Becx Machines OBKS90-45 User manual

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Weedbrush-Edgecutter

OBKS90-45

User Manual

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 2 of 27

Manufacturer Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

Tel: +31 (0) 13 2070760

info@becxmachines.com

http://www.becxmachines.com

© Copyright 2019

Nothing in this publication may be reproduced and/or made public in any form by print, photocopy,

microfilm, recording tape, electronically or by any other means without prior written permission

from Becx Machines B.V.

Becx Machines B.V. reserves the right to modify parts of the system, including the contents of this

manual, at any moment, without prior or direct notification to the buyer.

Although Becx Machines B.V. has taken the greatest care to make sure that individual parts have

been described correctly and in full where necessary, it accepts no liability for damage as a result of

inaccuracies or incompleteness of this manual.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 3 of 27

Preface

The Becx weed brush - edge cutter (in short: weed brush) has been specially developed for quick and

efficient removing of grass growing over the edge of the roadway

The combination of coulter blade and brush makes for a clean sweep in one run.

•Carefully read this manual before using the weed brush. Always

follow the safety instructions set out in chapter 3.

•One copy of this manual must be kept with the weed brush and

must be available to the user. All important servicing sessions and

any comments must be recorded and retained by the servicing

company.

•The user is responsible for selecting a suitable tool carrier for the

weed brush and for ensuring that the weed brush is properly

attached and connected.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 4 of 27

Table of Contents

PREFACE ...................................................................................................................................... 3

TABLE OF CONTENTS .................................................................................................................... 4

FIGURES:...................................................................................................................................... 4

CERTIFICATE OF CONFORMITY (IIA) (COPY) ................................................................................... 5

1TECHNICAL SPECIFICATIONS................................................................................................... 7

2SAFETY.................................................................................................................................. 8

2.1 GENERAL...................................................................................................................................... 8

2.2 IN USE ......................................................................................................................................... 8

2.3 OPERATING PERSONNEL.................................................................................................................. 9

3COMPONENT DESCRIPTION ................................................................................................. 10

3.1 MECHANICAL COMPONENTS TOOL CARRIER ATTACHMENTS................................................................. 11

3.2 MECHANICAL COMPONENTS COULTER BLADE ................................................................................... 12

3.3 MECHANICAL COMPONENTS BRUSH................................................................................................ 13

3.4 HYDRAULIC COMPONENTS ............................................................................................................ 14

4OPERATIONS ....................................................................................................................... 16

4.1 ASSEMBLY AND ADJUSTMENT OF THE WEEDBRUSH ............................................................................ 16

4.2 CARRY OUT BRUSH-AND CUTTING WORK......................................................................................... 17

5MAINTENANCE.................................................................................................................... 19

6FAILURE ANALYSES .............................................................................................................. 21

7REMOVAL............................................................................................................................ 22

8LOGBOOK............................................................................................................................ 23

Figures:

FIGURE 1: OVERVIEWPHOTO................................................................................................................... 10

FIGURE 2: OVERVIEWPHOTO MECHANICAL COMPONENTS TOOL CARRIER ASSEMBLY ......................... 11

FIGURE 3: OVERVIEWPHOTO MECHANICAL COMPONENTS COULTER BLADE ........................................ 12

FIGURE 4: OVERVIEWPHOTO MECHANICAL COMPONENTS BRUSH........................................................ 13

FIGURE 5: OVERVIEWPHOTO HYDRAULIC COMPONENTS....................................................................... 14

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 5 of 27

Certificate of conformity (IIa) (copy)

We:

Becx Machines B.V.

De Sonman 35

5066 GJ Moergestel

declare entirely under our sole responsibility, that this product:

Description : Becx weed brush - edge cutter.

Type : BECX OBKS90-45

serial number : .....................

to which this declaration applies, complies with the provisions of the Directives:

Machinery Directive 2006/42/EC

Complies with the following standards:

NEN-EN-12100-1 Safety of machinery. Basic definitions, general design principles.

Part 1: Basic terminology, methodology

NEN-EN-12100-2 Safety of machinery. General design principles. Part 2:

Technical principles and descriptions

NEN-EN 982 Safety of machines –Safety requirements for hydraulic and

pneumatic systems and their components: Hydraulics

NEN-EN 14121-1 Safety of machines –Risk assessment –Part 1: Principles

Director; Erwin Hommen

Netherlands, Moergestel,

Date: .........................

