©2021 Spyker Spreaders/A Brinly-Hardy Co. Page 3 1019225-D

Part List

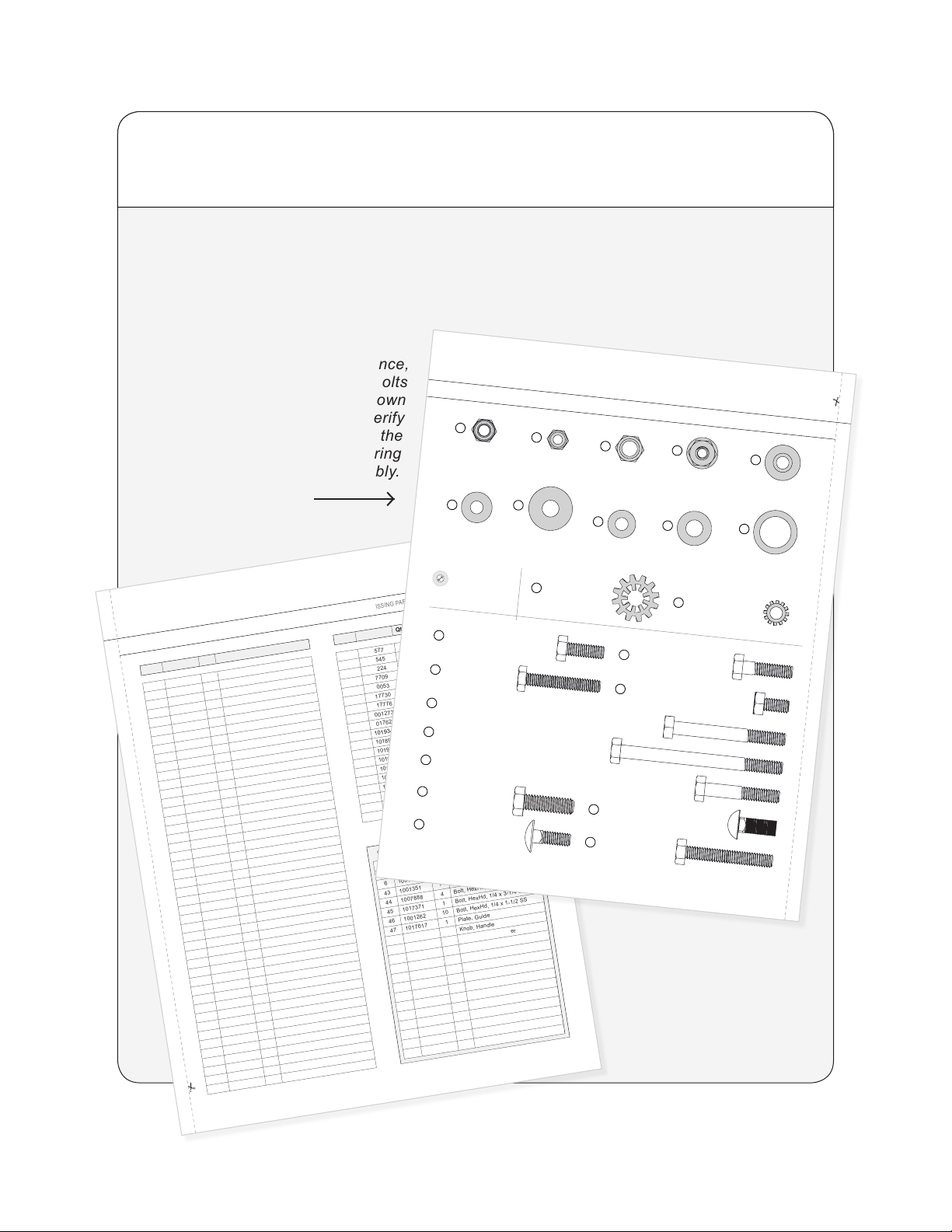

DO NOT RETURN PRODUCT IF YOU ARE MISSING PARTS. PLEASE CALL: 1 (800) 972-6130

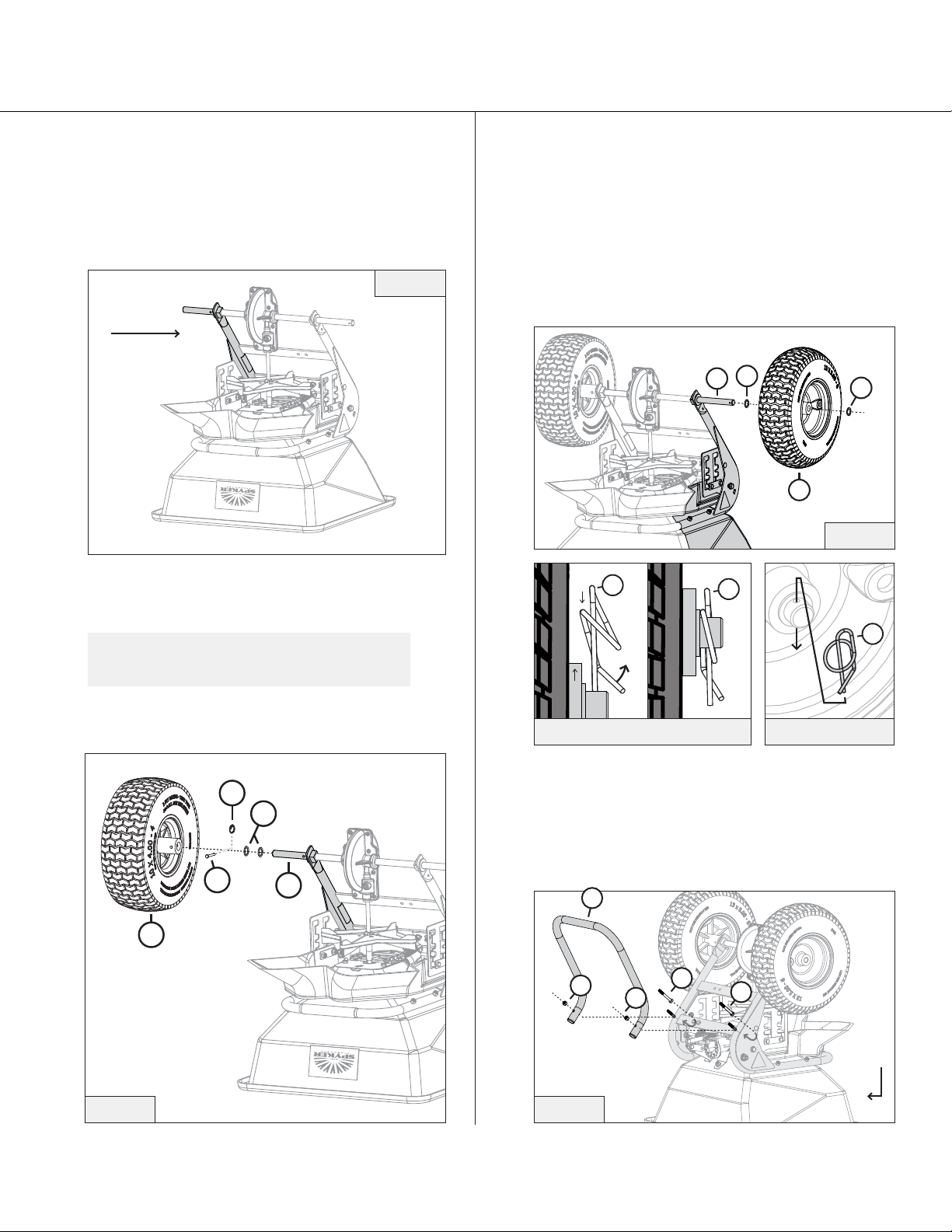

No. Part # Qty Description

11006084 5Bolt, HexHd 1/4 x 3/4 SS

3 1005198 6 Nut, NylonLock, SS: 1/4”-20

41017543 1Plate, Linkage

51017501 1Bracket, Linkage

71017340 1Control Linkage Assembly

81001255 3Bolt, 1/4-20 x 1" HexHd,SS

91017551 1Bolt, HexHd 1/4-20 x 1.50

10 1017503 1Spring, Gate

11 1008431 1Rate Gate Link, Formed

12 1017580 1Plate, Hopper Bottom

13 1000203 1Hopper Bottom Bearing

14 1004880 4Bolt, HexHd 1/4 x 1/2 SS

15 1001521 2Guide, Rate Gate/Accuway

16 1000210 1Rate Gate

20 1000215 1Pine Tree Clip

21 1000211 1Dial Mount

22 1000213 1Dial, Plastic

23 1000198 2Felt Washer

