BEEHIVE CE MVS User guide

77167 04/2004

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N,

,

O

OP

PE

ER

RA

AT

TI

IO

ON

N,

,

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

A

AN

ND

D

S

SA

AF

FE

ET

TY

Y

I

IN

NS

ST

TR

RU

UC

CT

TI

IO

ON

NS

S

F

FO

OR

R

B

BE

EE

EH

HI

IV

VE

E

I

IN

NC

C.

.

R

RS

ST

TD

D0

06

6F

F

&

&

R

RS

SB

BD

D0

06

6A

A

S

SE

EP

PA

AR

RA

AT

TO

OR

R

C

CE

E

M

MV

VS

S

B

BE

EE

EH

HI

IV

VE

E

I

IN

NC

C.

.

®

®

A Weiler Company

WEILER AND COMPANY, INC. WEILER BEEHIVE CANADA, LTD WEILER BEEHIVE EUROPE LIMITED

Corporate Headquarters St. Marys, Ontario, Canada Yate, Bristol, England

Whitewater, Wisconsin U.S.A. TEL 519-349-2620 ●800-558-8507 TEL +44 (0) 1454 320900

TEL 262-473-5254 ●800-558-9507 FAX 519-349-2631 FAX +44 (0) 1454 326262

FAX 262-473-5867

9100 SOUTH 500 WEST ●P.O. BOX 5002 ●SANDY, UTAH 84091-5002 U.S.A. 801-561-4211 ●800-621-8438 ●FAX 801-562-5857

PROVIDING SOLUTIONS FOR FOOD PROCESSING www.weilerinc.com

ii

TABLE OF CONTENTS

PAGE

Table of Contents ii

List of Figures v

CAUTION/WARNING 1

I. INTRODUCTION 2

General 2

Separator 2

Foreseeable misuse 2

Limits 3

Principles of operation 3

II. GENERAL SAFETY INFORMATION 4

Safety Procedures 4

III. CORRESPONDENCE AND SHIPPING 7

IV. PRE-INSTALLATION INSPECTION 7

V. INSTALLATION 8

General 8

Installation 8

Motor Rotation 11

VI. ELECTRICAL CONTROLS 12

General 12

Relay Panel 12

Control Panel 13

iii

VII. CLEANING 14

General 14

Sodium Hydroxide (NaOH) Cleaner 14

Cleaning the Chamber 17

Cleaning and Sanitizing 17

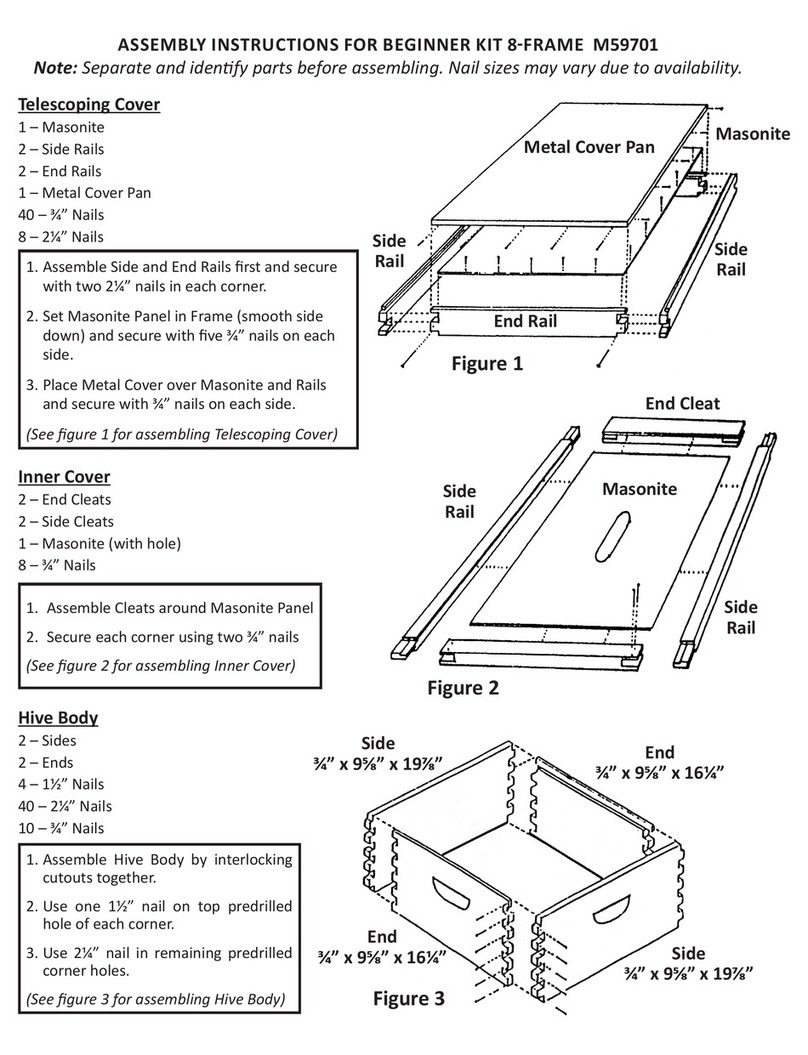

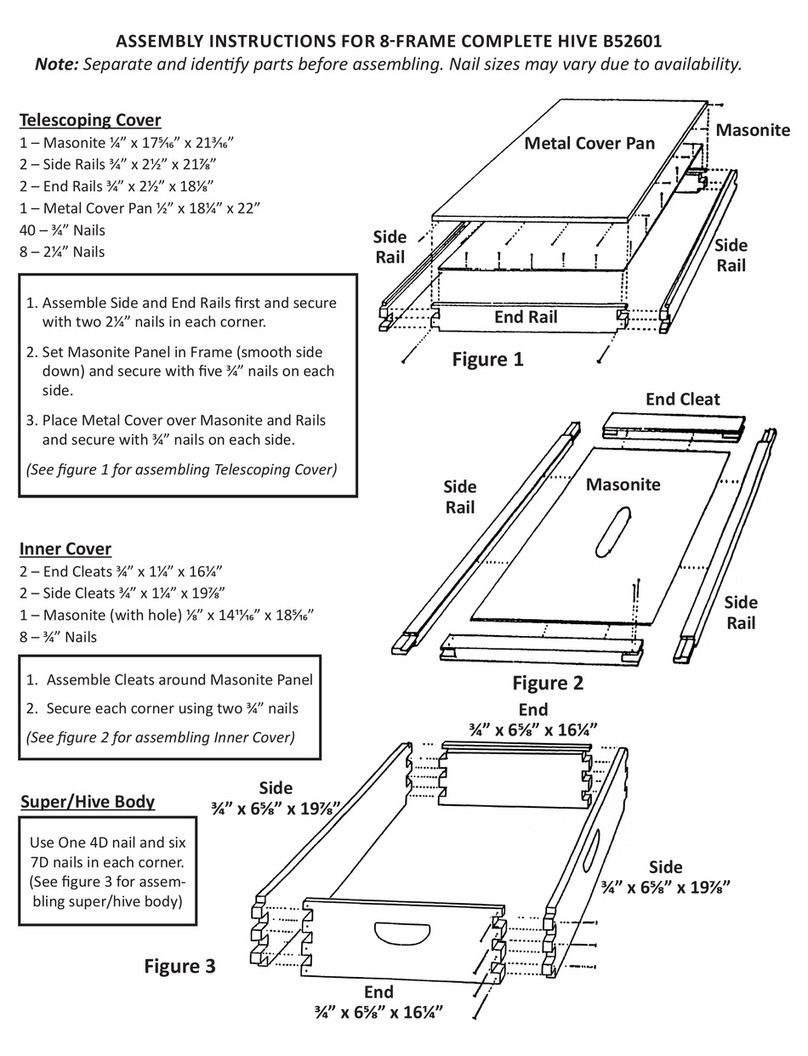

