When using the road queue pin, be careful that Revolutions Per Minute depends on

tractor’s speed and turning way can’t be opposite in back movement.

In machine’s carrying position, take care of from tractor wheels, excess outside.

The movements in curves, take care of freight condition and drift mass of the machine.

It’s dangerous to work with tractor in downhill.

Still If you have to do it, take care about it and don’t turn curves so severe.

To provide a safe movement stability, to cultivate the downhill working field; take care

of fitting the tractor with sufficient addition weight.

Before starting up in farm:

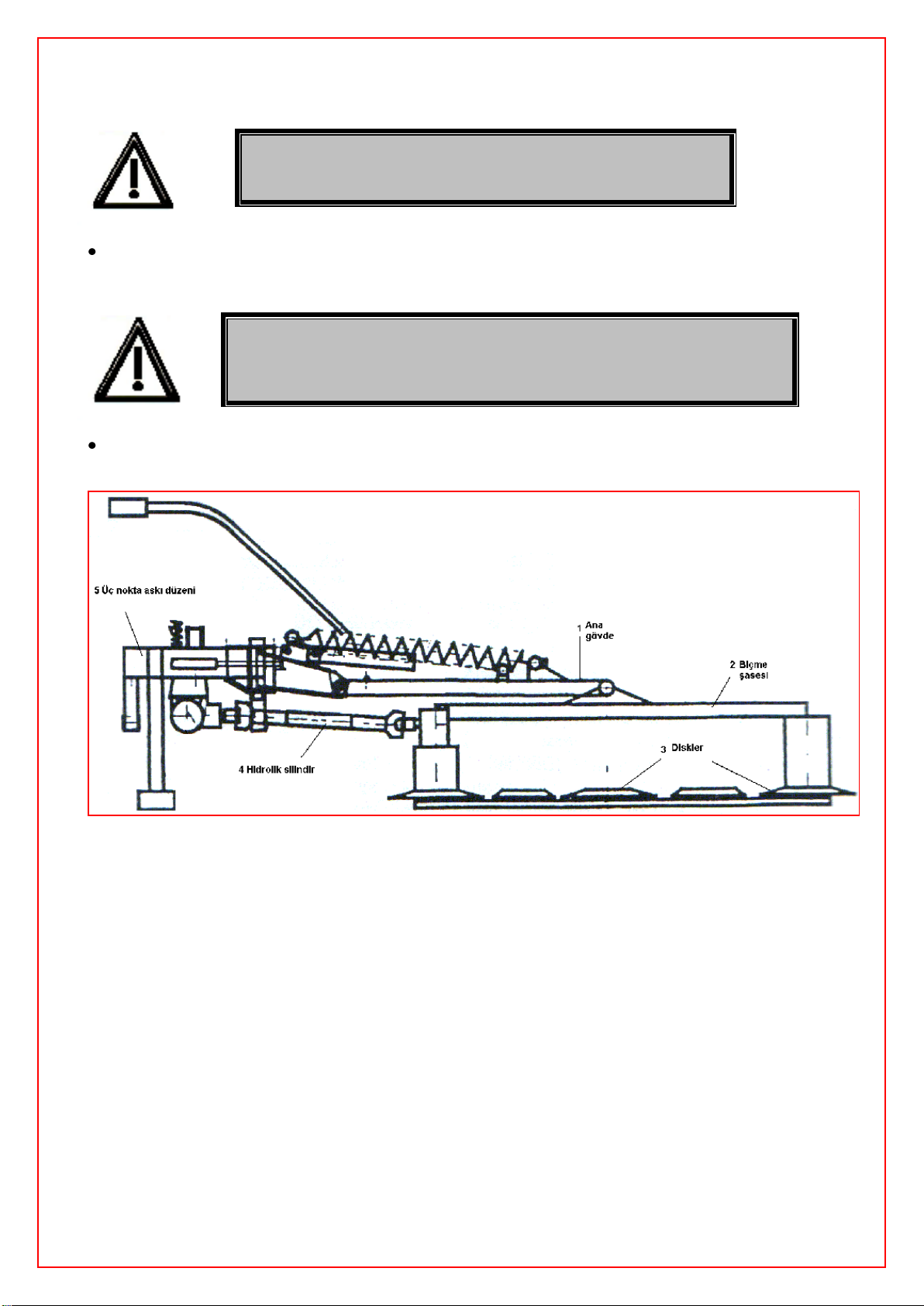

