17

Medical Gas Supply System

4109992485.00

Pressuredropleaktestvalidationnotes:

• The Manifold Changeover System uses medical

regulatorsapprovedtoBSENISO10524-2standard,

as required by ISO and HTM medical pipeline

standards. These standards have a maximum

allowableleakageacrosstheregulatorseat(internal)

andtoatmosphere(external)asfollows:

1ststageregulator,Internal 0.1ml/min

1ststageregulator,external 0.2ml/min

2ndstageregulator,Internal 0.2ml/min

2ndstageregulator,external 0.2ml/min

• Therefore, the maximum pressure increase or

decrease witnessed at the line pressure will be

based on 2 regulators, 0.4 ml/min. The maximum

pressure drop witnessed at the cylinder pressure

will be based on the internal and external leakage

fromthe1st and 2ndstageregulatoronthatbank,0.7

ml/min.

• Pressuredroptestsaremorecommonlyusedonsite,

asleakscanbediculttomeasure.Theequivalent

watercapacityvolumeundertestisusedtocalculate

thepressuredropfromanallowableleakagerate.

• Fromusingthemanifoldwatercapacitytheallowable

pressuredroporincreasebasedonaleakageof0.4

ml/mincanbecalculatedas0.0016bar/min,or0.096

bar/hrwitnessedatthelinepressure.Thepressure

dropwitnessedatthecylinderpressurefroma0.7

ml/min leakage would be as follows depending on

thenumberofcylinderconnections.

No.Cyl. 12345

Bar/Hr 1.78 1.09 0.78 0.61 0.5

No.Cyl. 67 8 9 10

Bar/Hr 0.42 0.37 0.33 0.29 0.26

• Althoughthemedicalregulatorallowableleakageis

onlysmall,theeectscanbewitnessedwithinafew

hours due to the manifold having a small volume.

To put into perspective how small 0.4 ml/min is, if

appliedtooneJ-sizecylinderitwouldtakenearly12

weeksforittodropby1bar.

2.6.8 Monitorthepressuredropandassessasperthe

abovenotes.Lengthoftimeforthetestwilldependon

theaccuracyofthegaugesusedtobeabletodetectthe

pressuredrop.

2.6.9 Opentestpointisolationvalve(gure1,item15)

andrelievethepressurefromwithinthemanifold,then

closetestpointisolationvalve.

2.6.10 TheinstallationmustnowbepurgedasperHTM

02-01forUKinstallations,orasperrelevantstandardsif

installedoutsidetheUK.

