HG E2000 User manual

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 1

User manual

HG E2000 HIGH TIP

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 2

Table of contents

1. Introduction............................................................................................................ 5

2. Definitions .............................................................................................................. 6

2.1 Abbreviations..................................................................................................... 6

2.2 Terms, concepts, and designations ....................................................................... 6

2.3 Icons/pictograms in this user manual.................................................................... 6

3. Signs/marks found on the machine............................................................................ 6

3.1 CE label/machine-type plate ................................................................................ 6

3.2 Safety signs....................................................................................................... 7

3.3 Other signs........................................................................................................ 8

4. Machine description ................................................................................................. 8

4.1 General machine design ...................................................................................... 9

4.1.1 Dimensional sketch ....................................................................................... 9

4.1.2 Main parts ................................................................................................. 11

4.1.3 Main components........................................................................................ 11

4.2 EU Declaration of Conformity ............................................................................. 13

4.3 Description of functionalities .............................................................................. 15

4.4 Technical specifications ..................................................................................... 16

4.6 Warranty......................................................................................................... 18

4.7 Machine use .................................................................................................... 19

4.7.1 User requirements and restrictions................................................................ 19

4.7.2 Intended use.............................................................................................. 19

4.7.3 Unintended use .......................................................................................... 19

4.8 Supplied equipment .......................................................................................... 20

5. 5. Residual hazard................................................................................................. 21

6. Transport, use, and operation of the machine ........................................................... 24

6.1 Machine transport/towing .................................................................................. 24

6.1.1 Transport................................................................................................... 24

6.1.2 Towing ...................................................................................................... 26

6.2 Operating space ............................................................................................... 26

6.3 Emergency stop –Use and location on the machine.............................................. 28

6.3.1 Scope of emergency stop............................................................................. 29

6.4 Information during operation ............................................................................. 29

6.4.1 Visual information/warnings ......................................................................... 29

6.4.2 Acoustic warnings ....................................................................................... 30

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 3

6.5 Normal use...................................................................................................... 30

6.5.1 Electrical supply (supply separator)............................................................... 30

6.5.2 Filling up the container ................................................................................ 30

6.5.3 How to operate the machines functions ......................................................... 31

6.5.4 Unloading the container............................................................................... 35

6.5.5 Charging.................................................................................................... 46

6.5.6 Preparing for use ........................................................................................ 48

6.5.7 Tire pressure and maintenance..................................................................... 49

6.5.8 Driving ...................................................................................................... 49

6.6 Cleaning.......................................................................................................... 54

6.6.1 Safety steps while cleaning .......................................................................... 54

6.7 Safety while operating ...................................................................................... 54

6.7.1 Built-in functionality limitations .................................................................... 54

6.7.2 Other safety notes ...................................................................................... 55

6.7.3 Start-up after a regular stop ........................................................................ 56

6.7.4 Starting up after an emergency stop ............................................................. 56

6.7.5 Start-up after service/repair......................................................................... 57

6.7.6 Freeing a person in the event of an overrun or jam ......................................... 57

6.8 Troubleshooting/FAQ ........................................................................................ 57

7. Service, repair, and maintenance ............................................................................ 59

7.1 General ........................................................................................................... 59

7.1.1 Maintenance............................................................................................... 59

7.1.2 Spare parts ................................................................................................ 60

7.1.3 Safety during repair/maintenance ................................................................. 61

7.1.4 Disposal of replaced parts ............................................................................ 61

7.2 Lubricating moving parts and filling with hydraulic oil ........................................... 61

7.2.1 Lubrication of moving parts.......................................................................... 61

7.2.2 Filling up hydraulic oil.................................................................................. 62

7.2.3 Security regarding lubrication and filling ........................................................ 64

8. Storage & disposal................................................................................................. 64

8.1 Storage........................................................................................................... 64

8.2 Disposal .......................................................................................................... 67

9. Appendix.............................................................................................................. 68

9.1 Diagrams ........................................................................................................ 68

9.1.1 Electric diagram.......................................................................................... 68

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 4

9.1.2 Hydraulic diagram....................................................................................... 69

9.2 Blueprints........................................................................................................ 69

9.2.1 Overview prints .......................................................................................... 69

9.2.2 Parts prints ................................................................................................ 69

9.3 Additional manuals ........................................................................................... 69

9.4 Third-party documentation ................................................................................ 69

9.5 Checklist for HG Machines HG E2000 and HG E2000 High Tip................................. 70

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 5

1. Introduction

The 100% electric 2-ton dumper runs for an entire workday –it is easy and quick to charge.

