BEAHM DESIGNS Bonder 220B User manual

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

2 | P a g e

TABLE OF CONTENTS

1.0 List of Components

2.0 General Description

2.1 System Data Sheet

3.0 Controls

3.1 Front Panel Controls

3.2 Rear Panel Controls

3.3 Installation

4.0 Parameter Setting

4.1 Pressure Regulator Setting

4.2 Cooling Air Flow Setting

4.3 Temperature Controller Setting

4.4 Process Timer Setting

4.5 Temperature Controller Layout

4.6 Auto-Tuning Instructions

5.0 System Operation

5.1 Facilities Requirements

5.2 Safety Precaution

5.3 System Controls

5.4 Die Head Sizing

5.5 Die Head Replacement

6.0 Maintenance

6.2 Calibration

6.3 Replacement Parts List:

6.4 Tool Change

7.0 Warranty Information

8.0 List of Drawings

8.1 1700-14 Front Panel Controls

8.2 1700-09 Blank Die Head

8.3 Document 10125-20 Process Instructions –Die Head Sizing.

8.4 System Schematic

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

3 | P a g e

9.0 Component Data Sheets

9.1 Eurotherm 2232 Temperature Controller

9.2 Split Die Thermal Bonder

1.0 List of Components

Standard System Components

1) Split Die Thermal Bonder

2) Split Die Thermal Bonder Ship Kit

Power cord, U.S. version, 115 VAC

Air pressure supply line

3) User’s Manual

Optional Components

Blank Die Heads p/n SD220C

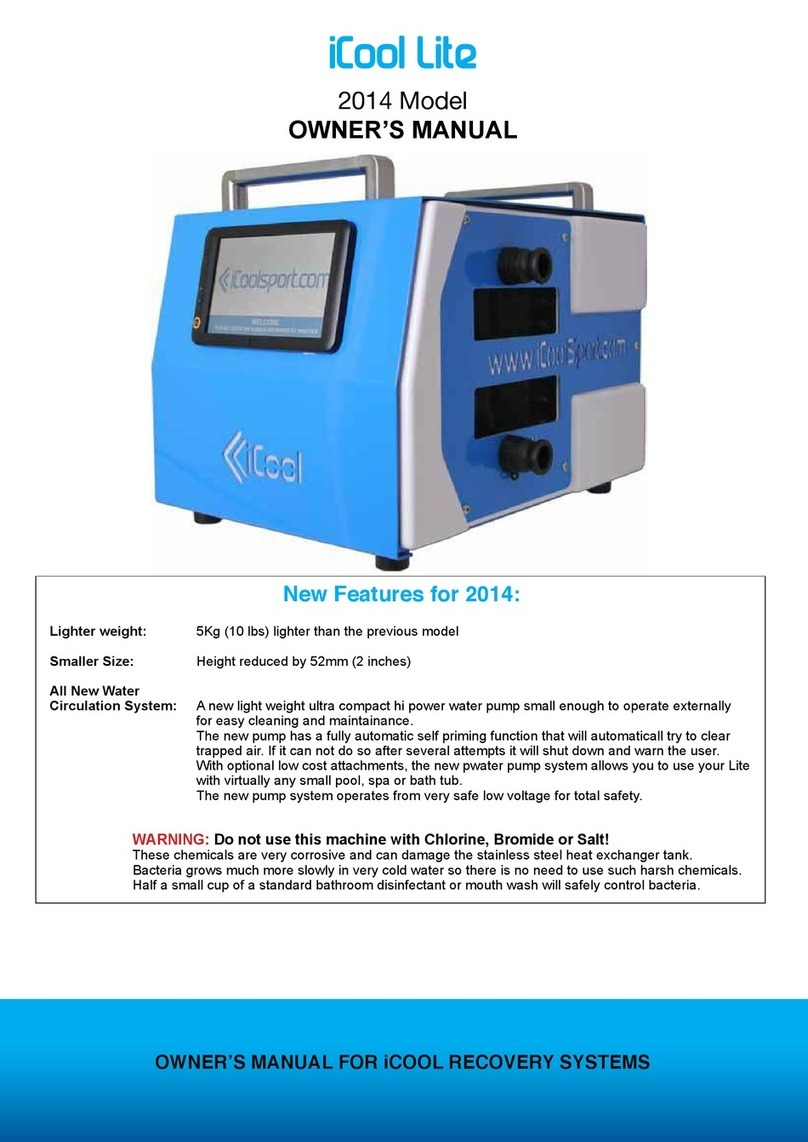

2.0 General Description

The unique and simple die head design of the Beahm Designs Split Die Thermal Bonder, provides a low cost

quick tool alternative to RF die bonding. The three parameter operation is easy to set-up and use and

simplifies system calibration and process validation. Upgrade options such as axial compression and cooling

further increases versatility and functionality. This system provides you with fast, highly repeatable bonds.

Allows you to perform highly precise bonds for demanding applications such as short balloon bonds and

ultra smooth lap & butt welds. Adjustable clamp pressure varies compression force on joint. Ultra compact

design provides you with greater work-space. Automation and axial compression

3.0 Controls

3.1 Front Panel Controls

Located on the front panel of the unit (see drawing p/n 170014 (7.1)) are:

System Power

Clamp Pressure

Clamp Pressure Regulator

Tempurature Controllers (front & rear)

Cooling Air Line

Cooling Air Flow Adjust

Cooling Air on/off toggle switch

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

4 | P a g e

Timer Reset Button

Process Duration Timer

3.2 Rear Panel Controls

Located on the rear panel of the unit are:

Power entry module

Industrial system air connection

System Fuse

