Beijer Electronics X2 pro User manual

ImageManual

English

MAEN205G,2022-08

Foreword

ImageManual

Foreword

The information in this document is valid for the latest versions of the panel

images at the time the document was released.

For information and updates, see https://www.beijerelectronics.com.

Order no: MAEN205G

Copyright © 2022-08 Beijer Electronics AB. All rights reserved.

The information in this document is subject to change without notice and is provided as available at the

time of printing. Beijer Electronics AB reserves the right to change any information without updating this

publication. Beijer Electronics AB assumes no responsibility for any errors that may appear in this document.

All examples in this document are onlyintended to improve understanding of the functionality and handling

of the equipment. Beijer Electronics AB cannot assume any liability if these examples are used in real

applications.

Inviewofthewider

ange of applications for this software, users must acquire sufficient knowledgethemselves

in order to ensure that it is correctly used in their specific application. Persons responsible for the application

and the equipment must themselves ensure that each application is in compliance with all relevant

requirements, standards, and legislation in respect to configuration and safety. Beijer Electronics AB will

accept no liability for any damage incurred during the installation or useof equipment mentioned in this

document. Beijer Electronics AB prohibits all modification, changes, or conversion of the equipment.

BeijerElectronics, MAEN205G

Contents

Contents

1 Introduction ............................................................. 5

1.1 Safetyprecautions ................................................ 5

1.2 Warning,caution,information,andtipIcons ................. 5

1.3 Trademarks ....................................................... 5

1.4 References ........................................................ 6

1.5 Operatingsystems ............................................... 7

2 Booting .................................................................. 8

2.1 Welcomescreen .................................................. 8

3 Servicemenu ............................................................. 9

3.1 Service menu in an empty panel ................................. 9

3.2 Service menu in a panel containing a project ................... 9

3.3 IPsettings ......................................................... 9

3.4 Date/Time ....................................................... 10

3.5 Editproject ....................................................... 10

3.5.1 Copyprojectfromexternalmemory ............................10

3.5.2 CopyprojecttoSDcard .........................................10

3.5.3 CopyprojecttoUSB .............................................11

3.5.4 Deleteproject ....................................................11

3.5.5 Restorepaneltopreviousimage .................................11

3.5.6 Restorepaneltofactoryimage ...................................11

3.6 Selftest ............................................................ 12

3.7 Touchcalibrate ................................................... 12

3.8 Debuglogging ................................................... 12

3.9 Diagnostic ........................................................ 13

3.9.1 Exportdiagnosticinformation ..................................15

4 Servicewarning .......................................................... 16

4.1 Synopsis .......................................................... 16

4.2 Glossary .......................................................... 16

4.3 Design ............................................................ 16

4.3.1 eMMCWear .....................................................16

4.3.2 Servicewarningmessage .........................................17

4.3.3 Showingtheservicewarning ....................................17

4.3.4 Suppressionofservicewarning ..................................17

4.3.5 Servicewarnings .................................................18

5 ImageandCODESYSupdate .......................................... 19

5.1 UpdatingthepanelimageusingUSBorSDcard .............. 19

5.1.1 Preferredway ....................................................19

5.1.2 Image+newiXDeveloperproject ...............................20

5.2 Updating the panel image over ethernet ........................ 20

5.3 iXDeveloperprojectstatusafterpanelimageupdate .......... 22

5.4 UpdatingtheCODESYSruntimeusingethernet ............. 22

5.5 UpdatingtheCODESYSruntimeusingUSB ................. 23

6 Creating a custom welcome screen ..................................... 25

7 X2control ................................................................ 29

BeijerElectronics, MAEN205G

Contents

7.1 Runtimeversion ................................................. 29

7.2 Change etherCAT / normal ethernet ........................... 29

7.3 CODESYSlicense ............................................... 29

7.3.1 ControlLicense ..................................................29

7.4 Loadproject ...................................................... 29

7.5 Devicedescription ............................................... 29

BeijerElectronics, MAEN205G

Introduction

1Introduction

1.1 Safetyprecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand the manual.

1.2 Warning,caution,information,and

tipIcons

This publication includes Warning, Caution, and Information where appropriate

to point out safety related or other important information. It also includes Tip

to point out useful hints to the reader. The corresponding symbols should be

interpreted as follows:

Electricalwarningiconindicatesthepresenceofahazardwhichcould

resultinelectricalshock.

