BECKWITH ELECTRIC M-0329B User manual

Instruction Book

M-0329B LTC

Backup Control

• Prevents a defective LTC tapchanger control from running the voltage

outside the upper or lower limits

• Prevents the line drop compensator from raising the voltage too high

under full or overload conditions

• Fully transient protected and operates within ±1% voltage accuracy over

a temperature range of –40° to +80° C

• Includes First Customer Protection

LTC Backup Control

M-0329B

CONTROLS

–2–

M-0329B Backup Control

The M-0329B LTC Backup Control provides the extra protection that can save your customers from the hazards

and inconvenience of excessively high or low voltage. Defective LTC tapchanger controls can cause either too

high or too low a voltage along the line, possibly damaging customers' motors, computers or televisions. Even

when the control is operating properly, customers close to the transformer may receive dangerously high voltage

as the line drop compensator attempts to maintain a constant voltage under heavy load at a central point on the

distribution line. The Beckwith Electric M-0329B LTC Backup Control can be installed as a solution to both of

these problems.

The LTC Backup Control will prevent a defective LTC tapchanger control from running the voltage outside the

upper and lower voltage limits and, in addition, will prevent the line drop compensator from raising the voltage too

high under full load or overload conditions. Setting the voltage bands on the M-0329B slightly wider than the

transformer control limits will assure that a failed control will not result in a runaway LTC transformer. Under full

or overload conditions, the control automatically takes over as an upper voltage limit control, not affected by load

current, to prevent damage to equipment close to the transformer. While the Block Raise contact prevents a raise

operation, a Lower contact forces the tapchanger down if the primary voltage should subsequently rise.

Features

Block Raise and Block Lower voltage levels are set by accurately calibrated BANDCENTER and BANDWITH

controls, similar to those found on LTC transformer controls.

BLOCK RAISE/LOWER and LOWER LEDs indicate backup control status.

Block Raise, Block Lower, Lower and Alarm contacts provide outputs to drive external components.

Inputs

Power: 90 to 140 V ac, 50/60 Hz, 2 W at 120 V ac

Voltage: Less than 0.2 VA burden at 120 V ac input

Front Panel Controls

BANDWITH VOLTS: An accurately calibrated dial adjusts the bandwidth between Block Raise and Block Lower

from 6 V to 24 V for 120 V ac.

BANDCENTER VOLTS: An accurately calibrated dial adjusts the Bandcenter from 100 V rms to 140 V rms

which allows the M-0329B to operate with most transformer controls.

TIME DELAY SECONDS: Adjustable from 1 to 30 seconds. If voltage remains above the maximum (Block

Raise) voltage by the selected amount for longer than the time set on the timer delay control, the M-0329B will

initiate a tapchanger operation to lower the voltage.

Selectable Deadband: The deadband is the voltage range above the Block Raise Level where no tap changer

operation takes place. In the M-0329B, it is selectable as 1, 2, 3, or 4 V rms. Measured voltages above the Block

Raise Level plus the deadband will cause the control to immediately issue a Lower command.

Terminals: Barrier Strip with 8 to 32 screws

LED Indicators

The BLOCK RAISE/LOWER LED will light to indicate when the voltage is outside the band.

The LOWER LED will light when the voltage exceeds the Block Raise level for an adjustable time period.

Output Contacts

Output Contacts: Contacts are rated at 2 A at 120 V ac.

Blocking Contacts: Contacts will operate within 0.2 seconds after a voltage excursion to prevent the transformer

control from causing another tapchange.

Alarm Contacts: After a fixed 3 minute time delay, if the voltage excursion is still present, the alarm is activated

to indicate control failure.

–3–

M-0329B Backup Control

EnvironmentalEnvironmental

EnvironmentalEnvironmental

Environmental

Temperature Range: Operates within ±1% voltage accuracy as per the following:

IEC 68-2-1 –40° C 96 hour duration

IEC 68-2-2 +80° C 96 hour duration

IEC 68-2-3 +40° C 93% RH 96 hour duration

Fungus Resistance: A conformal printed circuit board coating inhibits fungus growth.

Transient Protection

Input and output circuits are protected against system transients. The M-0329B will pass all the requirements

of ANSI/IEEE C37.90.1-1989, which defines oscillatory and fast transient surge withstand capability. All

inputs and outputs will withstand 1500 V ac to chassis or instrument ground for one minute. Voltage inputs

are electrically isolated from each other, from other circuits, and from ground.

All faces of the relay, with the chassis solidly grounded, have been exposed to Radio Frequency Immunity

testing and have successfully passed with a field intensity of 20 V per meter at typical utility frequencies of

144 MHz, 438 MHz, and at 450 MHz.

Physical

Size: 5–3/4" high x 8–3/4" wide x 3–1/2" deep (14.6 cm x 22.2 cm x 8.9 cm)

Approximate Weight: 3 lbs (1.4 kg)

Approximate Shipping Weight: 5 lbs (2.3 kg)

Patent & Warranty

The M-0329B LTC Backup Control is covered by a five year warranty from date of shipment.

Specification subject to change without notice.

I

S

O

9

0

0

1

:

2

0

0

0

R

e

g

i

s

t

e

r

e

d

BECKWITH ELECTRIC CO., INC.

6190 - 118th Avenue North • Largo, Florida 33773-3724 U.S.A.

PHONE (727) 544-2326 • FAX (727) 546-0121

E-MAIL [email protected]

WEBPAGE www.beckwithelectric.com

800-0329B-SP-02MC2 09/03

©1998 Beckwith Electric Co.

Printed in U.S.A. (06.19.02)

WARNING

DANGEROUS VOLTAGES, capable of causing deat or serious

injury, are present on t e external terminals and inside t e equip-

ment. Use extreme caution and follow all safety rules w en an-

dling, testing or adjusting t e equipment. However, t ese internal

voltage levels are no greater t an t e voltages applied to t e exter-

nal terminals.

DANGER! HIGH VOLTAGE

– This sign warns that the area is connected to a dangerous high voltage, and you

must never touch it.