VIII. ASSEMBLY 18

General 18

Auger/Chamber Clearance Adjustment 18

Separator Assembly 21

IX. SEPARATOR OPERATIONS 23

General 23

Control Panel 23

Separator Operation 24

Ring Valve Adjustment 26

Calculating Yield 28

Separator Head Cooling 28

X. DISASSEMBLY 29

XI. MAINTENANCE 31

General 31

Separator Lubrication 31

Separator Maintenance 32

Timing of Feed-screws 33

Auger Head Bearing 35

Bearing Cartridge 36

Auger Wear 38

Chamber Wear 39

Ring Valve Wear 40

Electrical Control 41

XII. TROUBLESHOOTING 42

Overload Procedure 42

Separator Troubleshooting 43

Electrical Control Troubleshooting 44

iv

XIII. PART ORDERING 45

Separator Information 45

Parts Lists (Electrical Kits) 46

Parts Lists (Auger, Chamber, and Ring Valve) 49

Parts Lists (Accessories) 50

XIV. WARRANTY 51

Material and Workmanship Warranty 51

Conditional Warranty 51

XV. APPENDIX 52

Installation Drawing #9188D REV 03

Assembly Drawing #9189D REV 04

Boom Assembly RH (Optional) #9259D REV 01

Boom Assembly LH (Optional) #9260D REV 02

Head Assembly #8540D REV 05

Electrical Schematic #8518C REV 06

Control Panel Assembly #8918D REV 01

Relay Panel Assembly #8924D REV 04

Control Installation #8639A REV 01

MANUFACTURER’S DATA

SEW Eurodrive MOTOR #09 793 67 US 02/01

Parts List (DV160M4) #08 635 587 US 08/02

Parts List (DV200L4) #08 640 587 US 08/02

Connection Diagram #USCS 01/00

SEW Eurodrive GEAR REDUCER #01 805 52 US 12/02

Parts List (R97) #01 254 496 US 06/01

Parts List (R107) #01 255 496 US 06/01

SEW Eurodrive VARIGEAR #12 783 00A US 06/99

Parts List (VU41) #12 256 292 US 09/02

Parts List (VU41 Pulleys) #11 256 292 US 06/01

v

LIST OF FIGURES