Front temperature controller thermocouple calibration port.

Rear temperature controller thermocouple calibration port.

Pressure gauge calibration port.

3.3 Installation

When installing the system, follow the sequence listed below.

Make sure that the system power is in the off position.

Connect the system air extension line to 80—100 psi clean dry compressed air source.

Connect main AC power to the power entry module on the rear panel.

4.0 Parameter Setting

4.1 Pressure Regulator Setting

Rotate the regulator knob clockwise to increase air pressure, counter clockwise to decrease

air pressure output to the die head actuation cylinder.

4.2 Cooling Air Flow Adjust

Rotate the flow meter valve counter clockwise to increase cooling airflow, clockwise to

decrease airflow.

4.3 Temperature Controller Setting

Depress the up arrow key on the temperature controller to increase the temperature

set-point depress the down arrow key to decrease the temperature set-point. Release up or

down arrow key when desired temperature is displayed in the upper read out. The new

setting will be accepted automatically after 2 seconds.

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

5 | P a g e

4.4 Process Timer Setting

Depress the upper half of the blue rocker buttons to increase time duration, depress the

lower half of the blue rocker button to decrease the time duration. Depress the timer reset

button for at least 1.0 seconds to accept the new value.

4.5 Temperature Controller Setting

Eurotherm Model 2132

To Set the temperature proceed as follows:

Press and hold “down arrow” to decrease temperature

Press and hold “up arrow” to increase temperature

After 2 secs the readout will ‘blink’ indicating that the new value has been accepted the

temperature will automatically ramp to the new value and stabilize.

4.6 Auto-Tuning Instructions

Switch main power on

1) Depress the page button until "TUNE LIST" appears in the display

2) Depress the scroll button until "ATUN" appears in the display

3) Depress the "UP" or "DOWN" arrow button twice to initiate tune sequence

4) Unit will resume normal operation automatically

For more details about Eurotherm Temperature Controller, see the manufacturers

Insturction Manual in the back of this manual.

5.0 System Operation

5.1 Facilities Requirements

110/120 v, 50/60 hz

2-3 amps (220 watts)

100-125 psi, clean dry compressed air

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

6 | P a g e

5.2 Safety Precaution

Hot die jaws will become hot during operation and, depending on temperature set-point, can cause severe

skin burns if contact occurs.

5.3 System Controls

•Switch main power on.