PERSONNEL SAFETY PRECAUTIONS

The following general rules and other specific warnings throughout the manual must be followed during application,

test or repair of this equipment. Failure to do so will violate standards for safety in the design, manufacture, and intended

use of the product. Qualified personnel should be the only ones who operate and maintain this equipment. Beckwith

Electric Co., Inc. assumes no liability for the customer’s failure to comply with these requirements.

– This sign means that you should refer to the corresponding section of the operation

manual for important information before proceeding.

Always Ground the Equipment

To avoid possible shock hazard, the chassis must be connected to an electrical ground. When servicing

equipment in a test area, the Protective Earth Terminal must be attached to a separate ground securely

by use of a tool, since it is not grounded by external connectors.

Do NOT operate in an explosive environment

Do not operate this equipment in the presence of flammable or explosive gases or fumes. To do so would

risk a possible fire or explosion.

Keep away from live circuits

Operating personnel must not remove the cover or expose the printed circuit board while power is ap-

plied. In no case may components be replaced with power applied. In some instances, dangerous volt-

ages may exist even when power is disconnected.To avoid electrical shock, always disconnect power and

discharge circuits before working on the unit.

Exercise care during installation, operation, & maintenance procedures

The equipment described in this manual contains voltages high enough to cause serious injury or death.

Only qualified personnel should install, operate, test, and maintain this equipment. Be sure that all per-

sonnel safety procedures are carefully followed. Exercise due care when operating or servicing alone.

Do not modify equipment

Do not perform any unauthorized modifications on this instrument. Return of the unit to a Beckwith

Electric repair facility is preferred. If authorized modifications are to be attempted, be sure to follow

replacement procedures carefully to assure that safety features are maintained.

PRODUCT CAUTIONS

Before attempting any test, calibration, or maintenance procedure, personnel must be completely familiar

with the particular circuitry of this unit, and have an adequate understanding of field effect devices. If a

component is found to be defective, always follow replacement procedures carefully to that assure safety

features are maintained. Always replace components with those of equal or better quality as shown in the

Parts List of the Instruction Book.

Avoid static charge

This unit contains MOS circuitry, which can be damaged by improper test or rework procedures. Care

should be taken to avoid static charge on work surfaces and service personnel.

Use caution when measuring resistances

Any attempt to measure resistances between points on the printed circuit board, unless otherwise noted

in the Instruction Book, is likely to cause damage to the unit.

TT

TT

TABLE OF CONTENTSABLE OF CONTENTS

ABLE OF CONTENTSABLE OF CONTENTS

ABLE OF CONTENTS

M-0329B LTC Backup Control

Instruction Book

1.1 Introduction ................................................................................................................... 1

Figure 1 Setpoint Voltage Levels ............................................................................... 1

2.1 Installation .................................................................................................................... 2

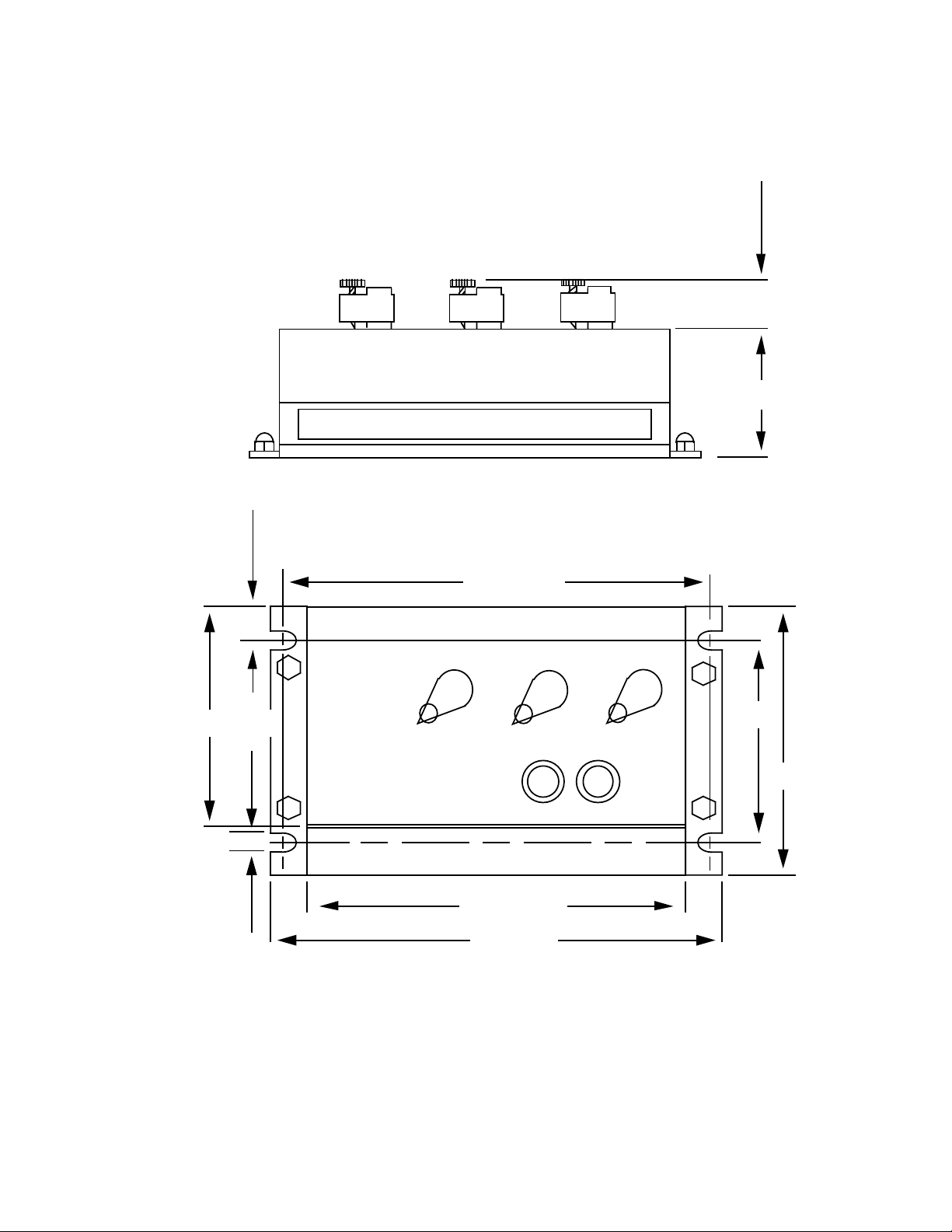

Figure 2 Mounting and Outline Dimensions ................................................................

