EASTMAN

8

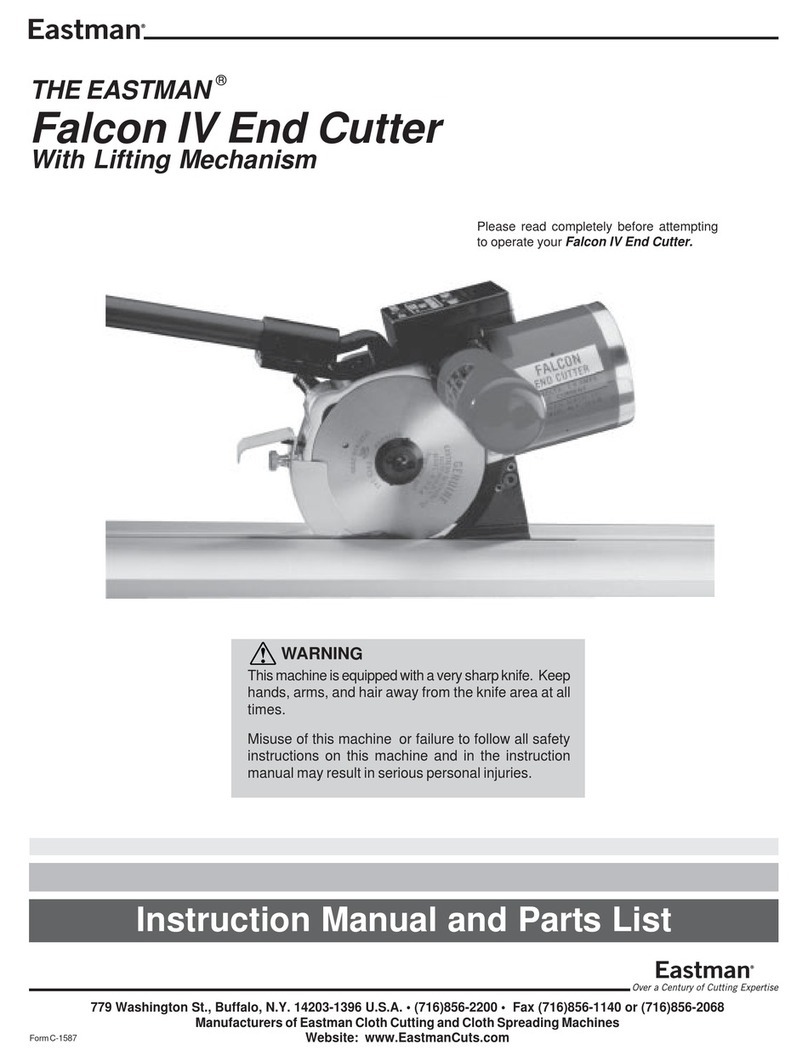

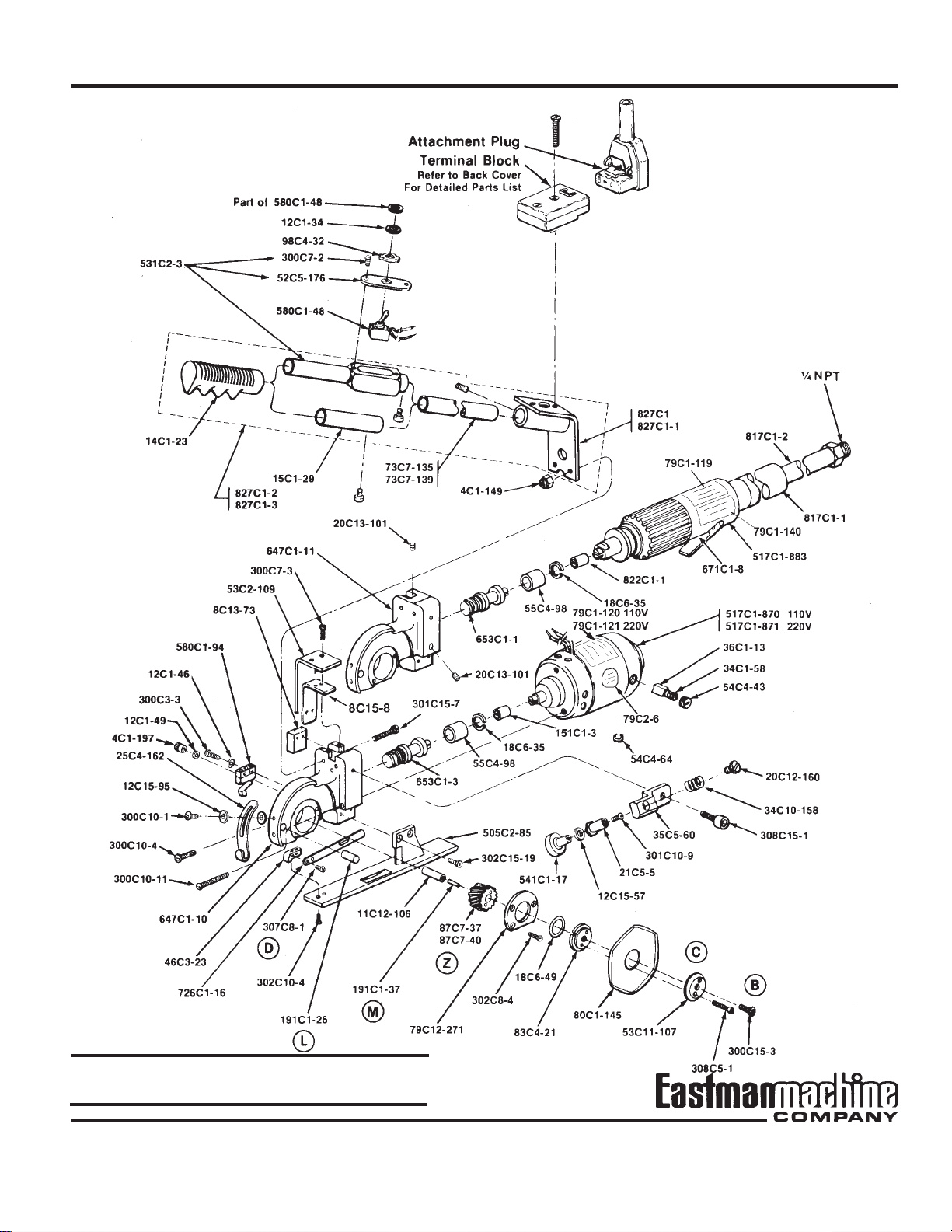

Falcon End Cutter

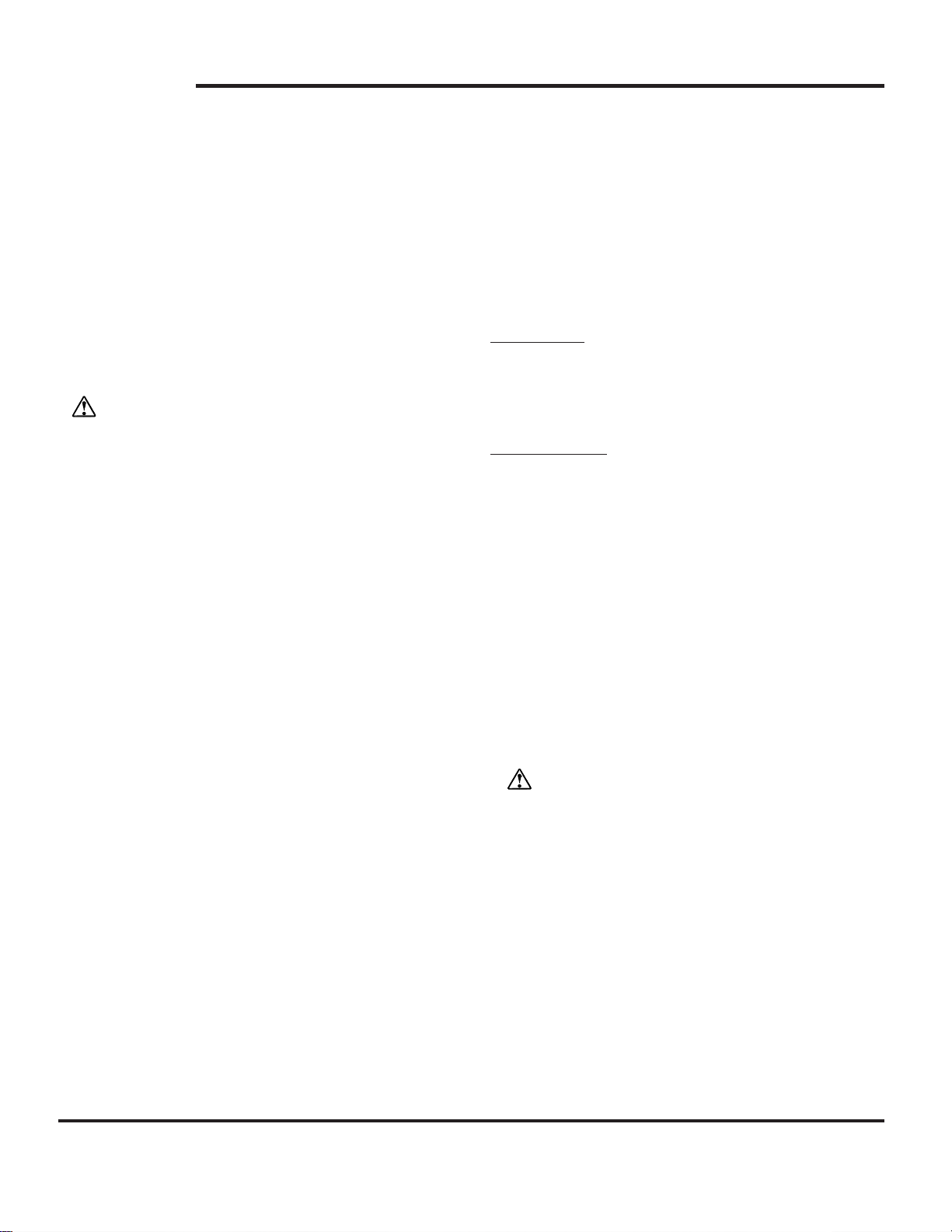

Illustrated Parts List

Air

110v

220v

Part Number Description

12C1-49 2 2 2 Washer

12C15-57 1 1 1 SpringWasher

12C15-95 4 4 4 Washer,#6Flat

14C1-23 1 1 1 HandleGripPlastic

15C1-29 1 0 0 StudHandle

18C6-35 1 1 1 SnapRing

18C6-49 1 1 1 OilSealRing

20C12-160 1 1 1 SharpenerScrew,ButtonHead

20C13-95 1 1 1 Screw, 6-32 x 1/4 Self TapScrew

20C13-101 3 0 0 Setscrew

21C5-5 1 1 1 SharpenerBushing

25C4-162 1 1 1 KnifeGuard

34C1-58 0 2 2 BrushSpring

34C10-158 1 1 1 SharpenerSpring

35C5-60 1 1 1 SharpenerBracket

36C1-13 0 2 2 Brush

46C3-23 1 1 1 SpringBlock

52C5-176 0 1 1 SwitchBase

53C2-109 0 1 1 SwitchCover

53C11-107 1 1 1 KnifeFlangeCover

54C4-43 0 2 2 BrushCap

54C4-64 0 1 1 HolePlug

55C4-98 1 1 1 SpacerBearing

73C7-135 0 1 1 TubeHandle36"

73C7-139 1 0 0 TubeHandle39"

79C1-119 1 0 0 FalconAirDecal

79C1-120 0 1 0 FalconDecal,110v

