BE Hemp Equipment TC-2 Quick start guide

TC-2 OPERATIONAL MANUAL

1

OPERATIONAL MANUAL

BE Hemp Equipment

Carson City, Nevada

TC-2

CYCLONIC TRIM

SAVER

TC-2 OPERATIONAL MANUAL

2

Safety

At BE Hemp Equipment (BE), safety is our number one priority. The following information provides

guidelines for safety when using BE equipment. Any piece of machinery can become dangerous to

personnel when improperly operated or poorly maintained. All employees operating and maintaining

BE equipment should be familiar with its operation and should be thoroughly trained and instructed

on safety. Most accidents are preventable through safety awareness.

Every effort has been made to engineer safety into the design of BE equipment per standards set

forth by ANSI, the National Electric Code, and others that apply as necessary. Areas of potential

danger are mechanically and/or electrically protected. Safety labels and instructional decals are

visible to the operator and located near any potential hazard.

General Safety Guidelines

Ensure that all power sources are turned off or unplugged when the machine is not in use.

Understand the LOCKOUT/TAGOUT procedure and use it before inspecting, maintaining,

servicing or cleaning the equipment to help prevent anyone from accidentally turning on

power to the machine.

Read the manual for any special operational instructions for each piece of equipment. A hard

copy can be made available if requested.

Know how the equipment functions and understand the operating processes.

Know how to shut down the equipment. Stop buttons, emergency stop buttons or cables are

located at various locations on the machinery.

Understand the equipment safety labels and heed them.

Wear the appropriate personal protective equipment for the job to be performed (EX: eye

protection, hearing protection, gloves, etc.). Ensure that nothing you are wearing could get

caught in the machinery

When working on or around all equipment, avoid wearing loose clothing, jewelry,

unrestrained long hair, or any loose ties, belts, scarves or articles that may be caught in

moving parts. Keep all extremities away from moving parts. Entanglement can cause death or

severe injury.

For new equipment, check plant voltage with the voltage specified on the machine. Electrical

specifications for your machine are printed on the machine serial number tag.

A properly grounded electrical receptacle is required for safe operation regardless of voltage

requirements.

Treat this equipment with the respect its power and speed demand. Use it only for its

intended purpose.

TC-2 OPERATIONAL MANUAL

3

Keep the operating zone free of obstacles that could cause a person to trip or fall toward an

operating machine. Keep fingers, hands or any part of the body out of the machine and away

from moving parts when the machine is operating.

Any machine with moving parts and/or electrical components can be potentially dangerous no

matter how many safety features it contains. Stay alert and think clearly while operating or

servicing the equipment. Be aware of operations and personnel in your surroundings. Be

attentive to indicator lights, warning lights and/or operator interface screens displayed on the

machine and know how to respond.

Do not operate machinery if you are fatigued, emotionally distressed or under the influence of

drugs or alcohol.

Know where the FIRST AID SAFETY STATION is located.

Know where FIRE EXTINGUISHING EQUIPMENT is located.

Never sit or stand on the machine or on anything that might cause you to fall against the

machine.

Rotating and moving parts are dangerous. Keep clear of discharge area of the machine.

Never put any foreign objects, other than what the machine is intended for, into the

machine’s input ports.

Do not operate without first attaching to Trimmer system. The TC-2 is intended to be

operated with a 6” trimmer outlet, however smaller can be used with the appropriate

adaptors.

Use proper lifting and transporting devices for heavy equipment. This equipment is heavy. An

appropriate lifting device should be used.

Use caution when moving portable equipment. In some cases the machinery can be heavy

and/or may be top heavy if loaded. Portable equipment can gain momentum during

transporting and must be controlled at all times.

Always operate in a well ventilated area and as intended. This machine is intended to collect

cannabis and hemp trimmings. Use outside of intention can be dangerous.

When emptying trim and kief from bag, wear a respirator and safety glasses.