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 6 of 27

List of symbols

This manual uses the following symbols for all actions and situations where the safety of the operator or

technician is at stake and where it is necessary to act with caution:

Warning!

Explanation.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 7 of 27

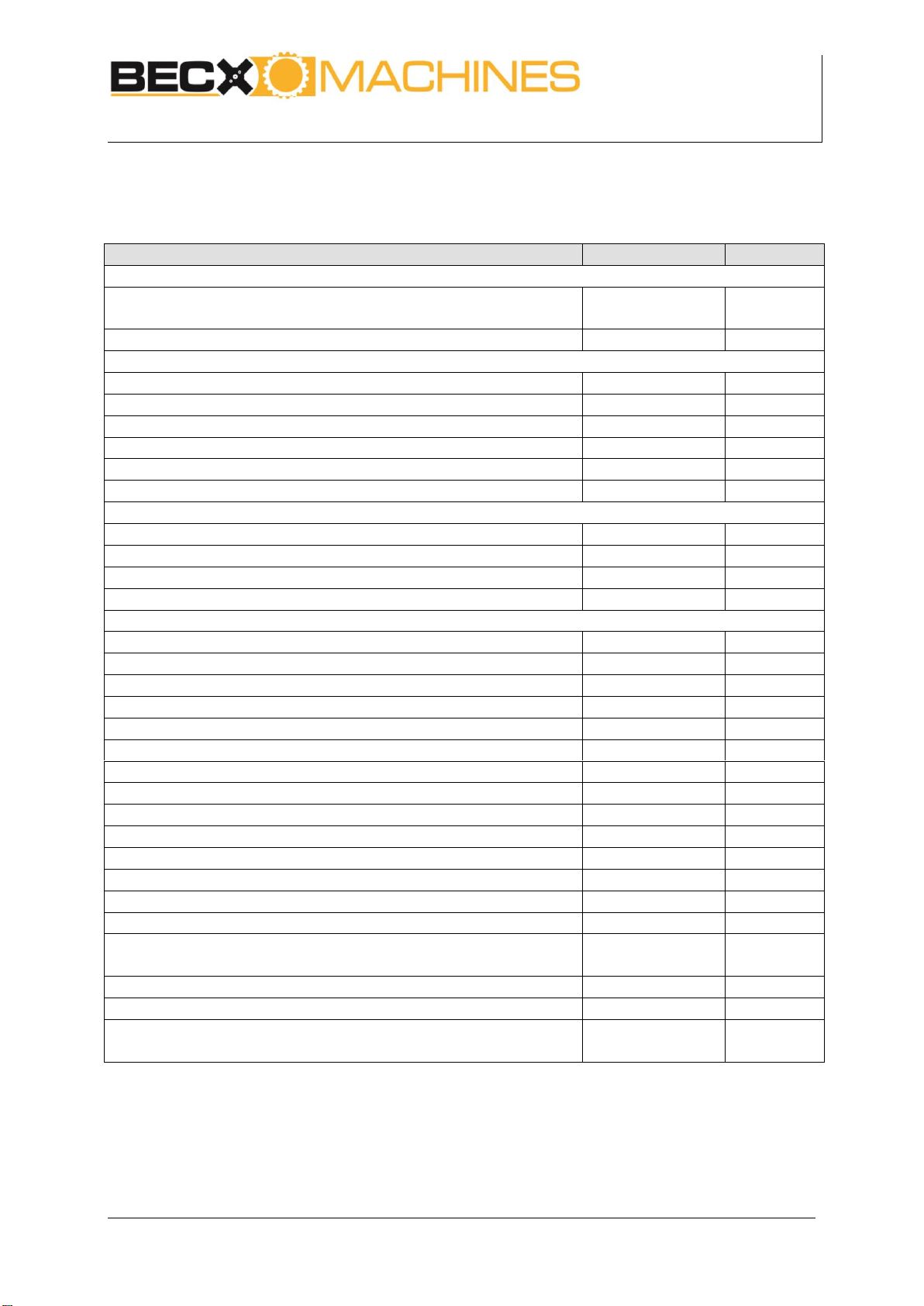

1Technical specifications

Description

Value

Unit

General

Noise pressure

See manual tool

carrier

dB(A)

Vibration level in normal use

Na

Dimensions and weights

Coulter blade

Width min.

