BeaconMedaes MEGA 2 Manual

Part No. 6-847684-00 Rev. D01 Pg. 1

MEGA 2

®

Medical Electronic Gas Alarm

Installation, Operation, and Maintenance Instructions

MAN 01-027

2Part No. 6-847684-00 Rev. D01

Table of Contents

Introduction

Alarm Modular Components...............................................................................4

Definitions...........................................................................................................5

Alarm Configuration............................................................................................6

Unpacking ..............................................................................................................7

Rough-In Installation

Alarm Panel Back Box Mounting........................................................................8

Remote Sensor Back Box Mounting ..................................................................9

Pipeline Connection

Sensor Module .............................................................................................9

Pressure Switch..........................................................................................10

Wiring Installation

General Requirements......................................................................................11

Wire Type and Size ..........................................................................................11

Wire Routing Inside The Alarm Panel ..............................................................11

Determining Number Of Conductors................................................................12

Wiring Schematics............................................................................................13

Alarm Wiring Examples ....................................................................................13

Finish Installation

Line Voltage Electrical Connection...................................................................27

Front Panel Installation.....................................................................................27

Sensor Installation

Remote Sensors.........................................................................................28

Local Sensors.............................................................................................29

Remote Sensor Wiring .....................................................................................29

Source Equipment Wiring.................................................................................30

Field Wiring Cable Shield Grounding ...............................................................31

Building Automation System Wiring

Multi-Signal Module Relays........................................................................32

Digital Display Module High/Low Relays....................................................32

Annunciator Module General Fault Relay ..................................................32

Annunciator Module Auxiliary Relay (optional)...........................................32

Johnson Controls METASYS® System......................................................33

Slave Panel Wiring ...........................................................................................33

3

Part No. 6-847684-00 Rev. D01

Table of Contents

Operation

Start-Up and Checking .....................................................................................34

Set-Up Procedure

Digital Display Module................................................................................35

Multi-Signal Module....................................................................................38

Monitoring Mode

Digital Display Module................................................................................40

Multi-Signal Module....................................................................................41

Testing

Digital Display Module......................................................................................41

Multi-Signal Module..........................................................................................42

Power Supply Module ......................................................................................43

Troubleshooting Guide ........................................................................................45

Replacement Parts

Front Panel Components .................................................................................50

Back Box Components.....................................................................................51

Sensor Components.........................................................................................52

Field Installation Kits.........................................................................................53

4Part No. 6-847684-00 Rev. D01

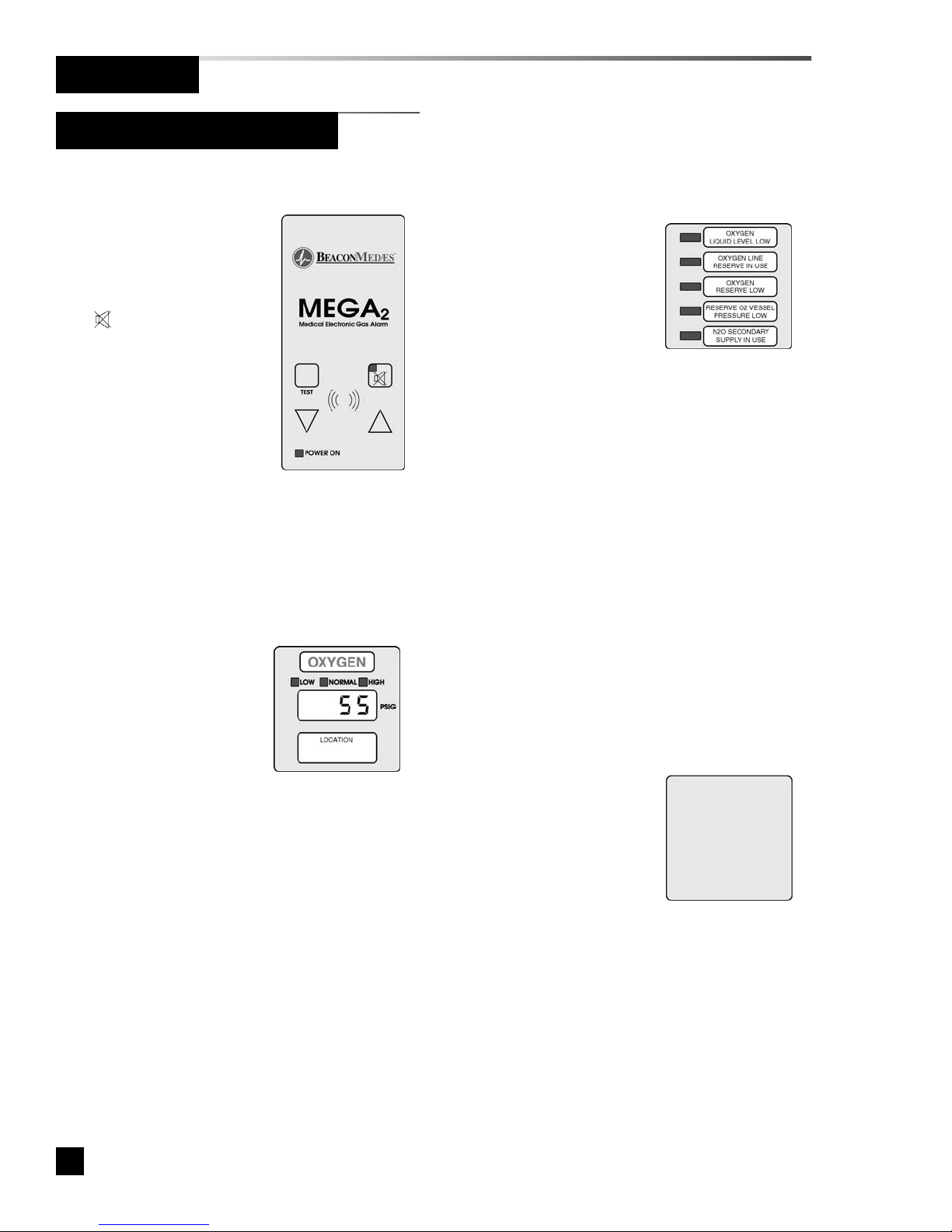

Annunciator Module

Features:

• User interface

pushbuttons for alarm

panel TEST function,

audible alarm MUTE

and set-up increase

!and decrease ".

• Green alarm panel

POWER ON and red

audible alarm mute

indicators.

• Audible alarm with

volume control.

• Network wiring terminals and test

connector.

• General fault relay that activates on any

alarm panel fault condition.

Alarm Modular Components

Introduction

Digital Display Module

Features:

• Digital LED readout

of system pressure

signal transmitted

from sensor module.

• Adjustable

brightness of digital

LED readout.

• Individual LED’s indicate when system

pressure/vacuum is HIGH (red), LOW

(red), or NORMAL (green).

• Programmable high and low alarm

thresholds.

• Adjustable audible alarm mute duration.

• Individual high and low alarm dry-contact

relay outputs.

• Can transmit pressure or vacuum signal to

another digital display module for remote

applications.

• Can be networked to communicate with a

personal computer or Johnson Controls

Metasys® building automation

system(using Metasys Integrator).

Multi-Signal Module

Features:

• Monitors up to five

normally closed dry-

contact switch

signals.

• Separate indicators

for each of five

signals for normal

(green) or abnormal (red) conditions.

• Available (optional) with separate dry-

contact relay outputs for each of five

signals.

• Can be networked to communicate with a

personal computer or Johnson Controls

Metasys® building automation system

(using Metasys Integrator).

Blank Module

Features:

• Reserves a space in

alarm panel for

future expansion.

• Used to fill unused

alarm panel module

locations.

5

Part No. 6-847684-00 Rev. D01

Definitions

Area Alarm Panel

Alarm panel that monitors medical gas and

vacuum systems serving a specific area.

Auxiliary Fault Relay (optional)

A single-pole double-throw dry-contact relay

output located on annunciator module. Used

to activate a remote alarm or building

management system. The relay will activate

whenever ANY audible alarm on panel is in

progress. Pressing MUTE button on

annunciator module deactivates relay until

audible alarm is again reactivated. Relay

contact ratings are 2 A @ 30 VDC/0.5 A @

125 VAC.

Dry-Contact

An electrical contact that is isolated or

unconnected from any electrical source.

General Fault Relay

A single-pole double-throw dry-contact relay

output located on annunciator module. Used

to activate a remote alarm or building

management system. The relay will activate

whenever ANY audible alarm on panel is in

progress. Unlike Auxiliary Fault Relay,

pressing MUTE button on annunciator

module WILL NOT deactivate relay. The

General Fault Relay will deactivate only after

alarm condition is corrected and alarm panel

resumes normal status. Relay contact ratings

are 2 A @ 30 VDC/0.5 A @ 125 VAC.

LED

Light Emitting Diode

Local Sensors

Pressure/vacuum sensors that are mounted

inside alarm panel box. The sensor rough-in

must be piped to medical gas/vacuum

pipelines.

Master Alarm Panel

Alarm panel that monitors medical gas and

vacuum source equipment and main pipelines.

Remote Sensors

Pressure/vacuum sensors that are mounted

outside of alarm panel box. Sensor rough-ins

may be mounted separately or ganged together

near pressure/vacuum pipelines. Sensors must

then be wired to alarm panel.