79C1-121 0 0 1 FalconDecal,220v

79C1-140 1 0 0 CautionDecal

79C2-6 0 1 1 CautionDecal

79C12-271 1 1 1 GearRetainingPlate

80C1-145 1 1 1 Knife(Hex)

83C4-21 1 1 1 KnifeFlange

87C7-37 1 0 0 2-LeadKnifeGear

87C7-40 0 1 1 4-LeadKnifeGear

98C4-32 0 1 1 On-OffSwitchClip

151C1-3 0 1 1 MotorCHKCoupling

191C1-26 1 1 1 KnifePadWipe

191C1-37 1 1 1 FeltWick

300C3-3 0 2 2 Screw,2-56x1/2RoundHead

300C7-2 0 2 2 Screw,4-36x3/16RoundHead

300C7-3 0 4 4 Screw,4-36x1/4RoundHead

300C10-1 2 2 2 Screw,6-32x3/16RoundHead

300C10-4 0 1 1 Screw,6-32x3/8RoundHead

300C10-11 0 2 2 Screw,6-32x1-1/8RoundHead

300C15-3 1 1 1 Screw,10-32x3/8RoundHead

301C10-9 1 1 1 Screw,6-32x3/16FillisterHead

301C15-7 2 2 2 Screw,10-32x1-1/4FillisterHead

302C8-4 3 3 3 Screw,4-40x3/8SocketFlatHead

302C10-4 2 2 2 Screw,6-32x5/16FlatHead

302C15-19 2 2 2 Screw,10-32x1"SocketFlatHead

307C8-1 2 2 2 Screw,4-40x1/4ButtonHead

308C5-1 2 2 2 Screw,3/48x1/2SocketHead

308C15-1 1 1 1 Screw,10-32x1/2SocketHead