Warningiconindicatesthepresenceofahazardwhichcouldresultin

personalinjury.

Cautioniconindicatesimportantinformationorwarningrelatedto

theconceptdiscussedinthetext. Itmightindicatethepresenceof

ahazardwhichcouldresultincorruptionofsoftwareordamageto

equipment/property.

Informationiconalertsthereadertopertinentfactsandconditions.

Tipiconindicatesadviceon,forexample,howtodesignyourprojector

howtouseacertainfunction.

1.3 Trademarks

Microsoft, Windows, Windows Embedded CE 6.0 R3, Windows Embedded

Compact 2013, Windows 7, Windows Embedded Standard 7 are registered

trademarks or trademarks of Microsoft Corporation in the USA and/or other

countries. Any additional trade names given in this documentation are trademarks

of their corresponding owners.

BeijerElectronics, MAEN205G 5

Introduction

1.4 References

Name Description

MAENxxx InstallationManualX2

The installation, technical data as well as cutout and outline dimensions of the

panels are described in the installation manual for each operator panel. Please refer

to the Installation manuals and the iX Developer manual for further information.

Note:

Currentdocumentationandsoftwareupdatescanbefoundon

http://www.beijerelectronics.com

BeijerElectronics, MAEN205G 6

Introduction

1.5 Operatingsystems

Panel family RuntimeVersions

(licenses) Description

–iXTxA

–iXTxB

–X2base

WindowsCE6 Includessupportofmostexisting

features.

–All4”X2panels

–X2pro

–X2control7

–X2motion7

–X2marine

–X2marineSC

WindowsEmbedded

Compact2013

Runtime(Entry)

Basiclicense,notsupporting:

StreamingMediaPlayback

PDFReader

VBScript

JCcript

–X2marineHB

–X2marineHBSC

–X2pro,X2control

andX2motionwith

screensizesgreater

than10”

–AllX2extreme-

basedpanels

WindowsEmbedded

Compact2013

Runtime(General

embedded)

Includessupportofmostexisting

features.

BeijerElectronics, MAEN205G 7

Booting

2Booting

2.1 Welcomescreen

1. Apply power to the operator panel.

2. Within 20–30 seconds, the welcome screen will appear.

The following items about theoperatorpanelarelisted:

•Size of external memory card, if applicable

•IP address

•Panel image version

If a project has been downloaded to the panel, it will be loaded automatically.

If there is no project in the panel, touching the screen will display the service menu.

If there is an SD card inserted into the panel, and the project on the SD card differs

from what is saved in the operator panel, then the user is asked if the project and

IP-settings should be restored.

The welcome screen for a X2 control 10 panel

Position Description

1Paneltype.

2 ExternalMemorycardstatus.

3 Networkstatus. Anattachednetworkcableisindicatedwithan

asterisk.

4 Panelimagemainversionandbuildnumber.

BeijerElectronics, MAEN205G 8

Service menu

3Servicemenu

The service menu for the operator panel can be accessed before a project is

downloaded.

3.1 Servicemenuinanemptypanel

When no project is loaded in the panel memory, the panel will boot, displaying the

welcome screen.

•Press anywhere on the panel display to enter the service menu.

3.2 Servicemenuinapanelcontaining

aproject

Perform the following steps to enter the service menu:

1. Apply power to the panel.

2. When the hourglass appears, press a finger on the screen and hold for

approximately 20 seconds.