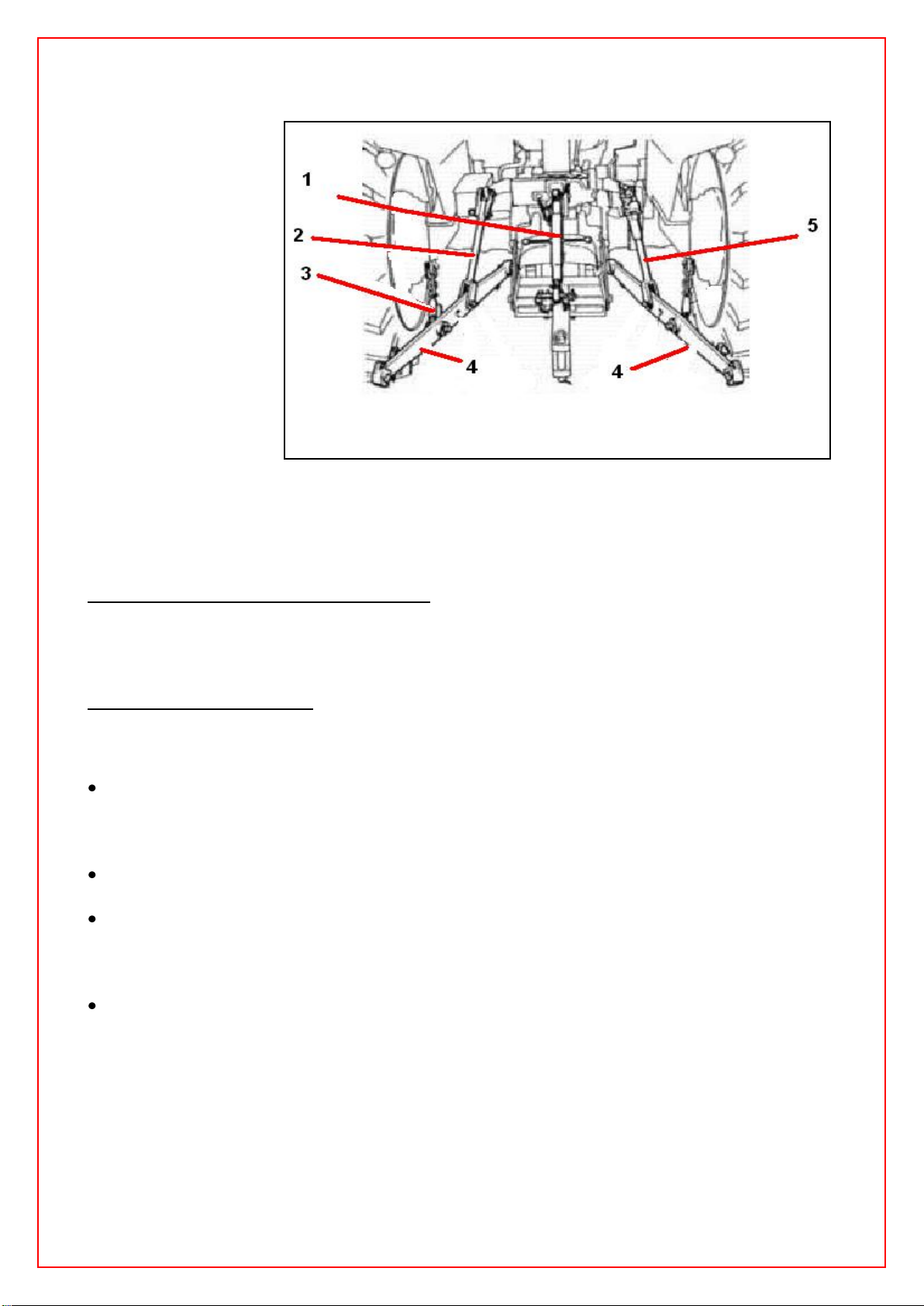

Put tractor hdyraulic control arm to position control condition and make the height

adjustment.

In position control condition, when you are moving hdyraulic arm a little, tool lifts up, stops in

a level, if you move the arm again, it lifts some more and stops, namely draw doesn’t rise the

top point like in control.

Note: Hdyraulic setdown-lifting arm is lifted up and put it in a certain level.

In this condition tool and machine completely lift up, front elect arm is in “DRAW CONTROL”

If tool and machine don’t lift completely, and lift in a certain level, it’s in “POSITION

CONTROL”.