3

3.1 Terminal Block Connections ......................................................................................... 4

F

igure 3 Wire Terminations for External Connections As Required for UL Listing .......

4

Figure 4 External Connections ....................................................................................

4

4.1 Application .................................................................................................................... 5

Figure 5 Power and Voltage Input Connections ..........................................................

5

Figure 6 M-0329B Interconnections with Beckwith

Tapchanger Controls and Regulator ..............................................................................

5

Table 1 TCC Connections ...........................................................................................

6

Figure 7 Interconnections for use with Centrifugal-type Capacitor Drive Motors .........

7

5.1 Adjustment ...................................................................................................................8

6.1 Theory of Operation ...................................................................................................... 8

Power Supply ................................................................................................................ 8

AC/DC Converter .......................................................................................................... 8

Level Detectors ............................................................................................................. 8

Power Supply Monitor ................................................................................................... 8

Lower Time Delay ......................................................................................................... 9

Alarm ............................................................................................................................ 9

Selectable Deadband .................................................................................................... 9

Table 2 Switch Position Settings ................................................................................

9

Figure 8 Schematic ..................................................................................................

10

Figure 9 Block Diagram ............................................................................................

12

7.1 Maintenance ............................................................................................................... 13

8.1 Test Procedure ........................................................................................................... 14

Equipment Required .................................................................................................... 14

Figure 10 Test Setup ................................................................................................

14

Test Setup .................................................................................................................. 15

Procedure for Determining Voltage Bandcenter ........................................................... 15

Test Procedure ........................................................................................................... 15

Bandcenter Test ......................................................................................................... 15

Bandwidth Test ........................................................................................................... 15

Deadband (Block Raise to Block Lower) Test ............................................................. 15

Lower Timer Delay Test .............................................................................................. 15

Fixed Alarm Time Delay Test ..................................................................................... 15

Removing the Printed Circuit Board ............................................................................ 16

Component Replacement Procedure ........................................................................... 16

9.1 Typical Voltages ......................................................................................................... 16

Table 3 Typical Voltages ..........................................................................................

16

10.1 Typical Resistances.................................................................................................... 17

Table 4 Typical Resistances ....................................................................................

17

Figure 11 Component Location .................................................................................

18

11.1 Calibration ................................................................................................................... 19

Parts List .................................................................................................................... 20

800-M0329B-IB-01MC2 09/03

© Beckwith Electric Co., Inc.

Printed in U.S.A. (06.25.02)

–1–

M-0329B Instruction Book

1.1 Introduction

Defective tapchanger controls can create either

too high or too low a voltage along the line, possibly

damaging customer's motors, computers or

televisions. Even when the control is operating

properly, customers close to the transformer may

receive dangerously high voltage as the line drop

compensator attempts to maintain a constant

voltage under heavy load at a central point on the

distribution line. The Beckwith M-0329B LTC

Backup Control can be installed as a solution to

both of these problems.

Designed to replace the Beckwith M-0029 LTC

Control Backup Relay as well as the M-0145 First

Customer Protector, the single-phase, solid-state

M-0329B has three main functions:

1. Prevent a defective LTC tapchanger

control from running the voltage outside

the upper and lower voltage limits.

2. Prevent the line drop compensator from

raising the voltage too high under full

load or overload conditions.

3. Lower the voltage if the regulated voltage

goes above the Block Raise setpoint by

a fixed bandwidth, as shown in Figure 1.

The Block Raise and Block Lower voltage levels

are set by accurately calibrated dials, labeled

BANDCENTER and BANDWIDTH, similar to those

found on LTC transformer controls.

The amount of Deadband between the Block Raise

and the Lower levels can be selected by the

customer, using a switch on the side of the unit.

The BANDCENTER dial has settings from 100 V

rms to 140 V rms that allow the relay to match any

transformer control.

Above the Block Raise level, the relay will detect

voltage above the Lower setpoint. This point is at a

fixed level above the Block Raise, and will initiate a

lower tapchange operation if exceeded for an

adjustable amount of time (1 to 30 sec) as set on

the TIME DELAY control.

Blocking contacts on the M-0329B will operate

within 0.2 seconds after a voltage excursion to

prevent the defective transformer control from

causing another tapchange. After a fixed 3 minute

time delay, if the voltage excursion is still present,

the ALARM contact is activated to indicate control

failure.

Under full or overload conditions, the M-0329B

automatically takes over as an upper voltage limit

control, not affected by load current, to prevent

damage to equipment close to the transformer.

While the Block Raise contact prevents a raise

operation, a Lower contact forces the tapchanger

down if the primary voltage should subsequently

rise.

FIXED DEADBAND

LOWER

BLOCK RAISE

BLOCK LOWER

V

BL

V

BR

V

CBANDCENTER

1/2 BW

1/2 BW

ADJUSTABLE

BANDWIDTH

Figure 1 Setpoint Voltage Levels

–2–

M-0329B Instruction Book

2.1 Installation

The mounting and outline dimensions are shown

in Figure 2, and the external connections in Figure 4.

■■

■■

■NOTE: TB refers to Terminal Block numbers

shown in Figure 4 External Connections.

The M-0329B can be connected as a two-terminal

device, by paralleling the Power Input (TB1-1 to

TB1-2) and the Voltage (Sensing) Input (TB1-3 to

TB1-4). With this connection, the BANDCENTER

and the BANDWIDTH controls can be set so that

an upper voltage and a lower voltage limit are

established at the desired levels. The M-0329B will

block any further tapchanger raise operations when

the regulated voltage exceeds the upper voltage

limit. Also, if the voltage drops below the lower

limit, the M-0329B will block any further lower

operations. Additionally, if the voltage level

increases above the upper limit (Block Raise) the

M-0329B will lower the voltage, protecting

customers from excessively high voltage levels.