24 1000051 1Spreading Spinner

25 1000844 1Agitator Blade

26 1017420 1Spinner Shaft, 50 Lb

27 1000054 1Roll Pin 1/8 x 7/8

28 1001301 23/8 Spinner Shaft Bushing

29 1001518 1Pinion Gear - Metal

30 1001299 2Gearbox Bushing 5/8"

31 1018126 1Axle, Wheel SS

32 1001304 1Dowel Pin, 3/16 x 1, SS

33 1001516 1Bevel Gear-metal

34 1005389 1Nylon Spacer, Pin Retain

35 1005336 1Gear Box Cover Front

36 1005368 1Grease Zerk 1/4 Drive IN

37 1017710 8Bolt, PhlpHd 10-24 x 5/8" SS

38 1005337 1Gear Box Cover Rear

39 1001308 8Nut, NylonLock, #10-24 SS

40 1000225 2Handle Grip

41 1019217 1Weldment, Handle, SS

42 1000000 1On-off Decal

51 1017502 1Linkage

52 1019222 1Handle, Lower, SS

57 1017504 2Cap, Plastic

58 L-1744-6 1Label, Serial#, Spyker

59 1019219 1Medium Frame Weldment, SS

60 1019223 1Stand, Med Frame, SS

63 1001607 2Wheel, 13”