3. If the service menu is password protected, you will be prompted for a pin code.

Enter pin code.

4. The touch calibration screen will display the following message:

“Tap anywhere on screen or touch calibrate will start in 10 seconds.”

5. Press the screen once again to enter the service menu.

3.3 IPsettings

The following parameters can be set:

•IP address

•Subnet mask

•Default gateway

•DNS settings for the ethernet port on the operator panel

The default setting for LAN A is: IP address 192.168.1.1, Subnet mask

255.255.255.0

BeijerElectronics, MAEN205G 9

Service menu

If the operator panel is equipped with two ethernet ports, then a second tab is

shown in the IP settings dialog. The default setting for LAN B is “Obtain an IP

address via DCHP”.

3.4 Date/Time

Thedate/timesettingsdialogallowssetting

oftheTimezone,date,timeandalsosetting

automaticadjustmentofclockfordaylight

saving.

3.5 Editproject

Theeditproject/restoreimagedialogallows

modifyingtheprojectinanoperatorpanel

and,ifneeded,restorethepanelimagetoa

previousversion.

3.5.1 Copyprojectfromexternalmemory

This option enables the function to copy an iX Developer project from an external

memory, USB flash drive or storage device connected to one of the operator panels

USB-ports.

3.5.2 CopyprojecttoSDcard

This option enables the function to copy the iX Developer project and all the files

neededtoruntheapplicationtoanexternalSDcard.

BeijerElectronics, MAEN205G 10

Service menu

Note:

ThisoptionisnotavailableonX2base.

3.5.3 CopyprojecttoUSB

The iX Developer project and all the files needed to run the application are copied

to an external USB flash drive or other USB connected storage device. Make sure

that the storage device is connected before trying this option.

3.5.4 Deleteproject

The iX Developer project and all its corresponding files are deleted from the

operator panel. There is no way of undeletingaproject,makesurethattheprojec

t

should be deleted before confirming the deletion.

3.5.5 Restorepaneltopreviousimage

The operator panel image can be restored to the panel image version the operator

panel was using, before a new panel image was loaded into the operator panel.

This option is used to restore a panel to a known working condition.

Note:

ThisoptionisonlyavailableonX2panels,withtheexceptionofX2base

Note:

IftheoperatorpanelcontainsaCODESYSRuntime,thentheCODESYSRuntimemustbe

downloadedonceagaintothepanelafterthepanelimagehasbeenchanged.

3.5.6 Restorepaneltofactoryimage

The operator panel image can be restored to the panel image version that the

operator panel was shipped with from the factory. Use this option if all else fails,

this will downgrade the operator panel to its initial state.

BeijerElectronics, MAEN205G 11

Service menu

Note:

ThisoptionisonlyavailableonX2panels,withtheexceptionofX2base

Note:

IftheoperatorpanelcontainsaCODESYSRuntime,thentheCODESYSRuntimemustbe

downloadedonceagaintothepanelafterthepanelimagehasbeenchanged.

3.6 Selftest

The self test screen looks a little different depending on operator panel type.

To be able to fully test the Carrier unit, a complete set of test plugs, SD card and a

USB flash drive is needed.

3.7 Touchcalibrate

The touch calibration screen enables the function to recalibrate the touch screen.

The recalibration consists of five steps, where a crosshair on the screen is pressed

and held. Take care and try to do this as precise as possible, an incorrect calibration

makes it hard to use the operator panel.

3.8 Debuglogging

TheDebugLoggingdialogenablesthefunction

toenableanddisablethedebugloggingonthe

operatorpanel. Italsoenablesthefunctiontomove

apreviouslycreatedsetofdebuglogfilesfromthe

operatorpaneltoanUSBflashdrive.

