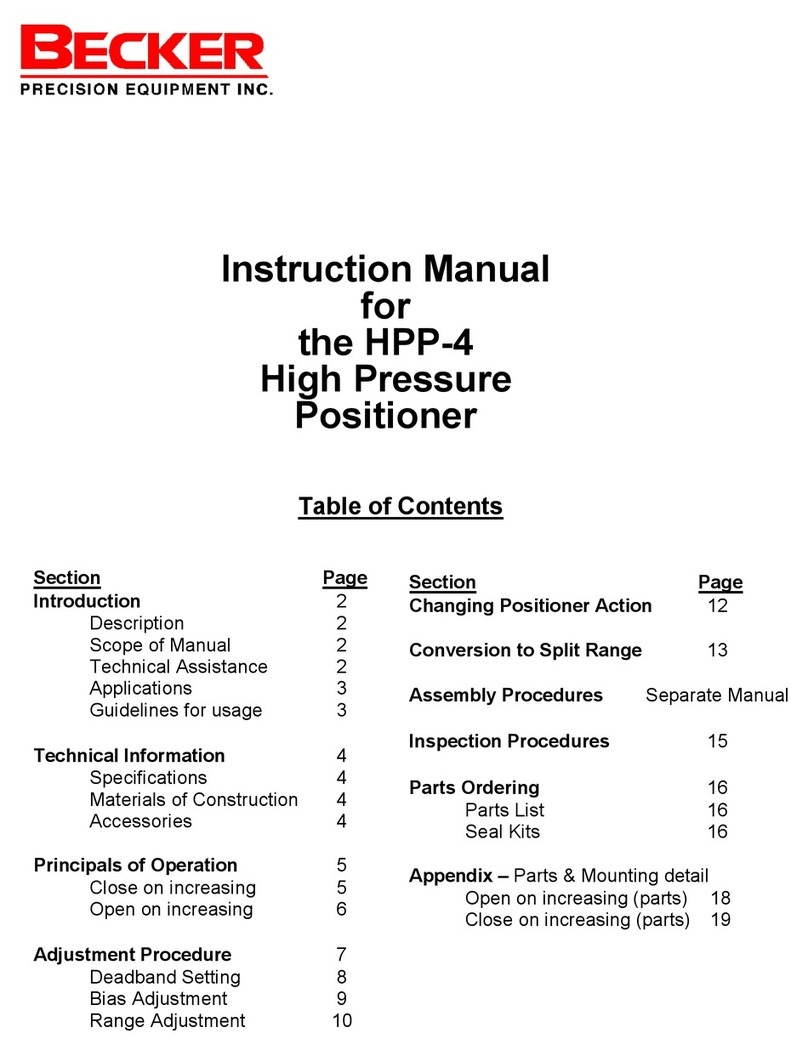

HPP-4 Positioner

Instruction Manual

Introduction

The Becker HPP-5series positioner

represents a breakthrough in valve con-

trol technology for the natural gas in-

dustry. Built to exacting specifications,

the easily maintained unit offers highly

accurate control with excellent control

characteristics in a broad range of oper-

ating environments. The HPP-5series

positioner is designed such that upon

reaching a valve position and achieving

a steady state, the gas consumption is

very low. Additionally, its bleed gas

can be routed to a lower pressure

downstream or fuel gas system, elimi-

nating bleed gas completely. This

means significant savings to your com-

pany in terms of minimizing expensive

bleed gas as well as a cost saving

means of minimizing the environmental

impact of atmospheric hydrocarbons

and diminishing natural resources.

Description

The Becker HPP-5positioner is used in

control valve assemblies with a control-

ler or I/P transducer and double acting

actuator to provide accurate flow or

pressure control. The HPP-5 can be

used with various valve types that utilize

a double acting pneumatic piston ac-

tuator. The HPP-5 design positioner

represents Becker’s commitment to

continuos development of new products

and updating of existing products to

maximize their performance while re-

taining simple operation and minimum

maintenance.

Valves over 16” in diameter require the

use of a Becker HPP-4positioner with

Volume boosters.

Scope of Manual

This manual provides information on in-

stallation, operation, adjustment, and

maintenance of the Becker HPP-5po-

sitioner. For information concerning ac-

tuators, valves, and accessories, refer

to the instruction manuals provided with

the specific product.

Note: Only those qualified through training or

experience should install, operate, or maintain

Becker positioners. If there are any questions

concerning these instructions, contact your

Becker sales representative, sales office, or

manufacturer before proceeding.

Technical Assistance

Should you have any questions, you

may contact your local Becker Preci-

sion sales representative or Becker

Precision technical assistance at:

Becker Precision Equipment, Inc.

Attn: Technical Assistance

950 Pratt Boulevard

Elk Grove Village, IL 60007 USA

Toll Free: (800) 323-8844

Tel: (847) 437-5940

Fax: (847) 437-2549

HPP-52September 1999