All MEGA2 alarm panels are factory pre-

configured. The configuration of alarm panel

varies dependent upon customer’s

requirements.

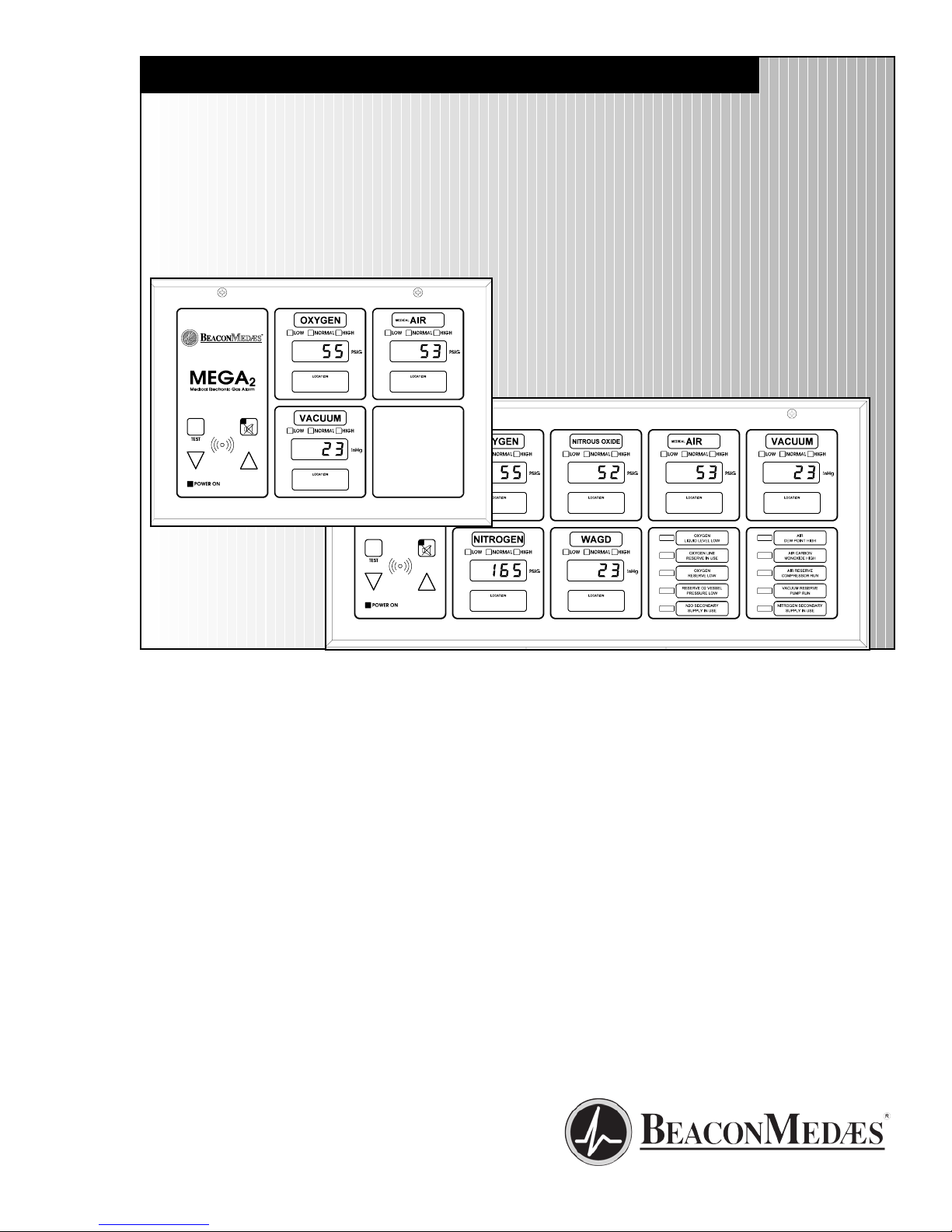

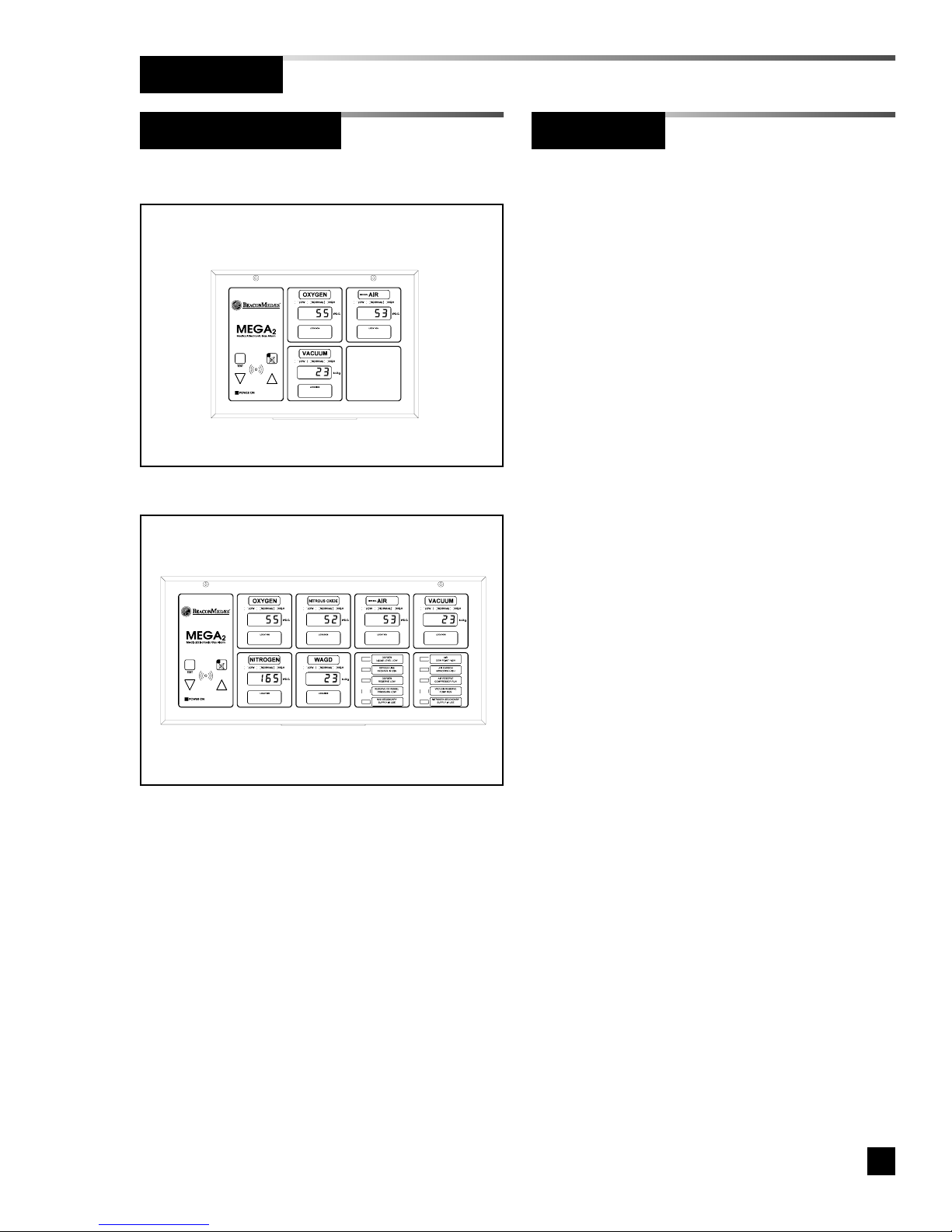

Two sizes of alarm panels are available. The

small alarm panel (Figure 1) will accommodate

an annunciator module with four alarm

modules. The large alarm panel (Figure 2) will

accommodate an annunciator module with

eight alarm modules.

Figure 1: Four Module Panel

Figure 2: Eight Module Panel

Alarm Configuration

Introduction

6Part No. 6-847684-00 Rev. D01

Alarm Configuration

Introduction

An alarm panel may consist of any

combination of digital display modules, multi-

signal modules, or blank modules.

If alarm panel is configured with digital display

modules, pressure/vacuum sensors will be

included for connection to pressure/vacuum

pipeline (except for 6-M2N).

Sensors may be located inside alarm panel

rough-in box (local sensors) or outside alarm

panel rough-in box (remote sensors).

Local sensors must be connected to

pressure/vacuum pipelines via copper tubing

(Figure 3). Remote sensor may be mounted

near pressure/vacuum pipeline and then wired

to alarm panel (Figure 4).

