Beijer Electronics 100-0973 User manual

BoX2base

InstallationManual

English

MAEN274,2018-03

Foreword

InstallationmanualforBoX2base

Foreword

All operator panels are developed to satisfy the demands of human-machine

communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel works primarily in an object-oriented way, making it easy to

understand and use. Configuration is carried out on a PC using iX Developer

software. The project can then be transferred and stored in the operator panel

itself.

Various types of automation equipment such as PLCs, servos or drives can be

connected to the operator panels. In this manual, the term “the controller” refers

to the connected equipment.

This manual explains how to install the operator panel. Please refer to the

iX Developer reference manual for further information.

Order no: MAEN274

Copyright © 2018-03 Beijer Electronics AB. All rights reserved.

The information in this document is subject to changewithoutnoticeandisprovidedasavailableatthe

time of printing. Beijer Electronics AB, including all its group companies, reserves the right to change any

information without updating this publication. Beijer Electronics AB, including all its group companies,

assumesnoresponsibilityforanyerrorsthatmayappear in this document. Read the entire installation

manual prior to installing and using this equipment. Only qualified personnel may install, operate or repair

this equipment. Beijer Electronics AB, including all its group companies, are not responsible for modified,

altered or renovated equipment. Because the equipment has a wide range of applications, users must acquire

the appropriate knowledge to use the equipment properly in their specific applications. Persons responsible

for the application and the equipment must themselves ensure that each application is in compliance with

all relevant requirements, standards and legislationinrespecttoconfigurationandsafety. Onlypartsand

accessories manufactured according to specifications set by Beijer Electronics AB, including all its group

companies, may be used.

BEIJER ELECTRONICS AB, INCLUDING ALL ITS GROUP

COMPANIES, SHALL NOT BE LIABLE TO ANYONE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE INSTALLATION, USE OR

REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL

BE THE REPAIR, REPLACEMENT, OR REFUND OF PURCHASE

PRICE, AND THE CHOICE OF THE APPLICABLE REMEDY SHALL

BE AT THE SOLE DISCRETION OF BEIJER ELECTRONICS AB,

INCLUDING ALL ITS GROUP COMPANIES.

BeijerElectronics, MAEN274

Foreword

BeijerElectronics, MAEN274

Contents

Contents

1 SafetyPrecautions ....................................................... 7

1.1 General ........................................................... 7

1.2 Hazardous Materials ............................................. 7

1.3 DisposalRequirementsUnderWEEERegulations ........... 8

1.4 UL and cUL Installation ......................................... 8

1.5 DuringInstallation .............................................. 9

1.6 DuringUse ....................................................... 10

1.7 Service and Maintenance ........................................ 10

1.8 Dismantling and Scrapping ..................................... 10

2 Installation ............................................................... 11

2.1 InstallationProcess .............................................. 11

2.1.1 ConnectionstotheController ..................................12

2.1.2 OtherConnectionsandPeripherals .............................13

3 TechnicalData ........................................................... 15

4 ChemicalResistance .................................................... 17

4.1 PlasticCasing .................................................... 17

5 OperatorPanelDrawings .............................................. 19

5.1 Connectors ....................................................... 19

5.1.1 CommunicationPorts ...........................................19

5.2 BoX2baseOutline ............................................... 20

6 Additional Installation Tips ............................................ 21

6.1 Grounding the operator panel .................................. 21

6.2 EthernetConnectionintheOperatorPanel ................... 22

6.3 To Achieve Better EMC Protection ............................. 23

6.4 AmbientTemperature ........................................... 24

6.5 Safety ............................................................. 25

6.6 GalvanicIsolation ................................................ 26

6.7 Cable and Bus Termination RS-485 ............................ 27

BeijerElectronics, MAEN274

Contents

BeijerElectronics, MAEN274

Safety Precautions

1SafetyPrecautions

Both the installer and the owner and/or operator of the operator panel must read

and understand this installation manual.

1.1 General

•Read the safety precautions carefully.

•Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

•Do not use the operator panel in an environment with high explosive hazards.

•The supplier is not responsible for modified, altered or reconstructed

equipment.

•Use only parts and accessories manufactured according to specifications of

the supplier.

•Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

•Neverallowfluids,metalfilingsorwiringdebristoenteranyopeningsinthe

operator panel. This may cause fire or electrical shock.

•Only qualified personnel may operate the operator panel.

•Thefiguresinthismanualserveanillustrativepurpose. Becauseofthemany

variables associated with any particular installation, the supplier cannot

assume responsibility for actual use based on the figures.

•The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

•It is recommended to turn on and shut down the operator panel at least once

before installing any components/cards or before connecting the operator

panel to external devices; for example serial devices.

•For Marine panels only:

–The operator panel must be installed and operated as described in this

document to meet this certification.

–Observe precautions for handling electrostatic discharge sensitive devices

1.2 HazardousMaterials

Toxicandhazardousmaterialsorelements

有毒和有害的材料或元素

Partdescription

零件描述

Pb Hg Cd Cr6+ PBB PBDE

PCBandelectronic

components

PCB和电子元件

XOO O O O

O:Indicatesthattheconcentrationofthehazardoussubstanceinallhomogeneous

materialsinthepartsisbelowtherelevantthresholdoftheGB/T26572-2011

standard.

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T26572-2011规定的限

量要求以下。

X:Indicatesthattheconcentrationofthehazardoussubstanceofatleastoneof

allhomogeneousmaterialsinthepartsisabovetherelevantthresholdoftheGB/T

BeijerElectronics, MAEN274 7

Safety Precautions

26572-2011standard. ButstillcomplieswiththeEURoHSDirective2011/65/EU.

X:表明该有害物质至少在部件的某一均质材料中的含量超出GB/T26572-2011规定

的限量要求。但仍然符合EURoHS指令2011/65/EU。

1.3 DisposalRequirementsUnder

WEEERegulations

For professional users in the European Union: If you wish to discard electrical

and electronic equipment (EEE), please contact your dealer or supplier for further

information.

For disposal in countries outside of the European Union: If you wish to discard

this product please contact your local authorities or dealer and ask for the correct

method of disposal.

1.4 ULandcULInstallation

Caution:

ThissectionisonlyvalidforULlabeledX2panels.

•This equipment is suitable for use in Class 2 non-hazardous locations only.

[Combinations of equipment in your system are subject to investigation by

the local authority having jurisdiction at the time of installation].

•All devices have to be supplied by a Class 2 power supply.

Warning:

OnlyULandcULapprovedexpansionunitsareallowedtobeconnectedto

theportdesignated“EXPANSION”. Atthemomenttherearenosuchunits

evaluatedorallowed.

SEULESLESUNITÉSD'EXTENSIONCERTIFIÉESULET

cULPEUVENTÊTRERACCORDÉESAUPORTDÉSIGNÉ«EXPANSION».

ÀL'HEUREACTUELLE,AUCUNEUNITÉDECETYPEN'AÉTÉTESTÉE

OUAUTORISÉE.

•This equipment is suitable for use in Class 2 non-hazardous locations only.

[combinations of equipment in your system are subject to investigation by the

local authority having jurisdiction at the time of installation].

•All devices have to be supplied by a Class 2 power supply.

Warning:

OnlyULandcULapprovedexpansionunitsareallowedtobeconnectedto

theportdesignated“EXPANSION”. Atthemomenttherearenosuchunits

evaluatedorallowed.

SEULESLESUNITÉSD'EXTENSIONCERTIFIÉESULET

cULPEUVENTÊTRERACCORDÉESAUPORTDÉSIGNÉ«EXPANSION».

ÀL'HEUREACTUELLE,AUCUNEUNITÉDECETYPEN'AÉTÉTESTÉE

OUAUTORISÉE

8BeijerElectronics, MAEN274

Safety Precautions

Warning:

Batterymayexplodeifmistreated. Donotrecharge,disassembleordispose

ofinfire.

LABATTERIEPEUTEXPLOSERENCASDEMAUVAISEMANIPULATION.

NELARECHARGEZPAS,NELADÉMONTEZPASETNELAJETEZ

PAS DANS LE FEU.

•This product contains a battery; this must only be changed in an area known

to be non-hazardous.

•Replace the battery with a BR 2032 battery. Use of another type of battery

may present a risk of fire or explosion.

