2

Installation Leaet IL04209006E

Eective July 2010

PROFIBUS Module for use with

Motor Insight, C440 and S611

EATON CORPORATION www.eaton.com

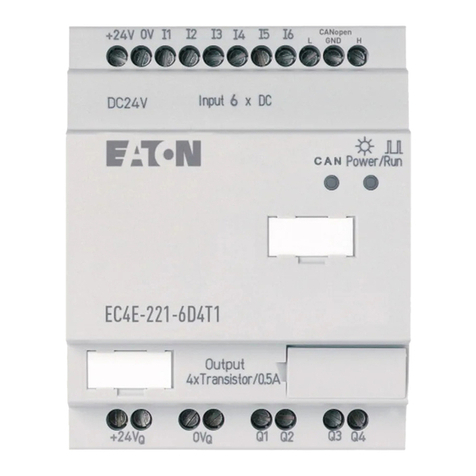

Specification Value

Number of Inputs 4

Nominal Voltage 24 Vdc

Nominal Current 5mA

Type Current Sinking

Input Type IEC 61131-2, Type 1 Digital

Max 24 Vdc Source Current 50mA

PROFIBUS Adapter Setup and Configuration

Configure C441 Profibus Adapter

1. Load the gsd le for the C441 Probus Adapter into the Master’s

conguration tool.

2. Select and add the C441 Probus Adapter to the network

conguration.

3. The default conguration for the C441 Probus Adapter is a

StandAlone IO base. If the C441 Probus Adapter is to connect

to a base device; remove the modules from all 28 slots of the

default conguration.

4. Select and add the attached device’s base module

to slot 1 of the C441 Probus Adapter conguration.

NOTE: The appropriate base module MUST be placed in slot 1 of

the conguration. Failure to do so will cause conguration to fail.

5. Select and add the desired modules for the data exchange into

slots 2 - 28. Select only those modules supported by the base

module (See the base device’s user manual for a list of sup-

ported modules)

Example Conguration:

I/O module Type Description

C441 MotorInsight Base base - no IO Attached Device

Com Adapter Outputs output - 1 byte Controls C441 adapter

outputs

MI Command Register output - 2 bytes Controls MI Relay-

start/stop

Com Adapter Inputs input - 1 byte Status of C441 adapt-

er inputs

MI RMS Current Ave input - 2 bytes Average rms current

reading

MI RMS Voltage Ave input - 2 bytes Average rms voltage

reading

MI Total Kilowatts input - 2 bytes Total power reading

Setup C441 Probus Adapter Device Parameters

1. Select the C441 Probus Adapter to display its device param-

eters.

2. Set the “Enable Device Parameters & Adapter Outputs ComLos

Behavior” parameters.

Note: To enable writing of the device parameters into the attached

base device “Enable Device Parameters” must be set to “Download

Device Parameters”.

Setup the Device Parameters

1. Select the base module in the conguration to display its device

parameters. The base module contains the parameters to en-

able/disable faults, set thresholds, etc. for the attached device.

Example: The following parameters can be found in C441

MotorInsight Base Module

• CT Multiplier

• Overload FLA

• Overload Trip Class

• GND Fault Trip Level

• Low KW Trip Level

• High KW Trip Level

• Under Voltage Trip Level

• Over Voltage Trip Level

After all conguration is complete, save and download the new

conguration settings to the Master(PLC) & C441 Probus

Adapter.

Probus Diagnostics

The C441 Probus Adapter provides the user with status information

along with fault and warning data relevant to the operation of the

attached base module. Fault and warning information is presented to

the user through extended diagnostics. All fault information is sent

to the Master as high priority diagnostic messages (ext. diag. bit set

in diagnostic message). All warning information is sent as low prior-

ity diagnostic messages (ext diag. bit clear). Low priority diagnostic

messages are issued as the fault condition clears.

See the User Manual for the attached base module’s diagnostic mes-

sage bit denitions

Environmental Ratings of the Module

Transportation

and Storage

Temperature -40ºC to 85ºC (-40ºF to 185ºF)

Humidity 5 - 95 % non-condensing

Operating

Temperature -20ºC to 50ºC (-4ºF to 122ºF)

Humidity 5 - 95 % non-condensing

Altitude Above 2000meters (6600feet)

consult factory

Shock

ICE 60068-2-27

15G any direction for

11 milliseconds

Vibration

IEC 60068-2-6

3G in any direction

Polution Degree 3