English Manual 31008754-B

Safety

OPERATING SAFELY

General:

• Read this manual and the manual of the vehicle

you are attaching the spreader onto. Be thoroughly

familiar with the controls and the proper use of the

equipment. Know how to stop the vehicle and

disengage the controls quickly.

• This spreader is intended for use in lawn care and snow

/ ice melt applications only. Do not use for applications

other than those intended by the manufacturer.

• Do not let an untrained person or children operate

spreader.

• Do not let anyone, especially children, ride on spreader.

Riders are subject to injury such as being struck by

foreign objects and being thrown off. Riders may also

obstruct the operator's view, resulting in the vehicle

being operated in an unsafe manner.

• Keep bystanders away when you operate spreader.

• Keep hands, feet, clothing, hair, and loose items away

from any moving parts. Failure to check could cause

personal injury.

• To prevent injury to hand:

Personal Protective Equipment:

• Always wear ear and eye protection while

operating the spreader.

• Wear appropriate clothing, footwear, and safety

equipment when operating spreader.

• Do not operate the spreader when barefoot or

wearing open sandals.

• NeverplacehandsintohopperoradjustAccuway

DirectionalControlwhilemotorisrunning.

• Ifusinghandtoopenorclosethegateactuator,

useextension.

RECOMMENDED VEHICLES

and Attachment Method

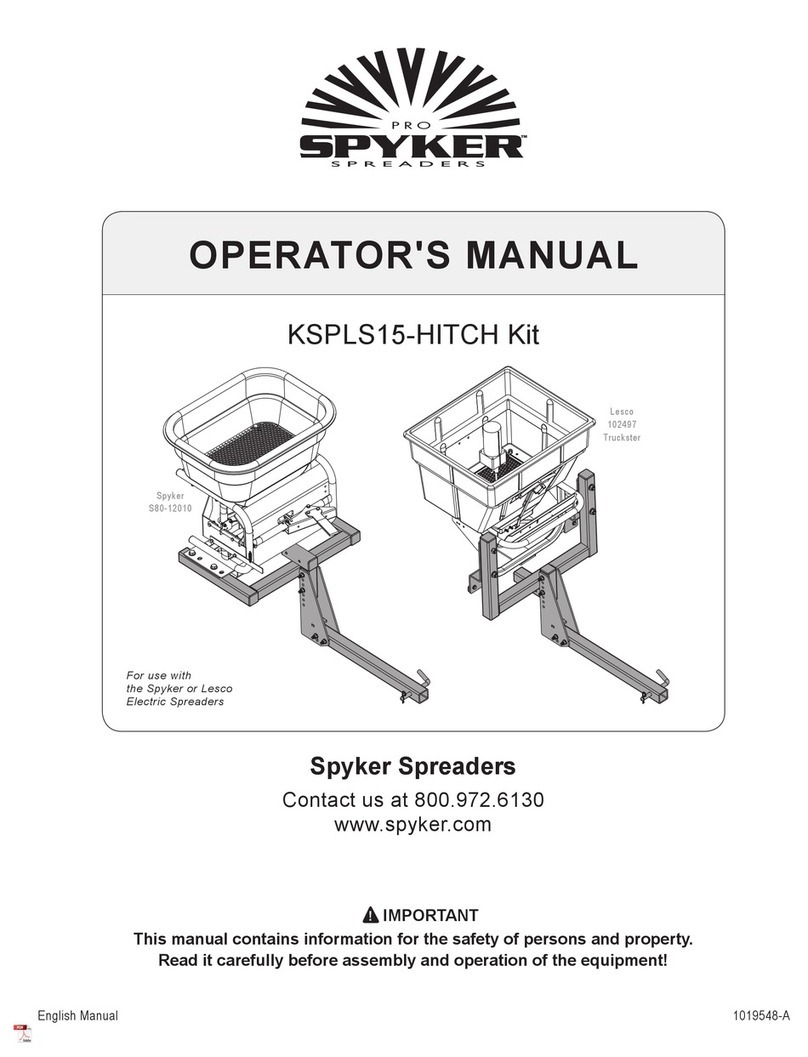

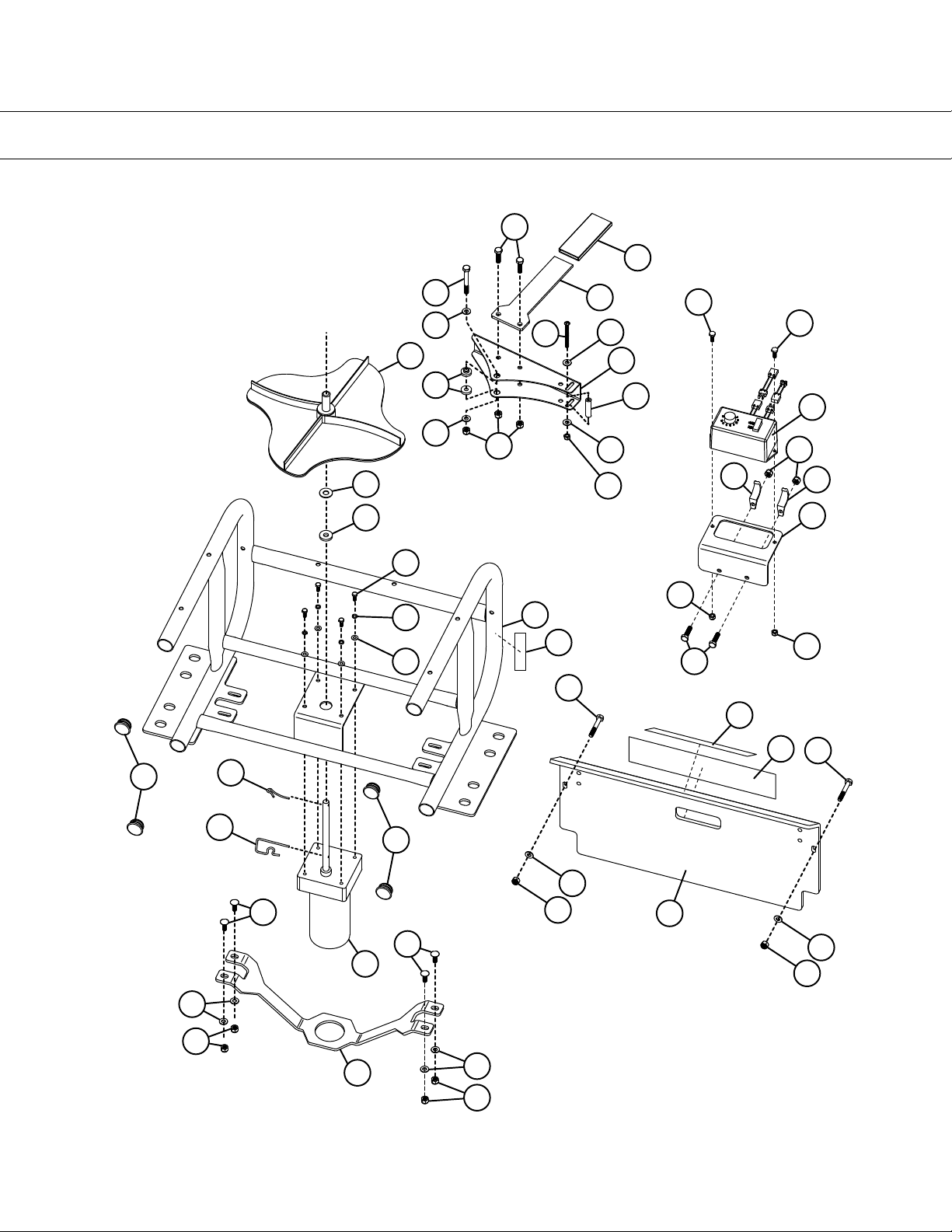

