WHITEHALL MANUFACTURING • P.O. BOX 3527 • City of Industry, CA 91744-0527 U.S.A

Phone (800) 782-7706 • (626) 968-6681 • Fax (626) 855-4862 • Web: www.whitehallmfg.com

3

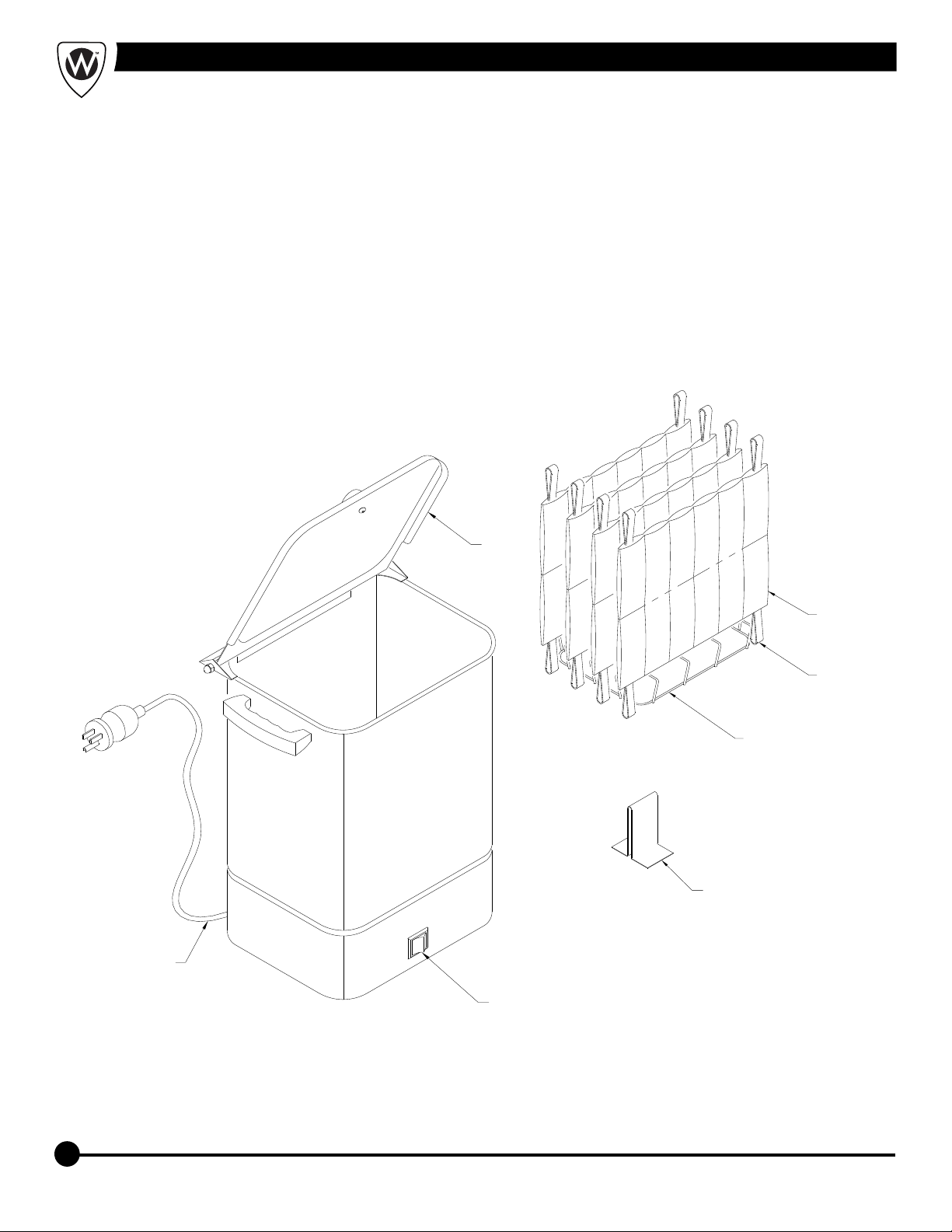

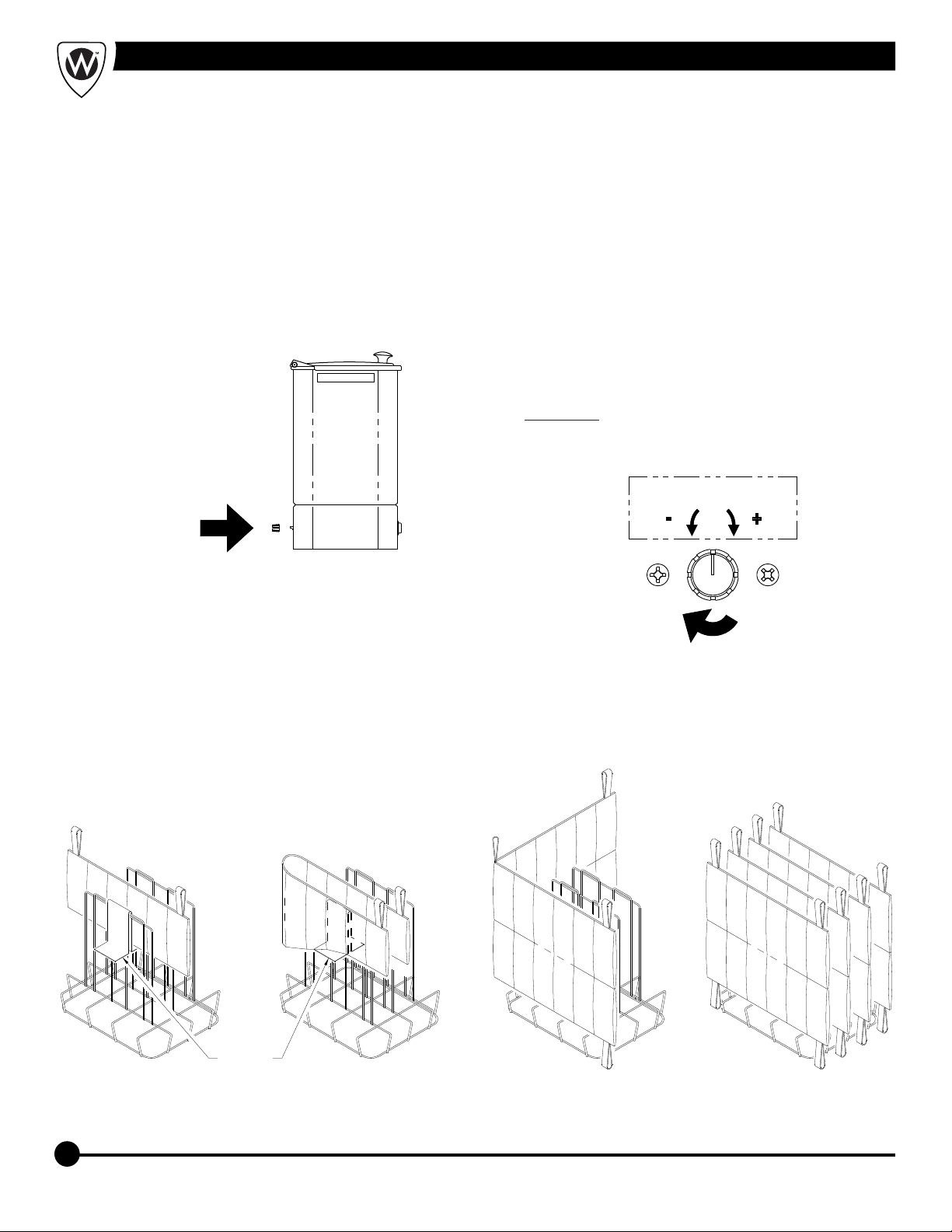

1 Thermalator Model T-4-S or ET-4-S

4 Thermal Packs (4 Standard)

1 Wire Rack - Small, Vinyl Coated

1 Rack Adapter (stainless steel)

1 Thermostat Knob

1 Warranty Registration Card

1 Instructions for Operation and Care

If you are missing anything, please call the phone

number listed on the back page.

