT operate near the edge of drop-os or banks

• DO NOT operate on steep slopes as overturn may result.

• Operate up and down (not across) intermediate slopes. Avoid sudden starts and stops.

HIGHWAY AND TRANSPORT OPERATIONS

Adopt safe driving practices:

• Keep the brake pedals latched together at all times. NEVER USE INDEPENDENT BRAKING WITH MACHINE

IN TOW AS LOSS OF CONTROL AND/OR UPSET OF UNIT CAN RESULT.

• Always drive at a safe speed relative to local conditions and ensure that your speed is low enough for an

emergency stop to be safe and secure. Keep speed to a minimum.

• Reduce speed prior to turns to avoid the risk of overturning. Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in gear to provide engine braking when going downhill. Do not

coast.

• Do not drink and drive!

• Comply with state and local laws governing highway safety and movement of farm machinery on public

roads.

• Use approved accessory lighting flags and necessary warning devices to protect operators of other

vehicles on the highway during daylight and nighttime transport. Various safety lights and devices are

available from your dealer.

• The use of flashing amber lights is acceptable in most localities. However, some localities prohibit their use.

Local laws should be checked for all highway lighting and marking requirements.

• When driving the tractor and equipment on the road or highway under 40 KPH (20 MPH) at night or

during the day, use flashing amber warning lights and a slow moving vehicle (SMV) identification emblem.

• Plan your route to avoid heavy trac. Be a safe and courteous driver. Always yield to oncoming trac in all

situations, including narrow bridges, intersections, etc.

• Be observant of bridge loading ratings. Do not cross bridges rated lower than the gross weight as which

you are operating.

• Watch for obstructions overhead and to the side while transporting. • Avoid overhead wires or other

obstacles. Contact with overhead lines could cause serious injury or death.

• Always operate equipment in a position to provide maximum visibility at all times. Make allowances for

increased length and weight of the equipment when making turns, stopping the unit, etc.

• Maneuver the tractor or towing vehicle at safe speeds.

• Pick the most level possible route when transporting across fields. Avoid the edges of ditches or gullies and

steep hillsides. Be extra careful when working on inclines.

• Avoid loose fill, rocks and holes; they can be dangerous for equipment operation or movement.

• Operate the towing vehicle from operator’s seat only.

• Never stand along side of unit with engine running or attempt to start engine and/or operate machine.

• Never leave running equipment and attachments unattended.

• As a precaution, always re-check the hardware on equipment following every 100 hours of operation.

Correct all problems. Follow the maintenance safety procedures.

6 BE-TSXXX USER MANUAL

OPERATION

Before attaching the rotary tiller to the tractor, check the unit to ensure there is oil in the top and side

gearbox. See Maintenance Section for lubricant specifications.

Before beginning operation, check oil and grease points.

Oil Level: Top gear box 1-1/2” from the end of the dip stick. When sitting slightly tilted forward, oil should be

at the bottom of the drain plug on the side gearbox cover.

Grease: Right Rotor bearing, PTO shaft Cross & Bearings.

Attaching to the tractor:

1. With the Rotary Tiller on a level surface, back the Cat. 1 so the tractor lift arms are even with the unit’s

lower hitch pins. Lower or raise the tractor hitch arms until the 7/8” bushing in the arm is inside the clevis

of lower hitch points. Be sure nothing is between the tractor and the tiller before backing up.

2. Insert the lower hitch pin through the lower hitch blocks and the tractor arm. The YCT series tillers have

adjustable lower hitch blocks that can be slid to facilitate usage on larger tractors.

3. Secure the lift arm in place by using a 7/16” lynch pin or other fastener.

4. Repeat with the other arm.

5. Connect the driveline to the tractor’s PTO output shaft. Secure it in place.

6. Connect the tractor top link to the upper hitch point of the rotary tiller.

7. Start the tractor and slowly raise the tiller. Check for draw bar interference. Be sure that the PTO driveline

does not bottom-out when lifting the machine to its maximum height. If it does appear that it could

bottom-out, it is necessary to shorten the PTO driveline. (See Shortening a PTO Driveline Section). Ensure

that in the working position there is an overlap of a minimum of 1/3 the length of each profile.