Position control condition provides the machine’s working in the field by putting tool and

machine which are depended hdyrolic connection arms in a certain height.

When you’re working with like Centrifuge fertilizer distributed machine, front election arm

must be in position control condition.

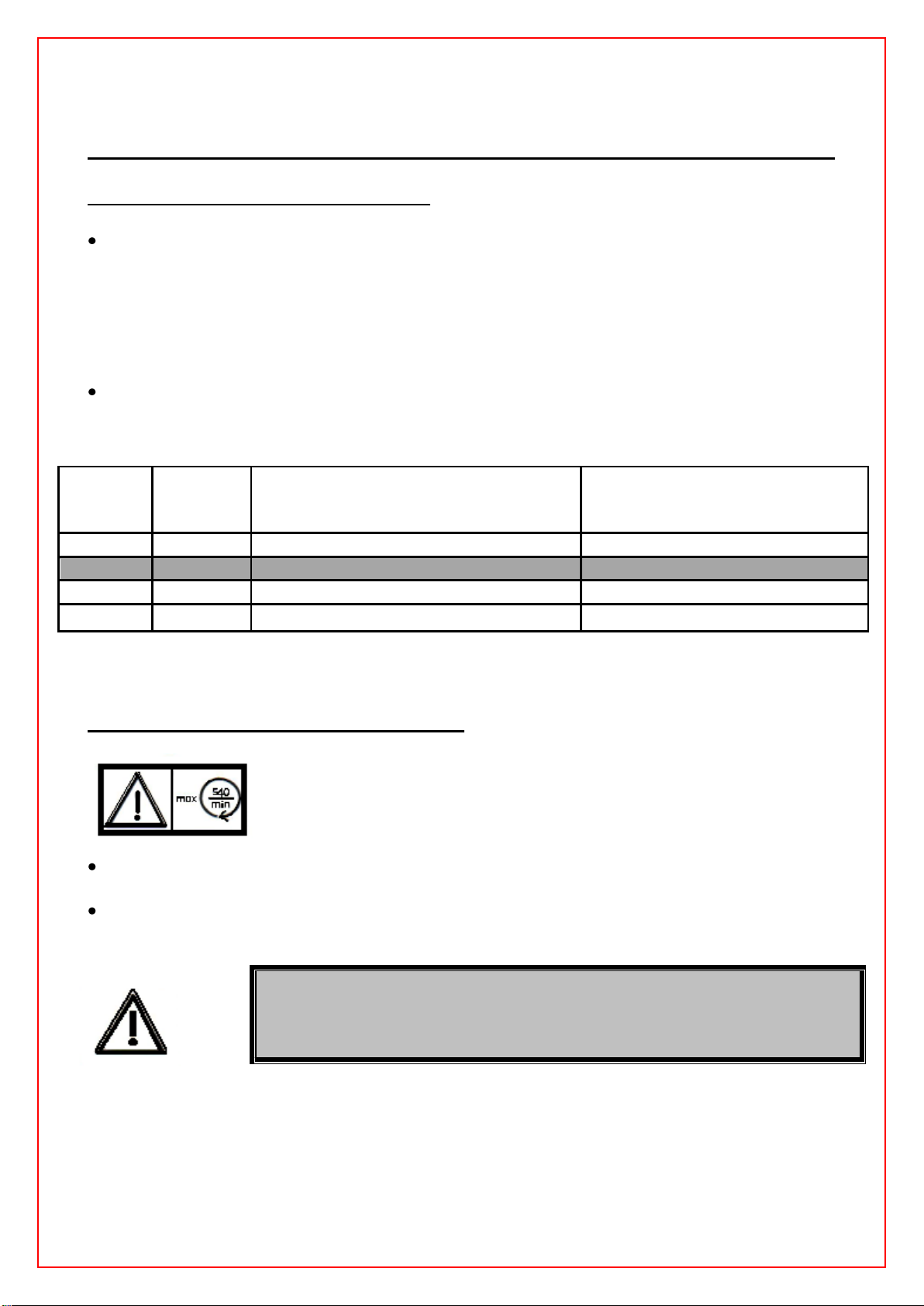

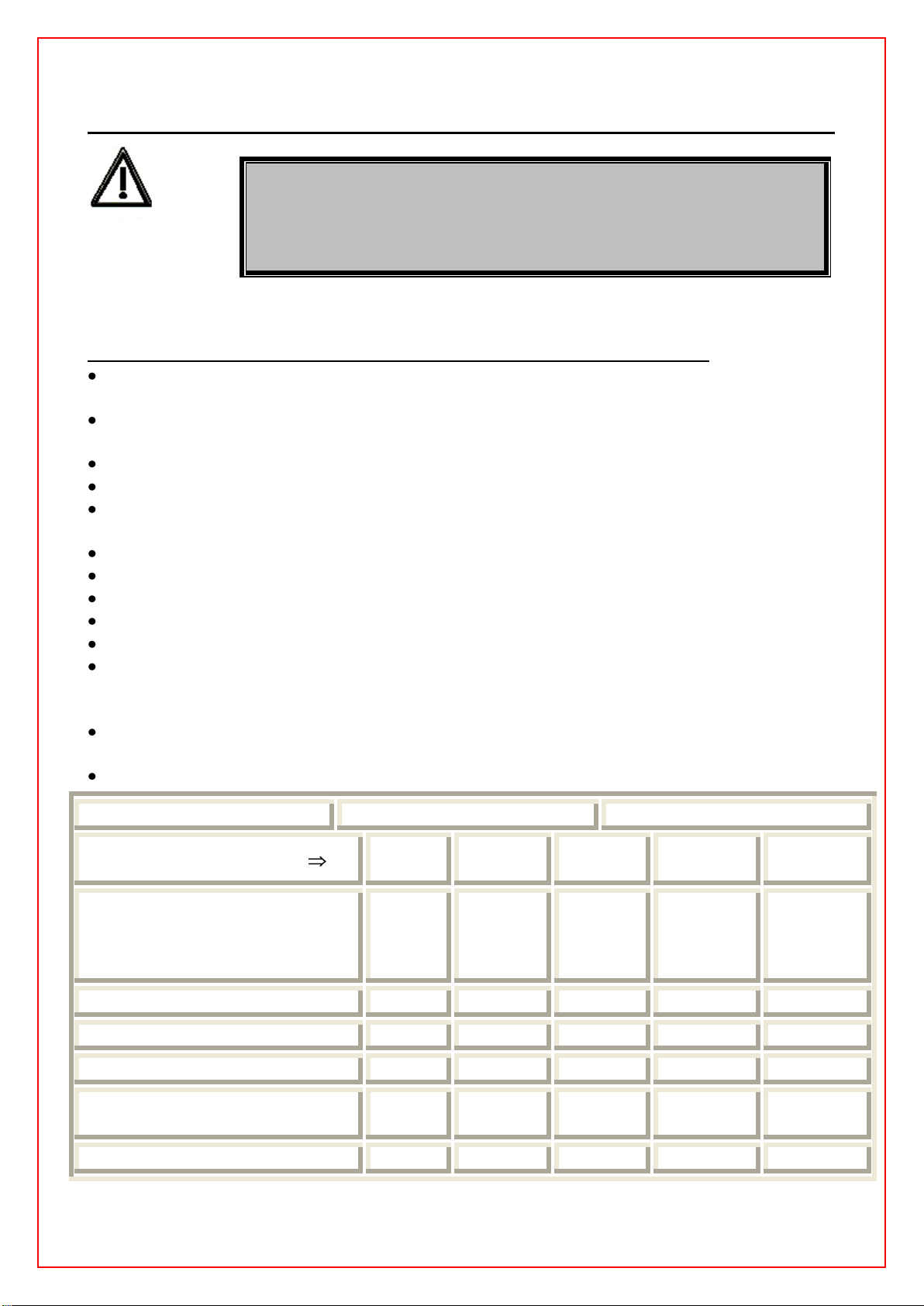

Safety Max. Input rotation speed of the Rotary Disc Mower is 540 RPM

After providing a convenient dept, the machine is taken to the field with a convenient gear it is

started up moving on and working.

Running and stopping of Hdyraulic Side Shifting Rotary Tiller is arranged only from tractor

driver place.

Rotary Disc Mower must works into the circle that has 5 m distance between itself and

people. Because in this field pieces that machine throws like stone and soil may come.

Rotary Disc Mower is worked only in flattened smoothy field.

Besides, be careful about if stone and chips exist in the field or not.

Then these strange materials is in working field, it can cause harm to machine’s cultivation

bodies, knives, and at the same time herbals and people.