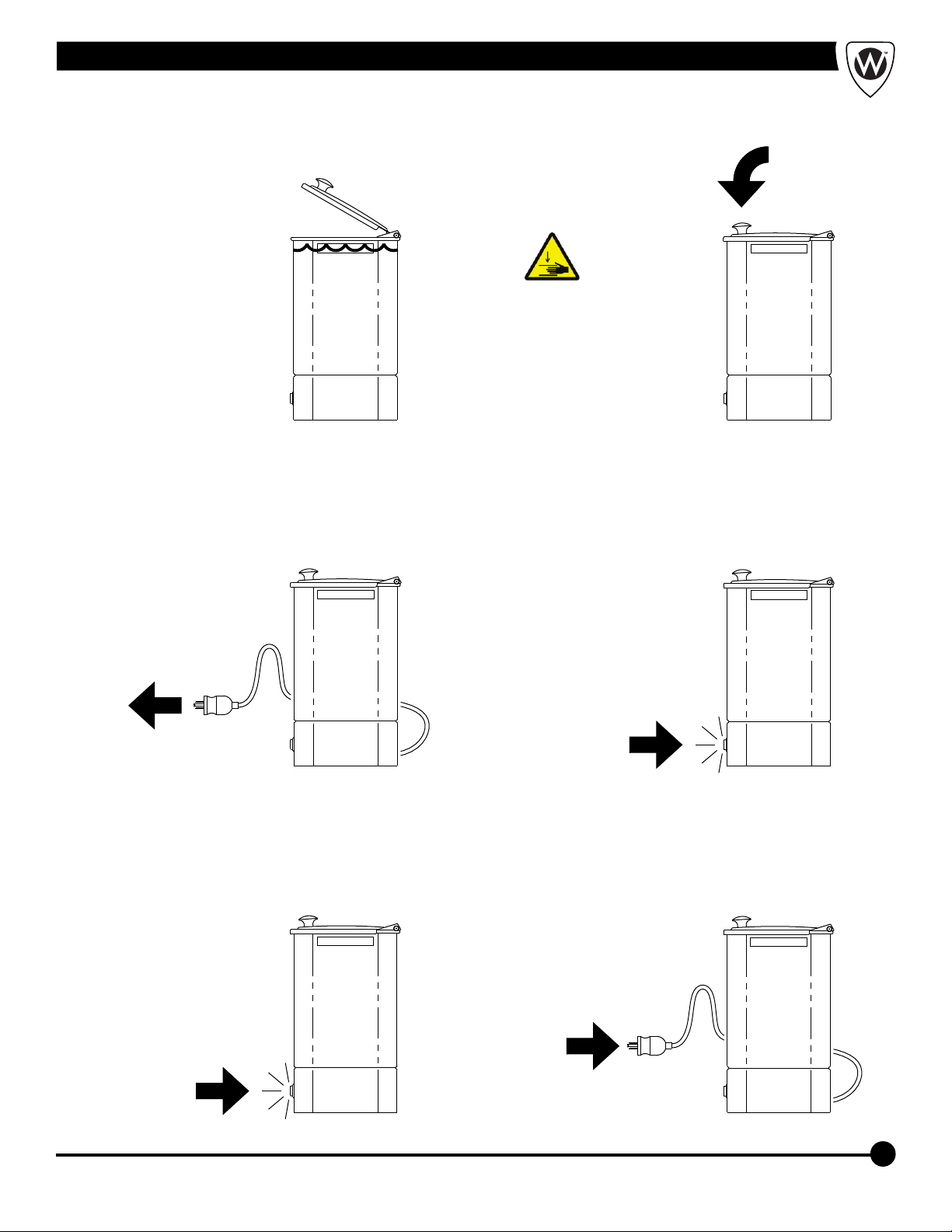

Remove all the shipping material. Remove Thermal

Packs and wire rack from inside the tank. Remove all

packaging from inside the tank, especially from under

the heating element inside the tank. Clean the unit

thoroughly before using.

Place the Thermalator at a convenient level, such as

on a table or a scratch resistant counter top. Before

moving the Thermalator, unplug and cool the unit.

Only move the unit to empty or fill it. Always use the

handles. The unit may be hot to the touch.