1100

mm

Width max

1750

mm

Length

1850

mm

Height

850

m

Own weight

+/- 270

kg

Attachment information

Front

Depends on carrier

-

-

Force on attachment point

3.000

N

Hanging moment

+/- 1600

Nm

Connection data

Maximum operating pressure

250

bar

Maximum speed brush

450

-/min

Normal speed

+/-225

-/min

Maximum Oil flow

60

L/min

Needed oil flow for good result

30

L/min

Line attachments brush motor

Pressure line attachment: with rapid flat seal attachment

3/4”

Return line connection: with rapid flat seal attachment

3/4”

Drain line connection: with rapid flat seal attachment

3/8”

Maximum pressure on drain line

Non-pressurized

bar

Line attachments swivel main-arm

Attachments in/out-lines (2*)

3/8”

Line attachments tilting brush-head

Attachments in/out-lines (2*)

3/8”

Line attachments control valve (rotate brush-head, height coulter

blade, swivel cutting-knife)

Line attachment in/out-lines (2*)

3/8”

Hydraulic oil filtering requirements

10

microns

Oil for the drive

HV-46 or

equivalent

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 8 of 27

2Safety

2.1 General

•No modifications must be made to the weed brush.

•The user is responsible for making sure that the correct tool carrier and

adapter are used (see chapter 3). The following are important points in this

regard:

•The maximum pressure and number of revolutions (oil flow) must not be

exceeded. Excess pressure and excess revving can damage the machine and

cause injury.

•The tool carrier must be strong and stable enough to absorb the forces and

moments exerted by the weed brush safely and under all circumstances.

2.2 In use

•Consult the tool carrier manual for the noise rating. Because this is

considerably louder than the weed brush itself, the noise load of the tool

carrier determines the rating.

•The machinery must only be used for the activities for which it is designed.

•Persons or animals who are present in or who approach the danger zone must

be stopped immediately and the weed brush must be switched off .

•If passers-by disrupt the brushing and cutting work too much, the operator

can consider temporarily cordoning off the site.

•If the weed brush starts to make a different sound and/or starts to vibrate,

work must stop immediately and the weed brush has to be switched off. Work

can only continue after the source of the noise has been identified and

resolved.

•Always complete inspection and maintenance jobs.

•The machinery must not be used for any other purposes during inspection and

maintenance.

•The hydraulic feed to the weed brush must be disconnected during inspection,

maintenance or cleaning to prevent accidental operation.

•Always comply with local work regulations and safety rules.

•If the machinery is used in the dark, use sufficient lighting (approx. 50 lux at

the work site).

•To prevent damage to the machine, switching on and off the machine should

be done at low speeds. Depending on the tool carrier this is done at idle speed

or minimal oil-flow.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 9 of 27

2.3 Operating personnel

•Operating personnel must be over 18.

•Only persons who have received permission from the owner are allowed to

operate the system.

•Persons must only carry out jobs for which they are trained. This applies to

both maintenance work and normal operations.

•Personnel who operate equipment must be familiar with all possible

situations that could arise.

•The owner or person in charge must be told if personnel operating machinery

identify faults or hazards or do not agree with safety measures.

2.4 Safety-symbols on the machine

1.

Read the manual before use!

2.