The M-0329B also provides the First Customer

Protection function that previously required a

separate relay. If the LDC raises the local voltage

due to heavy load current, the M-0329B will protect

nearby customers from high voltage, and will act

as an LTC control around the upper voltage limit.

On controls where compensated voltage from the

line drop compensator is available, the M-0329B

can be connected as a four-wire device. The Power

Input should be connected to a 120 V ac source

and the Voltage Input is then connected to the

LDC compensated voltage.

Since sudden changes in the transformer primary

voltage may move the secondary voltage outside

the range of the LTC control and the M-0329B, a 3

minute timer is provided to allow a normal control

to correct the voltage. After 3 minutes of abnormal

voltage, the M-0329B ALARM contact will indicate

an abnormal condition. The BLOCK RAISE/

LOWER LED will be on, the ALARM relay contacts

TB1-14 to TB1-15 will be closed and TB1-15 to

TB1-16 will be open. The ALARM contacts will

also indicate an alarm condition if the AC power to

the M-0329B fails.

The ALARM contacts should be used to alert

system operators that a problem has occurred and

that the LTC transformer or regulator is not

operating. It must be recognized that the ALARM

contacts may operate under conditions of heavy

load using the two-wire connections and the line

drop compensator.

The output blocking contacts should be connected

in series with the raise and lower contacts from the

LTC control. In some control circuits, a timing relay

is used. There, the blocking contacts should be in

series with the timing relay contacts. The blocking

relay contacts should not be connected to drop out

the motor starter relay once it is sealed in for a

tapchange, since most tapchangers should not be

stopped until the tapchange is completed. An

exception to this is a spring-driven tapchanger that

may be stopped at any time. Figure 6 shows the

connections for using the M-0329B with most of

the Beckwith Tapchanger and Regulator Controls.

When power is suddenly changed from raise to

lower, motors with centrifugal starters will continue

to run in the wrong direction without reversing. A

defective control timer, for example, could lead to

this type of runaway situation. Here, the M-0329B

will open up the wrong connection if connected as

described above. The circuit of Figure 7 may be

used instead, where timer relay KX permits the

motor to stop regardless of its direction. It is

assumed that the motor will start in the right direction

once it has stopped.

–3–

M-0329B Instruction Book

1-1/8" Max

(2.86 cm)

2-3/8"

(6.03 cm)

TB1

4-3/4"

(12.07 cm)

8-3/4"

(22.23 cm)

7-3/4"

(19.69 cm)

1/2"

(1.27 cm)

8-1/4"

(20.96 cm)

5-3/4"

(14.61 cm)

4-3/4"

(12.07 cm)

1/4"

(.64 cm)

■■

■■

■NOTE: Panel mount using four #10 bolts

Figure 2 Mounting and Outline Dimensions

–4–

M-0329B Instruction Book

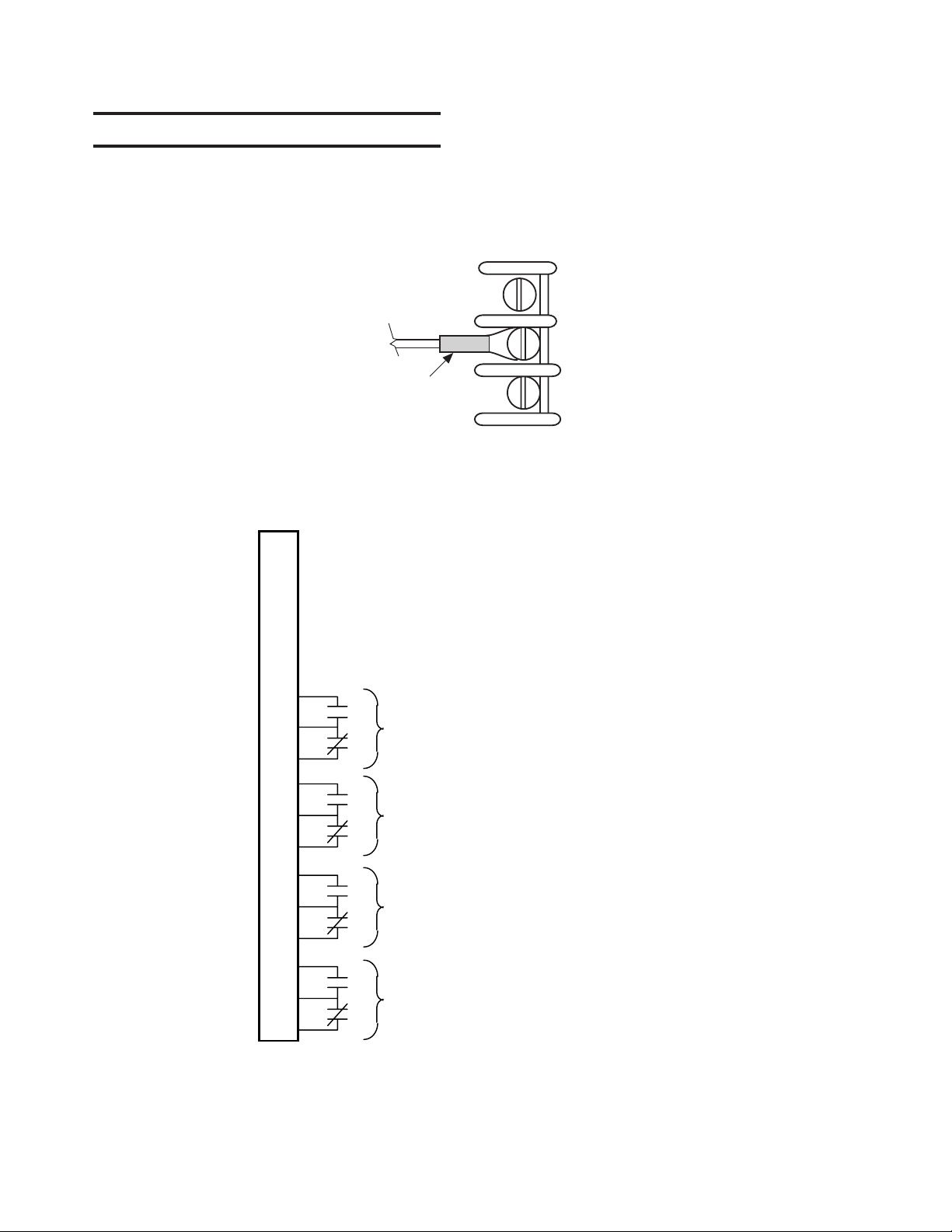

3.1 Terminal Block Connections

The M-0329B LTC Backup Control is listed to UL

Standards for Safety by Underwriters Laboratories

Inc. (UL). To fulfill the UL requirements, terminal

block connections must be made as illustrated in

the figure below. The wire should be No. 16 AWG

inserted in an AMP #51864-1 (or equivalent)

connector, and both screws tightened to 16 inch-

pounds torque.