FIGURE DESCRIPTION PAGE

2.1 Safety Labels 6

5.1 Mounting Pad Adjustment 9

5.2 Control Panel Installation 9

5.3 Relay Panel Installation 10

5.4 Motor Rotation 11

7.1 Mixing Sodium Hydroxide (NaOH) Cleaner 16

8.1 Assembly Separator Head 19

9.1 Control Panel 23

9.2 Ring Valve Adjustment 27

9.3 Calculating Yield 28

11.1 Timing of Feed-screws 34

11.2 Auger Head Bearing 35

11.3 Auger Wear 38

11.4 Chamber Wear 39

11.5 Ring Valve Wear 40

1

CAUTION!!!

READ ALL DIRECTIONS IN THIS MANUAL

1. Read and follow all directions contained in this manual. Failure to do so may result

in personal injury and/or Separator damage.

2. All electrical equipment may be hazardous if not properly operated. READ ALL

SAFETY INSTRUCTIONS AND FOLLOW RECOMMENDED PROCEDURES AT

ALL TIMES TO AVOID PERSONAL INJURY.

WARNING!!! Follow These Safety Rules

DO NOT operate this Separator until all safety rules (local and national) have been met.

Electrical and mechanical controls must be selected, located, and installed in

compliance with all local and national electrical and safety codes.

DO NOT operate unless Separator guards and safety devices are in place and working.

DO NOT reach into a running Separator.

DO NOT reach into a stopped Separator unless the power is disconnected and LOCKED

OUT.

DO NOT work above or stand beside the Separator inlet.

DO NOT operate the Separator in a careless manner.

DO NOT overload the Separator.

2

I. INTRODUCTION

GENERAL

This instruction manual is designed to provide the information required to operate, clean

and maintain this Separator.

All personnel involved in the operation, cleaning or maintenance of the equipment should

read this instruction manual.