Rotary Disc Mower don’t be worked in nonsmoothy fields.

Machine’s working speed is arranged only by depending working conditions.

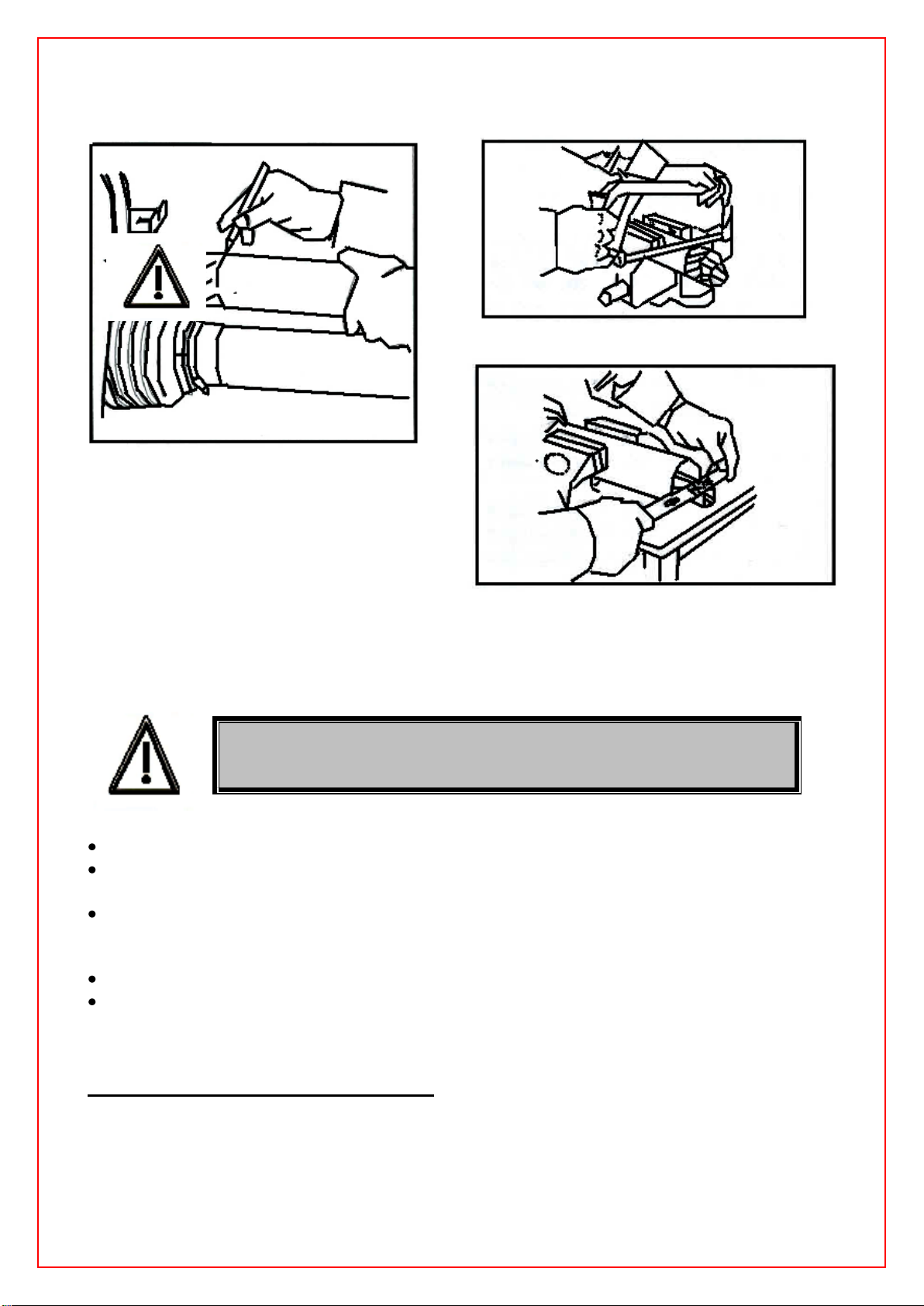

During working with the machine, in the end of the turnings tractor queue spindle is

stopped and you wait until the machine is stopped.

Before the turnings the machine is lifted and slinged. So danger of throwing field pieces

which the machine’s got disseapears.

If your tractor which you run Rotary Disc Mower with doesn’t have a close driver cabin,

please during the working use a protection glasses and noise.