TC-2 OPERATIONAL MANUAL

4

TECHNICAL SPECIFICATIONS

Wattage: 1500 W

Max Amps: 7.8 A

Horse Power: 3 HP

Speed: 3450 RPM

Airflow Capacity: 1400 CFM

Cord and Plug: 90” with 6-15P

Voltage: 220/230 V Single Phase

Freq.: 60 Hz

Max Noise: 84dB

Inlet Size: 6”

Filter: 1 Micron

Drum Capacity: 3.61 Cubic Feet

Kief Bag Dimensions: 23” x 30” x 4mil

Drum Bag Dimensions: 30” x 30” x 4mil

Width: 26”

Length: 48”

Height: 69”

Weight: 91 lbs

TC-2 OPERATIONAL MANUAL

5

CANNISTER

FILTER ASSY

MOTOR, 3HP

CYCLONIC FUNNEL

ASSY

FRAME ASSY

IMPELLER

HOUSING

TC-2 OPERATIONAL MANUAL

6

POWER SWITCH

FILTER SCRUBBER

HANDLE

WHEEL LOCKS

CANNISTER

CLAMPS

CIRCUIT BREAKER

VIEW WINDOW

VOLUTE

CLAMP

TC-2 OPERATIONAL MANUAL

7

REMOVING FROM BOX AND INSPECTING

1. The Trim Saver is not pre-assembled. Transport Trim Saver in its packaging to

location before unpacking it. If packing crate or boxes show signs of damage,

take pictures and carefully document damage.

2. Remove all contents from boxes and drums. Verify the following;

a. Frame, Base

b. Handle

c. Frame, Upright (qty 2)

d. Wheels, Frame (qty 4)

e. Impeller Housing

f. Cyclonic Funnel

g. Wheels, Collection Drum (qty 3)

h. Canister Filter

i. End Cap for Base

j. Kief Bag

k. Canister Bag

l. Bag Clamp

m. Hose (8’)

n. Hose Clamp, 6” (qty 2)

o. Collection Drum Assy

p. Hardware Package

i. M6 x 15mm Screw (qty 32)

ii. M6 Washers (qty 32)

iii. M8 x 40mm Screw (qty 4)

iv. M8 Washers (qty 22)

v. M8 Nuts (qty 6)

vi. M8 x 20mm Screw(qty 2)

vii. M8 x 20mm Screw (qty 4)

viii. M8 x 16mm Screw (qty 12)

ix. Plastic Handle

TC-2 OPERATIONAL MANUAL

8

ASSEMBLY

1. Assemble Frame Assy.

a. Flip Lower Frame Assembly upside down, paying special

attention to not damage painted surfaces and install

Wheels, Frame (item d) using M6 x 15mm screws and M6

washers. Torque to 12 in-lbs

b. If not already installed, install End Caps (item i) into

Lower Frame Assy.

c. Assemble Frames, Upright (item c) onto Frame, Base

(item a) using M6 x 15mm screws and washers. Torque to

12 in-lbs.

d. Assemble Bracket (item b) onto Frame Assembly using

M8 x 40mm screws, M8 washers, and M8 Nuts.

TC-2 OPERATIONAL MANUAL

9

2. Assemble Canister Assy.

a. Remove Inner Drum from Canister Assy, and place

Outer Drum on its side. Install Wheels, Canister (item

g) onto drum (item o). Hand tighten wheels only.

b. Place Outer Drum on its wheels and install Plastic

Handle onto drum assy using M8 x 20mm screws, M8

washers, and M8 nuts. Pay special attention to not

over tighten.

c. Place the Inner Drum into Outer Drum of Canister Assy.

Ensure Inner Drum and Outer Drum windows line up.

Install Canister Bag (item k) in between Outer and

Inner bag.

