2.9 Using extension cords

Use only extension cords of a type approved for the application and with conductors of adequate gauge. The

power tool may otherwise lose performance and the extension cord may overheat. Check the extension cord

for damage at regular intervals. Replace damaged extension cords.

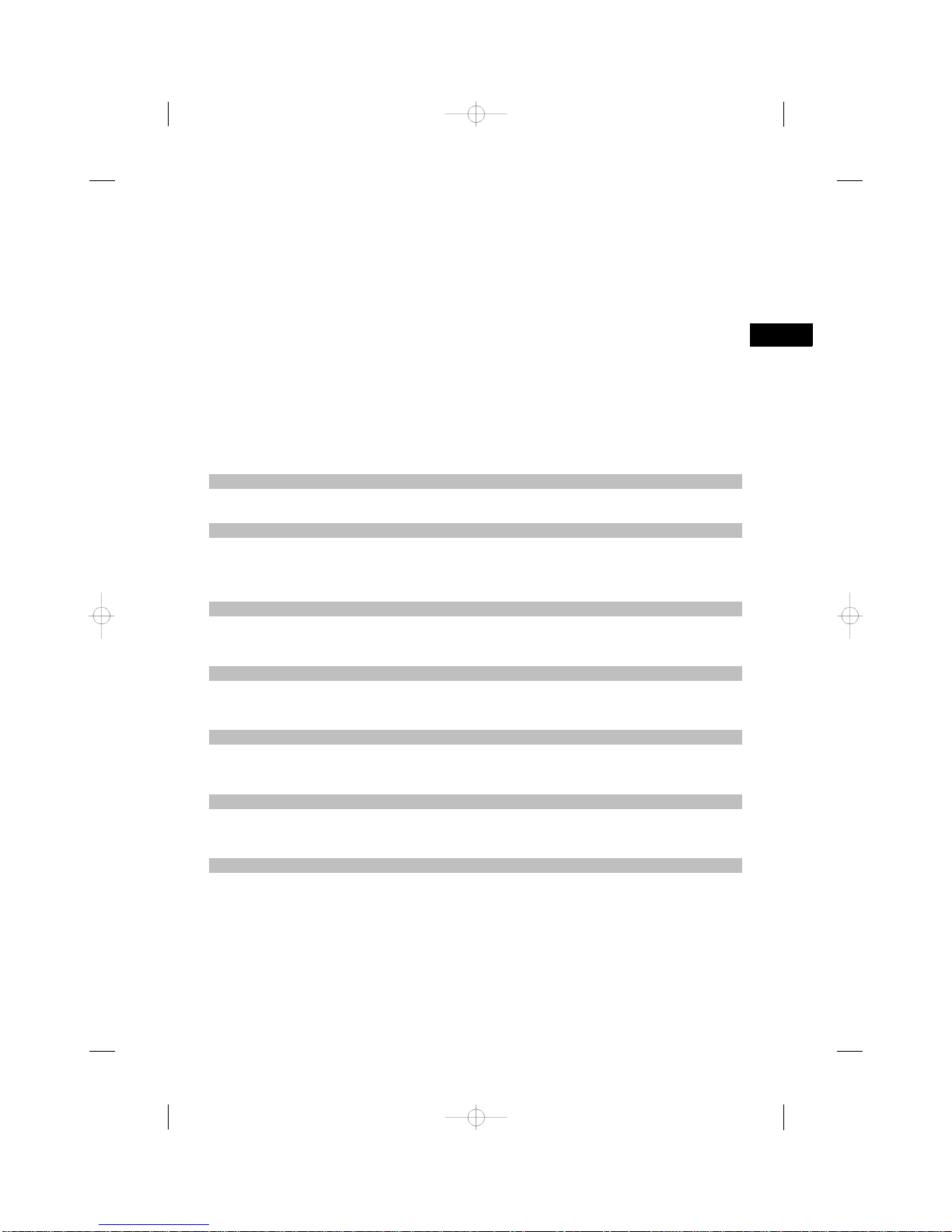

Recommended minimum conductor gauge (cross section) and max. cable lengths

Conductor cross section 1.5 mm²2mm²2.5 mm²3.5 mm²

Mains voltage 100V ‐30 m ‐50 m

Mains voltage 110‐120 V 20 m ‐40 m ‐

Mains voltage 220‐240 V 30 m ‐50 m ‐

Do not use extension cords with a conductor cross section of less than 1.5 mm².