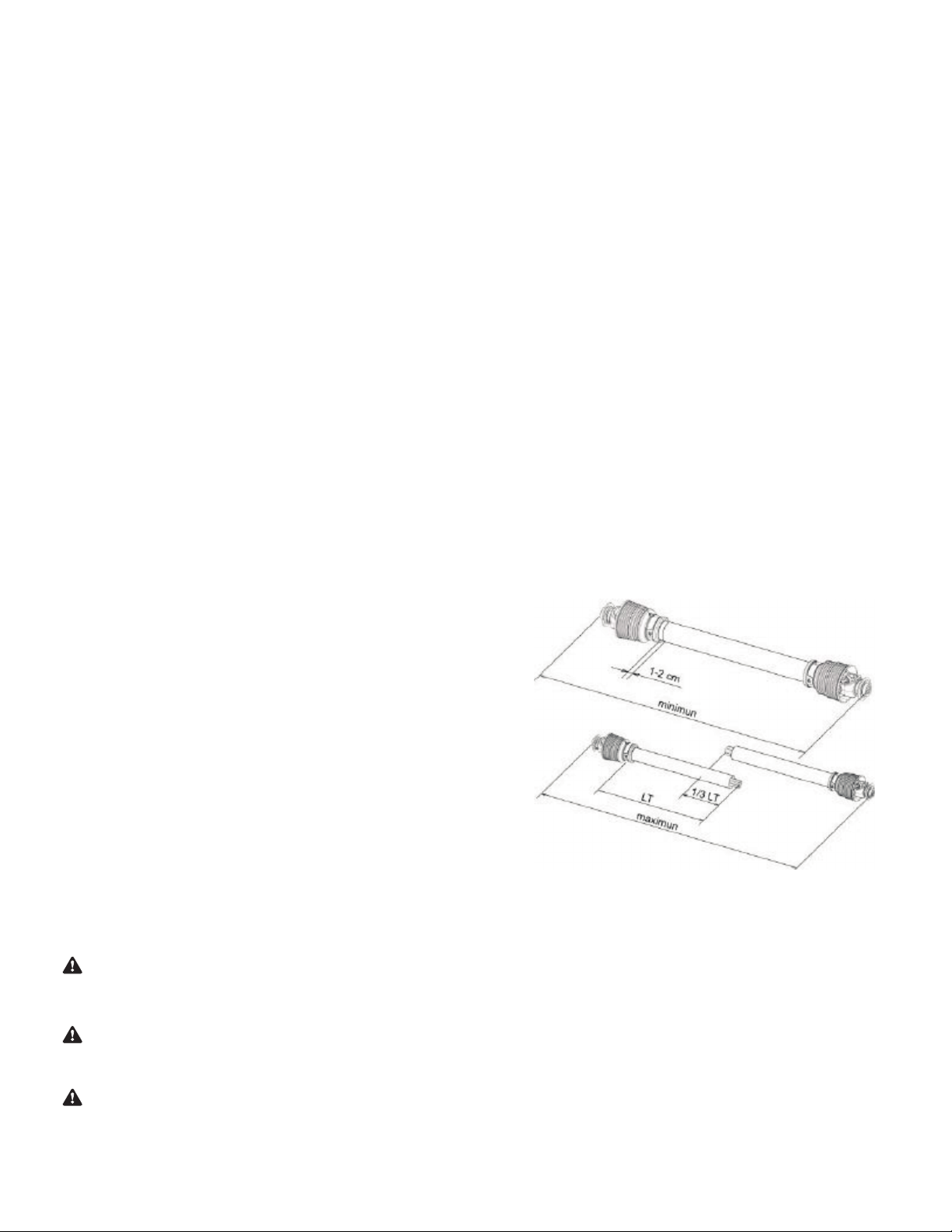

Shortening a PTO Driveline:

1. With the implement attached to the tractor’s 3-point

hitch, and the PTO driveline not installed, separate

the PTO driveline. Attach the implement end to the

implement and the other end to the tractor PTO input

shaft.