Safety zone

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 10 of 27

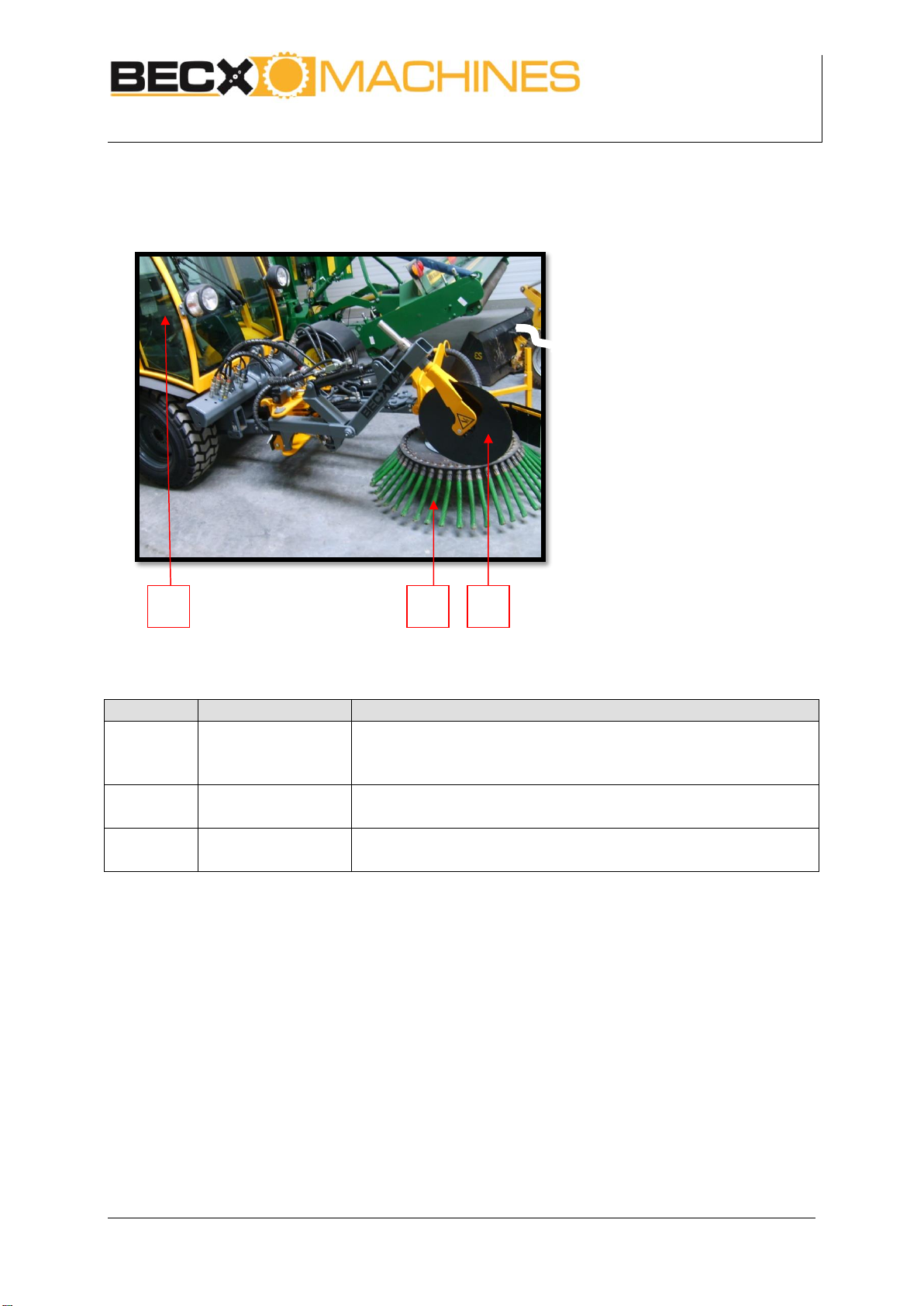

3Component description

Figure 1: Overview

Figure 1

Part

Explanation

1

Coulter blade

•The coulter blade cuts through the grass directly next to the

pavement so it cuts the grass which grows over the

pavement.

2

Brush

•The brush brushes the weed and cut loose grass entirely from

the pavement.

3

Tool carrier

•The tool carrier is not supplied. The user is responsible for

using a tool carrier that is suitable for the weed brush.

1

2

3

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 11 of 27

3.1 Mechanical components tool carrier attachments

Figure 2: General overview of the mechanical components

Figure 2

Part

Explanation

1 t/m 5

Tool carrier

attachment

•The unit is attached by an adapter (figure 2:2) attached to the

tool-attachment-point (figure 2:1) of the tool carrier.

•The attachment off the weed brush to the adapter consists of

2 mounting-pins (figure 2:5) and 2 locking pins (figure 2:3)

•When the unit is in the right position it can be locked with the

lever (figure 2:4).

