Bearcat BC-2016/CRC User manual

INSTRUCTION MANUAL

2016

Tandem Chip Spreader

8-16

10-20

2

2016

Revision 04/16

www.bearcatmfg.com/pdf/Chipper(2016).pdf

3

Intro

WARRANTY AND CLAIM PROCEDURES

LIMITED WARRANTY

BearCat Mfg.

3650 Sabin Brown Road

Wickenburg, AZ 85390

Phone: (928) 684-7851

4

2016

Warranty Claims

BEARCAT WILL NOT INSTALLAND WILL NOT PAYANY IN-

STALLATION COST, TRANSPORTATION COST, TRAVEL TIME,

MILEAGE, LABOR COSTS OR OTHER EXPENSES OF ANY

DEFECTIVE PARTS REPLACED OR REPAIRED UNLESS THE

USER HAS REACHED A PRIOR AGREEMENT WITH BEARCAT.

EXCLUSIONS

5

Intro

INTRODUCTION

NOTE: BearCat Manufacturing assumes no liability for accident or injury

incurred through improper use of this equipment.

WARNING: BEARCAT CHIP SPREADERS MOVE LARGE AMOUNTS

OF ABRASIVE MATERIAL AT HIGH SPEEDS. THIS

EQUIPMENT CONTAINS EXPOSED MOVING PARTS AND

BELTS. POTENTIALLY LIFE-THREATENING HAZARDS MAY

EXIST DURING EQUIPMENT OPERATION. PERSONNEL

MUST BE TRAINED AND FAMILIAR WITH SECTION 2

(SAFETY PRECAUTIONS) BEFORE OPERATING BEARCAT

EQUIPMENT.

WARNING: POTENTIALLY LIFE-THREATENING HAZARDS MAY EXIST

DURING EQUIPMENT OPERATION. ONLY QUALIFIED

PERSONNEL SHOULD ATTEMPT TO OPERATE, SERVICE

OR MAKE ADJUSTMENTS TO THE BEARCAT EQUIPMENT.

WARNING: FOLLOW THESE PRECAUTIONARY INSTRUCTIONS

EXACTLY. DO NOT TAKE SHORTCUTS. DO NOT ASSUME

THAT SOMEONE ELSE HAS ACTED ON YOUR BEHALF. IF

ANY RULE OR PRECAUTION IS NOT CLEAR TO YOU, SEE

YOUR SUPERVISOR BEFORE USING THE MACHINE.