BeijerElectronics, MAEN205G 12

Service menu

Option Description

EnableLogging Theoperatorpanelwillstartorcontinuetostore

additionaldebugloginformationinlogfiles. Atotal

of10logfilesofamaximumof100kBperfilewillbe

keptintheoperatorpanelinternalmemory. Ifthelog

filesarefilledtothelimit,theoldestfilewillbeover

writtenfirst.

Thisfunctionshouldonlybeusedforalimitedtime,as

itwillcontinuouslywritedatatotheflashmemoryand

bythataddtotheflashmemorywear.

DisableLogging Theoperatorpanelstopsstoringdebuglogdata.

Thedatawillremainintheoperatorpanelinternal

memory.

MoveLogtoUSBMemory Movesthedebuglogfilesintheoperatorpaneltoan

externalUSBstoragedevice.

3.9 Diagnostic

Category Description

Diagnostics Showshowmanytimestheoperatorpanelhasbeenstarted,

howlongtheoperatingpanelhasbeenrunning,measured

temperaturesandthewearoftheflashmemory.

Imageinformation Displaysalistofthepanelimagesavailableontheoperator

panel.

Panelinformation Showsthemake,modelandrevisionoftheoperatorpanel.

BeijerElectronics, MAEN205G 13

Service menu

Category Description

Systemboard ShowshardwareinformationoftheSystemboardinthe

operatorpanel.

Displaycard ShowshardwareinformationoftheDisplaycardinthe

operatorpanel.

Category Description

Selftest Showstheresultofthelastselftest.

Summaryofflash

drivestorage Showsasummaryoftheflashdrivestoragestatus.

Networkadapters ShowsIPconfigurationsandMACaddressesforthenetwork

adaptersintheoperatorpanel.

Note:

Theinformation(layoutandnumberofscreens)onthediagnosticscreenpages

appeardifferentlydependingonscreensize. Thescreenshotsabovearetakenfrom

aX2control10operatorpanel.

BeijerElectronics, MAEN205G 14

Service menu

3.9.1 Exportdiagnosticinformation

Click Save to USB memory to export the diagnostic information to an external

USB flash drive or other USB connected storage device. Make sure that the storage

device is connected before trying this option.

BeijerElectronics, MAEN205G 15

Service warning

4Servicewarning

4.1 Synopsis

This section describes the service warning message present in Galvatron (Supreme

and Starscream for the future). It is applicable fotr the X2 pro models.

4.2 Glossary

•eMMC - Embedded MultiMediaCard

•WEC2013 - Windows Embedded Compact 2013 Operating System

•Galvatron - X2 pro platform

•Supreme - X2 extreme platform

•Starscream - X2 base v2 platform

4.3 Design

4.3.1 eMMCWear

The following data about wear can be retrieved from the eMMC:

Table 1. Provides an estimated indication about the device life time that is reflected

by the average waer out of memory of Type A relative to it’s maximum estimated

life time.

DevicelifetimeextimationtypeA

Value Desription

0x00 Notdefined

0x01 0%-10%devicetimeused

0x02 10%-20%devicetimeused

0x03 20%-30%devicetimeused

0x04 30%-40%devicetimeused

0x05 40%-50%devicetimeused

0x06 50%-60%devicetimeused

0x07 60%-70%devicetimeused

0x08 70%-80%devicetimeused

0x09 80%-90%devicetimeused

0x0A 90%-100%devicetimeused

0x0B Exceededit’smaximumestimateddevicelifetim

Others Reserved

BeijerElectronics, MAEN205G 16

Service warning

Table 2. Provides indication about device life time reflected by average reserved

blocks.

PreEOL

Value Pre-EOLinfo. Desription

0x00 Notdefined

0x01 Normal Normal

0x02 Warning Cosumed80%ofreserved

block

0x03 Urgent

0x04~0xFF Reserved

ThisdatauslocatedintheeMMCextendedregister.

4.3.2 Servicewarningmessage

If a warning is issued the message pops up. In this example we have all four

available warnings.

4.3.3 Showingtheservicewarning

The servicewarningmessageisshownwithinoneminuteafterbootup.