•The implementation of the adapter and its attachment to the

tool carrier is dependent on the type of tool carrier.

•The up and down movement is realized by the fixture to be

tool carrier. This is not part of the weed brush, it’s controlled

by the tool carrier.

6

Support legs

•Two support legs are attached to the weed brush (figure 2.6)

•The support legs have to be completely raised or removed.

•If the unit is dismounted from the tool the support legs can be

installed to put the unit down and stable on the ground.

6

1

3

4

5

2

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 12 of 27

3.2 Mechanical components coulter blade

Figure 3: Overview mechanical components

Figure 3

Part

Explanation

1 + 3

Left/right

•From the tool-carrier the blade-position can be adjusted in the

width direction. The tube (figure 3.1) on which the blade

(figure 3:3) is mounted is then hydraulically moved to left or

right.

2

Height

•The tube (figure 3.2) on which the blade is mounted can be

adjusted up or down from within the tool carrier.

•While cutting the edges the blade must be in a downward

position. While driving to next location it must be pulled up.

1

3

2

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 13 of 27

3.3 Mechanical components brush

Figure 4: Overview mechanical components brush

Figure 4

Part

Description

4

Width adjustment

•The width-position of the brush from the blade can be

hydraulically adjusted (figure 4:4)

2

Mud guard

•The protective mudguard (figure 4.2) makes sure the debris

from the brush don’t get thrown in the wrong direction.

•The right position can be achieved by different adjustment-

points.

5

Tilt-adjustment

•The brush-head can be hydraulically tilted to make sure the

brush brushes in the right position (figure 4:5)

3

Angle adjustment

brush

•The angle in which the brush brushes the pavement can be

hydraulically adjusted (figure 4:3)

1

Brush-mounting

•When the brush is worn out it can be easily replaced by

unbolting the mounting bolts from the holder-plate (figure

4:1)

4

2

5

1

3

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 14 of 27

3.4 Hydraulic components

Figure 5: Overview hydraulic components

Figure 5

Part

Explanation

1

Hydraulic motor

brush

•The hydraulic has 3 attachments; in –out and a leak line. (figure

5:1)

4

Cylinders swivel

main brush-arm

•The cylinders for the swivel-adjustment of the main-brush-arm are

equipped with 2 lines which are routed in a way these cylinders get

the right in or out flow of oil. (figure 5:4)

3

Cylinder tilting

brush-head

•The cylinder for tilting the brush-head is a double-acting cylinder,

equipped with 2 lines (figure 5:3).

•Depending on the movement direction, the oil flows on one of the

lines.

8

Control valve

•The control valve sends the oil-flow to the desired function. The

control valve is attached via 2 rapid flat seal attachments to the

tool carrier (figure 5:8).

•Functions: turning brush-head, height-adjustment blade, swivel

function blade.

2

Control valve –

turning brush-

head

•When control valve is in right position it sends the oil flow to the

cylinder for turning the brush-head .

•Depending on the movement direction, the oil flows on one of the

lines. (figure 5:2)

5

Control valve –

height-adjusting

blade

•When control valve is in right position it sends the oil flow to the

cylinder for the height-adjusting of the blade.

1

7

4

2

3

5

6

8

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 15 of 27

Figure 5

Part

Explanation

•Depending on the movement direction, the oil flows on one of the

lines. (figure 5:5)

6+7

Control valve –

swivel

adjustment

blade

•When control valve is in right position it sends the oil flow to the

cylinder for swivel adjustment of the blade

•Depending on the movement direction, the oil flows on one of the

lines. (figure 5:6)

•The attached pressure gauge gives an indication of the pressure on

the blade from the pavement at falsely set settings or skewed trail

of the tool carrier (figure 5.7)

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 16 of 27

4Operations

4.1 Assembly and adjustment of the weed brush

Nr.

What to do

Action

Result

1

Select the correct tool

carrier and lifting arm

•make sure that the tool carrier and lifting

arm are sufficiently strong and stable for

the weed brush (see chapter 1 for the load

when lifting and the exerted moment of

the lifting).

•Make sure that the maximum pressure and

number of revolutions (oil flow) are not

exceeded.