6

2016

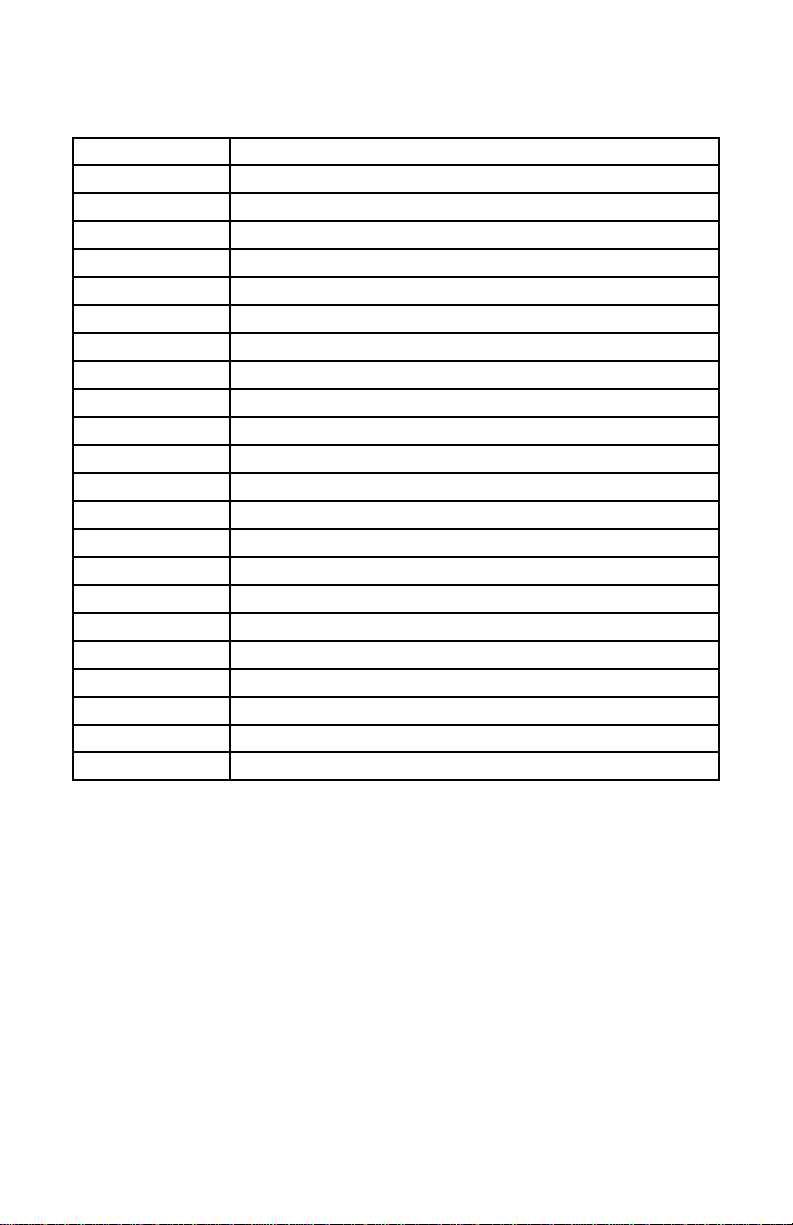

Abbreviation/Definition Table

ABBREVIATION DEFINITION

CRC

FCAL

GCAL

T3 Tier 3 Engine

T4 Tier 4 Engine

8’ 8’ to 16’ Tandem Chipper

10’ 10’ to 20’ Tandem Chipper

Contents

WARRANTY AND CLAIM PROCEDURES 3

3 LIMITED WARRANTY

4 Warranty Claims

4 EXCLUSIONS

5 INTRODUCTION

6 Abbreviation/DefinitionTable

SAFETY PRECAUTIONS 9

9 Safety Rules

7

Intro

EQUIPMENT DESCRIPTION 11

12 Power Train

12 Conveyors

13 Spread Hopper

14 Gate Control Valve Box

16 Chassis

16 Hydraulically Powered Remote Control Hitch

16 Operator Control Station Layout

17 DASH PANEL

19 CONSOLE

DISPLAY 26

26 Home Page

26 Side Buttons

27 Display Functions

28 Settings Menu

29 Settings Page

32 Diagnostic Menu

34 Engine

34 Defaults Page

INITIAL CHECKOUT OF MACHINE 36

36 Checkout

39 Check gate adjustment.

39 Prep for Operation

40 Calibration

OPERATING INSTRUCTIONS 43

43 Dump Trucks

46 Conveyor Belts & Augers

46 Visibility and Mirrors

48 Width Control

49 Radius

51 Cul-De-Sacs

52 Hydrostatic Drive

52 Transfer Case

52 Low Lock

53 Stall Pot

53 Automotive Control

56 BOLT TORQUE CHART

PARTS MANUAL 59

SCHEMATICS 87

8

2016

9

Safety

SAFETY PRECAUTIONS

Personal Safety

1. Persons responsible for the operation and maintenance of

BearCat Chip Spreaders should read the following safety

precautions and the remainder of this manual carefully

before operating the equipment.

WARNING: ALWAYS REMEMBER THAT CHIP SPREADING MACHINES

CAN BE DANGEROUS. THEY CONTAIN EXPOSED

MOVING PARTS AND BELTS, AND THEY MOVE LARGE

AMOUNTS OF ABRASIVE MATERIAL AT HIGH SPEED.

THE HYDRAULIC SYSTEM OPERATES AT HIGH

PRESSURE AND THE FLUID AND LINES CAN REACH HIGH

TEMPERATURES. YOU MUST HANDLE THIS MACHINE

CAREFULLY TO PROTECT YOURSELF FROM PAINFUL

OR EVEN FATAL INJURY. HAZARDS ASSOCIATED WITH

THIS MACHINE, AND THE NECESSARY PRECAUTIONS TO

AVOID DANGER, ARE GIVEN IN THIS MANUAL.

Safety Rules

Read each safety rule and make them a part of your daily work

routine.

WARNING: FOLLOW THESE PRECAUTIONARY INSTRUCTIONS

EXACTLY. DO NOT TAKE SHORTCUTS. DO NOT ASSUME

THAT SOMEONE ELSE HAS ACTED ON YOUR BEHALF.