TC-2 OPERATIONAL MANUAL

10

3. Assembly Cyclonic Funnel and Filter Canister

a. Using at least one person to lift the Impeller Housing

(item e) onto the Frame Assy, paying special

attention to line up mounting holes. Use M8 x 20mm

screws and M8 washers to secure

b. Unscrew Cyclonic Clamp and remove Lower Cyclonic

Funnel from Upper Cyclonic Funnel. Install Upper

Cyclonic Funnel to Impeller Housing (item e) using

M8 x 16mm screws and M8 washers.

i. Install Lower Cyclonic Funnel to Upper

Cyclonic Funnel using the Cyclonic Funnel

Clamp.

c. Fasten Canister Filter (item h) to Impeller Housing

(item e) using M8 x 16mm screws and M8 washers.

TC-2 OPERATIONAL MANUAL

11

4. Final Assembly

a. Fasten Collection Canister to Cyclonic Funnel using

two drum lock handles. Note: the two should fit

together loosely.

b. Secure Kief Bag (item j) to the bottom of the Filter

(item h) using the bag clamp (item l).

c. Remove screw on outlet of Cyclonic Funnel Assy and place to the side. Install hose and

use hose clamp to secure hose to Cyclonic Funnel.

TC-2 OPERATIONAL MANUAL

12

BEFORE OPERATION

Inspection

Inspect Trim Saver for obvious damage.

Ensure Filter Bag is secured to Filter Canister

Check Cord and Plug for damage.

Verify hose is securely attached to both Trim Saver and Trimmer using 6”hose clamps.

OPERATION

The TC-2, Trim Saver is a very simple vacuum which ensures the trim does not touch the impellers

during operation. This results in a higher quality trim. Kief and smaller particles will still pass through

the impeller chamber and will be collected by the Kief Bag.

To operate, simply turn on using the Power Switch. During operation, the Filter will ensure air quality

remains high, however, may end up getting clogged with particulate matter. During heavy operation,

the filter should be “scrubbed”periodically. This is done by rotating the Scrubber Handle a couple of

times. This knocks the kief from the inside of the filter which is then captured in the bag.

The Canister was designed to capture trim in a bag locate within in between the Inner Canister Drum

and the Outer Canister Drum. Levels should be checked periodically to ensure that the Canister is not

filled. This can be done through the window. Once approx. only 80% filled, The Trim should be

collected and the bag replaced.

When completed, simply turn Power Switch off.

TC-2 OPERATIONAL MANUAL

13

CLEANING

Cleaning of your machine will ensure that your TC-2 can be used for years to come. We suggest a light

cleaning daily after each shift and more thorough cleaning every week and/or before being stored.

Use standard water based, non-caustic, FDA Food grade approved detergents and/or clean water to

clean machine.

Daily Cleaning

1. Unplug Machine from Power Source.

2. With compressed air, blow all loose material from all surfaces of machine.

Caution: Wear eye protection when using compressed air. Failure to do so, can result in eye

damage.

3. Scrub inside of Filter by operating Scrubber Handle for at least 5 rotations.

Deep Cleaning

BE Hemp recommends pressure washing with light detergent weekly, however, deep cleaning

requirements should be determined by operator.

1. Unplug machine from power source.

2. Remove Filter Assy by unscrewing. See Assembly instruction.

3. Remove Lower Volute from Volute Assy by unscrewing Volute Clamp.

4. Place bag over Motor Assy and Cord.

5. Pressure wash until all dirty surfaces are no longer dirty….

6. Pressure wash removed components as required.

7. Dry with towel and then wipe all surfaces with alcohol to remove water spots.

TC-2 OPERATIONAL MANUAL

14

REPLACEMENT PARTS

BE Hemp is happy to supply parts, however, also want to make the best effort to allow customers to

re-supply themselves, as desired with standard consumable parts. If you should need additional

support or other parts not on this list, BE Hemp is happy to offer support in whatever fashion needed.