64 F-283 2Bearing, Axle

67 1019225 1Manual

No. Part # Qty Description

68 1017577 1Cover, Hopper 50#

69 1017545 1Screen, 50#

70 1019224 1Hopper, 50# Blue

72 1017709 1Decal Spyker Ice

74 1000053 1Roll Pin, 1/8 x 3/4

75 1017730 1Spacer, Plastic

77 1017776 1Support Bracket

78 1001273 1Hairpin (299 Agitator), SS

79 1017626 3Label, Reflective

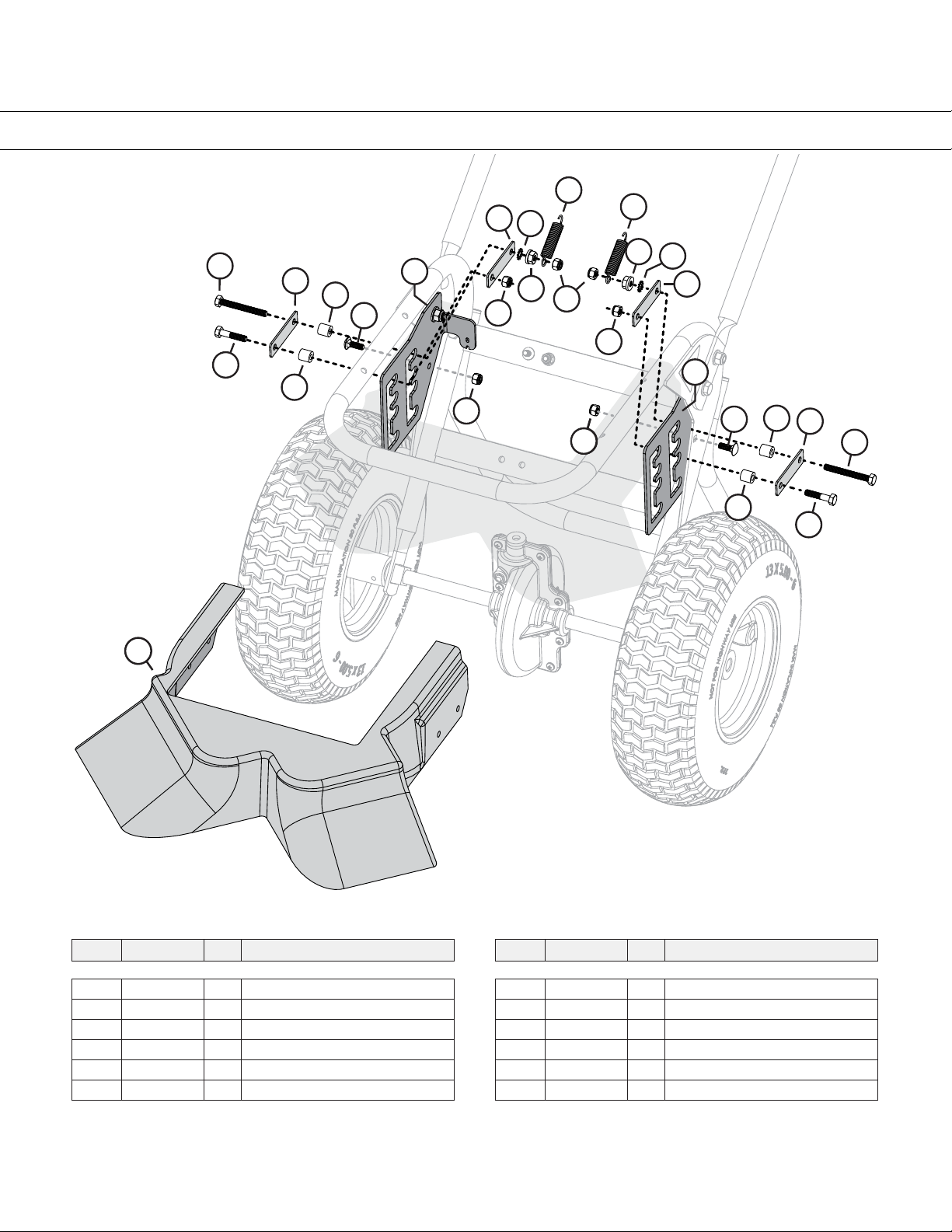

80 1019349 1Deflector

81 1018993 4 Spacer, Plastic

82 1019231-LH 1 Mounting Bracket, LH

83 1019231-RH 1 Mounting Bracket, RH

84 1018708 4 Stiffener Plate

86 1018738 2 Spring

87 1018740 2 External Tooth Lockwasher

88 1004975 2 Nut, 1/4-20 Hex Flange

89 1007386 2 Bolt, Carriage, SS: 1/4”-20 x 3/4”

90 1019001 2 Bolt, HexHd: 1/4”-20 x 1-3/4”

92 1018577 1 Parts Bag

21001554 9Washer, Nylon

31005198 23 Nut, NylonLock 1/4-20, SS

61001533 2Nylon Flange Bushing

43 1001351 7Washer, 1/4" SS

44 1007888 4Bolt, HexHd, 1/4 x 2-1/4 SS

45 1017371 1Bolt, HexHd, 1/4 x 3-1/4 SS

46 1001262 10 Bolt, HexHd, 1/4 x 1-1/2 SS

47 1017617 1Plate, Guide

48 1007828 2Knob, Handle

49 1017346 1Spring, Control Lever

50 1017345 1Lever, Control

53 1001315 4Nut, NylonLock 5/16-18

54 45M1111SS 6 Washer, Flat, SS-5/16"

55 1008811 2Bolt, Hex 5/16-18 x 1 SS316

56 1017374 2Bolt, Carriage, 5/16 x 3/4

61 1005414 1Rue Ring Locking Pin

62 1001350 5Washer, Flat SS

65 1001274 1Clevis Pin, 3/16 x 1-3/4

66 1019596 1Cotter Ring

73 1017344 1Control Lever Stop

76 1017725 2 Lock Washer Ext/Int Tooth 5/16