The E2000 can carry up to 2 tons, while the lithium battery allows it to run for 12 hours –more than a full

working day. This makes it simple to use without worrying about emptying the battery. As a matter of fact, it

charges from 20-80% in just 2.5 hours.

It is made for urban construction sites for landscapers, contractors, demolition companies, and rental

companies.

HG E2000 is designed in Denmark and built at our factory.

•12 hours of effective driving time –more than enough for a full working day

•Fast charging –20 to 80% battery in 2 hours, 0-100% in 3.

•Charges with a simple car charger, 16A power, or 220v EU plug

•Lithium battery technology –LiFePO4

•Drive with one pedal for maximum comfort

•Significantly reduces noise levels

•Emission-free work environment

Fabrikant:

HG Poland Sp. Z. O. O. HG Machines ApS

+48 91 885 23 04 +45 75 89 12 44

Prosta 34 hello@hg-machines.com

72-100 Łozienica www.hg-machines.com

Poland Vejlevej 15, 8722 Hedensted

CVR-nr.: PL7010040430 Denmark

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 6

2. Definitions

2.1 Abbreviations

Table 1: Abbreviations

Abbreviation

Terms

Explanation

OADC

On-Air Data Communication

Device to get live updates from the machine

(optional equipment).

EM break

Electromagnetic brake reduction

Built-in brake functionality

2.2 Terms, concepts, and designations

Table 2: Expressions

Terms

Explanation

Intended use

The function(s) the machine is designed and manufactured to perform.

Unintended use

Description of the improper and illegal use of the machine that can reasonably be

expected to occur.

Residual hazard

A hazard that cannot be eliminated through its own safe construction or functional

safety.

2.3 Icons/pictograms in this user manual

Table 3: Icons

Icon

Meaning

Explanation

General information

Information that should be read before using the

machine.

Safety regulation

Safety regulation that informs the operator to orient

himself when operating the machine.

3. Signs/marks found on the machine

3.1 CE label/machine-type plate

The CE marking plate is on the machine's left side behind the swivel joint (see Figure 1). The nameplate must

not be removed or replaced if it is missing or is so damaged that it has become unreadable (see Figure 2).

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 7

Figure 1: CE marking plate

Figure 2: Placement of CE marking plate

3.2 Safety signs

Safety-related labels and symbols attached to the machine and their mean.

Pictogram

Definition

Warning: Electrical voltage

Warning: Hand-crushing

Warning mark for swivel arms

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 8

3.3 Other signs

The labels and signs attached to the machine and what they mean.

Pictogram

Definition

It shows where the charger is located on the machine.

Shows where tools can be stored on the machine.

Overview with meaning and explanation of battery diode color.

Overview of joystick functionalities.

Dashboard

4. Machine description

The HG E2000 High Tip is an emission-free dumper used to transport and load/unload various materials (see

Figure 3). It is a machine for professionals on, for example, construction sites, but it is also approved for driving

on public roads.