SEPARATOR

This Separator is an all stainless steel, mechanically regulated, self-feeding processor

used to process poultry, red meat, seafood and certain types of fruits and vegetables. This

Separator is a twin-motor design with separate control of the Feed-screws and Separator

Head for maximum product control.

This Separator Head has been specifically designed for maximum product quality and

production for a specific processing requirement. Please contact Beehive Inc. if there are

any changes to the product requirements.

FORESEEABLE MISUSE

Purposes for which Separator was not intended.

Prohibited application.

Purposes for other materials not intended (foreign objects).

Dimensional variation of material to be processed.

Input of large, hard, frozen material or ice.

Operator carelessness.

Operator taking “line of least resistance” in carrying out a task.

Operator handling parts without regard for personal safety.

Reaching into Hopper without stopping Separator.

Adjusting Ring Valve without stopping Separator.

Operation without covers and guards in place.

Operation without upper Hopper extension in place.

Use of Separator cabinet as a step.

Installation, assembly, disassembly, cleaning and maintenance without making sure all

electrical power to the Separator has been shutoff, disconnected and LOCKED OUT.

3

LIMITS

This Separator is designed for its intended use. Trained operators and skilled maintenance

personnel are required for safe operation. Proper use and adherence to specified

application will result in safe, efficient processing.

PRINCIPLES OF OPERATION

Pre-sized product is conveyed by the Feed-screws into the Pump Housing where it is

forced into the Adapter Bracket. The product is picked up in the Adapter Bracket by the

Auger and accumulated against the Ring Valve. Internal pressure increases with the

accumulation of material, which causes the "softer" portion of the product to pass through

the perforations in the Chamber. The "harder" material passes on through the ports in the

end of the Auger and is discharged through the Ring Valve. Repositioning the Ring Valve

varies yields.

4

II. GENERAL SAFETY INFORMATION

All operating and maintenance personnel should be familiar with all aspects of the

operation and care of the Separator. The following Safety Summary should be used as a

guide for the safe operation and maintenance of the Separator. Additional safety warnings

and cautionary statements are given on the equipment throughout this manual.

WARNING - Severe physical injury can result from poor safety practices.

Establish good safety practices when handling the parts and when

working around the Separator. Never operate the Separator

without all drive covers and safety devices installed correctly.

SAFETY PROCEDURES

Rotating Parts Safety - Keep hands away from all rotating parts when the Separator is

in operation. When it is necessary to adjust any part, be certain

all rotation has stopped and all electrical power is turned off,

disconnected and LOCKED OUT.

Maintenance Safety - Turn off, disconnect and LOCK OUT power before attempting

any maintenance procedure or removing covers and access

panels. After completing any maintenance procedure, be

certain parts are properly tightened and all safety panels and

covers have been replaced.

Hopper Safety - DO NOT reach into the Hopper during operation or at any time

while electrical power is connected. If a foreign object falls into

the Hopper or Feed-screw, DO NOT try to remove the object

without first disconnecting the electrical power. If the Feed-

screws becomes locked or stopped, DO NOT try to free the

Feed-screws without first disconnecting the electrical power.

Clothing Safety - Loose clothing, such as lab coats and packing aprons, can

get caught in rotating parts resulting in possible injury. Keep

loose clothing clear of all rotating parts.

5

Sodium Hydroxide

(NaOH) Cleaner Safety - Sodium hydroxide (NaOH) cleaner, used for cleaning the

perforated area of the Chamber, is an alkali blend. Improper

handling of the cleaner can cause severe burns to the skin

and eyes. Refer to Section VII. CLEANING for instructions

regarding the safe use and handling of sodium Hydroxide

(NaOH) cleaner.

WARNING - Lethal voltages are present within the relay panel when power is

applied.

Electrical Safety - Keep the area under cabinet dry. Keep the cabinet access

panels in place during cleaning, rinsing, and sanitizing to keep

moisture away from the electric drive motor. Disconnect and

LOCK OUT power during any maintenance, assembly,

disassembly, cleaning or inspection. Make sure all electrical

plugs are in good working order and dry before using.