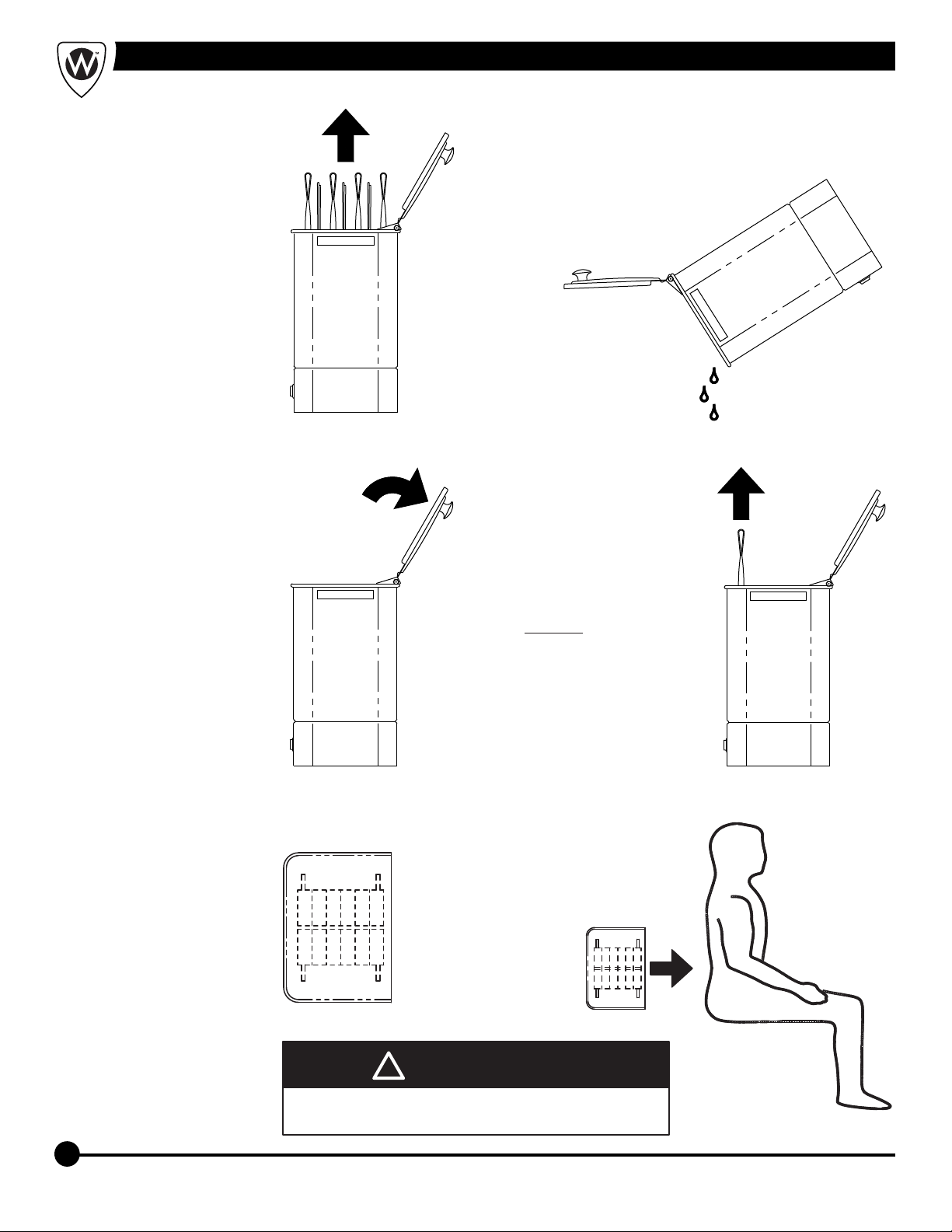

Before the first use, you must condition each Thermal

Pack.