2. Raise the implement by using the tractor’s hydraulic

3-point hitch to its maximum lift height.

3. Hold the half shafts next to each other and mark them

so each end is approximately 1/2” from hitting the end of

the telescopic profiles.

4. Shorten the inner and outer guard tubes equally.

5. Shorten the inner and outer profiles by the same length

as the guard tubes. Using a rat tail file, round o all sharp

edges and burrs.

Grease the telescopic profile generously before reassembling.

Do not shorten too much, the proper overlap is a minimum of 1/3 the length of each profile.

CAUTION:

Slip Clutches may become hot. Do Not Touch!

Keep the slip clutch area clear of any material that may catch fire.

CAUTION:

Slip clutches have adjustable torque settings. The torque setting varies with the dierent compression of

each spring. All the springs should have an equal amount of compression.

IMPORTANT:

Do not over-tighten the compression nuts as this may impair performance or cause premature wearing of

the slip clutch.

OPERATION BE-TSxx

Before attaching the rotary tiller to the tractor, check the unit to ensure there is oil in the top and

side gearbox. See Maintenance Section for lubricant specifications.

Before beginning operation, check oil and grease points.

Oil Level: Top gear box 1-1/2” from the end of the dip stick. When sitting slightly tilted forward, oil should be at

the bottom of the drain plug on the side gearbox cover.

Grease: Right Rotor bearing, PTO shaft Cross & Bearings.

Attaching to the tractor:

1. With the Rotary Tiller on a level surface, back the Cat. 1 so the tractor lift arms are even with the unit’s lower

hitch pins. Lower or raise the tractor hitch arms until the 7/8” bushing in the arm is inside the clevis of lower

hitch points. Be sure nothing is between the tractor and the tiller before backing up.

2. Insert the lower hitch pin through the lower hitch blocks and the tractor arm. The YCT series tillers have

adjustable lower hitch blocks that can be slid to facilitate usage on larger tractors.

3. Secure the lift arm in place by using a 7/16” lynch pin or other fastener.

4. Repeat with the other arm.

5. Connect the driveline to the tractor’s PTO output shaft. Secure it in place.

6. Connect the tractor top link to the upper hitch point of the rotary tiller.

7. Start the tractor and slowly raise the tiller. Check for draw bar interference. Be sure that the PTO driveline

does not bottom-out when lifting the machine to it’s maximum height. If it does appear that it could

bottom-out, it is necessary to shorten the PTO driveline. (See Shortening a PTO Driveline Section).

Ensure that in the working position there is an overlap of a minimum of 1/3 the length of each profile.

Shortening a PTO Driveline:

1. With the implement attached to the tractor’s 3-point hitch,

and the PTO driveline not installed, separate

the PTO driveline. Attach the implement end to the implement

and the other end to the tractor PTO

input shaft.

2. Raise the implement by using the tractor’s hydraulic

3-point hitch to it’s maximum lift height.

3. Hold the half shafts next to each other and mark them so

each end is approximately 1/2” from hitting the

end of the telescopic profiles.

4. Shorten the inner and outer guard tubes equally.

5. Shorten the inner and outer profiles by the same length as the guard tubes.

Using a rat tail file, round o all sharp edges and burrs.

Grease the telescopic profile generously before reassembling.

Do not shorten too much, the proper overlap is a minimum of 1/3 the length of each profile.

CAUTION: Slip Clutches may become hot. Do Not Touch!

Keep the slip clutch area clear of any material that may catch fire.

6

BE-TSXXX USER MANUAL 7

Slip Clutch Adjustments:

Slip Clutch must be adjusted before first use or after a storage period.

6. Using a marker, scribe a line across the exposed edges of the clutch plate and friction discs.

7. Back o compression nuts to free friction discs by turning each nut 2 revolutions.

8. Start the tractor and run the driveline at a low idle to slip the friction discs. This will remove the dirt,

corrosion and surface floss from the clutch plate faces.

9. Disengage the PTO, shut down tractor and wait for all components to come to a complete stop.

10.Inspect the clutch and ensure that the scribed marking on the disc and plates have changed position.