FAILURE TO FOLLOW THESE SAFETY RULES CAN

RESULT IN DEATH OR SERIOUS INJURY. IF ANY RULE

OR PRECAUTION IS NOT CLEAR TO YOU, SEE YOUR

SUPERVISOR BEFORE USING THE MACHINE.

• Keep clear of all moving parts.

• Stay out of the chip box when the diesel engine is running.

• Keep hands away from gates when connecting air hoses.

• Use caution around conveyor belts. They can start

automatically.

• Keep clear of rear handrail. Contact with a dump truck

tailgate is possible.

• Keep clear of the hitch. You could be injured if it actuates

10

2016 against any part of your body.

• Engage the parking brake and place both the mechanical

transmission and the hydrostatic transmission in neutral

before leaving the machine.

• Stop the engine before crawling under the machine.

• Keep the surface of the hydraulic oil cooler clear of

obstructions.

NOTE: BearCat Manufacturing assumes no liability for accident or injury

incurred through improper use of this equipment.

11

Description

Equipment Description

12

2016

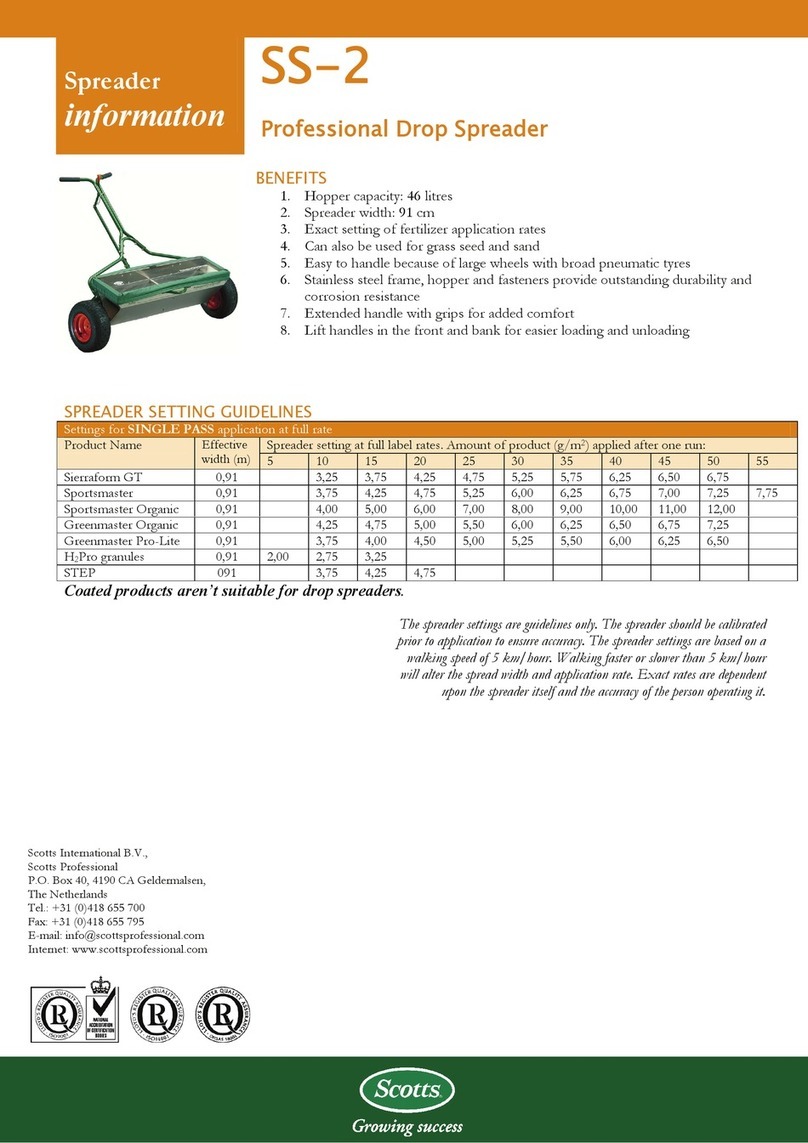

Power Train

Conveyors

13

Description

Spread Hopper

14

2016

Gate Control Valve

Box

Computerized Rate Control (CRC)

15

Description

16

2016

Chassis

Hydraulically Powered

Remote Control Hitch

NOTE: When equipped with the optional hitch lift, hitch height is also

adjustable from the operator’s control panel.