2.10 Using extension cords outdoors

When working outdoors, use only extension cords that are approved and correspondingly marked for this

application.

2.11 Using a generator or transformer

This tool may be powered by a generator or transformer when the following conditions are fulfilled: The unit

must provide a power output in watts of at least twice the value printed on the type identification plate on

the power tool. The operating voltage must remain within +5% and ‐15% of the rated voltage at all times,

frequency must be in the 50 – 60 Hz range and never above 65 Hz, and the unit must be equipped with

automatic voltage regulation and starting boost.

Never operate other power tools or appliances from the generator or transformer at the same time. Where

applicable, use a generator or transformer designed for simultaneous power tool and vacuum cleaner operation.

Switching other power tools or appliances on and off may cause undervoltage and / or overvoltage peaks,

resulting in damage to the power tool.

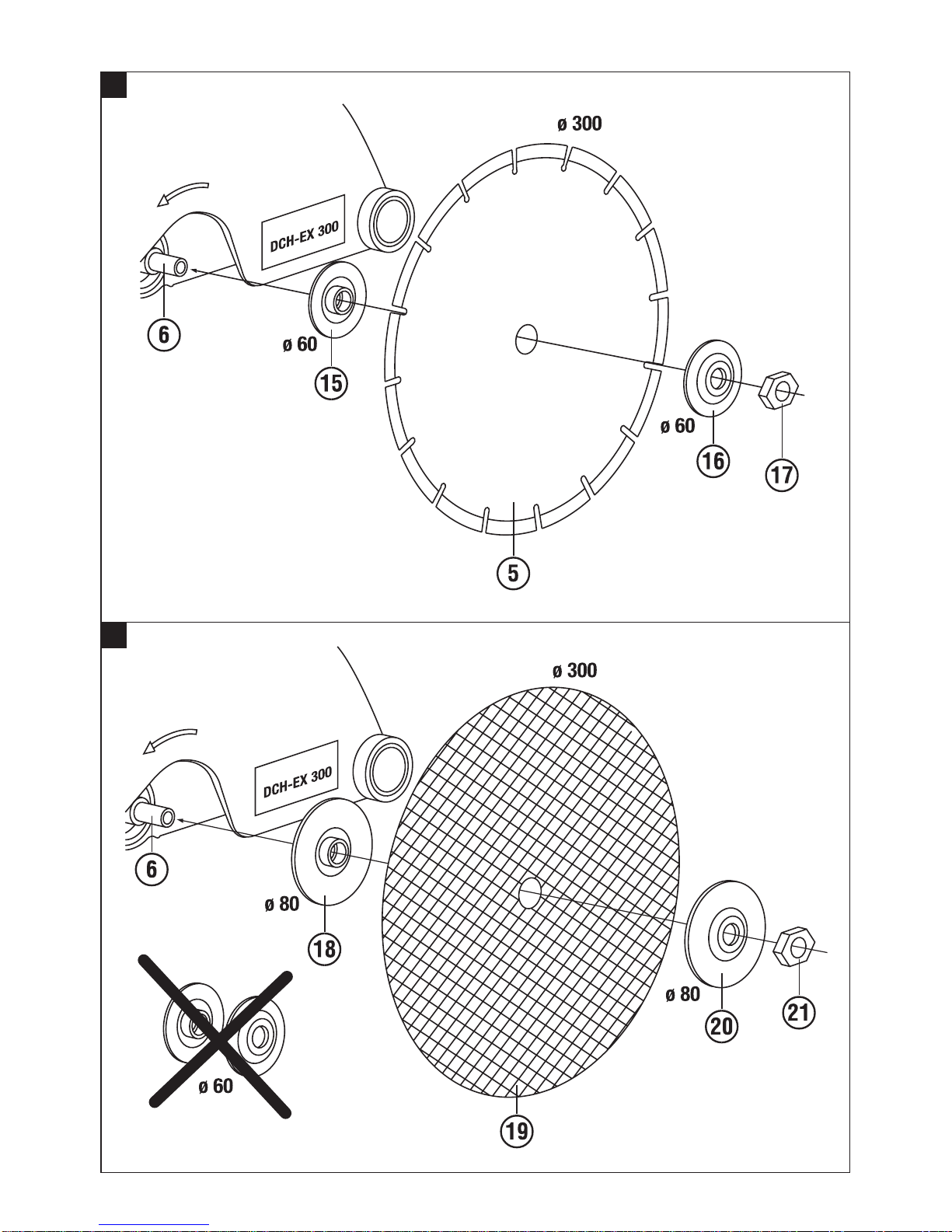

2.12 Depth gauge (optional)

The power tool can be fitted with an optional depth gauge. This improves dust removal performance for cutting

mineral materials. The maximum cutting depth can be set with the aid of the cutting depth scale on the hood

extension.