Item

Part Number

Description

Qty

Notes

1

5-0001-01

Filter Assy

1

2

5-0002-01

Hose, 6”x 8’

1

Not pictured

3

5-0003-01

Bag Clamping Strap

1

Not pictured

4

E-5001-01

Bag, Canister

1

5

E-5001-02

Bag, Kief

1

Not pictured

6

45955K73

Hose Clamp, 6”

2

Not Pictured

1

2

4

5

3

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Case

Case J-72 Operator's manual

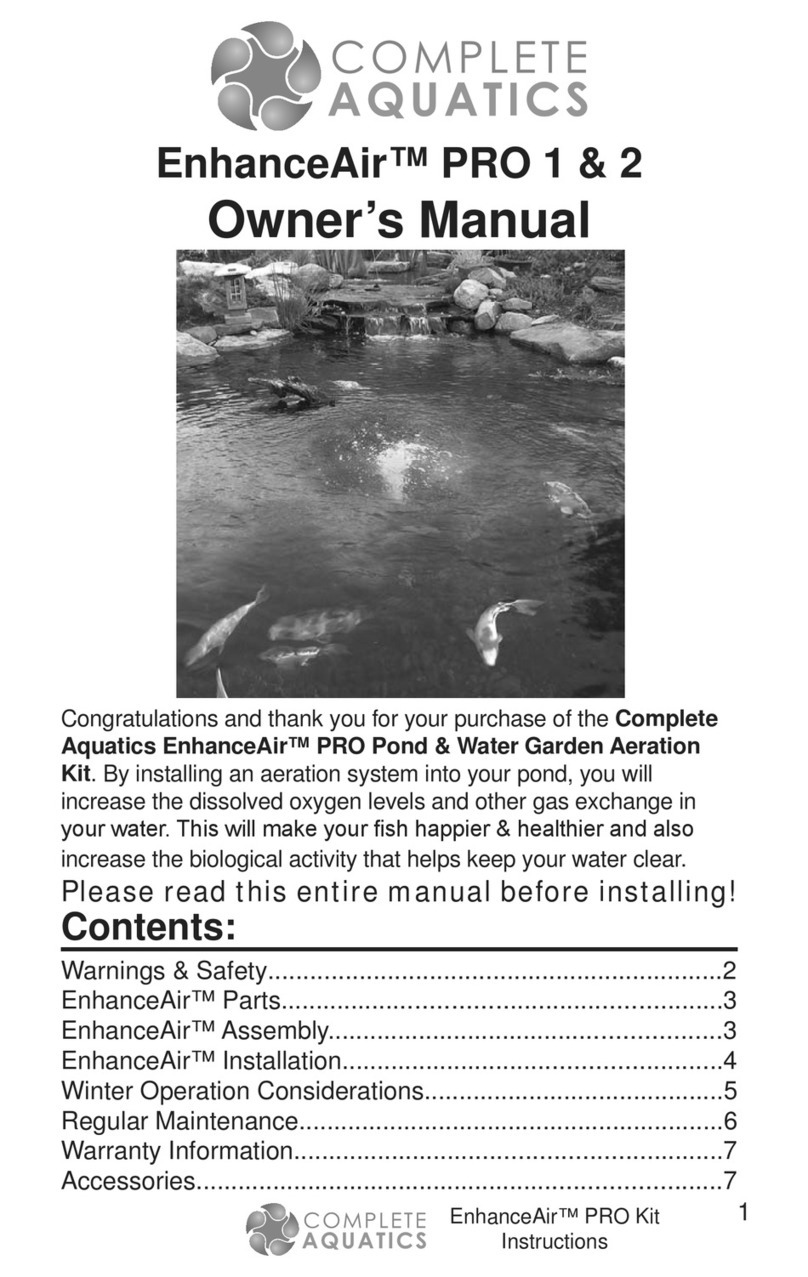