•Set die temperature on EACH temperature controller by pressing the UP/Down arrow key once to display

the set temperature, then again to change it.

•Set timer to desired duration in seconds.

•Position components to be bonded within thermal jaws.

•Depress footswitch.

•To cool assembly when cycle is complete, position the heated area at the tip of the cooling air nozzle

and toggle the cooling air switch to the “on” position.

5.4 Die Head Sizing and Replacement

Required Tools and Equipment

Milling Machine

.25” diameter end mill

reamer as required

Caliper or micrometer

•Assemble components to be bonded over mandrel(s).

•Measure bond length, tubing overlap or balloon sleeve length.

•Position the protective sleeve over the bond area.

•Measure the O.D. of the protective sleeve. Set timer to desired duration in seconds.

•Position components to be bonded within thermal jaws.

•Depress footswitch.

•To cool assembly when cycle is complete, position the heated area at the tip of the

cooling air nozzle and toggle the cooling air switch to the “on” position.

5.5 Die Head Replacement

Caution: ensure that the die heads arecooled to within 15 degrees f of ambient temperature

before proceeding with replacement.

•Loosen the set screw located on the top of each die head and withdraw the

thermocouple.

•Remove the two screws at the base of each die head.

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

7 | P a g e

•Position new die heads in place of removed die heads, install two screws at the base

of each die head. Do not overtighten the screws.

•Install the thermocouple in the rear of each die head and gently tighten the set screw

to hold them in place.

6.0 Maintenance

6.1 Calibration

Calibration Method:

Calibration ports are provided at the rear of the main control unit to prevent the need to open the enclosure

and disconnect wiring or plumbing.

Calibrate every 12 months. Send unit to an NIST certified calibration service (this service can be coordinated

by Beahm Designs for an additional fee).

Calibration procedures are carried out by certified services. Their procedures are derived from the N.I.S.T.

(National Institute of Standards and Technology). http://www.nist.gov/index.html

System Specifications Range Resolution Accuracy

6.1.1 Temperature 200-500 deg f 1.0 degree +/- .25% F.S.

6.1.2 Timer 1-9999 sec 1.0 second +/- .1 seconds

6.1.3 Pressure 0-100 psi 5 psi +/-3.5% F.S.

6.2 Calibration

6.2.1 Calibrate the temperature controller annually.

6.2.2 Calibrate the process timers annually.

6.2.3 Calibrate the pressure gauges annually.

6.3 Replacement Parts List: (the below items are available through Beahm Designs)

Description

P/N

Delivery

Heater Cartridge

5018

1 week

Thermocouple

5071

1 week

Blank Die Heads

6066

1 week

Air Pressure Gauge

5021

1 week

Temperature

Controller

5347

1 week

Equipment User Manual

1502 Gladding Ct. Milpitas, Ca. 95035.

408-395-5360

www.beahmdesigns.com

8 | P a g e

6.4 Die Head Replacement

6.4.1 Loosen the thermocouple set screw in each die head and slide the thermocouple out of

each head.

6.4.2 Remove the fasteners at the base of each die head and remove the die heads.

6.4.3 Position the replacement die heads on the die bases with the thermocouple mounting

holes facing away from each other.

6.4.4 Re-install the fasteners at the base of each die head, DO NOT tighten the fasteners.

6.4.5 Manually close the die heads and ensure that they are aligned left-to-right and, while

holding the heads together, tighten the base fasteners.

6.4.6 Fully insert each thermocouple into each die head and lightly tighten each set screw.

7.0 Warranty Information

Beahm Bonders are backed by a 1 year warranty on parts and labor.

BDI will have no liability for any Product returned if BDI determines that:

•The asserted defect:

1. is not present,

2. is attributable to misuse, improper installation, alteration (including removing or

obliterating labels and opening or removing external covers (unless authorized to

do so by Beahm Designs), accident or mishandling while in the possession of

someone other than Beahm Designs, Inc.

The Product was not sold to you as new.