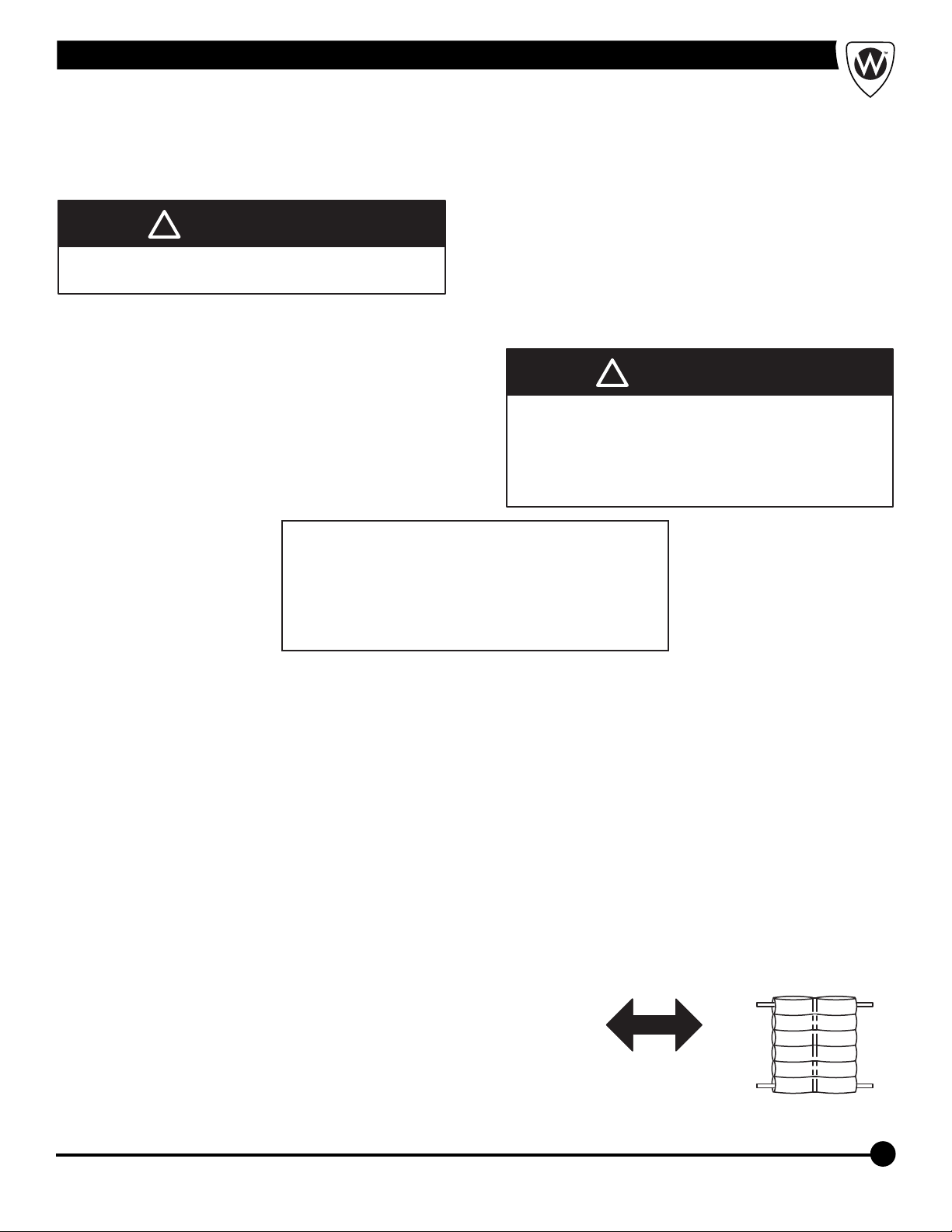

1- Take the Thermal Pack by the corner loops - one

white and one blue or black - so the sections are

horizontal.

2- Gently shake the pack back and forth to evenly

distribute the filler material.

SETTING UP

1. Your new Thermalator includes the following:

2. Unpacking your Thermalator

3. Device Placement

Shake to distribute

the dry material

4. Pre-Soaking Thermal Packs

Instructions for Operation and Care of Stationary 4 Pack Thermalator

TRAINING

Operator trainees need to:

Ÿbe trained in occupational therapy protocols.

Ÿread and understand this manual.

Skills:

Operators using the Thermalator need a working

knowledge of occupational therapy procedures.

WARNING

!

Only trained personnel to operate the Thermalator.

Untrained operators can cause injury or be injured.

WARNING

!

OPERATOR SKILLS AND TRAINING

INSPECTING THE THERMALATOR

Inspection Checklist

Is the Thermalator free of excessive wear?

Is a properly-grounded and voltage-matched

receptacle available?

Is the outlet equipped with a functioning GFI?

Ÿ

Ÿ

Ÿ

This Whitehall product has been carefully packaged at

the factory to minimize the possibility of damage during

shipping.

— Inspect the packaging for external signs of

damage.

— Inspect the contents for damage.

If there is visible damage to the instrument upon receipt,

inform the shipping company and Whitehall immediately.

WARNING

!

Do not attempt to operate this equipment if there is

evidence of shipping damage or you suspect the unit

is damaged. Damaged equipment may present

additional hazards to you. Contact Whitehall technical

support for advice before attempting to plug in and

operate damaged equipment.

WARNING

!