Complete Aquatics

Complete Aquatics EnhanceAir PRO 1 owner's manual

Behlen Country

Behlen Country M-15 Assembly instructions

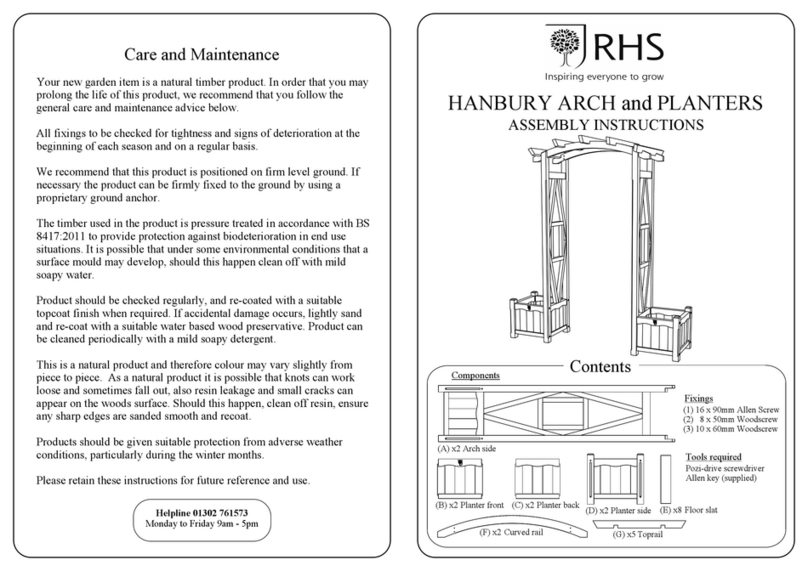

RHS

RHS HANBURY ARCH and PLANTERS Assembly instructions

DeWalt

DeWalt DWH079D instruction manual

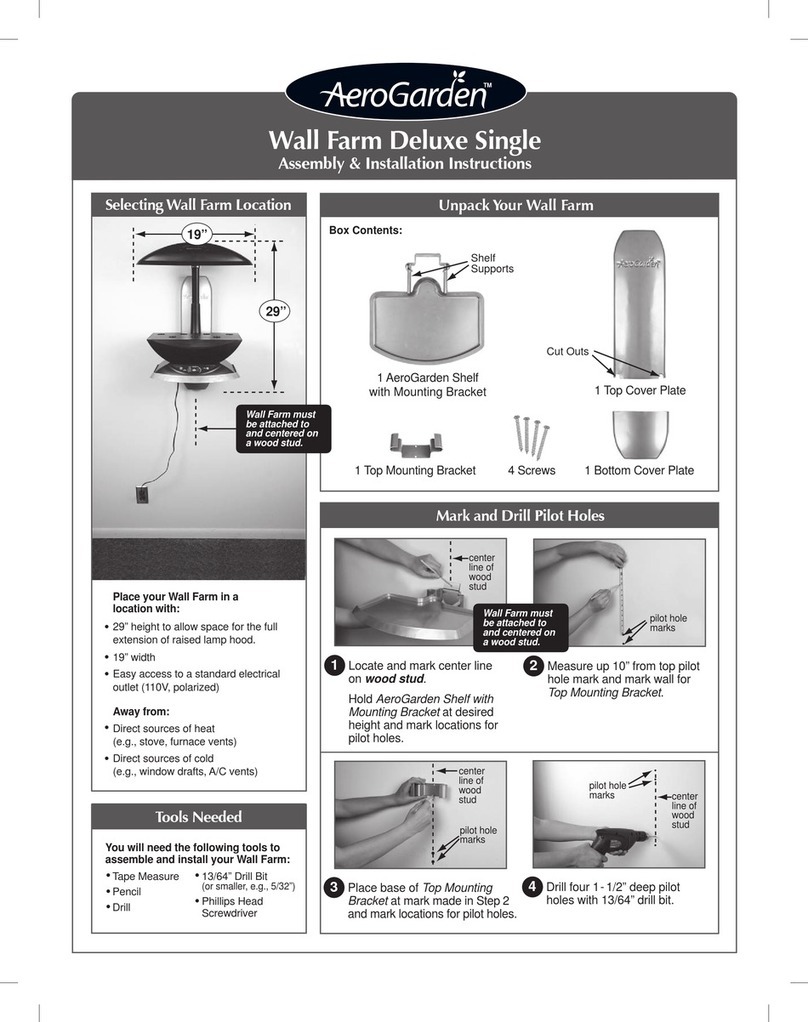

AeroGarden

AeroGarden Wall Farm Deluxe Single Assembly/installation instructions