If you have purchased an optional mount kit, follow mount

kit instructions for proper assembly of spreader to vehicle.

If a mount kit is not available for your vehicle, and you are

fabricating your own mount kit, please read and under-

stand the following.

This spreader is to be attached to 4 wheel vehicles only.

The following are the recommended types of vehicles and

minimum vehicle requirements needed to properly mount

the spreader. While significant effort was made to ensure

that the recommended vehicles are safe for operation, it is

up to the operator to use the spreader and vehicle with the

following safe operating practices.

• When spreader is attached to vehicle, be aware that

handling characteristics of vehicle may be affected. To

prevent loss of control when spreader is attached to

vehicle.

• Do not drive on wet slopes. Slippery conditions reduce

traction and could cause loss of control.

• Look behind machine before you back up. Back up

carefully.

• Travel slowly over rough terrain.

• Do not load spreader hopper with more than the

maximum weight capacity.

• Evenly distribute loads in the cargo bed (UTV) or cargo

rack (ATV).

• ReadspreaderOperatorsManual.

• Allowforlongerbrakingdistances.

• Vehicle speed should be less than 10mph.

Speedshouldalwaysbeslowenoughtomaintain

control.Ifyourvehiclemanualspeciesaspeed

slowerthan10mphwhencarryingloads,thendo

notexceedspeciedspeed.

• Donotdriveonslopesgreaterthan10degrees.

• Emptyspreaderhopperandtravelslowlywhile

goingupanddowntrailerramps.