It is alsoshowedonceeachperdayat9(localtime).

4.3.4 Suppressionofservicewarning

The battery warning message can be suppressed via settings menu in Diagnostics

application.

BeijerElectronics, MAEN205G 17

Service warning

The eMMC wear can be suppressed via settings menu in Diagnostics application.

- This suppression is only active until device life time in CSD register is changed.

Note:

Theservicewarningmessagecanbesuppressedfor7daysbycheckingthecheckbox

andpressOK.

4.3.5 Servicewarnings

•Rapid flash wear warning

“The unit internal disk lifetime is rapidly decreasing. Please consult the

documentation how to reduce wear, or how to minimize it.”

Occurs when the user’s program is quickly decreasing the flash memory’s wear.

Consultthe“X2andiXDeveloper2.40–Flashmemorybestpractice”guide

found under Resources for the unit’s product page on Beijer Electronics’

webpage.

•Flash lifetime warning

“The unit should be scheduled for preemptive maintenance service. The internal

disk memory is soon reaching its expected lifetime.”

This warning appears when that the unit’s flash memory is reaching its

expected lifetime. The only solution is to replace the entire unit.

•Battery warning

“The unit internal battery is due and needs to be replaced.”

Indicates the Real Time Clock (RTC) battery is depleted. This battery is used

by the system to power the internal clock and maintain a few stored settings.

The solution is to replace the 3V battery (CR 2032) with an equivalent one.

Warning: Opening the unit will void the warranty!

•License warning

“Operating system license doesn’t match device type.

Occurs when the runtime version license running on the unit for Windows

Embedded Compact 2013 is incorrect. Contact support for solution.

BeijerElectronics, MAEN205G 18

Image and CODESYS update

5 ImageandCODESYSupdate

The operator panel comes pre-loaded on delivery with an image.

iX Runtime can be updated via ethernet using a PC.

The Image Loader utility is used to create Image Loader SD cards and USB-sticks

or to transfer a panel image to an operator panel over ethernet.

Theimagecanbeupdatedinthefollowingway:

Updatemethod iXDeveloperprojectremains IPadressremains

Ethernet X X

USB X X

SD X X

RecoverySDcard - -

Ifyouwantacompletesystemupdate,chooseMakeRecoverySDcard. The

iXDeveloperwillthenbesettodefaultsettings,exceptfortouch.

5.1 UpdatingthepanelimageusingUSB

orSDcard

5.1.1 Preferredway

Using a USB flash drive or SD card to update the image in an operator panel is the

preferred method of updating the panel. This makes it possible to upgrade the

panel image without the use of a PC.

BeijerElectronics, MAEN205G 19

Image and CODESYS update

Note:

ImageloaderforiXTxAandX2baseonlysupportsupdatingpanelimageusingethernet.

5.1.2 Image+newiXDeveloperproject

It is possible to upgrade both the panel image and the iX Developer project on an

operator panel. This is done in two steps:

1. Create a panel image USB flash drive or SD card using the Image Loader

utility.

2. Export the iX Developer project from within iX Developer, to that same USB

flash drive or SD card.

5.2 Updatingthepanelimageover

ethernet

The Image Loader utility can be used to upgrade the panel image over ethernet.

Note:

Beforetryingtoupdatethepaneloverethernet,makesurethatyourPCisonthesame

IP-subnetastheoperatorpanel. IfyourpanelhasanIPaddressof192.168.1.1,and

anetmaskof255.255.255.0,thenyourPChastohaveanIPaddressintherangeof

192.168.1.2–192.168.1.254andanetmaskof255.255.255.0,inordertobeableto

communicatewiththepanel.

ToentertheupdatemodeonaiXTxAorX2base,pressafingeronthescreenandapply

powertothepanel.

1. Enter the panel target IP address in the dialog and click on Update to start the

update.