If any two marks are still aligned, this is an indication that these discs have not slipped. It may be

necessary to completely disassemble the clutch to free them up.

11. After ensuring all discs are free, tighten the compression nuts, uniformly, exactly 2 revolutions to reset the

clutch original pressure.

Working Depth Adjustments:

The working depth is controlled by raising or lowering the side skids. If the side skids are raised, the working

depth increases. By lowering the skids, the tilling depth will decrease.

Tailgate Adjustment:

The tailgate can be adjusted to help smooth and compact the tilled ground.

Release the chain can secure to the desired height.

Start Up:

After making the necessary adjustments, lower the rotary till until the

blades are a couple of inches from the ground.

Engage PTO and slowly lower the tiller to begin working.

Removal and Storage

After finishing, remove the rotary tiller from the tractor.

1. Put the PTO driveline in a safe location so it will not become damaged.

2. Clean and dry the equipment.

3. Replace any damaged or worn parts.

4. Check all bolts and nuts for tightness.

5. Lubricate and protect the machine from the elements.

FOLLOWING OPERATION

• Following operation, or when unhitching, stop the tractor or towing vehicle, set the brakes, disengage the

PTO and all power drives, shut o the engine and remove the ignition keys.

• Store the unit in an area away from human activity.

• Do not park equipment where it will be exposed to livestock for long periods of time. Damage and

livestock injury could result.

• Do not permit children to play on or around the stored unit.

• Make sure all parked machines are on a hard, level surface and engage all safety devices. • Wheel chocks

may be needed to prevent unit from rolling.

PERFORMING MAINTENANCE

• Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

• Make sure there is plenty of ventilation. Never operate the engine of the towing vehicle in a closed building.

The exhaust fumes may cause asphyxiation.

• Be certain all moving parts on attachments have come to a complete stop before attempting to perform

maintenance.

• Always use the proper tools or equipment for the job at hand.

8 BE-TSXXX USER MANUAL

• Use extreme caution when making adjustments.

• Never replace hex bolts with than grade 5 bolts unless otherwise specified. • After servicing, be sure all

tools, parts and service equipment are removed.

• Where replacement parts are necessary for periodic maintenance and servicing, genuine factory

replacement parts must be used to restore your equipment to original specifications.

The manufacturer will not claim responsibility for use of unapproved parts and/or accessories and other

damages as a result of their use.

• If the equipment has been altered in any way from original design, the manufacturer does not accept any

liability for injury or warranty.

MAINTENANCE

8 Hours:

• Grease the Rotor support (GP grease TXG and YCT only) • Grease PTO shaft cross & bearings (GP grease)

• Check Hardware for tightness

16 Hours:

• Check oil level in center gearbox (90wt) • Check oil level in side gearbox (140wt)

• Check Hardware for tightness

200 Hours:

• Replace oil in center gearbox (90wt)

• Replace oil in side gearbox (140wt)

• Change chain tensioner spring (DLT model only) • Check Hardware for tightness

REPLACING BLADES

In order for the tiller to perform optimally, make sure the tiller blades are in good working condition and

their bolts and nuts are tight. Always replace the blades with the bolt head against the blade and the washer

and nut on the flange side to help prevent the blades from loosening.

When several blades are to be replaced, replace them one blade at a time in order to maintain the scroll

pattern on the rotor.

Note: To determine Left or Right Blades, hold the blade by the bolt hole and the cutting edge facing

downward. if the blade curves to the left it is a left-hand blade, curving to the right indicates a right hand

blade.