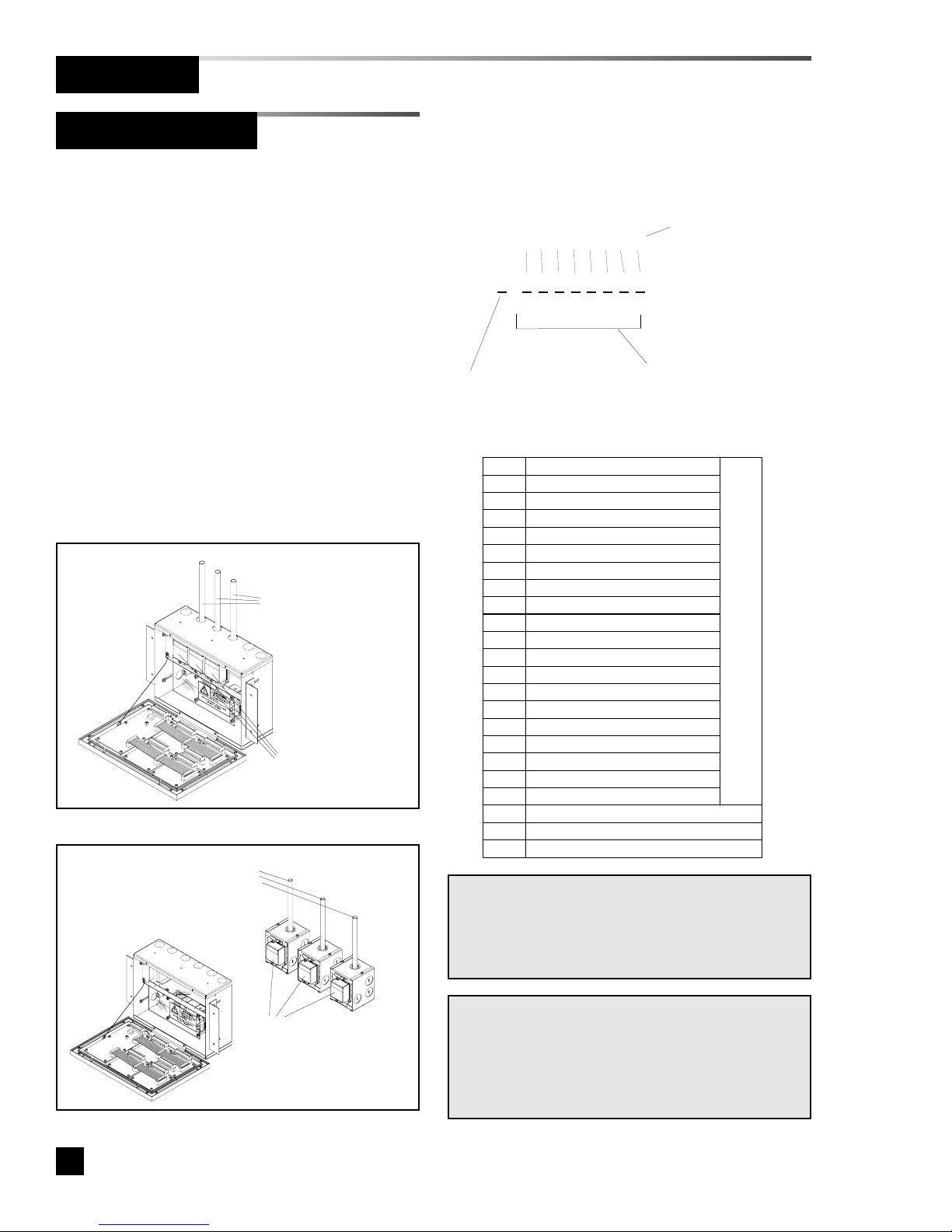

The required alarm panel configuration may be

specified within the part number scheme as

described below:

Part Number Scheme:

6-M2 ?-? ? ? ? ????

Figure 3: Local Sensors

Figure 4: Remote Sensors

1 2 3 4 5 6 7 8 Position within alarm

panel (Figures 1 and 2)

L = Local Sensors

R = Remote Sensors

N = No Sensors

(Slave Applications)

Designates type of

alarm panel component

from chart below

O

OXYGEN

D

OXYGEN - 100 PSI

X

NITROUS OXIDE

A

MEDICAL AIR

F

MEDICAL AIR - 100 PSI

5

AIR (ISO)

7

LABORATORY AIR

2

O2-CO2

4

O2-He

C

CARBON DIOXIDE

G

CARBON DIOXIDE - 100 PSI

1

CO2-O2

3

He-O2

H

HELIUM

V

VACUUM

6

VACUUM (ISO)

8

LABORATORY VAC

W

WAGD

N

NITROGEN

9

INSTRUMENT AIR

DIGITAL DISPLAY MODULES

M

MULTI-SIGNAL MODULE

R

MULTI-SIGNAL MODULE W/ RELAYS

B

BLANK

Sensor modules are

mounted inside the

alarm panel box

Copper tubes connect to

pressure/vacuum

pipelines

Sensors have separate

mounting boxes for mounting

near pressure/vacuum

pipeline and then must be

wired to alarm panel

Copper tubes connect to

pressure/vacuum

pipelines NOTE:

When an alarm panel is ordered with either local

or remote sensors, ALL sensors will either be

local or remote. Alarm panels with a combination

of local and remote sensors are not available.

NOTE:

Alarm panel components in table above are listed

in order of criticality. Unless otherwise specified,

the most critical component will fill position one,

the next less critical component will fill position

two, etc. etc.

7

Part No. 6-847684-00 Rev. D01

Introduction

Alarm Configuration

Example: P/N 6-M2R-OAVB

Example: P/N 6-M2R-OXAVNWMM

Unpacking

1. Remove alarm panel back box from

shipping carton. Do not remove alarm

front panel (wrapped in anti-static

shipping bag).

2. If alarm panel is configured with

remote sensors, remove sensor

rough-in and mounting box from small

individual boxes shipped within main

alarm panel shipping carton.

3. Store all other components not

removed in steps 1 and 2 inside

shipping carton in a safe place for

installation later.

4. Install back box and sensor rough-in

as described in this manual.

8Part No. 6-847684-00 Rev. D01

Rough-In Installation

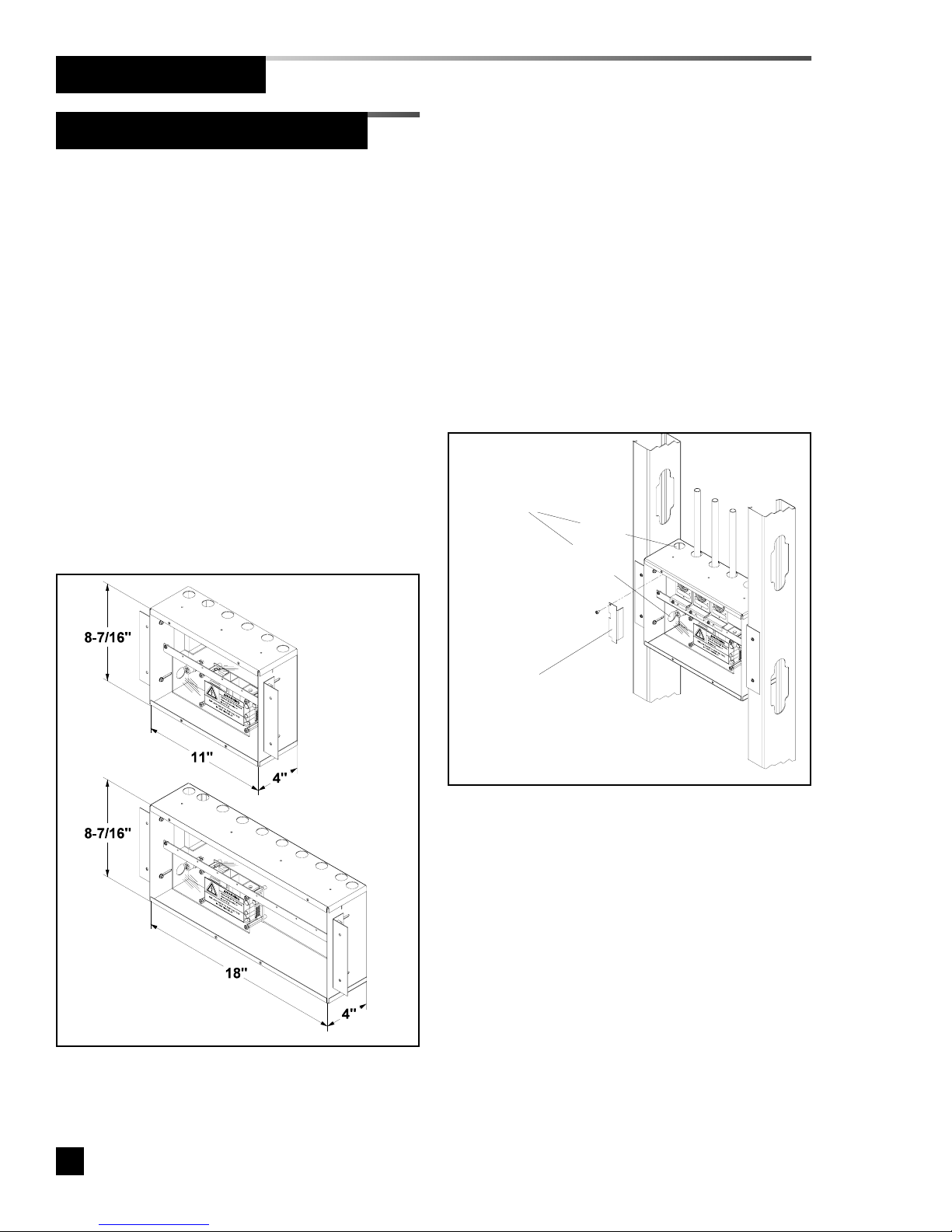

The alarm panel back box will be one of

two sizes. The height and depth of both

size boxes are the same. Refer to Figure

5 below for dimensions of both boxes.

If alarm panel is configured with digital

display modules, sensor assemblies will

be included for connection to

pressure/vacuum pipeline.