6

Safety Labels- The safety labels in Figure 2.1 should be clearly visible and

maintained on equipment at all times. Contact Beehive Inc.

for replacement labels.

Figure 2.1

7

III. CORRESPONDENCE AND SHIPPING

In all correspondence with Beehive Inc. about a specific Separator, please include the

Model and Serial Number of the Separator. This will ensure a quick response and

shipment of the correct parts.

The Separator is assembled and tested at the factory. It is then shipped as four

components.

* Separator * Accessory Kit

* Control Panel * Relay Panel

* Boom Assembly (Optional)

* One-year spare parts kit (Optional)

To prevent any damage and for security, the Separator is shipped in a fully enclosed

shipping container. Standard accessories, tools and spare parts are packaged in a

separate box and banded within the container.

IV. PRE-INSTALLATION INSPECTION

Shipping containers should be opened with care to prevent possible damage to the

equipment. Using the packing list attached to the container, inspect all parts to determine

the Model Number of the Separator, and to ensure the correct Chamber, electrical

control(s), accessories, tools and spare parts are received as ordered.

Damaged parts, missing parts and parts received that are not on the applicable purchase

order should be reported immediately to Beehive Inc.

8

V. INSTALLATION

GENERAL

The Separator can be installed safely and correctly in a minimum amount of time using the

outlined procedure and the following reference documents.

∗Installation Drawing #9188D ∗Electrical Schematic #8518C

∗Assembly Drawing #9189D ∗Control Panel Assembly #8918D

∗Boom Assembly RH #9259D (Optional) ∗Relay Panel Assembly #8924D

∗Boom Assembly LH #9259D (Optional) ∗Control Installation #8639A

∗Head Assembly #8540D ∗Manufacturer’s Data

∗Located in the Appendix in the back of this manual.

INSTALLATION

Refer to Installation Drawing #9188D for installation dimensions.

WARNING - Make sure that electrical power has been shut off, disconnected

and LOCKED OUT before proceeding with the installation. Many

of the Separator parts are heavy so use caution when handling to

prevent Separator damage and/or personal injury.

1. Install the Separator using the machine dimensions shown on the Installation

Drawing #9188D. All product inlet and outlet locations are indicated.

2. The Separator must be mounted on a rigid platform stand or directly on the floor.

The Separator is equipped with four adjustable pads. The pads (shown in Figure

5.1) must be adjusted to level the Separator and provide equal support. Tighten the

pad locking nuts to maintain proper adjustment.

3. The Control Panel should be wall or stand mounted in an easily accessible

area within 15 feet (5 m) of the Separator. Easy access to the Control Panel must

be maintained at all times. Physical dimensions are shown in Figure 5.2.

4. The Relay Panel in Figure 5.3 should be wall mounted in a separate dry room/area.

Cable length from the Control Panel to the Relay Panel should not exceed 150 feet

(45 m).

9

2.2 [56.7] MIN.

4.2 [107.5] MAX.

LOCKING

NUT

Figure 5.1

BEEHIVE CONTROL PANEL

7.9

[200]

11.8

[300]

Figure 5.2

10

BEEHIVE 400-575V RELAY PANEL

23.6

[600]

23.6

[600]

Figure 5.3

For complete electrical installation and connection information, see Section VI.

ELECTRICAL CONTROLS.

5. After the initial installation of the Separator, sanitize all parts that will come in

contact with food products. Refer to Section VII. CLEANING.

11

MOTOR ROTATION

Figure 5.4

The motor must be checked for proper rotation before installing the initial Separator Head.

The Auger must rotate counterclockwise when facing the motor output shaft.

CAUTION: Incorrect rotation may damage the Separator.

If motor rotation is incorrect, interchange any two motor leads and recheck the output shaft

rotation. Refer to Electrical Schematic #8518C.

12

VI. ELECTRICAL CONTROLS

GENERAL

The Motor Relay Panel and Control Panel are designed for ease of installation. Installation

must be in accordance with all applicable electrical codes. Use a registered electrician or

electrical contractor for wiring installation. Refer to Electrical Schematic #8518C and

Control Installation Drawing #8639A for complete wiring and installation information.