BE-TSXXX USER MANUAL 9

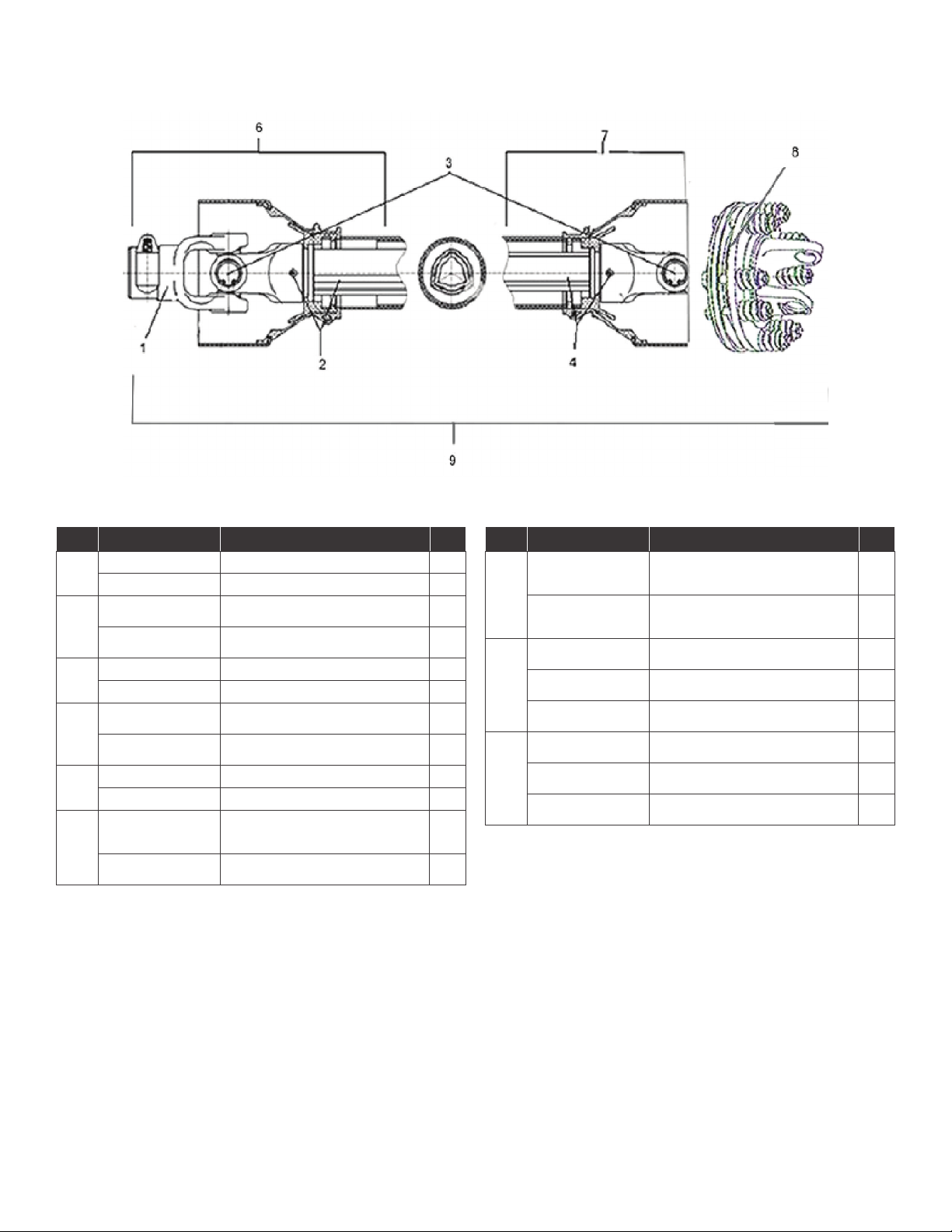

PARTS DIAGRAM BE-TSxx

10

EXPLODED VIEW & PARTS LIST

10 BE-TSXXX USER MANUAL

REF PART NO DESCRIPTION QTY

1 GB/T5783-2000 Bolt M10x25 Side Panel Bracket 10

2

TS58-01-01-00 Frame Weldment 58 1

TS66-01-01-00 Frame Weldment 66 1

TS72-01-01-00 Frame Weldment 74 1

TS82-01-01-00 Frame Weldment 81 1

3 TS66-01-02-03 “R” Clip 4mm 3

4 TS66-01-02-02 Hitch Pin (Lower Hitch Block) 2

5 TS66-01-02-01-00 Lower Hitch Bracket 2

6 TS66-01-02-01 “U” Bolt (Lower Hitch Bracket) 2

7 GB/T5783-2000 Bolt - A Frame 14

8 TS66-03-01 U Bolt - Drive Shaft Housing 2

9 TS66-03-02 Support - Drive Shaft Housing 2

10 TS0304 Gearbox Shielding (Complete) 1

11 TS66-01-03-01-00 A Frame 1

12 TS66-01-03-01 Top Hitch Pin 1

13 GB/T5783-2000 Bolt - Drive Tube Housing 14

14

TS58-04-00 Gearbox Support Tube - 58 1

TS66-04-00 Gearbox Support Tube - 66 1

TS72-04-00 Gearbox Support Tube - 74 1

TS82-04-00 Gearbox Support Tube - 81 1

15 HG4-692-67 Oil Seal (Input Gearbox) 1

16 GB/T893.1-1986 Snap Ring - Input Shaft (Front) 1

17 GB/T276-1994 Bearing - Input Shaft (Front) 1

18 TS66-02-05 Input Shaft 1

19 GB/T5783-2000 Bolt - Shielding 4

20 TS660303000 Gearbox Oil Plug (Dip Stick) 1

21 TS66-02-01 Housing - Gearbox 1

22 GB/T276-1994 Bearing (Rear of Center GB) 1

23 TS66-02-04 Spacer - Back GB 1

24 TS66-02-03 Gearbox Back Gasket 1

25 TS66-02-02 Gearbox Cap 1

26 Breather Cap - Side Housing 1

27 GB/T5783-2000 Bolt - Side Drive Cover 16

28 TS66-08-01-00 Side Drive Cover 1

29 TS66-08-01 Gasket - Side Gear/Chain Case 1

30 GB/T894.2-1986 Snap Ring Ext. (Output Shaft) 2

31 Shim

32 TS66-02-09 Input Gear - Side Drive 1

33 TS66-02-08 Output Gear Shim 3

34

TS58-02-10 Drive Shaft 58 1

TS66-02-10 Drive Shaft 66 1

TS72-02-10 Drive Shaft 74 1

TS82-02-10 Drive Shaft 81 1

35 GB/T276-1994 Bearing (Output Shaft - Driven

End) 1

36 GB/T5783-2000 Bolt - Drive Shaft Housing (Outer) 2

