T A B L E O F C O N T E N T S

SAFETY REGULATIONS ........................................................................................... 3

SAFETY REGULATIONS ........................................................................................... 4

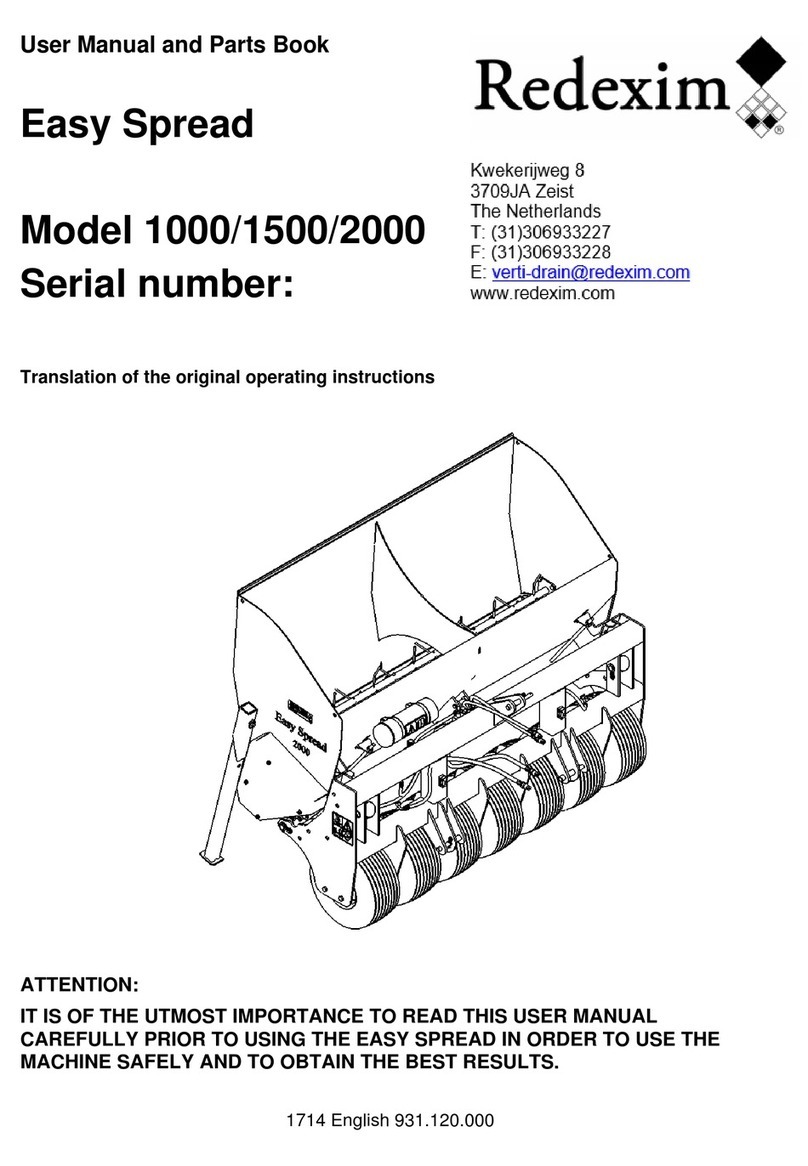

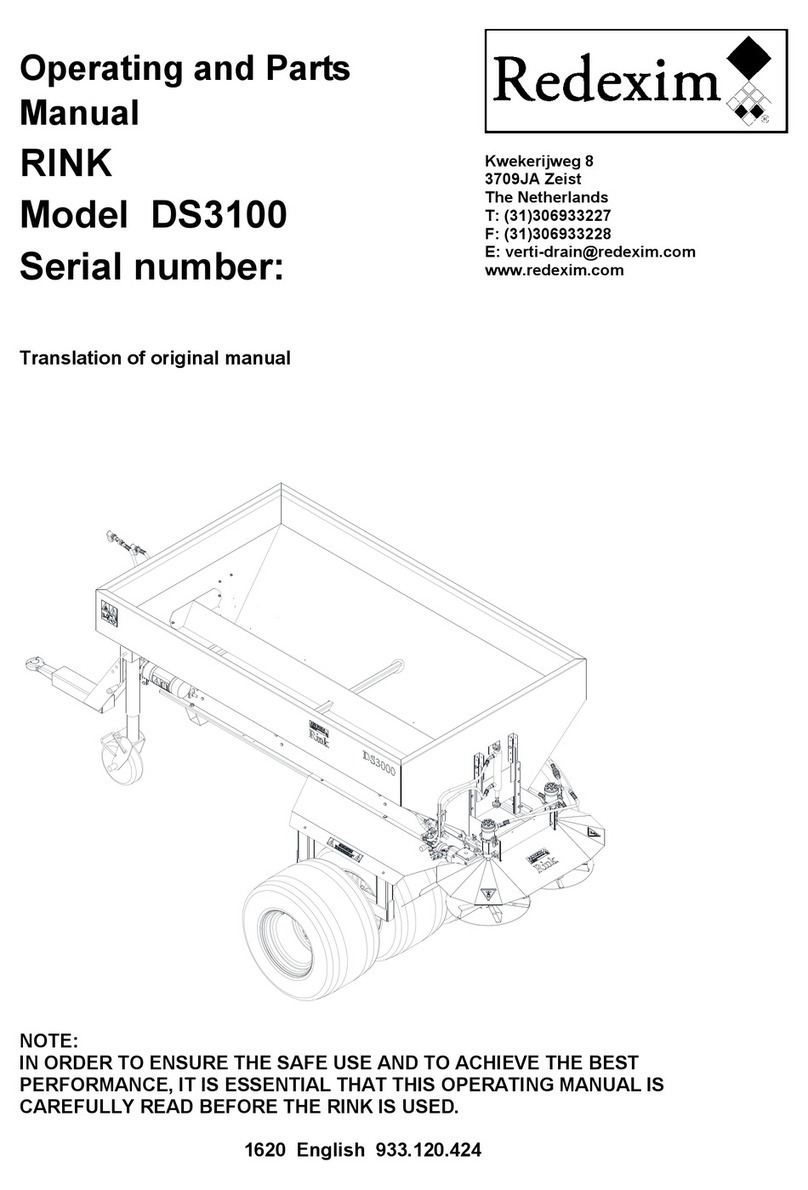

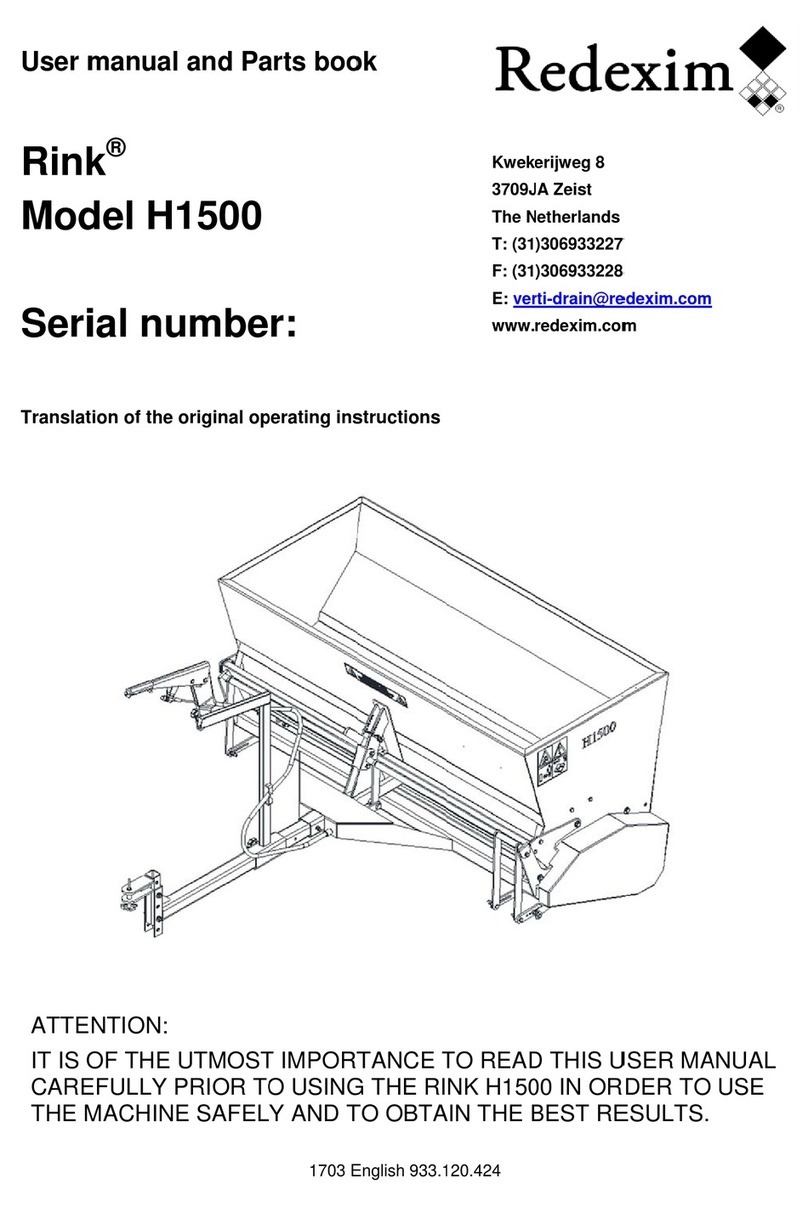

BRIEF DESCRIPTION ................................................................................................ 5

TECHNICAL DATA ..................................................................................................... 5

INITIAL OPERATION ................................................................................................. 6

SERVICE .................................................................................................................... 7

Attaching and detaching ...................................................................................................................... 7

Before each use .................................................................................................................................. 8

Loading ................................................................................................................................................ 8

Starting ................................................................................................................................................ 8

Control panel ....................................................................................................................................... 9

SPREADING ............................................................................................................. 11

Spreading using the disc spreader .................................................................................................... 11

Control elements ............................................................................................................................... 11

Spreading various scatter materials .................................................................................................. 13

Disc setting for uneven spreading pattern ......................................................................................... 13

Spreading using the cross conveyor ................................................................................................. 14

Control elements ............................................................................................................................... 14

Set spreading thickness (spreading disc or cross conveyor belt) ..................................................... 16

Spreading table ................................................................................................................................. 16

CARE and MAINTENANCE ..................................................................................... 17

Lubricate bearings with multipurpose grease (after every 50 hours of operation) ............................ 17

Change oil on the pump gearbox (every 100 operating hours) ......................................................... 19

Change oil of the conveyor belt transmission (every 100 operating hours) ...................................... 19

Change pressure filter (display via ERROR light) ............................................................................. 1 9

Setting cylinder stop of position switches .......................................................................................... 19

Change hydraulic tank oil (as required) ............................................................................................. 21

Service shaft (every 100 operating hours) ........................................................................................ 22

Retension conveyor belt (if slipping) ................................................................................................. 22

Removing and installing conveyor belt ................................................................. 23

Retensioning the conveyor belt after installation ............................................................................... 23

Lighting system # ............................................................................................................................... 25

Hydraulic brake axle# ......................................................................................................................... 26

Troubleshooting ................................................................................................................................. 27

Subject to technical changes.

The equipment marked #is only available as special equipment.