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 9

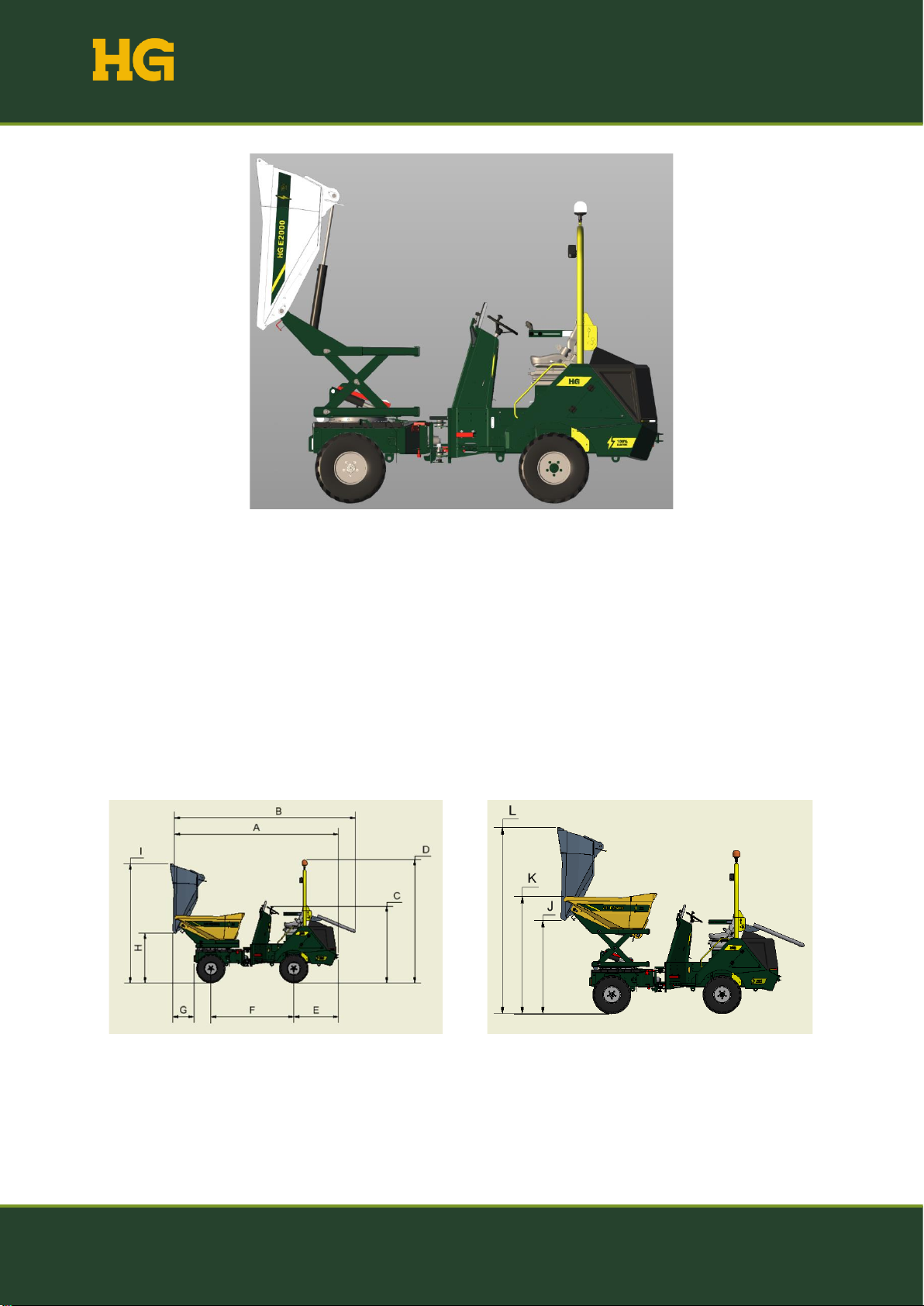

Figure 3: HG E2000 High Tip

The central part of the HG E2000 is a hydraulically driven container that can be rotated and tipped. For this,

the machine has hydraulically operated swivel arms that allow the container to be raised and lowered. The

machine is equipped with a swivel joint that connects the front and rear, making the machine maneuverable.

Each wheel is driven by an electric motor with built-in brake functionality (EM brake). This construction gives

the machine four-wheel drive.

4.1 General machine design

4.1.1 Dimensional sketch

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 10

Figure 4: Machine measurement

Symbol

(mm)

Symbol

(mm)