16 AWG

AMP #51864-1

or equivalent

Recommended Wire Terminations

Tighten to 16 inch-pounds

Figure 3 Wire Terminations for External Connections as Required for UL Listing

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

TB1

•

•

•

•

BLOCK

120 V ac Power Input Hot

120 V ac Power Input Neutral

Voltage (Sensing) Input Hot

Voltage (Sensing) Input Neutral

BLOCK

RAISE

ALARM

LOWER

LOWER

■■

■■

■NOTE: All contacts are shown in the inactive (normal) condition, i.e. the output contact between TB1-14

and TB1-15 is open for the No Alarm condition and will close to indicate an Alarm Condition.

Figure 4 External Connections

–5–

M-0329B Instruction Book

TB1

120 V

1

2

3

4

M-0329

TB1

M-0329

1

2

3

4

LDC VOLTAGE

120 V POWER

Figure 5 Power and Voltage Input Connections

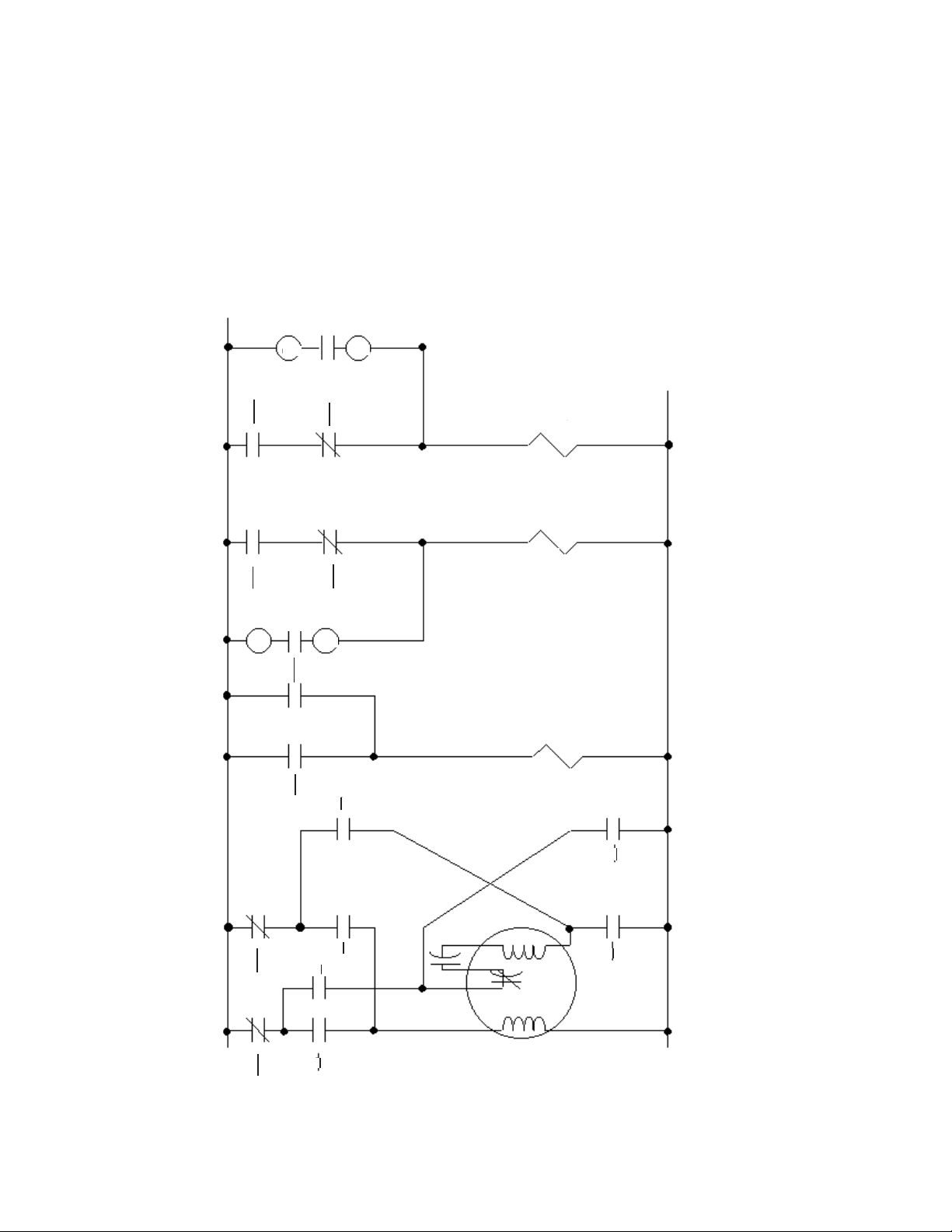

TAPCHANGER CONTROL

90

MOTOR

SUPPLY

R

L

L

c

R

LOWER

BLK RAISE

BLK LOWER

11

12

*

*

6

7

9

10

90 B.U.

C

84R 84L

Limit switcher, auxiliary contacts as

required in motor control circuits.

84R - Raise Motor Auxiliary Relay

84L - Lower Motor Auxiliary Relay

1

120 Vac

POWER

2

3

4

Voltage

14

15

Alarm

■■

■■

■NOTE: *If first customer protection is not required, delete these connections.

