5

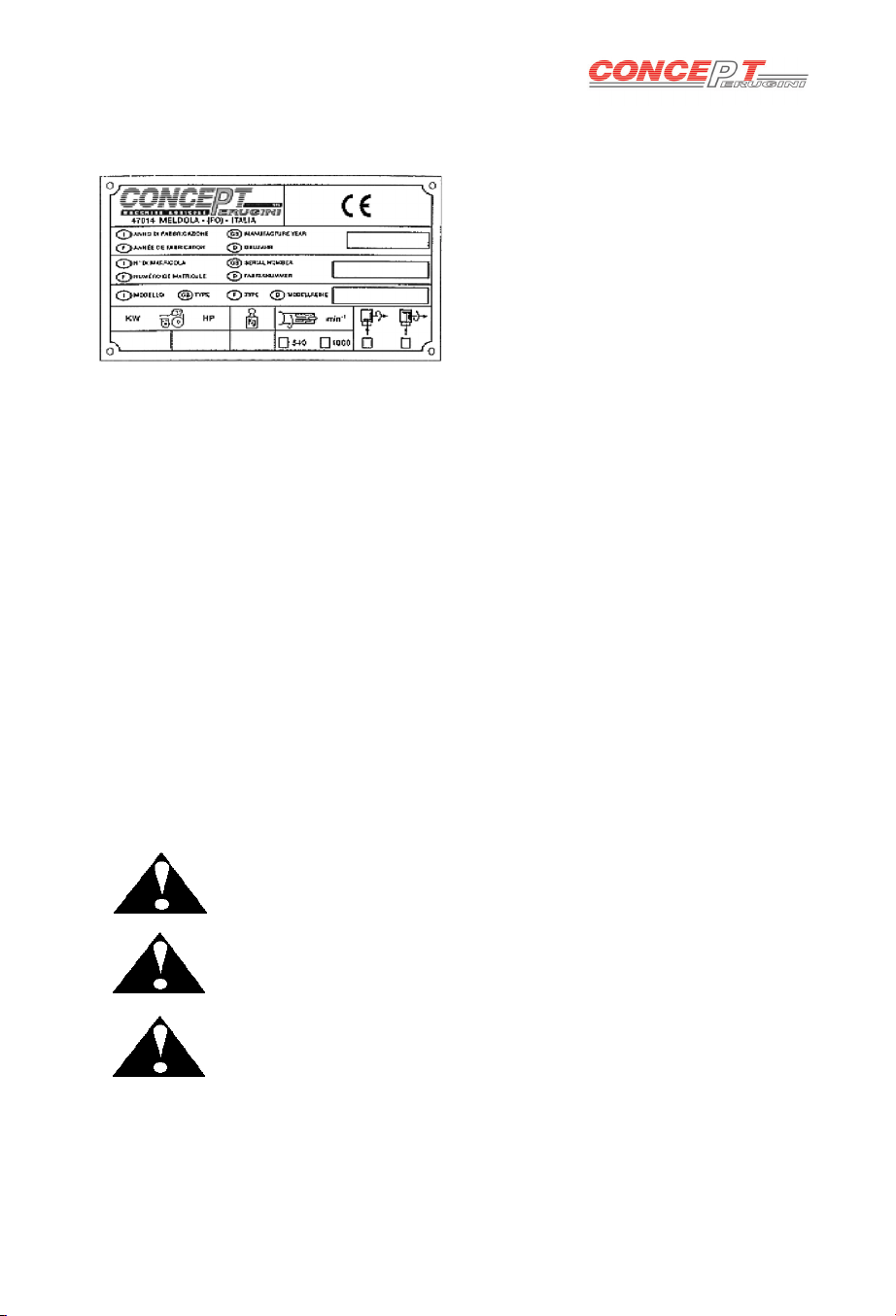

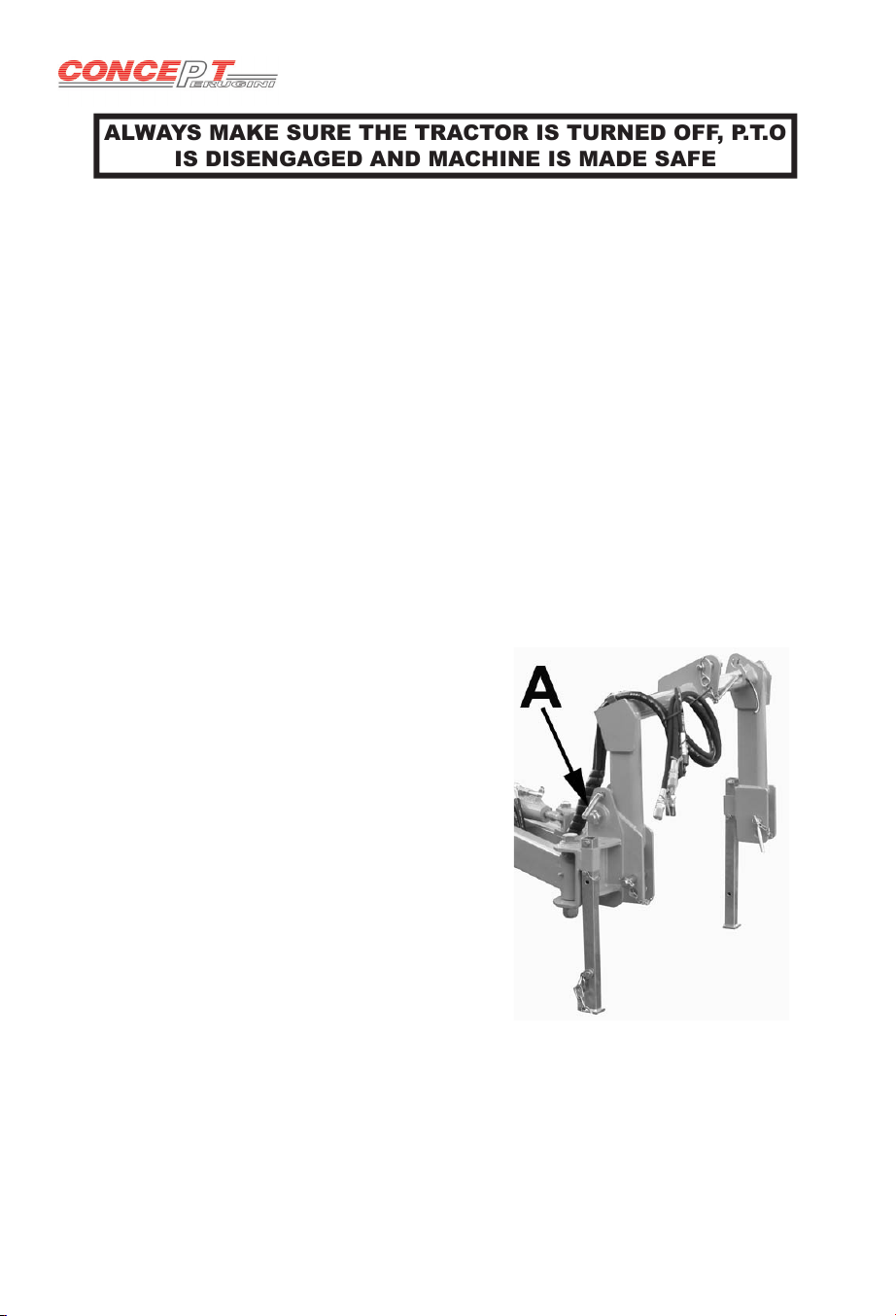

Identication

The identication plate, attached to the machine shows the following information:

• Manufacturer’s Name

• CE mark

• Year of production

• Serial number

• Recommended tractor horsepower

• Overall weight

• P.T.O. speed and direction of

rotation

These data are very important in order to check the compatibility between the

machine and the tractor and when ordering spare parts

Before operation

At the factory each machine is carefully inspected to guarantee proper

functioning. In addition, the dealer, before delivering the machine should have

carried out a pre delivery inspection. However as a precaution measure check:

• Oil level in the gearbox

• Grease all those components provided with grease nipples

• Air pressure in the tractor’s tyres, length of lift arms

• Tractor PTO speed to match the machine transmission speed

Safety

Symbols

In this booklet three dierent symbols are used to highlight danger levels or

important information

DANGER

To draw the operator’s attention to situations which could

endanger his or other people safety.

CAUTION

To draw the operator’s attention to situations which could aect

the machine performances but not his or other people safety.

IMPORTANT

To draw the operator’s attention to situations which do not aect

the machine performances and his or other people safety.

It is important to comply with the instructions given by the safety stickers, which

must always be on the machine. If new ones are required, contact your dealer.