A

3975

K

2145

B

4390

L

3405

C

1860

M

280

D

2989

N

1480

E

1082

O

764

F

2010

P

452

G

517

Q

396

H

1205

R

1475

I

2890

S

310

J

1705

T

211

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 11

4.1.2 Main parts

Figure 5: E2000 main parts

1: Front

2: Back

4.1.3 Main components

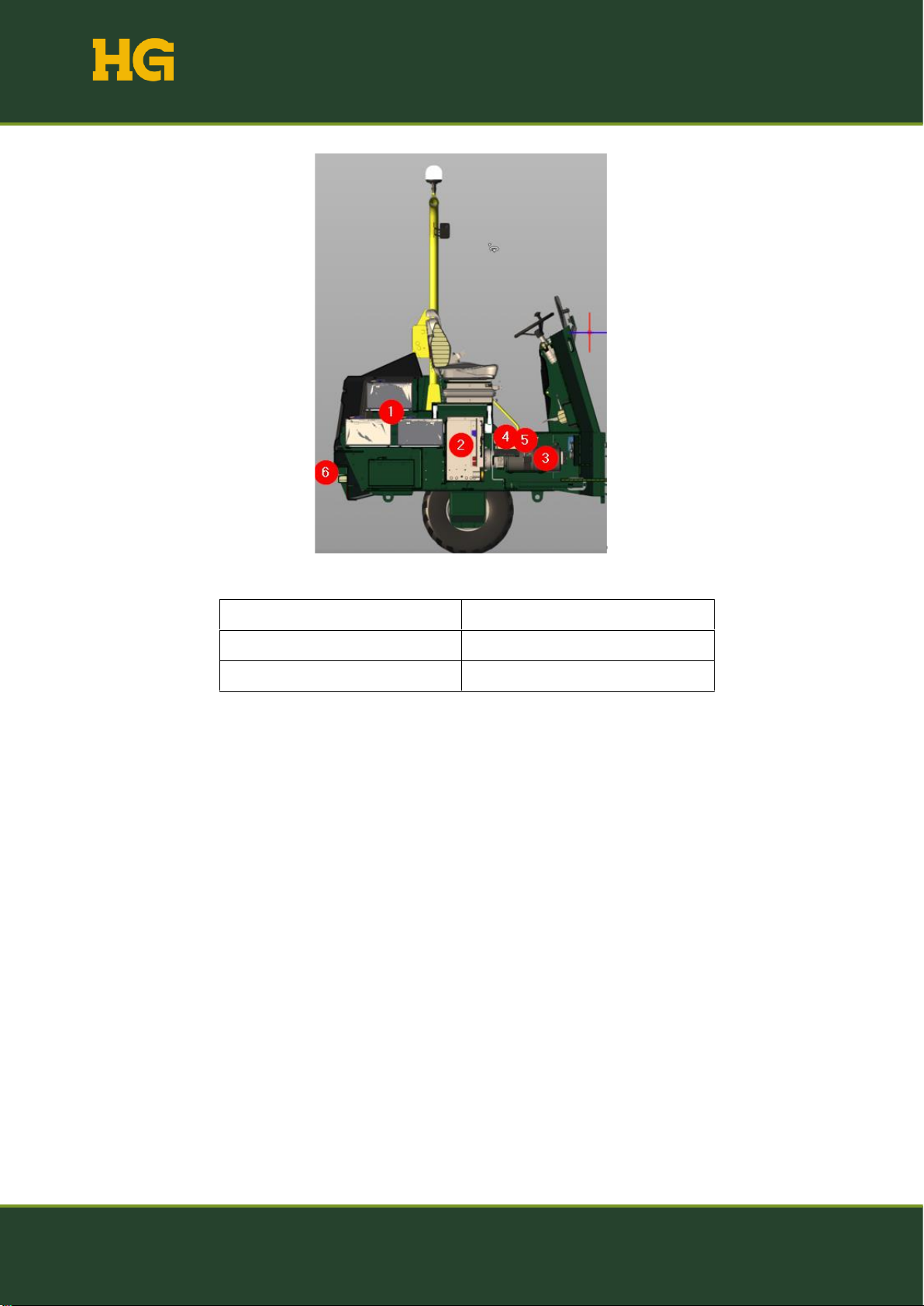

Figure 6: Main components - front

1: Container

2: Tip cylinder

3: Swivel arm

4: Lifting cylinder (h+v)

5: Top frame

6: Bottom frame

7: Turntable

8: Turning cylinder (h+v)

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 12

Figure 7: Main components - back

1: Battery pack

2: Fast charger

3: Hydraulic pump and tank

4: Main controllers (left side)

5: Slave controllers (right side)