Figure 6 M-0329B Interconnections with Beckwith Tapchanger Controls and Regulator

4.1 Application

The M-0329B can be used in many applications

not related to LTC backup for a very accurate

overvoltage and/or undervoltage relay. The Block

Raise (BLK R) and the Block Lower (BLK L)

outputs can be used as overvoltage and

undervoltage outputs, respectively.

–6–

M-0329B Instruction Book

SNOITCENNOCCCT

TINU

SREBMUNLANIMRET

R C L

7602-M/7600-M789

1722-M/)1BT(1720-M596

0722-M/0720-M596

)3BT(0822-M/)2BT(0820-M647

)3BT(8722-M/)2BT(8720-M01911

)1BT(3922-M/3920-M596

)NN(3922-M/3420-M72-NN9-NN82-NN

3230-MLJC

4232-M/4230-M522V32

8330-M01911

)4BT(9332-M/9330-M01911

5430-M21V3

5532-M/5530-M3RmV3L

7530-M51E2E81E

Table 1 TCC Connections

–7–

M-0329B Instruction Book

KX BL

BR

**

BR

1

BL

1

BR

3

BL

3

R

3

BR

2

BL

2

L

2

L

4R

4

5

6

9

8

KX

1

KX

2

KX

R,L

BR, BL

O

New Timer Relay - Delay on pickup to assure motor stops before powering in reverse direction.

Existing Raise and Lower.

New Block Raise and Block Lower Relays.

Terminals on M-0329B Backup Relay.

* M-0329B K1 & K2 Contact

s

shown In Band state.

** Timer Relay Contact

shown before timing out.

* M-0329B K3

Block Lower.

* M-0329B K2

Block Raise.

L

3B

2

Figure 7 Interconnections for use with Centrifugal-Type Capacitor Drive Motors

M-0329 K3

Block Lower

–8–

M-0329B Instruction Book

5.1 Adjustment

Accurately calibrated dials, labeled BANDCENTER

and BANDWIDTH, set the Block Raise and Block

Lower voltage levels. The dials on the M-0329B

cover are calibrated in volts for use with a 120 V ac

nominal voltage.

The following equations will assist the user in

choosing the correct setpoints for the M-0329B.

VBR = the Upper Voltage Limit (Block Raise) desired.

VBL = the Lower Voltage Limit (Block Lower) desired.

The Base Voltage is 120 V ac.

VBR + VBL

The Bandcenter Voltage VC= (1)

2

The Bandwidth VBW = VBR - VBL (2)

6.1 Theory of Operation

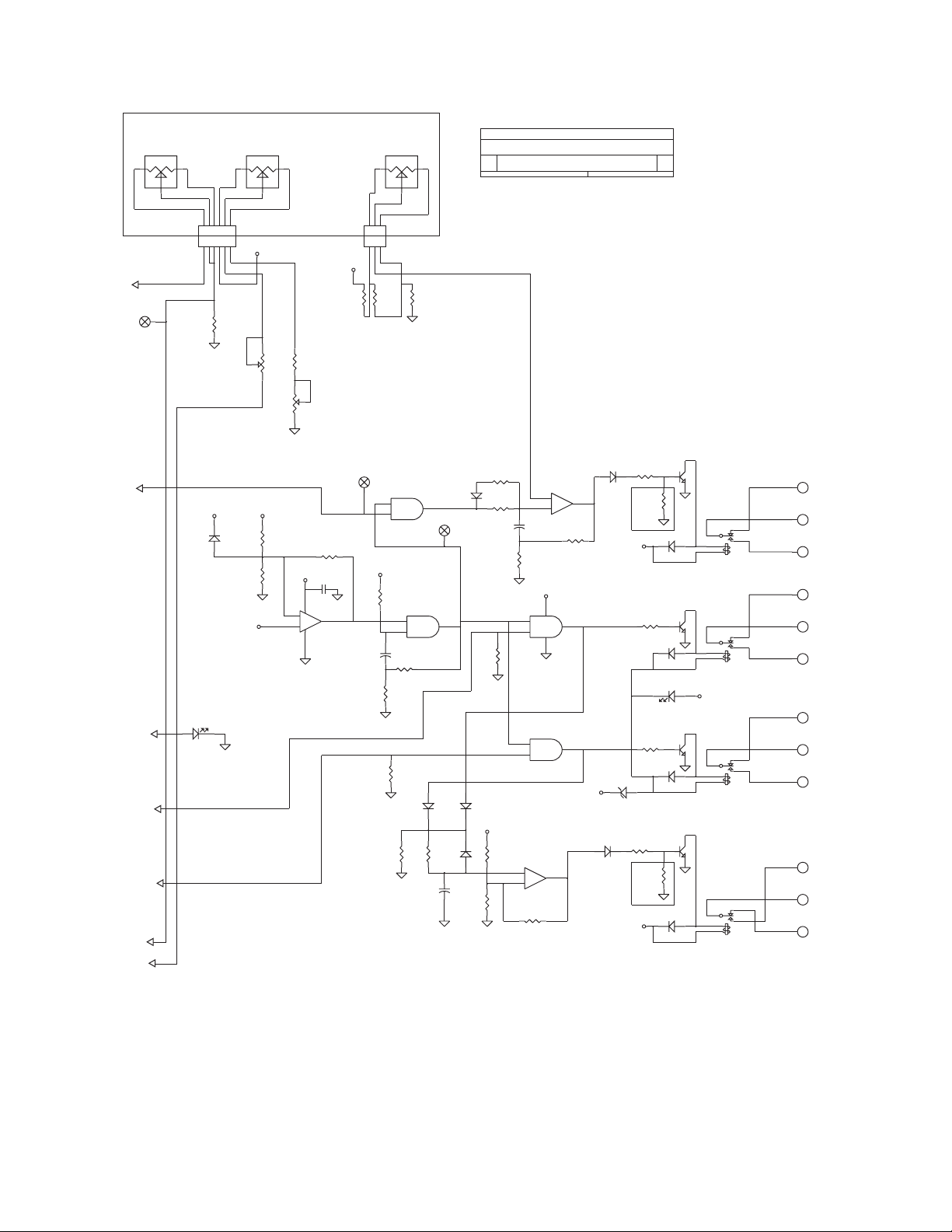

Refer to Figure 8, Schematic and Figure 9, Block

Diagram.