Sensors may be located inside alarm

panel rough-in box (local sensors) or

outside alarm panel rough-in box (remote

sensors).

If equipped with local sensors, copper

tubes will extend from top of back box to

be connected to pressure/vacuum

pipeline.

Figure 5: Alarm Panel Back Box Dimensions

Alarm Panel Back Box Mounting

1. Prepare a rough wall opening large

enough to accommodate alarm panel

back box. Alarm panel back box must

have rigid vertical members for

support on both left and right sides.

Power to alarm panel shall enter

through lower left or top left conduit

hole in back box.

2. Remove cardboard dust cover and

insert alarm panel back box into wall

opening. Secure with fasteners

suitable for vertical supports as shown

in Figure 6.

3. Mounting brackets on each side of

back box are adjustable and factory

preset for 5/8” thick drywall. After

drywall installation, front edge of back

box should be flush with finished

surface of wall. If needed, make any

necessary bracket adjustments at this

time. Refer to Figure 7.

4. Reinstall cardboard dust cover.

Figure 6: Back Box Mounting

Two choices of

conduit holes for

entrance of AC

mains power

Small box - (four modules)

Large box - (eight modules)

top entry

side entry

For top entry, remove

shield for access.

Reinstall shield after

connection is made

9

Part No. 6-847684-00 Rev. D01

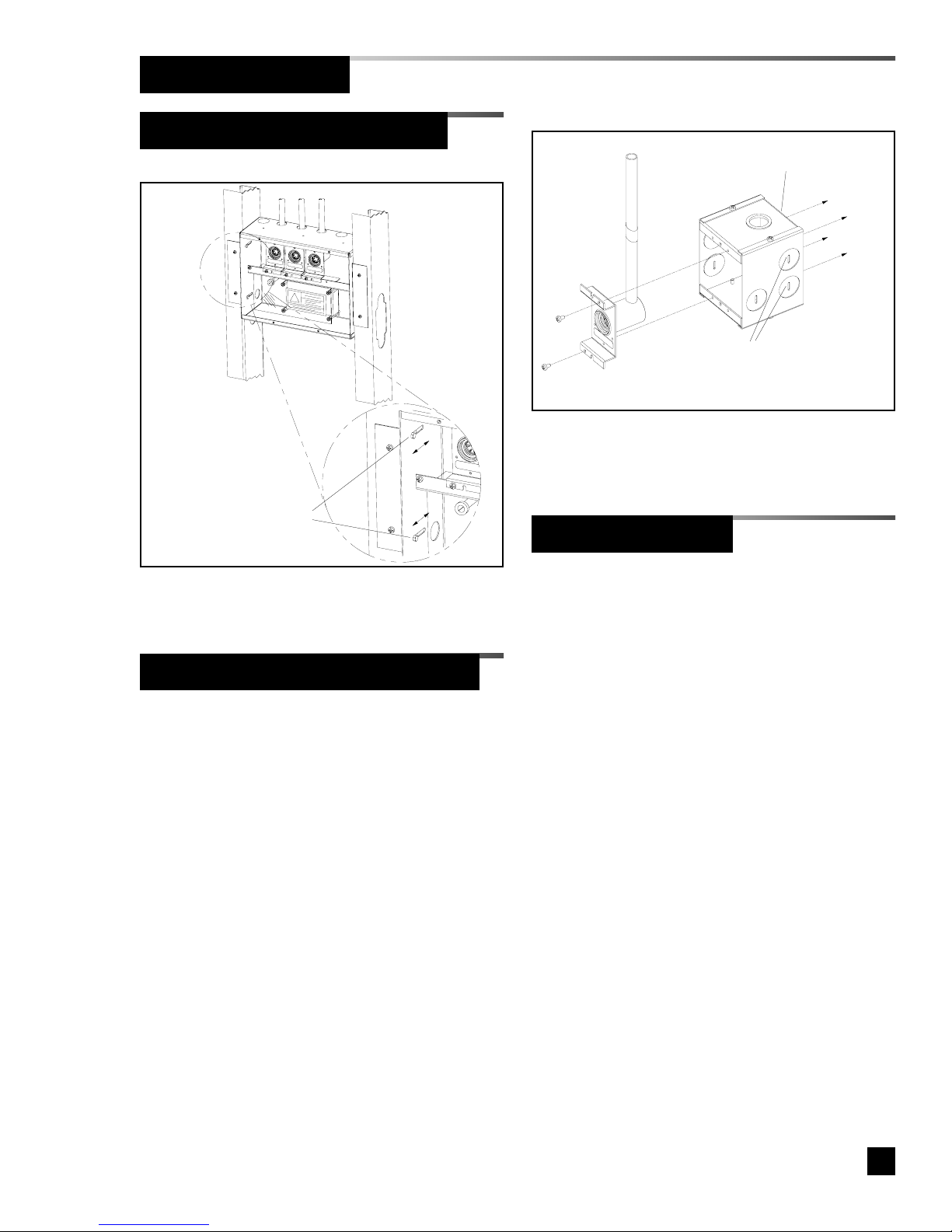

Figure 7: Mounting Bracket Adjustment

Rough-In Installation

Pipeline Connection

Figure 8: Remote Sensor Back Box

Sensor Module

1. Braze copper extension tubes from

sensor rough-in to appropriate

pressure/vacuum piping system drops

as shown in Figure 9. Braze

connections per procedures required

by NFPA 99 or CAN/CSA-Z305.1.

Use appropriate measures to prevent

overheating and damage to internal

components of sensor rough-in

assemblies.

2. Perform standing pressure tests and

cross connection tests as required by

NFPA and CSA.

Loosen screws to

adjust back box depth

(same each side)

Four holes in back of box are

provided for surface mounting

Alarm panels ordered with remote

sensors are provided with separate metal

boxes for each sensor. Mount each

sensor box as follows:

1. Remove sensor rough-in from

mounting box (Figure 8).

2. Using four mounting holes provided,

attach box to a wall or other structural

support. (fasteners by others).

3. Reinstall sensor rough-in.

Rear conduit knockouts

(either side) are recommend-

ed for sensor wiring

Alarm Panel Back Box Mounting

Remote Sensor Back Box Mounting

10 Part No. 6-847684-00 Rev. D01

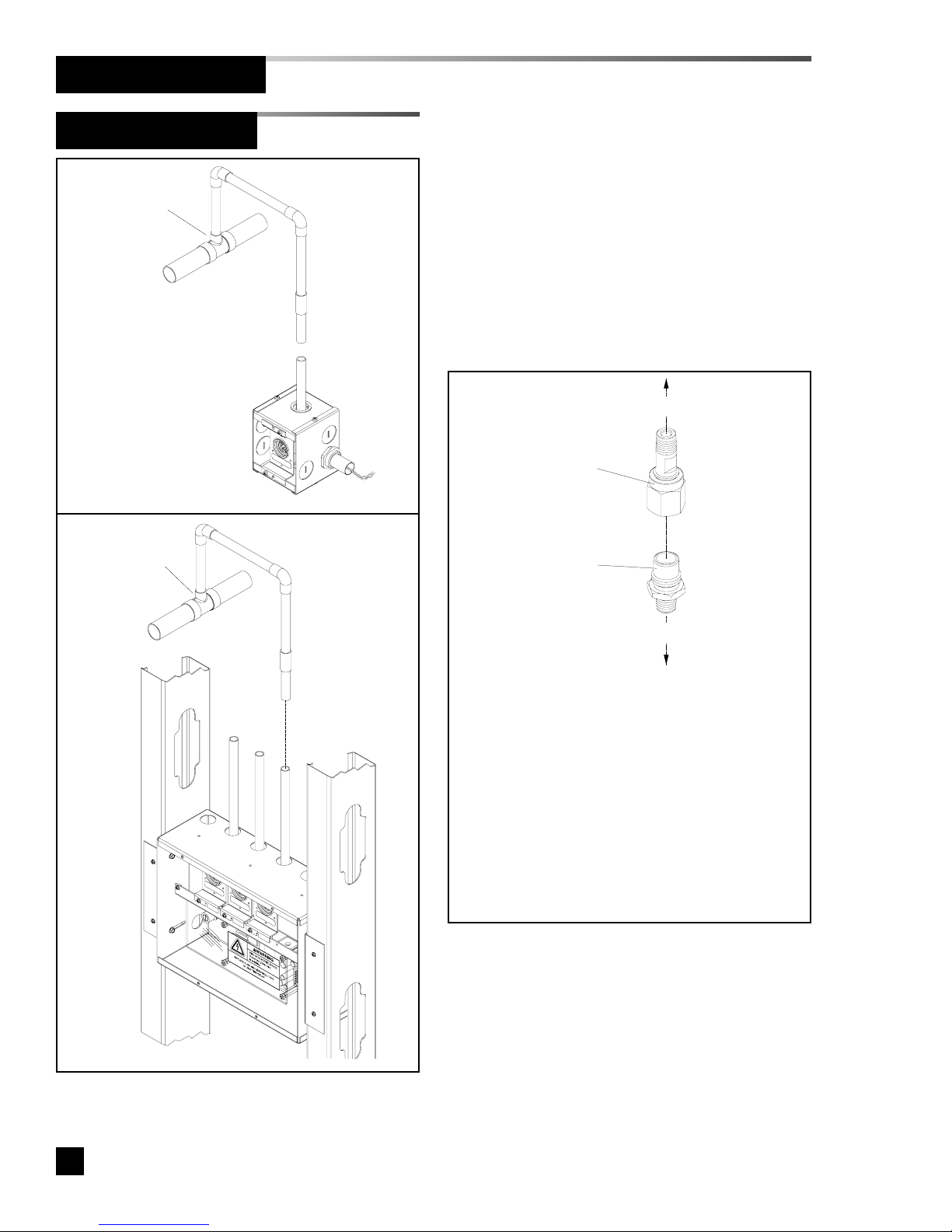

Rough-In Installation

Pipeline Connection

Pressure Switch

DISS (Diameter Index Safety System)

connection kits are recommended for use

when attaching pressure switches to

pressure/vacuum pipeline. To utilize

these kits, a 1/4-18 NPT female thread

must be provided in piping system. All

necessary components are included in

each gas specific kit as shown in Figure

10.