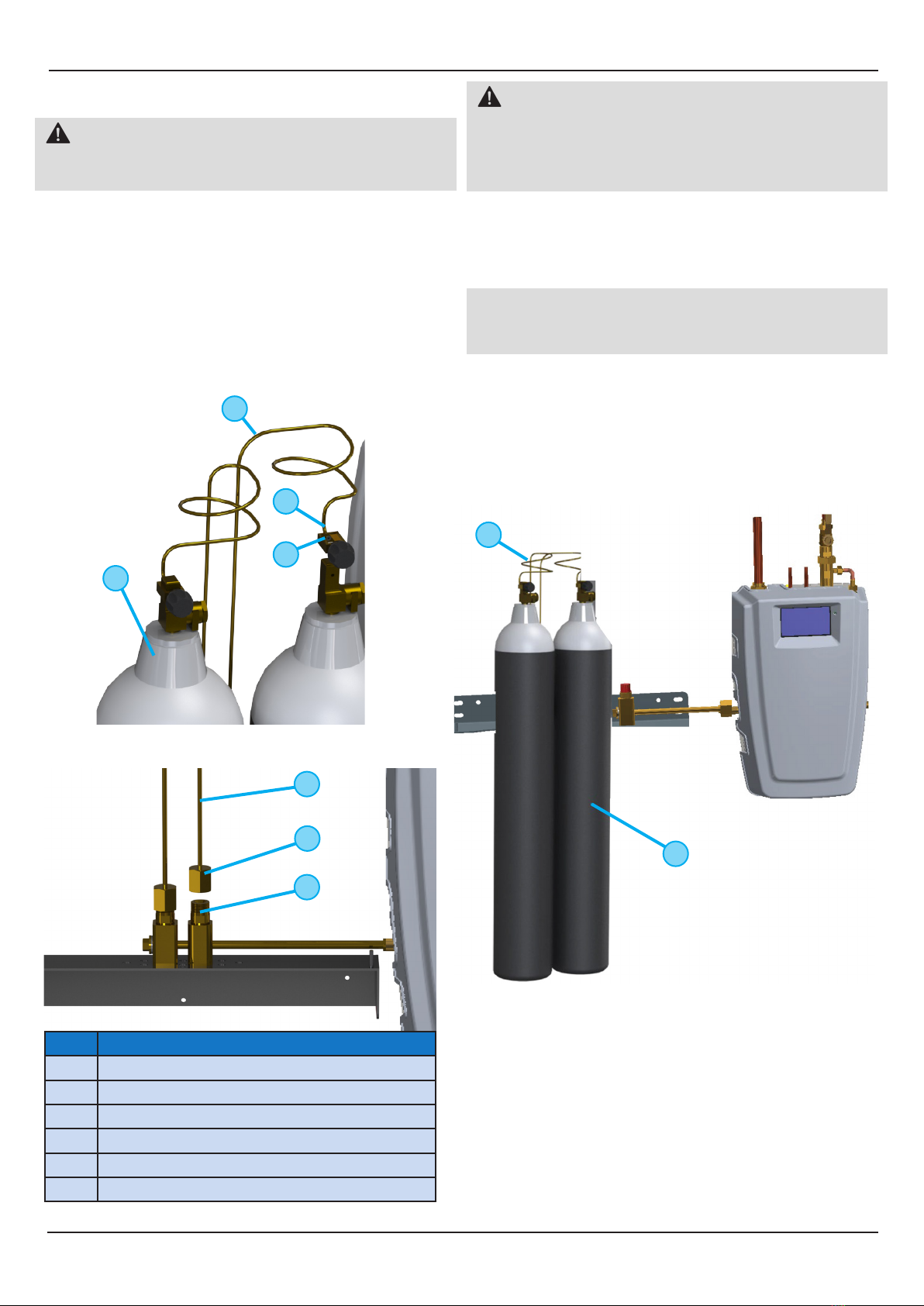

2.6 Installation Check.

2.6.1 Ensure that all tailpipes are connected to the

cylinders and manifolds on both sides and that the

restraintchainsaresecurearoundthecylinders.

2.6.2 Isolate the device from the pipeline using the

mainisolationvalve(showningure15,item3).

2.6.3 Ensure that both bank isolation valves (Figure

15,item1and2)arefullyopen.

2.6.4 Ensurethe test point isolation valve(gure 15,

item4)isclosed.

2.6.5 Use 1 cylinder per bank, slowly pressurise the

manifold (see section 4.10 - Cylinder operation). Both

cylinder gauges (gure 1, item 23) should indicate full

cylinderpressure.Thelinepressuregauge(gure1,item

18)shouldreadtypicallyaspertable6,Section4,adjust

asnecessary(seesection4.5).

CAUTION!Ifusedasabackupmanifolditwould

berecommendedtosetthelinepressureatleast0.2bar

below the main supply source pressure at full design

ow,toensurethemanifolddoesnotsupplythepipeline

duringnormalprimarysourceoperation.

2.6.6 Check for leaks, typically by listening for gas

escapingorleakdetectionuidonjoints.

2.6.7 Nowensureallbank cylindervalvesare closed

readyforpressuredropleaktest.

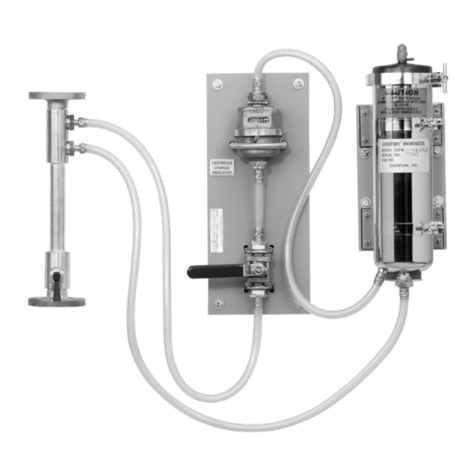

Figure 15 - Leak Test Valve Conguration.

3

4

1

2

No. Description

1LineIsolationValve

2IntermediateIsolationValve(ThreeWay)

3LockableIsolationValve

4TestPointIsolationValve