2.13 The items supplied as standard include:

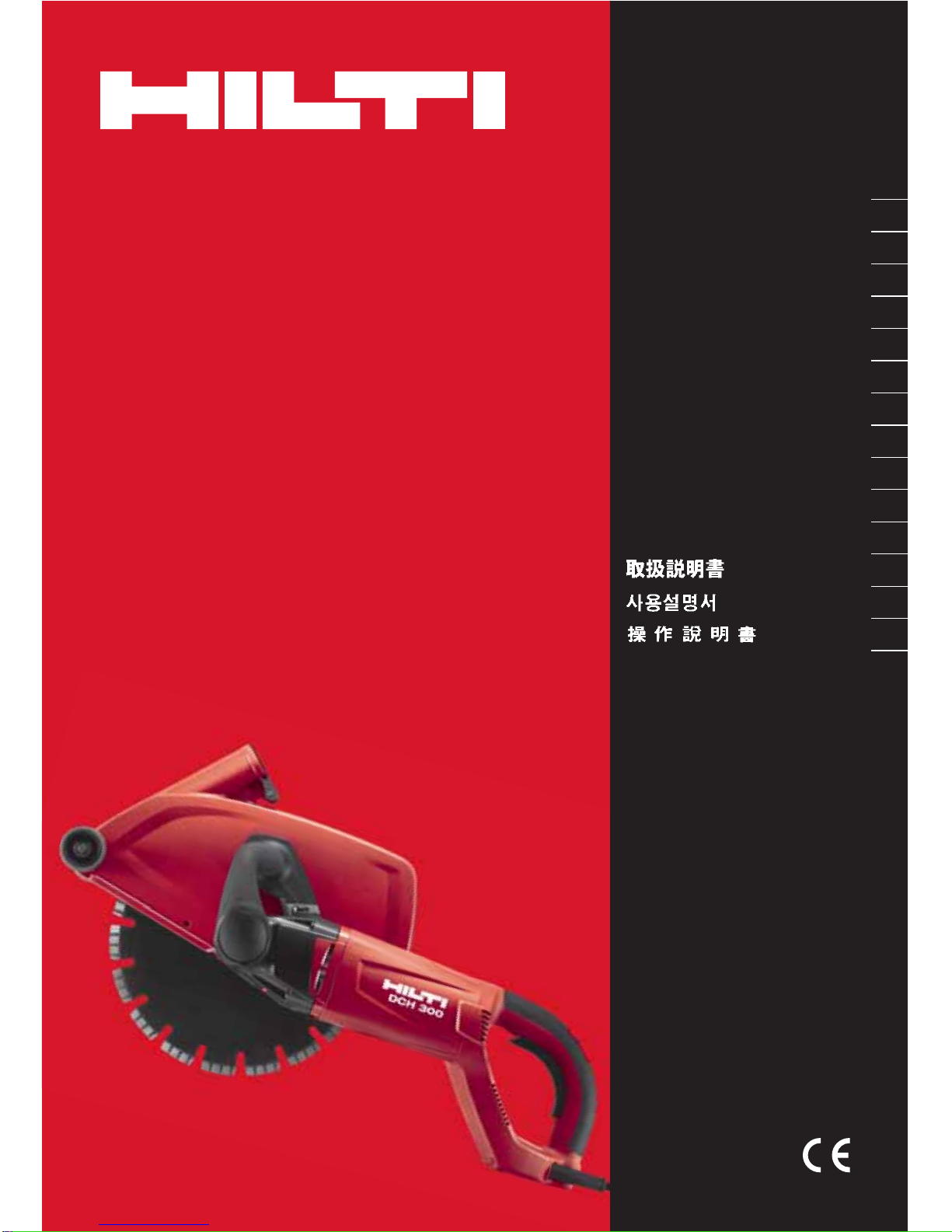

1 Power tool with DCH‑EX 300 hood

1 Reversible flange 60 mm dia.

1 Clamping flange, 60 mm dia.

1 Clamping nut, M16 x 1.5

1 Clamping nut wrench, 24 mm AF / 10 mm

AF

1 Hex. socket wrench, 6 mm AF

1 Cardboard box

1 Operating instructions

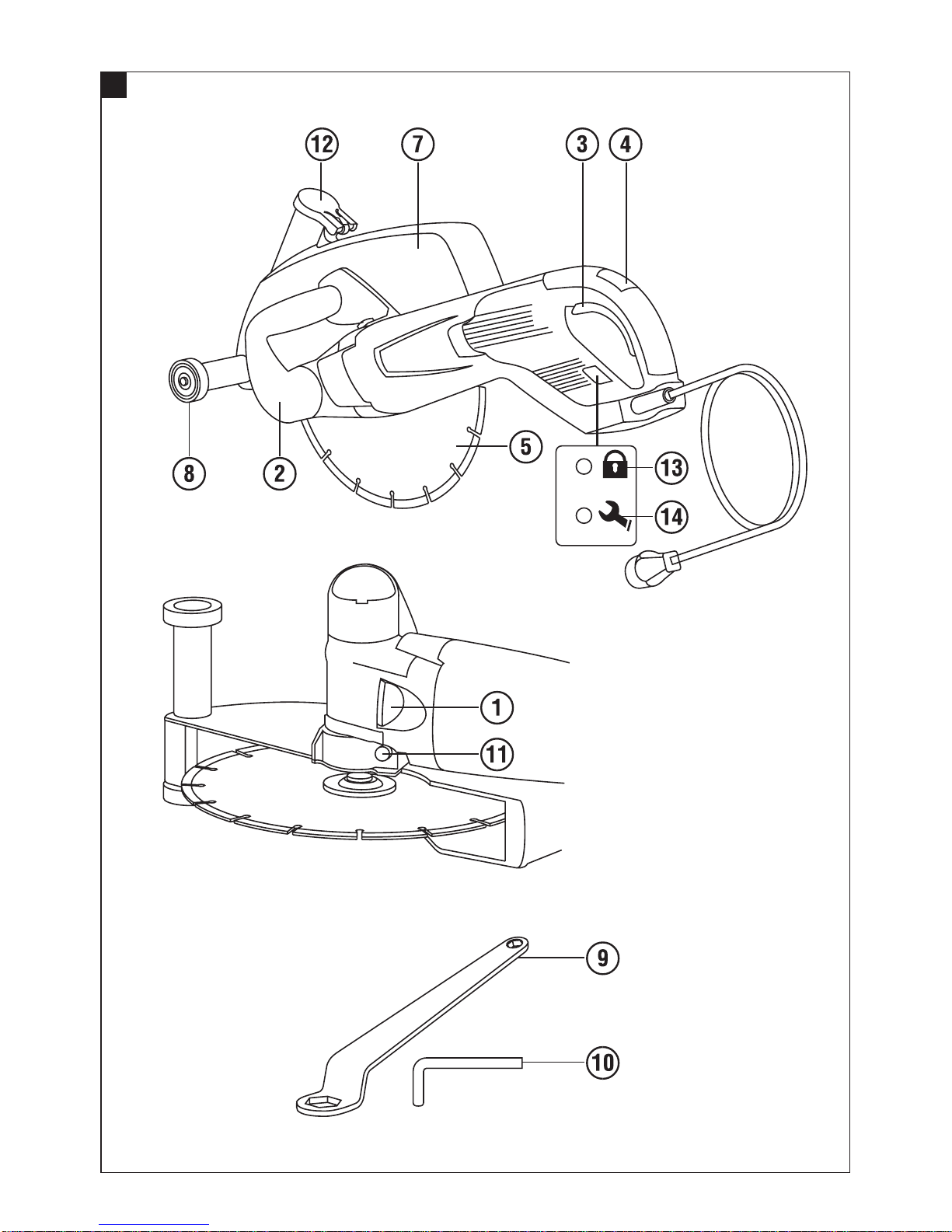

2.14 Cutting disc specifications

Diamond cutting discs in compliance with the requirements of EN 13236 are to be used with the power tool.

Synthetic resin‐bonded fiber‐reinforced cutting discs in compliance with EN 12413 (straight, not offset, type

41) may also be used with this power tool for working on metals. In this case, the appropriate DCH 300 ABR

disc mount (see accessories) must be used with the power tool.

en

22