Figure 10: Pressure Switch Pipeline Connection

DISS Kit P/N Gas Service

6-120004-10 Oxygen

6-120004-11 Nitrous Oxide

6-120004-12 Medical Air

6-120004-13 Vacuum

6-120004-14 Nitrogen

6-120004-18 Instrument Air

6-120004-19 Evac. (WAGD)

6-120004-20 Carbon Dioxide

6-120004-21 CO2/O2

6-120004-22 O2/CO2

6-120004-23 He/O2

6-120004-24 O2/He

6-120004-25 Helium

To pipeline

To pressure switch

DISS male

body

with check

DISS nut

and nipple

Figure 9: Sensor Pipeline Connection

Connection

should be made

on top of pipe

Horiz. run of pipeline

Horiz. run of pipeline

Connection

should be made

on top of pipe

REMOTE SENSOR

LOCAL SENSOR

11

Part No. 6-847684-00 Rev. D01

Wiring Installation

• Power all alarms from life safety

branch of emergency power system as

required by applicable standards.

• Protect all wiring from physical

damage by raceways or conduit as

required by applicable standards.

• Wire master panels directly to

switches or sensors as required by

applicable standards.

• Wiring runs should be made with color

coded wire. Record color, signal, and

source of signal for each wiring lead to

aid in connection of alarm finish

components.

• Avoid installing alarm panels near

radio transmitters, electrical motors, or

switchgear.

Figure 11: Wire Routing

General Requirements

Wire Type And Size

Wire Routing

Holes for entrance of

low voltage field wiring

All low voltage MEGA2 wiring must meet

the following criteria:

• Copper wire no smaller than 22 AWG.

• Circuit length not to exceed 5000 feet.

• Cable must be twisted pair shielded

type. Multi-pair cables within one

common shield are acceptable.

Two 7/8” holes are provided for entrance

of AC mains power. One hole on lower

left side and one hole on top left of alarm

panel back box. NO OTHER HOLES

SHOULD BE PUNCHED OR USED. If

hole on top left is used, remove shield for

access. Reinstall shield after connection

is made.

Several additional 7/8” holes are provided

on right side of top panel for entrance of

low voltage field wiring. Refer to Figure

11.

Two choices of

conduit holes for

entrance of AC

mains power

top entry

side entry

For top entry, remove

shield for access. Reinstall

shield after connection is

made

12 Part No. 6-847684-00 Rev. D01

Wiring Installation

MEGA2 alarm panels can be ordered in

numerous configurations. The following

rules along with references to this

manual’s schematics clarify wiring

requirements.

• All alarm panels require 100 to 250

VAC 50/60 Hz. power. Refer to

Wiring Schematic 1 (Pg. 14).

• Sensor modules send

pressure/vacuum signals to digital

display modules. If the alarm panel

configuration contains digital display

modules and sensor modules that are

remotely mounted, two conductors are

required between EACH sensor

module and digital display module. A

sensor module can not be wired to

more than one digital display module.

Refer to Wiring Schematic 2 (Pg. 15).

• Multi-signal modules monitor signals

from dry normally closed switch/relay

contacts. These signals can originate

at source equipment or from pressure

switches mounted on main

pressure/vacuum pipelines. When two

master alarms are required, the same

switch/relay contacts can be wired to

both alarm panels. Two conductors

are required for each alarm panel for

each signal. That is, for any given

signal, two wires will route to first

alarm panel and another two wires will

route to second panel. Both pairs of

wires will originate from switch/relay

contacts. This wiring is duplicated for

each source equipment/pressure

switch signal. Refer to Wiring

Schematics 3 and 8 (Pgs. 16 and

20).

Determining Number Of Conductors

• Two panels may be connected

together so digital display module

pressure reading(s) of first panel will

be duplicated at second panel. Two

conductors for EACH digital display

module must be routed from first

alarm panel to second alarm panel.

Refer to Wiring Schematic 4 (Pg. 17).

• If an alarm panel is to be connected to

a Johnson Controls METASYS®

system, two conductors must be

connected between alarm panel’s

annunciator module and monitoring

system’s two-wire data bus. Refer to

Wiring Schematic 9 (Pg. 21).

• Most building automation systems are

capable of monitoring dry normally

closed relay contacts. If alarm panel

is to be connected to this type of

building automation system, two

conductors must be routed from alarm

panel to building automation system

for each signal monitored. Refer to

Wiring Schematics 5,6, and 7 (Pgs.

18 and 19).

13

Part No. 6-847684-00 Rev. D01

Wiring Schematics Alarm Wiring Examples

Wiring Installation

The wiring schematics listed below are

provided. Call BeaconMedæs at 1-888-

4MEDGAS (1-888-463-3427), for technical

support .

1. Power Supply Module

2. Sensor Module to Digital Display

Module

3. Multi-Signal Module

4. Remote Pressure/Vacuum

Transmission

5. Multi-Signal Module Relays

6. General Fault/Auxiliary Relays

7. Digital Display Module High/Low Relays

8. Remote Pressure/Vacuum Switches

9. Johnson Controls METASYS®

Wiring examples of master/area alarms for

the following systems are provided:

1. Two master alarm panels with digital

displays - high-pressure manifold/no

reserve (oxygen shown) - Pg. 22.

2. Two master alarm panels with digital

displays - liquid manifold/high-pressure

reserve (oxygen shown) - Pg. 23.

3. Two master alarm panels with digital

displays - liquid bulk/liquid reserve

(oxygen shown) - Pg. 24.

4. Two multi-signal master alarm panels -

duplex air compressor and vacuum

pump systems - Pg. 25.

5. Area alarm panel - gas services for

oxygen, medical air, and vacuum - Pg.

26.