37 TS66-01-04-00 Side Panel - Left 12

38 TS66-02-07 Gasket - Drive Shaft 1

39

TS48-02-01-00 Drive Shaft Tube Housing 58 3

TS66-02-01-00 Drive Shaft Tube Housing 66 1

TS66-01-02-01-00 Drive Shaft Tube Housing 74 1

TS72-02-01-00 Drive Shaft Tube Housing 81 1

40 TS82-02-01-00 Lifting Hook 1

41 TS66-02-11 Oil Seal - Drive Shaft Tube

Housing 1

42 TS66-02-06 Ring Gear 1

44 Oil Plug Center GB (Drain Plug) 1

REF PART NO DESCRIPTION QTY

45 Lock Nut - Idler Gear Support

Shaft 1

46 GB/T3452.1-2005 O-Ring - Idler Gear Support Shaft 1

47 GB/T297-1994 Bearing (Idler Gear) 2

48 GB/T893.1-1986 Snap Ring (Idler Gear) 1

49 TS66-08-02 Idler Gear 1

50 TS66-08-03 Spacer - Idler Gear 1

51 Lock Nut - Rotor Support Left

Side 1

52 GB/T858-1988 Retaining Washer 1

53 TS66-08-04 Bottom Gear 1

54 TS66-08-06 Shim 55*40*2 1

55 GB/T893.1-1986 Snap Ring - Rotor Bearing 1

56 TS66-08-08 Gasket - Rotor (ø160*115*0.5) 1

57 GB/T276-1994 Bearing - Rotor (Left Side) 1

58 Oil Seal - Rotor Support (Left

Side) 2

59 TS66-08-05 Bearing Support (Left Side) 1

60 TS66-08-07 Rotor Support Shaft (Left Side) 1

61 TS66-08-09 Labyrinth Dust Cover (Left Side) 1

62 GB/T5783-2000 Bolt - Bearing Support (Left Side) 1

63

GB/T5786-2000 Blade Bolt - 12x35 Fine Thread 1

Hex Nut M12 1

Lock Washer 12mm 1

64

TS66-09-01-01

(02) Blade (Left) 1

Blade (Right) 1

65

TS58-09-01-01-00 Rotor Weldment - 58 1

TS66-09-01-01-00 Rotor Weldment - 66 1

TS72-09-01-01-00 Rotor Weldment - 74 1

TS82-09-01-01-00 Rotor Weldment - 81 1

66 TS66-09-01 Labyrinth Dust Cover (Right Side

- Outer) 1

67 TS66-09-03 Rotor Support Shaft (Right Side

- Outer) 1

68 HG4-692-6T Oil Seal - 62x45x12 1

69 TS66-09-04 Bearing Support 1

70 TS66-09-08 Retaining Washer 1

71 GB/T5783-2000 Retaining Bolt 1

72 TS66-09-02 Labyrinth Dust Cover (Right Side

- Inner) 1

73 TS66-09-07 End Cap - Rotor Right Side 1

74 GB/T5783-2000 Bolt - End Cap Right Side 4

75 M10X1 Grease Fittings 1