WARNING - The panels should be installed, adjusted and serviced by

qualified electrical maintenance personnel. Improper installation

or operation of the panels may cause injury to personnel or

damage equipment. The panels must be installed and grounded

in accordance with local and national electrical codes.

Potentially lethal voltages exist within the panels. Extreme care must be

taken to ensure all power sources are disconnected and LOCKED OUT before starting

installation, maintenance or repair procedures.

RELAY PANEL

The Relay Panel is suitable for most areas where industrial equipment is installed. The

area must be well ventilated, allowing unrestricted airflow. Locations subject to steam,

excessive moisture, oil vapors, chemical fumes, corrosive gases/liquids, or excessive dirt

must be avoided. If these are unavoidable, the appropriate enclosures must be supplied or

a separate clean air supply provided.

The ambient temperature should not exceed 105oF (40 C).

Use the following procedure to install the Motor Relay Panel.

1. Mount the Relay Panel in a dry, enclosed area. Total cable length (customer

supplied) between the Relay Panel and the Control Panel should not exceed

150 feet (45 m). Consult local and national codes for specifications. The front of

the Relay Panel must be accessible. The rear and sides need not be accessible;

however, there must be room for adequate ventilation.

13

2. Input power to the relay panel and motor, as supplied by the customer, varies

according to the following electrical kit descriptions. Beehive Inc. recommends

that power to the relay panel be hard wired.

2

20

00

0

V

Vo

ol

lt

t

5

50

0

H

Hz

z

3

3

P

Ph

ha

as

se

e2

22

20

0

V

Vo

ol

lt

t

5

50

0

H

Hz

z

3

3

P

Ph

ha

as

se

e

1

16

68

8

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.1

15

52

2

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.

3

30

0

k

kW

W

m

mo

ot

to

or

r

1

12

20

0

F

F.

.L

L.

.A

A.

.3

30

0

k

kW

W

m

mo

ot

to

or

r

1

10

08

8

F

F.

.L

L.

.A

A.

.

1

11

1

k

kW

W

m

mo

ot

to

or

r

4

48

8

F

F.

.L

L.

.A

A.

.1

11

1

k

kW

W

m

mo

ot

to

or

r

4

44

4

F

F.

.L

L.

.A

A.

.

2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l

2

23

30

0

V

Vo

ol

lt

t

6

60

0

H

Hz

z

3

3

P

Ph

ha

as

se

e4

40

00

0

V

Vo

ol

lt

t

5

50

0H

Hz

z

3

3

P

Ph

ha

as

se

e

1

14

46

6

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.8

84

4

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.

4

40

0

H

HP

P

m

mo

ot

to

or

r

1

10

04

4

F

F.

.L

L.

.A

A.

.3

30

0

k

kW

W

m

mo

ot

to

or

r

6

60

0

F

F.

.L

L.

.A

A.

.

1

15

5

H

HP

P

m

mo

ot

to

or

r

4

42

2

F

F.

.L

L.

.A

A.

.1

11

1

k

kW

W

m

mo

ot

to

or

r

2

24

4

F

F.

.L

L.

.A

A.

.

2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l

4

40

00

0

V

Vo

ol

lt

t

6

60

0

H

Hz

z

3

3

P

Ph

ha

as

se

e4

46

60

0

V

Vo

ol

lt

t

6

60

0H

Hz

z

3

3

P

Ph

ha

as

se

e

8

84

4

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.7

73

3

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.

4

40

0

H

HP

P

m

mo

ot

to

or

r

6

60

0

F

F.

.L

L.

.A

A.

.4

40

0

H

HP

P

m

mo

ot

to

or

r

5

52

2

F

F.

.L

L.

.A

A.

.

1

15

5

H

HP

P

m

mo

ot

to

or

r

2

24

4

F

F.

.L

L.

.A

A.