14 Part No. 6-847684-00 Rev. D01

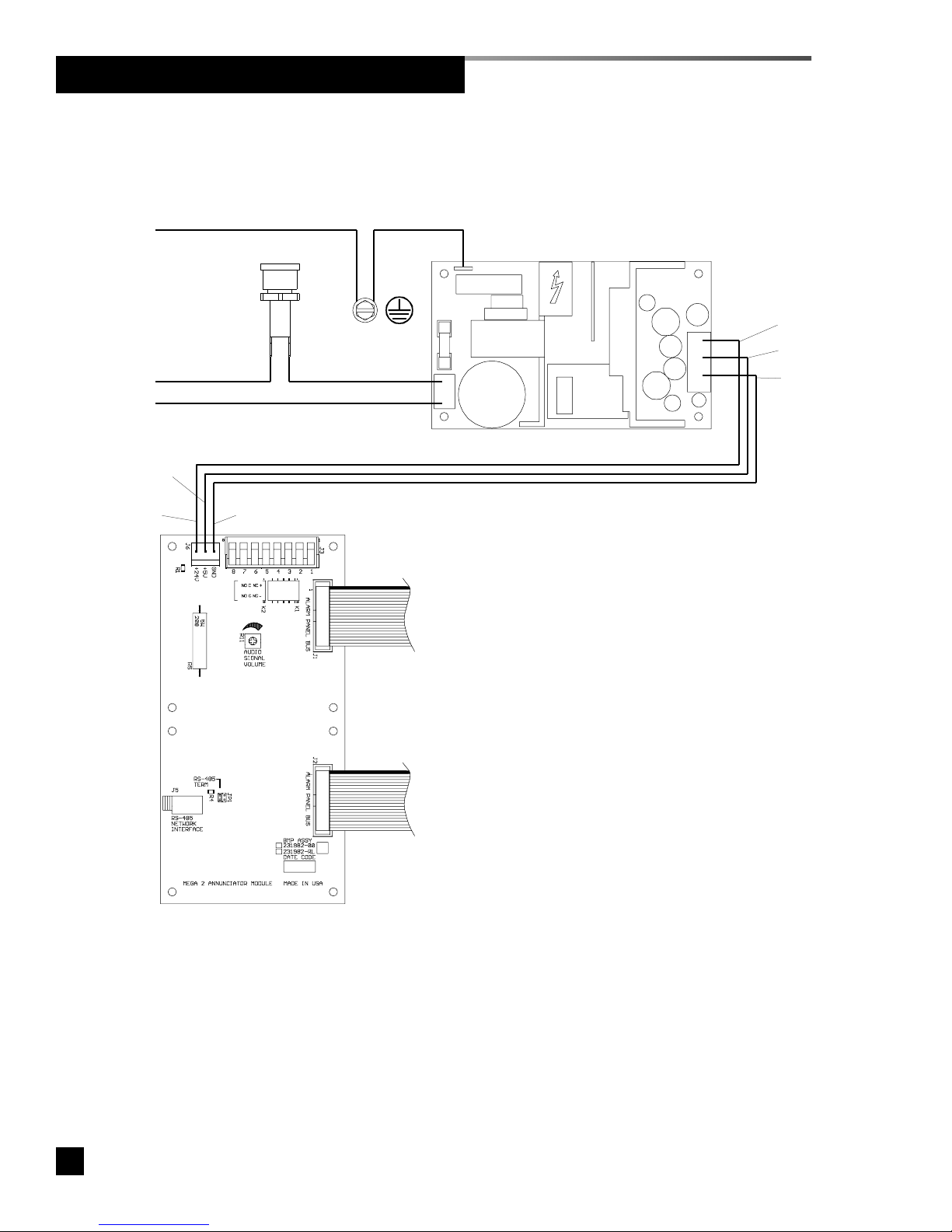

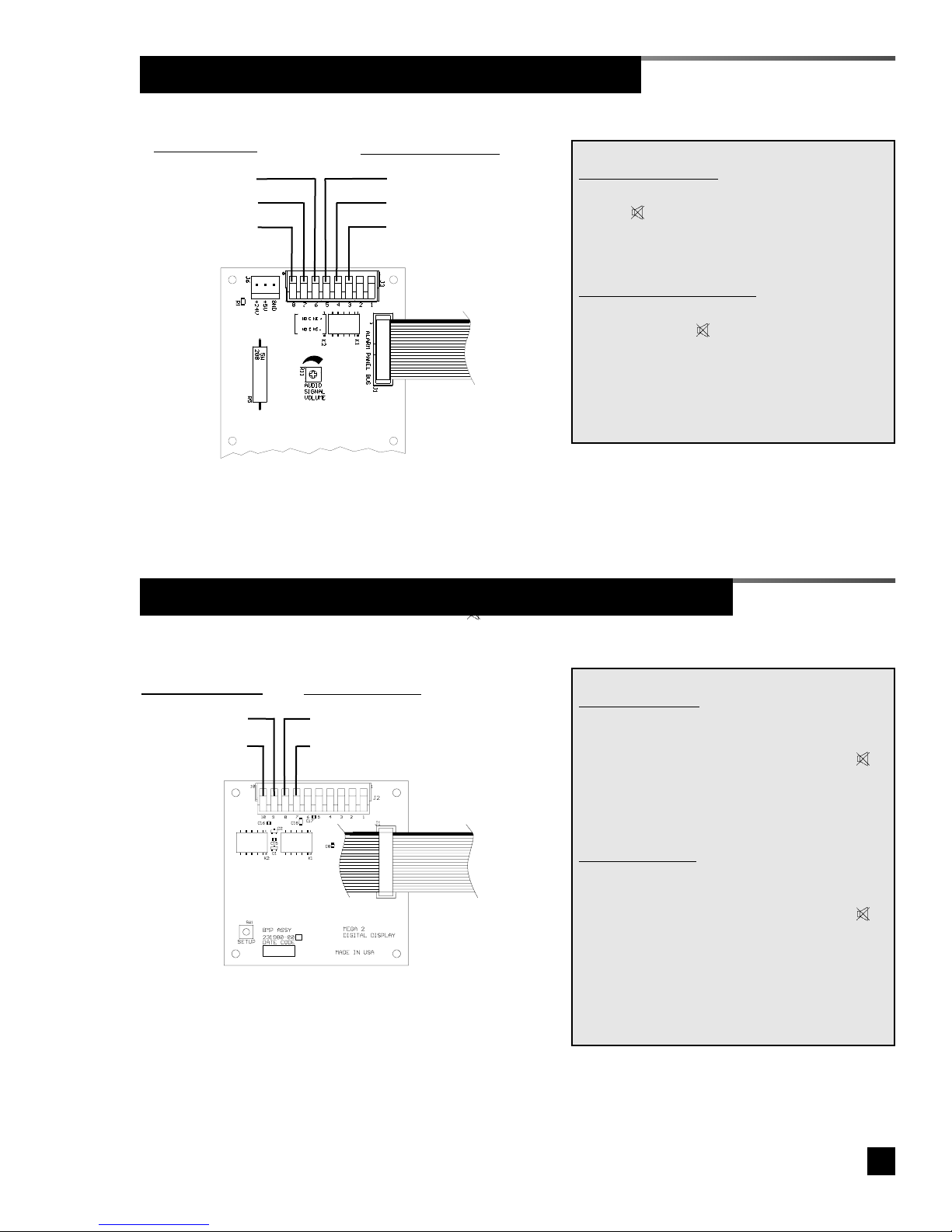

Wiring Schematic 1: Power Supply Module

Annunciator Module

20-wire ribbon cable

to adjacent module

20-wire ribbon cable

to adjacent module

Power Supply

Fuse Holder

Ground (green)

Line (black)

Neutral (white)

3-wire power supply harness

120V AC Mains Power Connections

Ground

Screw

Red

Orange

Black

Red

Orange

Black

15

Part No. 6-847684-00 Rev. D01

Wiring Schematic 2: Sensor Module to Digital Display Module

Digital Display Module

Digital Display Module Remote sensor mounting box

(remote from alarm panel)

Local sensor

(inside alarm panel back box)

2-pin polarized connector

2-pin polarized connector

ribbon to

adjacent

module

LOCAL SENSOR

REMOTE SENSOR

ribbon to

adjacent

module

*Sensor pigtail

Sensor pigtail

(provided)

Wire nuts

Field wiring

(by others)

*NOTE:

Sensor pigtails for local sensors

are factory connected to digital dis-

play module.

Pin 5 - red (+)

Pin 6 - black (-)

Pin 5 (+)

Pin 6 (-)

NOTE:

Field wiring cable shields must be grounded at

only one end, inside alarm panel back box. Refer

to page 31 for details.

16 Part No. 6-847684-00 Rev. D01

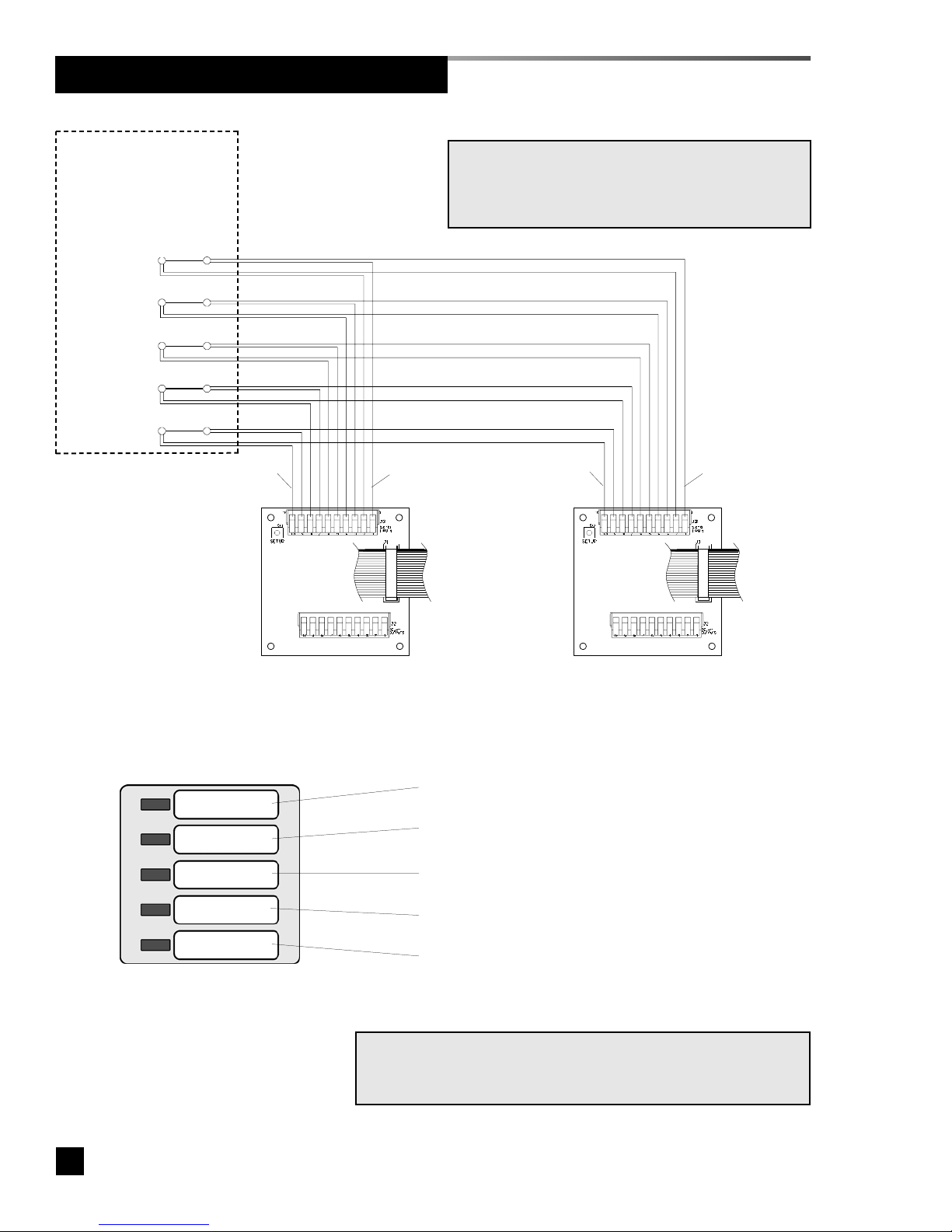

Wiring Schematic 3: Multi-Signal Module

SIGNAL 1

SIGNAL 2

SIGNAL 3

SIGNAL 4

SIGNAL 5

Dry normally-closed

contacts at source

equipment or line

pressure switches

COM +

COM +

COM +

COM +

COM +

ribbon to

adjacent

module

ribbon to

adjacent

module

Pin 1

Pin 10 Pin 1

Pin 10

Multi-Signal Module

at FIRST master alarm

panel

Multi-Signal Module

at SECOND master alarm panel

SIGNAL 1 - pin 1 (+), pin 2 (COM)

SIGNAL 2 - pin 3 (+), pin 4 (COM)

SIGNAL 3 - pin 5 (+), pin 6 (COM)

SIGNAL 4 - pin 7 (+), pin 8 (COM)

SIGNAL 5 - pin 9 (+), pin 10 (COM)

NOTE:

Installer assigns source signals to desired front panel locations

and installs provided labels (Refer to Figure 23, page 31).