Operator Control Station Layout

17

Description

CONTROLS

DASH PANEL

1 Pre-Heat

2 4 x 4

3 TURN SIGNAL

4 EMERGENCY FLASHER

5 LEFT TURN LAMP

6 PARK BRAKE

18

2016

7 ACC. POWER

8 IGNITION

9 RIGHT TURN LAMP

10 LOW/LOCK

11 TRANSFER-CASE

12 BEACON

13 WORK LIGHTS

14 HEADLIGHTS

15 DISPLAY

19

Description

CONSOLE

1 FWD-REV.

2 HITCH

3 HITCH LIFT

4 STALL POT

5 MAX SPEED

6 HORN

20

2016

7 CRUISE CONTROL

8 MEET LINE

9 MASTER

10 LEFT BOX Manual Gate Operation (Optional)

11 RIGHT BOX Manual Gate Operation (Optional)

12 GATES (Taper Cut from left)

13 GATES (Taper Cut from right)

14 LEFT BELT CONTROL

15 RIGHT BELT CONTROL

16 LEFT (FRONT) AUGER

17 RIGHT (REAR) AUGER

18 MANUAL LEFT BELT & AUGER

Table of contents

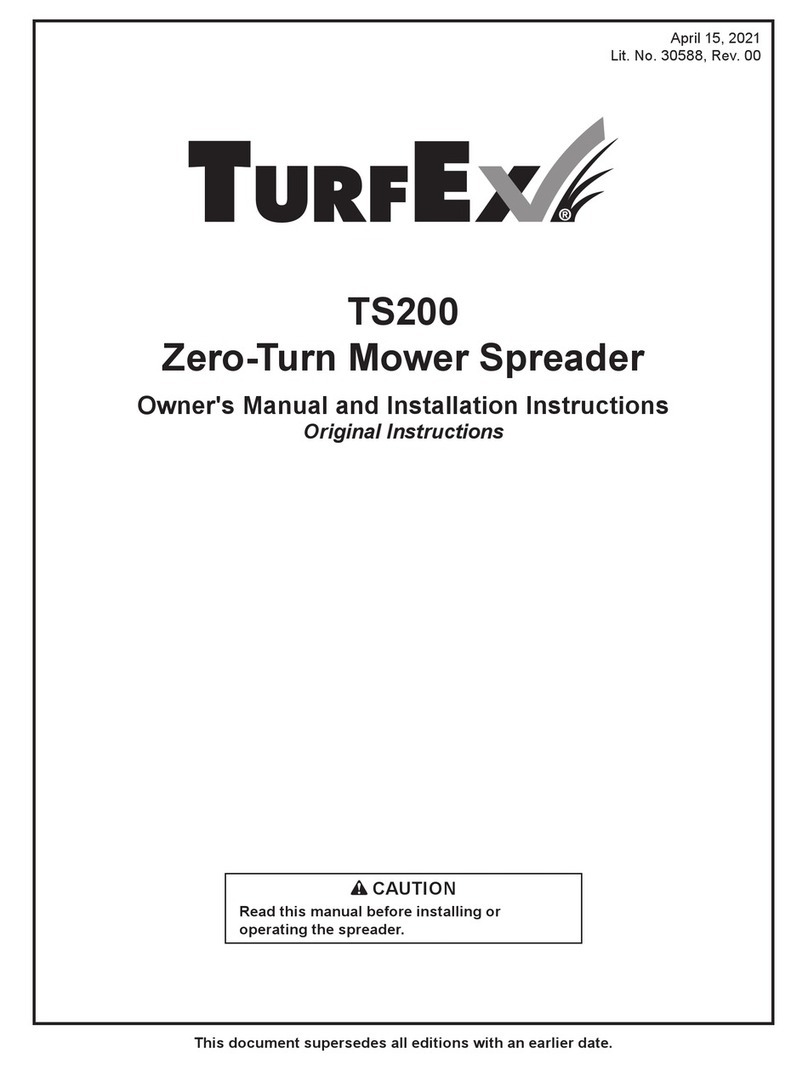

Popular Spreader manuals by other brands

Enerpac

Enerpac WR-13 Repair Parts Sheet

TurfEx

TurfEx TS-200 Owner's manual and installation instructions

Trynex International

Trynex International TurfEx TT5000 owner's manual

The Handy

The Handy THTS Operators manual & parts lists

SPYKER

SPYKER S80-12010 Operator's manual

Turf Equipment

Turf Equipment Z-SPRAY JUNIOR Series Operator's manual