•Make sure that the correct rapid

attachment connections are installed for

the feed line, return line and drain line.

•Make sure that the correct clasp is used.

Ignoring the stated

values can result in

damage to

equipment and

injury to persons.

2

Connect the hoses

•Connect the rapid attachment connections

for the feed line, return line and drain line .

3

Adjust the hydraulic

system

•Adjust the setting of the hydraulic

aggregate so that the maximum pressure

and number of revolutions cannot be

exceeded.

•This will depend on the type of tool carrier

that is used. Please refer to the manual of

the tool carrier.

4

Adjust the positions

for the blade and

brush

•With help of the different hydraulic

functions the blade and brush can be

adjusted to achieve the correct result with

the weed brush.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 17 of 27

4.2 Carry out brush- and cutting work

•At driveways or other obstacles in the cutting-lane the blade needs to be lifted

in time, to prevent damage to the pavement and machine

No.

What to do

Action

Result

1

Check the machinery

•Check the following points:

•Check the blade on cracks or damages

•Check the speed of the brush-motor

(50% of the capacity (30 liter)) is usually

enough for a good result

•Check whether the brush-motor runs

without excessive shaking and without

abnormal sounds.

•Check the control of the width and

height-adjustment of the blade.

•If a defect is identified in one of the above

points, this must first be remedied before it

is allowed to put the weed brush back into

operation.

2

Drive to the site

where the work will

take place.

•Always switch off the weed brush if you are

not doing any brushing.

3

Switch on brush-

motor

•Please refer to the detailed instructions in

the manual for the tool carrier.

•It is important always to switch on and off

at a low revolution speed to prevent

damage to the machinery. The revolution

speed can be increased after switching on

the brush-engine.

Switching on and off

at a high speed of

revolutions will

result in system

overload.

4

Setup the blade in

desired position

•The knife can be adjusted in width-position

and in height, make sure it is in desired

position. For detailed instruction, see

manual of tool carrier.

•Watch for people or animals in near

working area.

5

Cut and brush the

edges

•Drive the tool carrier along the edge of the

pavement.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 18 of 27

No.

What to do

Action

Result

6

Stop in following

situations!!

•The operator must stop immediately in

the following situations and switch off the

weed brush:

•Persons or animals being or coming

directly into the working area.

•The weed brush begins making

abnormal sounds or excessive shaking

Serious injury could

result if the

machinery is not

stopped in time.

7

Switch off the weed

brush

•switch off the weed brush once the area to

be cleaned had been brushed and cut.

Please refer to the detailed instructions in

the manual for the tool carrier.

•It is important always to switch on and off

at a low revolution speed to prevent

damage to the machinery.

Switching on and off

at a high speed of

revolutions will

result in system

overload.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 19 of 27

5Maintenance

•Only components supplied or approved by the manufacturer must be used for

replacement or repair of parts.

•Always disconnect the weed brush from the feed line when work is carried out

on the machinery. This is done by disconnecting the rapid attachment.

•Only persons who can show that they have adequate knowledge of

mechanical and hydraulic machinery through their training and experience are

allowed to carry out maintenance work.

•The installation can be cleansed with a high pressure cleanser, never point

directly at hydraulic components.

Weekly maintenance

No.

What to do

Action

Result

1

Grease the pivot

points

•Squeeze grease into the grease nipples.

These are located at all pivot points

2

Tightening bolts

•Check and tighten all bolts

3

Visual check

•Visually check the construction, the

hydraulic aggregate and the cutter blades

for damage and cracks.

•Check cylinder-rods for damages and dirt.

4

Retighten adjusting

bolts

•Whitin 4 working hours, tighten the set

screws of the clamping sleeve mounting on

the motor shaft and then check it regularly!

( 48NM) See image on page 20.

Weedbrush-Edgecutter

Type: BECX OBKS90-45

Version: 2

November 2019

Page 20 of 27

Image of clamping sleeve bottom of brush head.

Annual maintenance

No.

What to do

Action

Result

1

Inspecting the drive

•Check following parts for damage, cracks

and looseness:

•Tubes + bushings of the width and

height directional adjusting

installation

•Bearings and seals

Table of contents