6: Tow

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 13

4.2 EU Declaration of Conformity

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 14

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 15

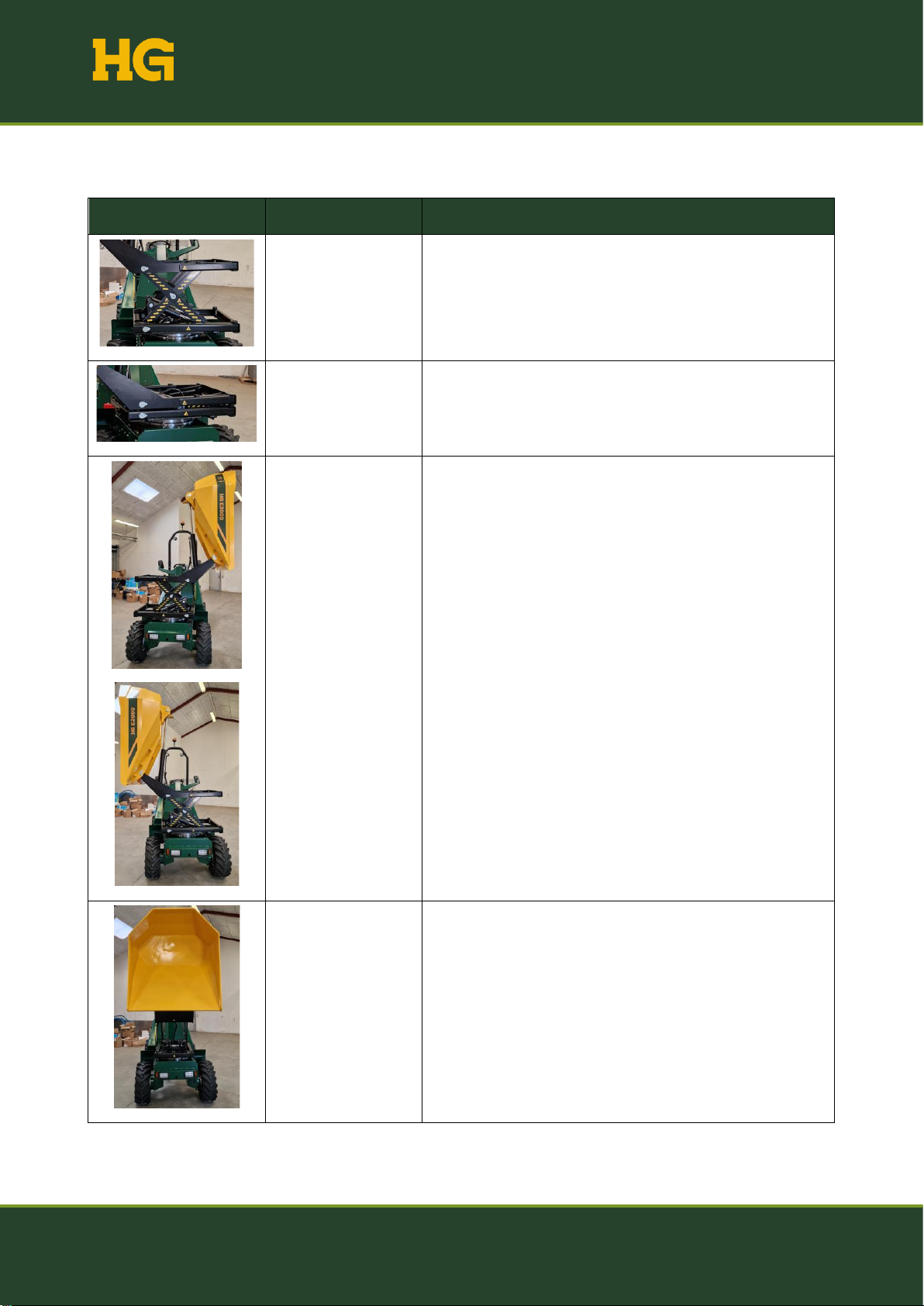

4.3 Description of functionalities