Multi-Signal Module front panel

NOTE:

Field wiring cable shields must be grounded at

only one end, inside alarm panel back box. Refer

to page 31 for details.

17

Part No. 6-847684-00 Rev. D01

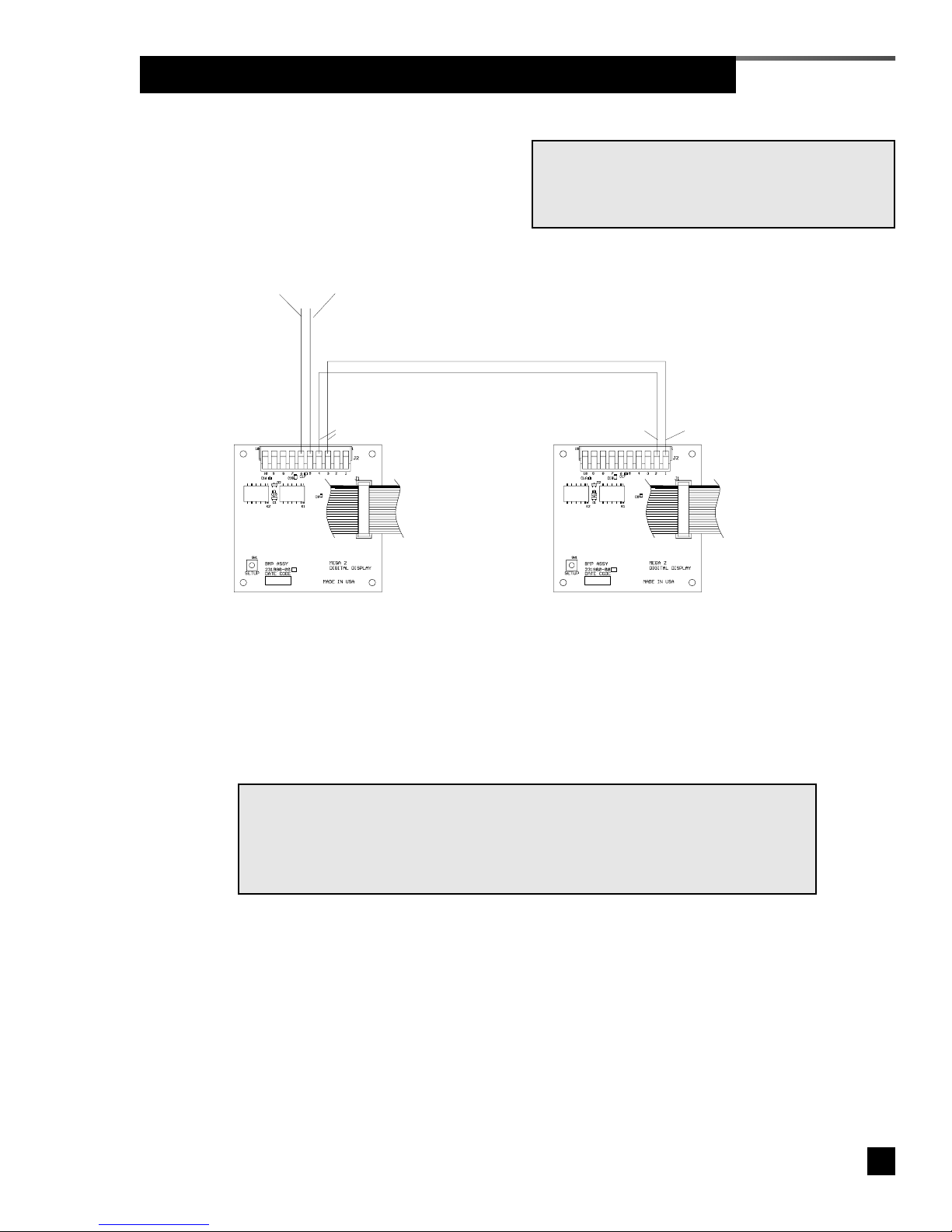

Wiring Schematic 4: Remote Pressure / Vacuum Transmission

Digital Display Module

at master alarm panel

Digital Display Module

at slave alarm panel

Signal from

sensor module

Pin 5 (+)

Pin 6 (-)

Master output

to slave

Pin 4 (-) / Pin 3 (+)

Slave input

from master

Pin 1 (+)

Pin 2 (-)

ribbon to

adjacent

module

ribbon to

adjacent

module

NOTE:

The above master to slave wiring configuration DOES NOT comply with NFPA 99

wiring guidelines for two required master panels. In order to comply, EACH mas-

ter panel must be directly connected to a Sensor Module for each pressure/vacu-

um service. Additional panels, if desired, may be connected as indicated above.

NOTE:

Field wiring cable shields must be grounded at

only one end, inside alarm panel back box. Refer

to page 31 for details.

18 Part No. 6-847684-00 Rev. D01

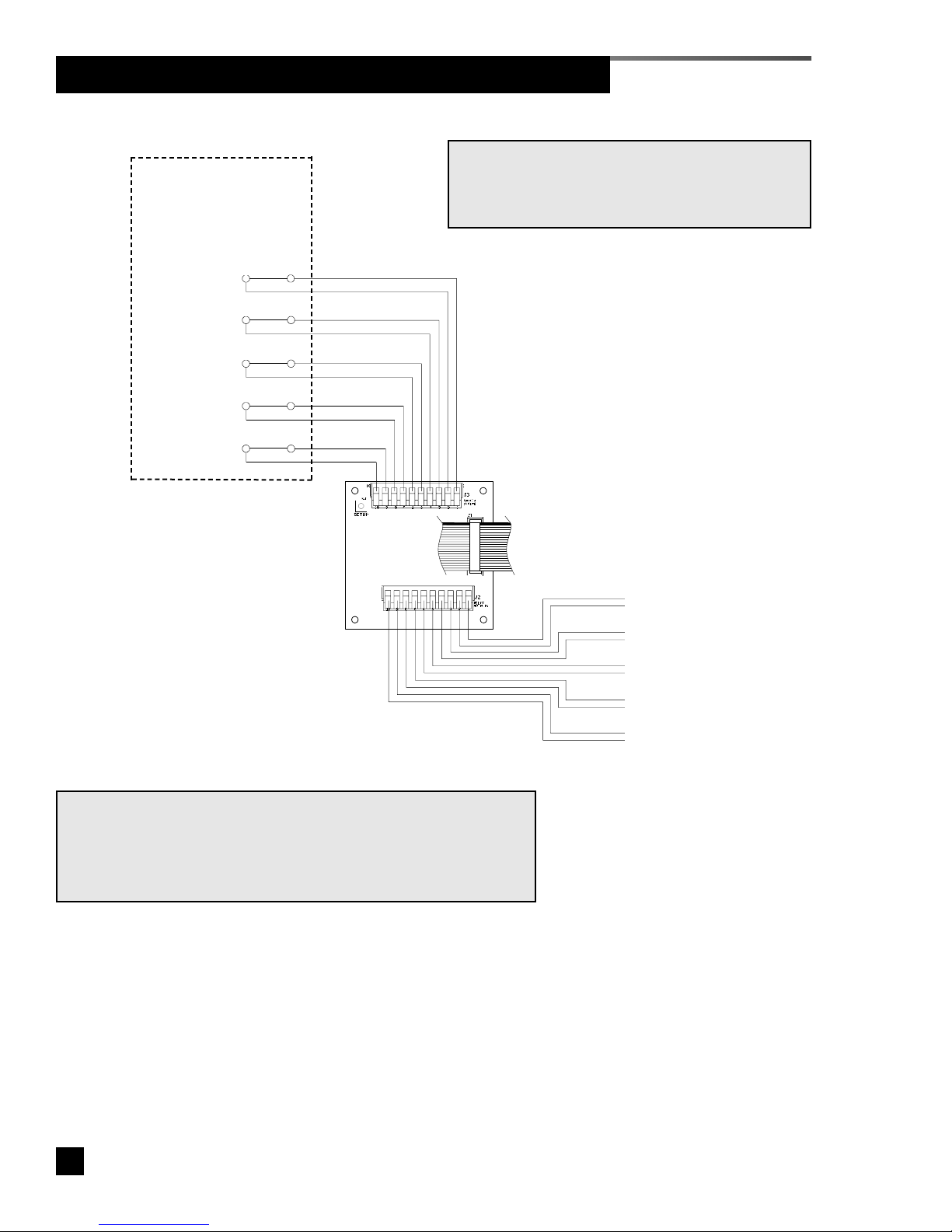

Wiring Schematic 5: Multi-Signal Module Relays (Optional)

SIGNAL 1

SIGNAL 2

SIGNAL 3

SIGNAL 4

SIGNAL 5

Dry normally-closed

contacts at source

equipment or line

pressure switches

COM +

COM +

COM +

COM +

COM +

Multi-Signal Module

ribbon to

adjacent

module

SIGNAL 1 - pins 1 & 2

SIGNAL 2 - pins 3 & 4

SIGNAL 3 - pins 5 & 6

SIGNAL 4 - pins 7 & 8

SIGNAL 5 - pins 9 & 10

Dry normally-closed output

relay contacts

NOTE:

Output relay contacts are dry normally closed type. Contacts open

upon designated alarm activation. Contacts remain open until

alarm condition is corrected. Alarm mute DOES NOT affect relay

condition.