76 TS66-05-01 Pin - Stand 1

77 TS66-05-02 R-Clip - Stand 1

78 TS66-05-02-00 Stand Bracket 1

79 TS66-05-01-00 Stand Leg 1

80 TS66-06-00 Skid Weldment - Left 1

Skid Weldment - Right 1

81 Bolt - Tailgate 1

82

TS58-07-01-00 Tailgate 58 2

TS66-07-01-00 Tailgate 66 1

TS72-07-01-00 Tailgate 74 1

TS82-07-01-00 Tailgate 81 1

83 TS66-07-02-01 Tailgate Chain Assembly Ø 8 1

84 TS66-01-01 Side Panel - Right 1

85 TS66-09-05 Gasket1 (Ø 150x108x0.5) 1

86 TS66-09-06 Gasket2 (Ø 119x95x0.5) 1

BE-TSXXX USER MANUAL 11

REF PART NO DESCRIPTION QTY

1DP1075-40 PTO Yoke Series 40 1

DP1075-60 PTO Yoke Series 60

2

DP1079-40 Female Yoke & Tube - Series 40

(Tractor End) 1

DP1079-60 Female Yoke & Tube - Series 60

(Tractor End)

3DP1076-40 Cross & Bearings - Series 40 2

DP1076-60 Cross & Bearings - Series 60

4

DP1078-40 Male Yoke & Tube - Series 40

(Implement End) 1

DP1078-60 Male Yoke & Tube - Series 60

(Implement End)

5180-510-30 Friction Disc (4-3/4” OD) 2-4

180-510-40 Friction Disc (5-1/2” OD)

6

DP1074F-40

Complete Female End PTO

Shielding Series 20-40 (Tractor

End)

DP1074F-60 Complete Female End PTO

Shielding Series 60 (Tractor End)

REF PART NO DESCRIPTION QTY

7

DP1074M-40

Complete Female End PTO

Shielding Series 20-40

(Implement End)

DP1074M-60

Complete Female End PTO

Shielding Series 60 (Implement

End)

8

DP1098-30 Slip Clutch Complete 150mm

Clutch (2 Disc)

DP1098-40 Slip Clutch Complete 180mm

Clutch (2 Disc)

DP1098-60 Slip Clutch Complete 180mm

Clutch (4 Disc)

9

147120 Complete PTO - Series 40 150mm

Slip Clutch

147122 Complete PTO - Series 40 180mm

Slip Clutch

147125 Complete PTO - Series 60 200mm

Slip Clutch

PTO SHAFT

12 BE-TSXXX USER MANUAL

PHONE: 604-850-7770

FAX: 604-850-7774

TOLL FREE PHONE: 1-877-588-3311

TOLL FREE FAX: 1-800-665-7334

BRABEREQ.COM

WGSALES@BRABEREQ.COM

This manual suits for next models

5

Other BE Ag & Industrial Farm Equipment manuals