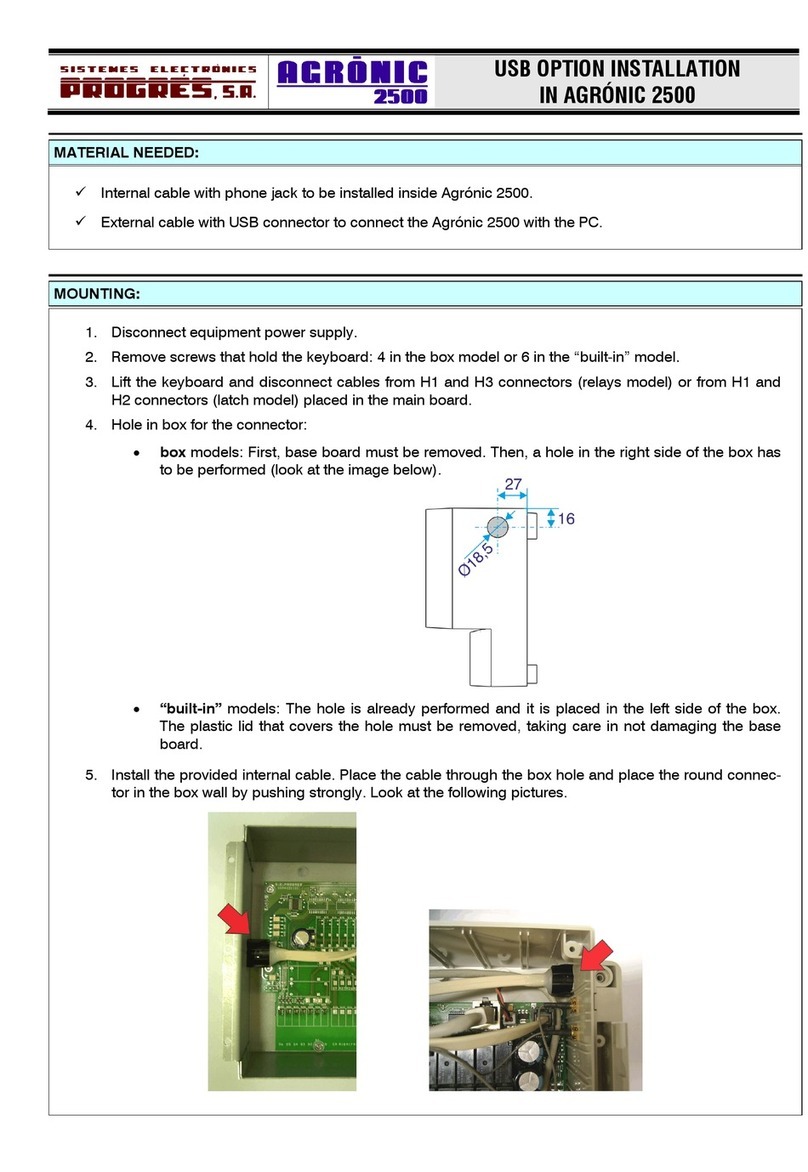

Image

Function

Description

Raising

Hydraulically driven raising function.

Lowering

Hydraulically driven lowering function.

Turning

A hydraulically driven turntable can turn the container 90

degrees to the left and right.

Tipping

A hydraulically driven tip function.