.1

15

5

H

HP

P

m

mo

ot

to

or

r

2

21

1

F

F.

.L

L.

.A

A.

.

2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l

5

57

75

5

V

Vo

ol

lt

t

6

60

0

H

Hz

z

3

3

P

Ph

ha

as

se

e

5

58

8

T

To

ot

ta

al

l

F

F.

.L

L.

.A

A.

.

4

40

0

H

HP

P

m

mo

ot

to

or

r

4

41

1

F

F.

.L

L.

.A

A.

.

1

15

5

H

HP

P

m

mo

ot

to

or

r

1

17

7

F

F.

.L

L.

.A

A.

.

2

24

4V

VA

AC

C

C

Co

on

nt

tr

ro

ol

l

CONTROL PANEL

The Control Panel should be located within 15 feet (5 m) of the Separator and must be

within easy access at all times. The panel is a stainless steel, watertight design that is

wash down resistant. Internal components should be inspected at regular intervals for

moisture. If moisture is found, all components must be dried completely.

14

VII. CLEANING

WARNING - Make sure all electrical power to Separator has been shut off

disconnected and LOCKED OUT before proceeding with cleaning.

Many of the Separator parts are heavy so use caution when

handling to prevent Separator damage and/or personal injury.

GENERAL

The Separator must be disassembled, cleaned and sanitized after each work period.

The following parts must be removed and cleaned:

* Head Housing * Feed-screws

Auger Plastic Seals

Adapter Bracket Chamber

Ring Valve

*CAUTION: DO NOT lift alone

The Hopper also must be thoroughly cleaned. The Chamber must be soaked in sodium

hydroxide (NaOH) cleaner before washing and sanitizing.

SODIUM HYDROXIDE (NaOH) CLEANER

WARNING - Sodium hydroxide (NaOH) cleaner is an alkaline solution that can

cause severe burns. Read this section carefully before using the

solution.

Safety Precautions -

1. Avoid spillage. Sweep or flush with water immediately if spillage occurs.

2. Avoid contact with skin and eyes.

3. Use only steel, nickel, monel, rubber or resistant plastic containers to store or

transport the cleaner solution.

4. For the protection of others, thoroughly rinse all empty containers that have been

used to store or transport sodium hydroxide (NaOH) cleaner.

15

5. DO NOT take internally. If taken internally, call a physician at once. DO NOT induce

vomiting. Immediately give large quantities of water or (preferably) milk.

6. Use and handle all alkali-cleaning agents as directed in applicable plant and local

safety manuals.

Personal Precautions - Persons who may be exposed to alkali should be provided

with the proper eye, skin, respiratory and mucous membrane

protection as follows:

1. Close fitting industrial goggles and face shield.

2. Rubber gloves and apron.

3. Rubber safety-toe shoes or boots (tops should be covered by trousers).

4. Cotton overalls that fit snugly at the neck and wrists.

5. Respirators of an approved type, if alkali dust is present.

6. Rescue harness and lifelines for those entering the tanks or closed storage spaces.

7. Readily accessible supply of large volumes of water. (flooding shower or running

hose).

First Aid Treatment - In all cases of contact with alkali in any form,

serious injury may result. First aid should be started

at once. Speed in removing alkali is of primary

importance. Follow these first aid steps:

1. Call a physician at once even if the injury appears to be slight. Give the physician a

detailed account of the incident.

2. Flood the affected areas (body or eyes) instantly with clean water for a prolonged

period.

3. Remove contaminated clothing.

4. Wash affected body areas with a mild vinegar solution or continue washing with

water.

5. DO NOT apply ointments or grease to burned areas.

This manual suits for next models

2

Table of contents

Other BEEHIVE Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Monosem

Monosem CS 3000-16 manual

REIST INDUSTRIES

REIST INDUSTRIES RR72 Operator and parts manual

Norwest

Norwest Pivot track filler owner's manual

BROWN

BROWN BDH Series Owner's/operator's manual

breviglieri

breviglieri Hypermaster XL Operating and maintenance manual

Harvest TEC

Harvest TEC 747C installation manual