309C12-2 1 1 1 Setscrew,8-32x5/16

505C2-85 1 1 1 BasePlateAssembly

517C1-870 0 0 1 MotorAssembly110v

517C1-871 0 1 0 MotorAssembly220v

517C1-883 1 0 0 MotorAssembly,Pneumatic

531C2-3 0 1 1 CompleteAssembly

541C1-17 1 1 1 EmerywheelAssembly

580C1-48 0 1 1 ToggleSwitch

580C1-94 0 1 1 SwitchforCam

647C1-10 0 1 1 Standardw/Shaft&FeltWick

647C1-11 1 0 0 Standardw/Shaft&FeltWick

653C1-1 1 0 0 WormShaft(Pneumatic)

653C1-3 0 1 1 WormShaft(Electric)

671C1-8 1 0 0 MotorValve

726C1-16 1 1 1 ShearPlatewithBlank

817C1-1 1 0 0 ExhaustOverHose

817C1-2 1 0 0 AirIntakeHose

822C1-1 1 0 0 AirMotorCoupling

827C1 0 1 1 HandleBracketAssembly

827C1-1 1 0 0 HandleBracketAssembly

827C1-2 0 1 1 HandleBracketAssemblyComplete

827C1-3 1 0 0 HandleBracketAssemblyComplete

Air

110v

220v

Part Number Description

4C1-149 2 2 2 ElasticStopNut

4C1-197 2 2 2 AllenNut

8C13-73 0 1 1 MicroSwitchInsulation

8C15-8 0 1 1 SwitchCoverInsulation

11C12-106 1 1 1 GearShaft

12C1-34 0 1 1 Lockwasher

12C1-46 0 2 2 Lockwasher