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 16

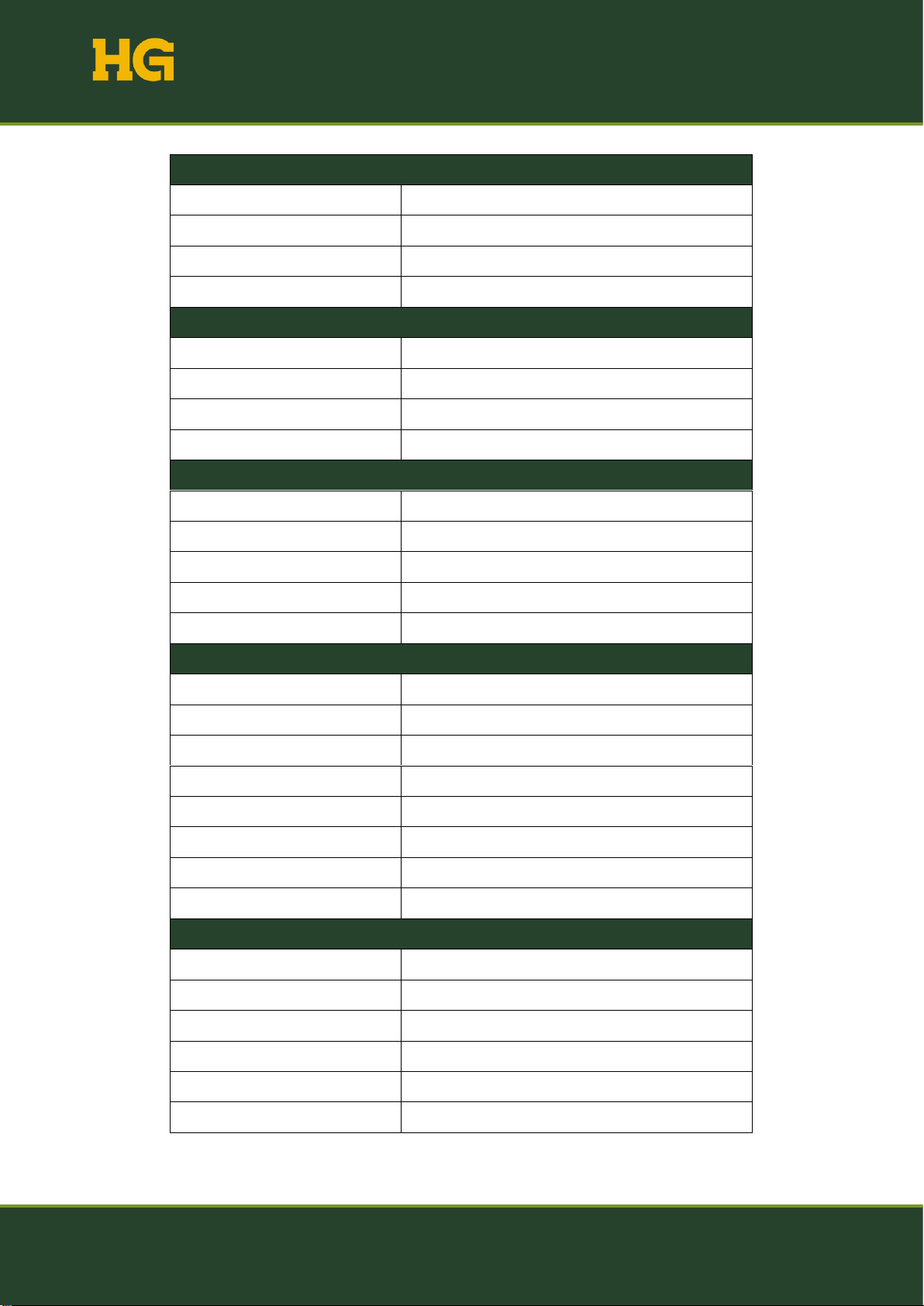

4.4 Technical specifications

The overall technical specifications of the machine are given in Table 4.

4.5 Table 4: Technical specifications

Specifications

Width

1480 mm

Length

3979 mm

Height (Operating mode, roll

bar up)

2989 mm

Height (Transportation mode)

1910 mm

Own weight

2150 kg

Content in liters

892 L

Content in kg

2000 kg

Unloading height (Low)

1210 mm

Unloading height (High)

1715 mm

Driving speed (Hare)

0-20 km/h

Driving speed (Turtle)

0-10 km/h

Reverse speed

0-20 km/h

Battery

Lithium

360 Ah

Voltage

48V

Run time

12 hours

Temperature, charge

0°C to +55°C

Temperature, in use

-10°C to +60°C

Temperature, long-term

storage

+15°C

Protection class (IPXX)

IP 54

Charger 1 –Fast charge –160 A

Plug

CEE 5P 16A

0-100% charging time

4,1 hours

20-80% charging time

2,6 hours

Integrated charger

10000 W

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 17

Charger 1 - Adapter type 2 car charger –160 A

Plug

CEE 5P 16A for type 2 car charger

0-100% charging time

4,1 hours

20-80% charging time

2,6 hours

Integrated charger

10000 W

Charger 2 –35A

Plug

230V plug standard EU

0-100% charging time

16 hours

20-80% charging time

10 hours

Integrated charger

1000 W

Motor

Electric

PMAC three-phase electric motor 48V

Performance

3000 W

Moment (Rated)

9,5 Nm

Moment (Peak)

19,5 Nm

Moment (Instant)

41 Nm

Pulling wheels

Dimensions

11.0/65x12/8 TL AS-504

Inches

12

Diameter

700

Width

273

Bar

4.0

Load/Kg

1400

Rim

8.50x12

Rolling circumference

2072

Other

Container function

Hydraulic tip. Tip cylinder, double-acting

High tip

Hydraulic tip. 2x Tip cylinder, double-acting

Container rotation

Hydraulic tip. 2x Tip cylinder, double-acting

Hydraulic tank

10-liter Handel 46

Sound pressure

Lpa, eq max = 81 dB(A)

Vibrations

Weighted arm/hand level max - 2.5 m/s2

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 18

4.6 Warranty

Warranty period

HG Danmark APS provides a guarantee for 12 months. The warranty period begins on the date of delivery.