Relay contact ratings are 2 A @ 30 VDC/0.5 A @ 125 VAC

.

NOTE:

Field wiring cable shields must be grounded at

only one end, inside alarm panel back box. Refer

to page 31 for details.

19

Part No. 6-847684-00 Rev. D01

Wiring Schematic 6: General Fault / Auxiliary Relays

Wiring Schematic 7: Digital Display Module High / Low Relays

Annunciator Module

Digital Display Module

ribbon to

adjacent

module

General Fault Relay

N/C (pin 5)

N/O (pin 3)

Common (pin 4)

N/O (pin 6)

Common (pin 7)

N/C (pin 8)

Auxiliary Relay NOTE:

General Fault Relay activates when ANY

alarm on panel is in progress. Pressing

MUTE on Annunciator Module DOES

NOT reset relay. Relay deactivates when

alarm condition is corrected.

Auxiliary Relay (optional) activates when

ANY audible alarm on panel is in progress.

Pressing MUTE on Annunciator Module

WILL deactivate relay until audible alarm is

again reactivated.

Relay contact ratings are 2A @ 30 VDC/0.5

A @ 125 VAC.

ribbon to

adjacent

module

Low Alarm Relay

N/C (pin 8)

Common (pin 7)

N/C (pin 10)

Common (pin 9)

High Alarm Relay NOTE:

High Alarm Relay activates when high line

pressure alarm on digital display module is

in progress. When relay activates normally

closed contacts open. Pressing MUTE

on Annunciator Module DOES NOT deacti-

vate relay. Relay deactivates when high line

pressure alarm condition is corrected.

Low Alarm Relay activates when low line

pressure alarm on digital display module is

in progress. When relay activates normally

closed contacts open. Pressing MUTE

on Annunciator Module DOES NOT deacti-

vate relay. Relay deactivates when low line

pressure alarm condition is corrected.

Relay contact ratings are 2A @ 30 VDC/0.5

A @ 125 VAC.

20 Part No. 6-847684-00 Rev. D01

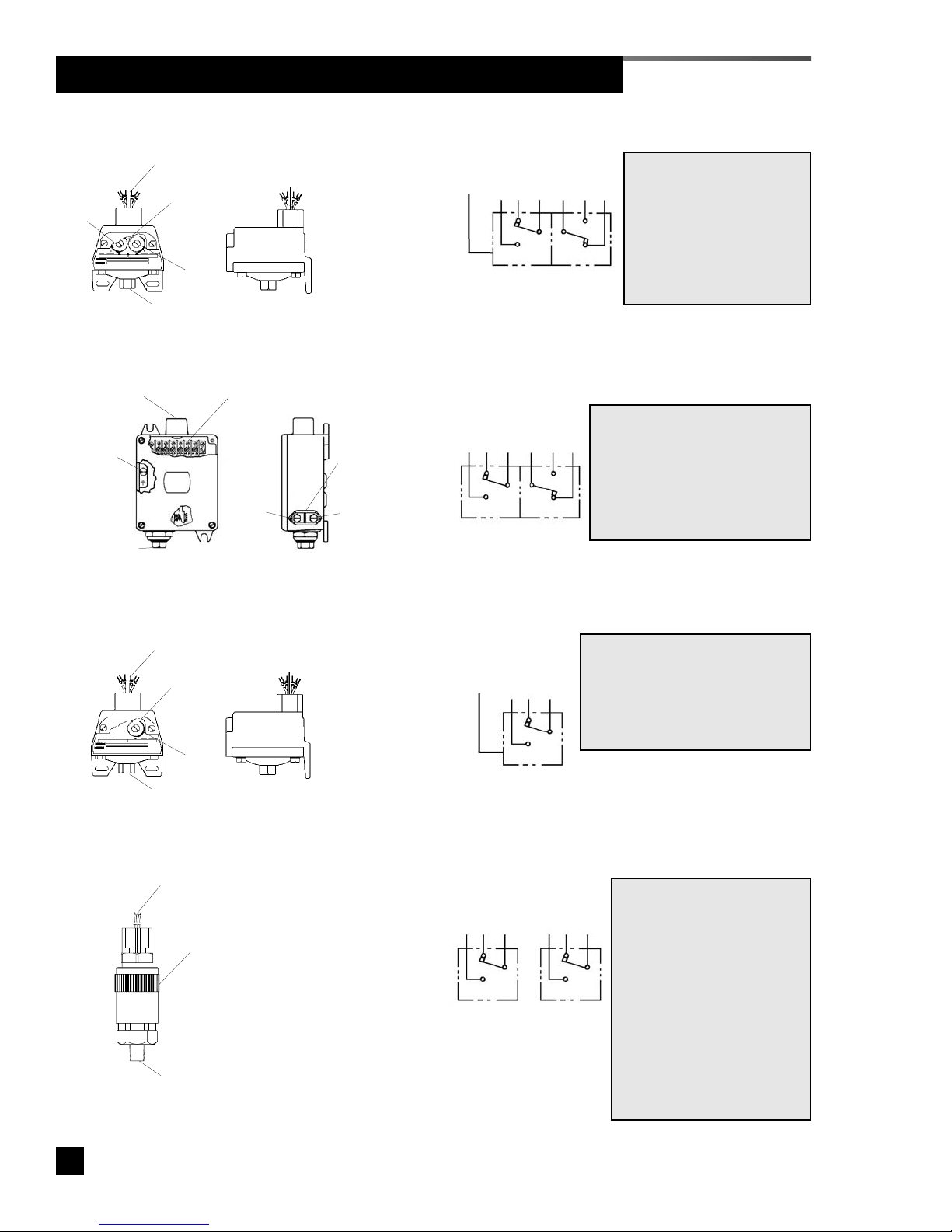

Wiring Schematic 8: Remote Pressure / Vacuum Switches

P/N 6-129020-01 (Dual switch for medical gases with 50 PSI nominal pressure)

P/N 6-129021-01 (Dual switch for medical gases with 175 PSI nominal pressure)

P/N 6-129022-01 (Single switch for vacuum)

1/4 NPT female port

1/4 NPT

female port

seven - approx. 18” free leads

through 3/4” conduit connection

terminal strip

1/2” conduit

connection

ground

screw

low

high

adjustment

dials

high

low high

yellow

brown*

orange*

purple*

red*

blue

(N/C)

(N/C)

(N/O)

(N/O)

(C)

(C)

NOTE:

Switch contacts shown with

50 PSI pressure applied.

Low switch is

preset at 40 PSI.

High switch is preset at 60

PSI.

*Wires/contacts to be used with MEGA2 alarm system

adjustment

screws

NOTE:

Switch contacts shown with 20

inHg vacuum applied.

Low switch is

preset at 12 inHg.

green

ground

low low high

yellow

brown*

orange*

purple*

red*

blue

(N/C)

(N/C)

(N/O)

(N/O)

(C)

(C)

NOTE:

Switch contacts shown with 175

PSI pressure applied.

Low switch is

preset at 140 PSI.

High switch is preset at 190 PSI.

*Wires/contacts to be used with MEGA2 alarm system

1/4 NPT female port

four - approx. 18” free leads

through 3/4” conduit connection

low

adjustment

dial

*Wires/contacts to be used with MEGA2 alarm system

low

purple*

red*

blue

(N/C)

(N/O)

(C)

green

ground

P/N 0208-5096-300 (Single switch for medical gases with 175 PSI nominal pressure)

1/4 NPT male port

three - approx. 12” free leads

through 1/2” NPT conduit connection

adjustment

sleeve

NOTE:

2 Switches Required.

Switch contacts shown

with 175 PSI pressure

applied.

Switch is preset at 195

PSI increasing.

Installer must set low

switch to 140 PSI

decreasing.

*Wires/contacts to be used with MEGA2 alarm system

low

purple*

red*

blue

(N/C)

(N/O)

(C)

high

purple*

red

blue*

(N/C)

(N/O)

(C)

Table of contents

Other BeaconMedaes Security System manuals