Power Supply

The Power Supply converts the 120 V ac power

input to the dc voltages required for the M-0329B

circuitry. Components C1 and RV1 are used to

suppress transverse-mode transients on the input.

RV2 and RV3 are common-mode suppressors that

allow up to 1500 V rms common-mode voltage but

will clip any transients above this level. T1 converts

the 120 V ac input to 36 V ac, center-tapped at

T1-4. T1 also employs a Faraday shield that isolates

the secondary windings from common-mode

transients on the primary.

Diodes CR1 through CR4 form a full-wave recti-

fier that produces +24 V dc and -24 V dc from

the secondary of T1. Capacitors C2 and C3 filter

the ac ripple off the +24 V dc; C7 smooths out

the -24 V dc. VR1 is a zener diode that clips off,

to a safe level, any transients that may remain

on the +24 V dc, protecting U1 and U5.

U1 converts the +24 V dc to a precision +10.00 V dc

reference voltage for use by the internal circuitry.

The +V supply is a +15 V dc level formed by U5,

R102, R103, C19 & C4. The -15 V is a zener diode

supply using VR3 and dropping resistor R9.

AC/DC Converter

The Voltage Input, TB1-3 to TB1-4, is the voltage

that the M-0329B will monitor to provide the voltage

protection functions described previously. The input

protection circuitry for the Sensing Input is the

same used for the Power Input. Transformer T2

steps down the input level to a lower level used by

the Ac/Dc Converter. U2-1, U2-7 and associated

circuitry form a precision active full-wave rectifier/

filter that converts the ac Sensing Input to a dc

voltage that is proportional to the average voltage

level of the Sensing Input. This dc level at U2-1 is

offset by the BANDCENTER adjustment network,

consisting of R3, R16, R17, R15 and R14; so that

the voltage at U2-1 equals +5.0 V dc when the

Sensing Input level is equal to the setting of the

BANDCENTER dial. Any variation of the input level

from the BANDCENTER setting will cause the U2-1

voltage to deviate from +5.0 V dc by approximately

0.072 V dc/%.

Level Detectors

The Level Detector circuits compare the dc voltage

from U2-1 to dc levels set by the BANDWIDTH

control. R21 and R4 are used in a voltage-divider

circuit to establish the bandwidth. The voltage

across R21 and R4 is centered around +5.00 V dc

so that a symmetrical band is formed around the

BANDCENTER setting. If the U2-1 voltage rises

above the voltage at U2-9, the output at U2-8 goes

high to block any further raise operations of the

tapchanger. If the voltage drops below the level at

U2-12, the voltage at U2-14 goes high, blocking

any further lower operations of the LTC. When the

U2-1 output voltage exceeds the level at U3-6, the

voltage at U3-7 goes high, lighting the LOWER

LED and initiating a lower operation. R23 through

R28 provide a small amount of hysteresis at each

of the voltage levels in order to avoid oscillations in

the level detector outputs.

Power Supply Monitor

The Power Supply Monitor is used to delay the

operation of the BLK R, BLK L, and LOWER relays

for approximately 2 seconds when power is applied.

This eliminates any relay chatter when the M-0329B

is put in service. Also, this circuit monitors the level

of the Power Input and disables the above relays if

the voltage level is below 75 V ac.

–9–

M-0329B Instruction Book

Amplifier U3-1 and associated components form

the voltage level detector that monitors the +24 V

dc level. If the level is below 13.7 V dc, the output at

U3-1 will be low, forcing the output at U4-10 low.

This disables the three relay drive circuits for K1,

K2, and K3. When the +24 V dc level exceeds

14.8 V dc, the output at U3-1 will be high, enabling

the relay drive circuits.

Components R32 and C15 provide the Power Up

delay. C15 is discharged when the power is off.

When power is applied, C15 is charged from +V

through R32. When the voltage on C15 reaches

one half the +V level, the U4-10 output is enabled.

If the voltage at U4-9 is also high, then the output at

U4-10 will go high. This enables the other three U4

gates so that the level detector outputs are enabled

to control the output relays.

Lower Time Delay

Op Amp U3-14 and associated components form

an adjustable time delay for the LOWER relay

operation. By adjusting the TIME DELAY control, a

voltage level is established at the wiper of R5 which

determines the length of the time delay. When the

output at U4-11 goes high, C16 begins charging

through R39. CR14 blocks charging current from

flowing through R38. When the voltage at U3-12

reaches the level set by R5, the output at U3-14

goes high, turning on Q2 and energizing K1. R40

and R41 provide the positive feedback to prevent

oscillations. The length of the time delay is

determined by the setting of R5.

Alarm

The ALARM relay provides an indication that the

M-0329B is in a blocking condition or that the power

is off. Relay K4 is normally energized when there is

no Alarm condition. When K4 is de-energized, an

Alarm is generated by the closing of TB1-14 to

TB1-15 and the opening of TB1-15 to TB1-16.

Therefore, if power to the M-0329B is off, an Alarm

is generated.

In the normal (No Alarm) condition, the output of

U3-8 is high, turning on Q5 through R54 and CR22.

This condition will remain as long as the outputs of

U4-4 and U4-3 remain low. When either of these

goes high, C17 is charged by this voltage through

R50. After 3 minutes, the voltage on C17 will exceed

the voltage established at U3-10, causing the output

at U3-8 to go low, generating an Alarm.

Selectable Deadband

Switch S1 controls the deadband voltage selection.