Return Material Authorization (RMA)

No Product may be returned directly BDI without first contacting BDI for a Return Material

Authorization ("RMA") number. If it is determined that the Product may be defective, you will be

given an RMA number and instructions for Product return. End Users are required to include a

copy of the RMA receipt inside the return box to receive replacement product under warranty. An

unauthorized return, i.e. one for which an RMA number has not been issued, will be returned to

you at your expense. To request an RMA, please call 408-871-2351.

8.0 List of Drawings

Table of contents

Popular Medical Equipment manuals by other brands

Respironics

Respironics ESPRIT Service manual

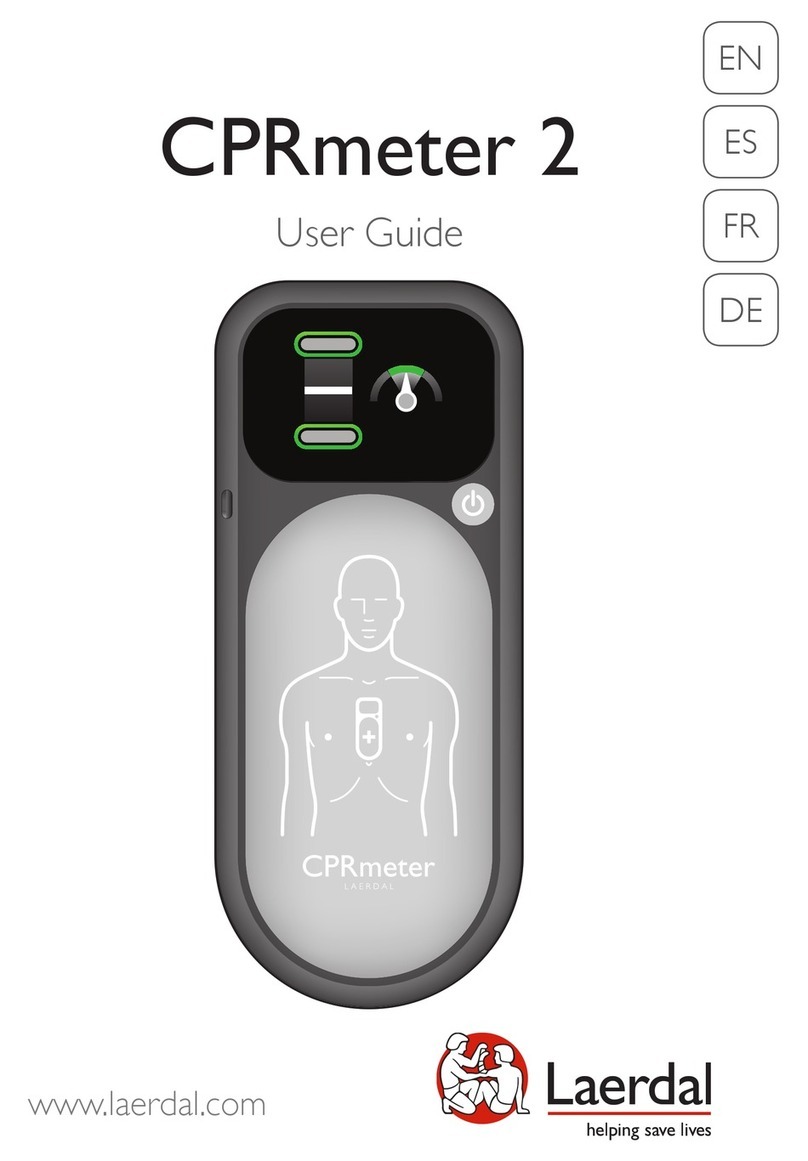

laerdal

laerdal CPRmeter 2 user guide

Storz

Storz FIVE Series instruction manual

Mercado Medic

Mercado Medic REAL 9000 PLUS Series Instructions for use

HD Rehab

HD Rehab HD Motion 39620-1 User manual & assembly instructions

Orliman

Orliman DS04 Use and maintenance instructions