The warranty includes:

•Components that must be replaced or repaired due to material or manufacturing defects.

•The warranty does not cover wear and consumable parts such as:

oTires and hydraulic oil

The manufacturer's warranty expires if:

•The machine is misused.

•The machine is used without following the user manual and safety regulations.

•The machine is not maintained according to the instructions, or outdated spare parts are used.

•The machine is used after a fault has been detected, resulting in a more expensive repair than the

original fault.

The owner's insurance should cover:

•Fire, burglary, theft, and vandalism.

•Water and frost damage.

•Damage caused by wind and weather.

The manufacturer's warranty does not apply in such cases.

Approval of compensation claims:

The manufacturer's approval of a compensation claim requires that the defective part be shown to the

manufacturer or its representative within two weeks after the damage. Ownership of the damaged part(s) is

transferred to the supplier of the new parts.

According to the warranty, it only replaces components. It, therefore, does not cover the following:

•Shipping costs.

•Costs related to waiting time, the machine owner's working time, and travel costs.

•Operating losses and other subsequent costs.

Other

Before repair under warranty, the manufacturer must be contacted to agree on the procedure. It is too late to

claim the warranty if the repair has been initiated or completed. These warranty provisions can only be changed

through a separate agreement.

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 19

4.7 Machine use

4.7.1 User requirements and restrictions

The operator of the HG E2000 must meet the following requirements and restrictions:

•The instructions must be read carefully. The operator must know all the machine's functions and

their correct use, as well as knowledge of controls, switches, etc.

•The operator must be at least 18 years old and have a normal state of mind and ability to use the

dumper. Please note that the legislation in the individual country may specify a different age limit for

persons who may use the dumper in given situations.

•The operator is responsible for accidents or any dangerous situations that may occur to other people

and their property.

•The operator must have adequate instructions on the use of the dumper. These instructions should

emphasize the following:

oThe importance of being careful and concentrated when working with self-propelled

machines.

oThe operator must have a good overview of the machine's surroundings - especially where

other people may be walking.

4.7.2 Intended use

The machine will be used to transport building materials and waste. The machine is operated by a seated

operator who must meet the requirements mentioned in section 4.6.1, User Requirements and Restrictions.

It is permitted to drive the machine on construction sites, areas without road surfaces, and public roads (see

section 6.5.8.1 Requirements for driving on public roads).

4.7.3 Unintended use

The machine may not be used for the following:

•It may not be operated by persons who do not know the machine's functions or are below 18 years

old.

•Do not transport with a raised container.

•Do not use it to tow other vehicles.

•Do not use it in case of insufficient ceiling height.

•Do not use in ATEX areas.

•It must not be used to lift people in the container

•It must not be used to transport people other than the operator

•May not be used for underground work (e.g., mining)

•Do not use in areas where there is insufficient lighting or daylight.

•It may not be used to transport materials weighing more than 2,000 kg.

User Manual HG E2000 HIGH TIP

HG Machines ApS hg-machines.com hello@hg-machines.com

Page 20

•Do not use it if the machine is damaged (Reduced functionality or apparent damage).

•Do not drive on uneven or steep surfaces that exceed the design limitations.

•Must not be used if all applicable regulations (cf. applicable legislation) and regulations on building

sites are not observed.

4.8 Supplied equipment

Table 5 contains an overview of the equipment delivered with the HG E2000.

Table 5: Overview of supplied equipment

Picture

Equpment

Charging cable with extension for charger (CEE type)

Safety bracket for tipping cylinder on container

Safety bracket for the swivels

Safety bracket for swivel cylinders on swivel joints (1 on each side

of the machine)

This manual suits for next models

1

Table of contents

Other HG Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Pottinger

Pottinger Original inside NOVACAT 3007 T ED Operator's manual

Fransgard

Fransgard DM-3250 manual

Agria

Agria Bison 5900 Series Translation of the original operating instructions

abi

abi ARENA RASCAL PRO Setup guide

breviglieri

breviglieri b25f Series Operating and maintenance manual

Boumatic

Boumatic HD2 Rapid Exit Operator's manual