When position 1 is up and positions 2, 3, and 4 are

down, the deadband selection is 1 V. When position

2 is up and positions 1, 3, and 4 are down, the

deadband selection is 2 V. If more than one switch

is in the “up” position, the control's operation and

deadband setting will be unpredictable.

noitisoPhctiwS

dnabdaeD

gnitteS 1-1S2-1S3-1S4-1S

V1 pU nwoDnwoDnwoD

V2nwoD pU nwoDnwoD

V3nwoDnwoD pU nwoD

V4nwoDnwoDnwoD pU

Table 2 Switch Position Settings

–10–

M-0329B Instruction Book

U2D

LM224

12

13 14

+

-

R6

10

2W,5

CR5

1N4004

TP12

TP8

R25

1K

1/4W,5

R27

9.1K

1/4W,5

T1

U-0256

111

4

28

6

C9

.01uf

125V

R24

330K

1/8W,5

C13

.68uf

50V

R28

7.5M

1/8W,1

U2A

LM224

3

21

+

-

CR7

1N4148

TP6

RV4

250V

R1

100K

1/8W,1

R26

750K

1/8W,1

R14

182K

1/8W,1

R23

1K

1/4W,5

R11

24.9K

1/8W,1

R2

100K

1/8W,1

U2B

LM224

5

67

4

11

+

-

RV5

1KV

C11

.1uf

50V

C12

3.3uf

50V

C4

.01uf

50V

C10

2500pf 1KV

CR9

1N4148

CR10

1N4148

R12

66.5K

1/8W,1

R58

41.2

1/8W,1

S1

DPST

1

16

2

15

3

4

5

6

7

8

14

13

12

11

10

9

R59

16.5

1/8W,1

TP1

R60

0

1/8W,1

R10

49.9K

1/8W,1

R103

1.37K

1/4W,1

R20

24.3

1/8W,1

TP3

TP7

R102

124

1/4W,1

R61

48.7

1/8W,1

TP4

R62

73.2

1/8W,1

TP5

T2

U-0255

212

57

10

R63

97.6

1/8W,1

CR12

1N4148

TB1-4

4

R21

102

1/8W,1

F2

1/2A

TP21

TB1-3 3

TP2

C8

.01uf

125V

RV6

275V

JP2

C19

1uf

50V

R13

24.9K

1/8W,1

R18

1.78K

1/8W,1

JP1

VR1

1N5365B

36V

CR6

1N4004

C7

470uf

50V

+

CR2

1N4004

CR3

1N4004

CR4

1N4004

C2

.05uf

600V

C3

470uf

50V

+

CR13

1N4148

U5

LM317

VIN

3

ADJ

1

VOUT 2

U1

LH0070

IN

1OUT 2

GND

3

C18

.01uf

50V

C6

.01uf

50V

C5

.01uf

50V

CR1

1N4004

VR3

CMZ5929B

15V

(1N965B)

R19

64.9

1/8W,1

R44

3.9K

1/4W,5

CR8

1N4148

U3B

TLC274

5

67

+

-

C1

.01uf

125V

RV2

1KV

RV3

275V

F1

1A

TB1-1 1

RV1

250V

TB1-2 2

R9

1.5K

2W,10

U2C

LM224

10

98

+

-

-15V

+10V

-15V

+24V

+15V

+10V

+10V -15V

-24V

+15V

HOT

NEUTRAL

POT.

INPUT

HOT

NEUTRAL

120VAC

X2

X3

X4

X5

X6

X7

X1

Figure 8 Schematic

–11–

M-0329B Instruction Book

R45

100K

1/4W,5

TB1-14

14

TP10

TB1-16

16

TP11

R80

K4

T75-24VDC

54

3

1

2

R29

100K

1/4W,5

R52

182K

1/8W,1

Q5

2N2222A

2

1

3

R54

20K

1/4W,5

U3A

TLC274

3

2

1

4

11

R35

53.6K

1/8W,1

R51

39.2K

1/8W,1

R30

267K

1/8W,1

CR18

1N4148

R36

56.2K

1/8W,1

R37

2.37

1/8W,1

Q4 2N2222A

2

1

3

CR25

LED

Q3 2N2222A

2

1

3

2N2222A

2

1

3

R38

10K

1/4W,5

C17

4.7uf

63V

R39

10M

1/4W,5

R49

20K

1/4W,5

R50

20M

1/4W,5

CR23

1N4148

R4

500

R16

750

1/8W,1

TLC274

1

9

8

+

-

R47

100K

1/4W,5

CR15

1N4004

P1

C16

4.7uf

63V

R22

1.87K

1/8W,1

R40

100K

1/4W,5

TB1-12

12

TB1-11

11

TB1-13

13

K1

T75-24VDC

5

4

3

1

2

R43

5.1K

1/4W,5

R3

2K

R41

1K

1/4W,5

R5

500K

J2

3

2

1

CR11

1N4148

R33

100K

1/4W,5

CR19

1N414

R34

2K

1/4W,5

CR17

1N4148

C15

4.7uf

25V

+

TB1-6

6

R46

15K

1/4W,5

TB1-8

8

TB1-5

5

TB1-9

9

C14

.1uf

50V

J1

6

5

4

3

2

1

TB1-7

7

TB1-10

10

K3

T75-24VDC

5

4

3

1

2

CR21

MMBD1501/A

U4D

4081

12

13

11

R48

15K

1/4W,5

U4B

4081

5

6

4

14

7

TP9

U4C

4081

8

9

10

U4A

4081

1

23

CR24

LED

P2

1

2

3

R32

510K

1/4W,5

VR4

CMPZ5227B

(1N747A)

3.6V

R15

50K

1/2W,20

R81

?

CR16

1N4148

U3D

TLC274

12

13 14

CR22

1N4004

CR20

1N4148

K2

T75-24VDC

5

4

3

1

2

R31

680K

1/4W,5

CR14

MMBD1501/A

R56

3.9M

1/4W,5

TB1-15

15

R17

200

1/2W,20

+24V

+24V

+24V

+24V

+10V

+15

+15V

+15V

+24V

+15V

+10V

+15V

+15V

BANDCENTER

VOLTS

BANDWITH

VOLTS

TIME DELAY

SECONDS

LOWER

BLOCK

RAISE

BLOCK

LOWER

BLOCKING

ALARM

LOWER

BLOCK RAISE / LOWER

FUTURE

FRONT PANEL

CONNECTIONS

X1

X2

X3

X4

X5

X6

X7

X-0329B B

LTC BACKUP CONTROL

D

Table of contents

Other BECKWITH ELECTRIC Protection Device manuals