BeijerElectronics, MAEN205G 20

Other manuals for X2 pro

1

Table of contents

Other Beijer Electronics DC Drive manuals

Beijer Electronics

Beijer Electronics BFI-P2 Installation manual

Beijer Electronics

Beijer Electronics BFI-H3 Installation manual

Beijer Electronics

Beijer Electronics Korenix JetNet 7612G User manual

Beijer Electronics

Beijer Electronics SUEN00403 User manual

Beijer Electronics

Beijer Electronics BFI-E3 Series Installation and operation manual

Popular DC Drive manuals by other brands

GEZE

GEZE E 170 /230 V AC Wiring diagram

Motor Power Company

Motor Power Company DUET AD installation guide

Knauer

Knauer Azura V 2.1S user manual

ABB

ABB ACS250 Technical Instruction

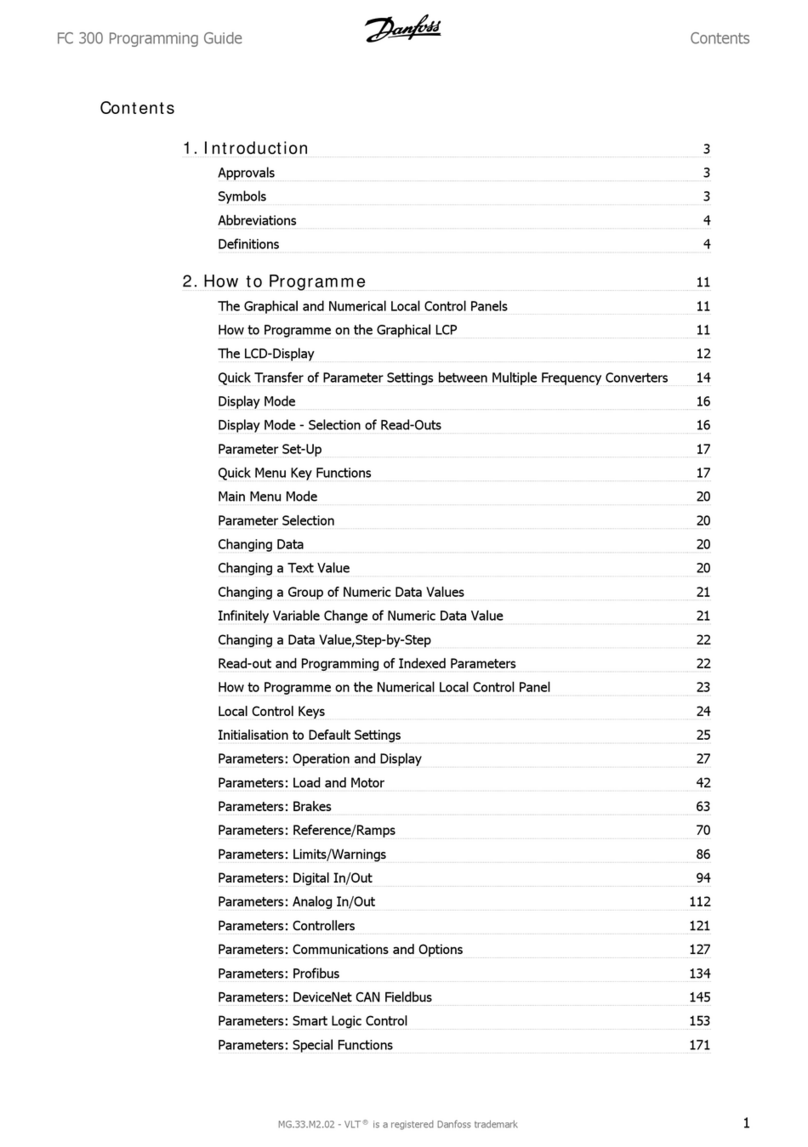

Danfoss

Danfoss FC 300 Programming guide

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 20P Hardware Service Manual