•For use on a flat surface of a type 4X enclosure indoor use only.

•Use minimum 75°C copper conductors only.

•To make wiring connections to the power supply connector, follow the table

with cable and torque specifications below:

TerminalBlockConnector WireSizeAWG Torque(Lb.In.)

X1/X100Phoenixconnectors AWG30–12 5–7

X1/X100Anytekconnectors AWG24–12 3.5

X1/X100DECAconnectors AWG24–12 7

•ThesedevicesareClass2suppliedprogrammablecontrollers(industrialPCs)

for the use in industrial control equipment and are intended to be (front)

panel mounted (Type 12 and 4x for indoor use only).

Caution:

TheenclosureprovidesadegreeofprotectionofatleastIP20,butwheninstalledinan

apparatus,itshouldmeetIP65..

LEBOÎTIEROFFREUNDEGRÉDEPROTECTIOND'AUMOINSIP20,MAIS

LORSQU'ILESTINSTALLÉDANSUNAPPAREIL,ILDOITÊTREDECLASSEIP65.

1.5 DuringInstallation

•The operator panel is designed for stationary installation on a planar surface,

where the following conditions are fulfilled:

–no high explosiverisks

–no strong magnetic fields

–no direct sunlight

–no large, sudden temperature changes

•Install the operator panel according to the accompanying installation

instructions.

•Ground the operator panel according to the accompanying installation

instructions.

•Only qualified personnel may install the operator panel.

•Separate the high voltage, signal, and supply cables.

•Make sure that the voltage and polarity of the power source is correct before

connecting the operator panel to the power outlet.

BeijerElectronics, MAEN274 9

Safety Precautions

•Peripheral equipment must be appropriate for the application and location.

1.6 DuringUse

•Keep the operator panel clean.

•Emergency stop and other safety functions may not be controlled from the

operator panel.

1.7 ServiceandMaintenance

•Only qualified personnel should carry out repairs.

•The agreed warranty applies.

•Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

1.8 DismantlingandScrapping

•The operator panel or parts thereof shall be recycled according to local

regulations.

•The following components contain substances that might be hazardous to

health and the environment: lithium battery and electrolytic capacitor.

10 BeijerElectronics, MAEN274

Installation

2Installation

2.1 InstallationProcess

The BoX2 base can be used as a as a bench top device or clipped onto a DIN rail.

The following is needed:

•No tools required - standard usage

1. Unpack and check the delivery. If damage is found, notify the supplier.

Note:

Placetheoperatorpanelonastablesurfaceduringinstallation.

Droppingtheoperatorpanelorlettingitfallmaycausedamage.

BeijerElectronics, MAEN274 11

Installation

2. Connect the cables in the specified order, according to the drawing and steps

below.

Caution:

•Theoperatorpanelmustbebroughttoambienttemperaturebeforeitisstarted

up. Ifcondensationforms,ensurethattheoperatorpanelisdrybeforeconnecting

ittothepoweroutlet.

•Ensurethattheoperatorpanelandthecontrollersystemhavethesameelectrical

grounding(referencevoltagelevel),otherwiseerrorsincommunicationmay

occur.

•Ensurethatthevoltageandpolarityofthepowersourceiscorrect.

•Separatehighvoltagecablesfromsignalandsupplycables.

•Shieldedcommunicationcablesarerecommended.

24V DC

RS232/

RS422/

RS485

24V DC

A

D

Controller

Power

B

Ethernet

C

The image is illustrative only and may differ slightly from the actual panel.

–Connect cable A.

–Connect cable B, using 14-20 AWG (2.08–0.52 mm2), 180–220 N-cm

torque.

–Connect cable C.

–Connect cable D. The recommended cross-section of the cable is 1.5

mm2.

2.1.1 ConnectionstotheController

For information about the cables to be used when connecting the operator panel to

the controller, please refer to the help file for the driver in question.

12 BeijerElectronics, MAEN274

Installation

2.1.2 OtherConnectionsandPeripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. For further details or recommendations, please refer to the

supplier.

BeijerElectronics, MAEN274 13

Installation

14 BeijerElectronics, MAEN274

Technical Data

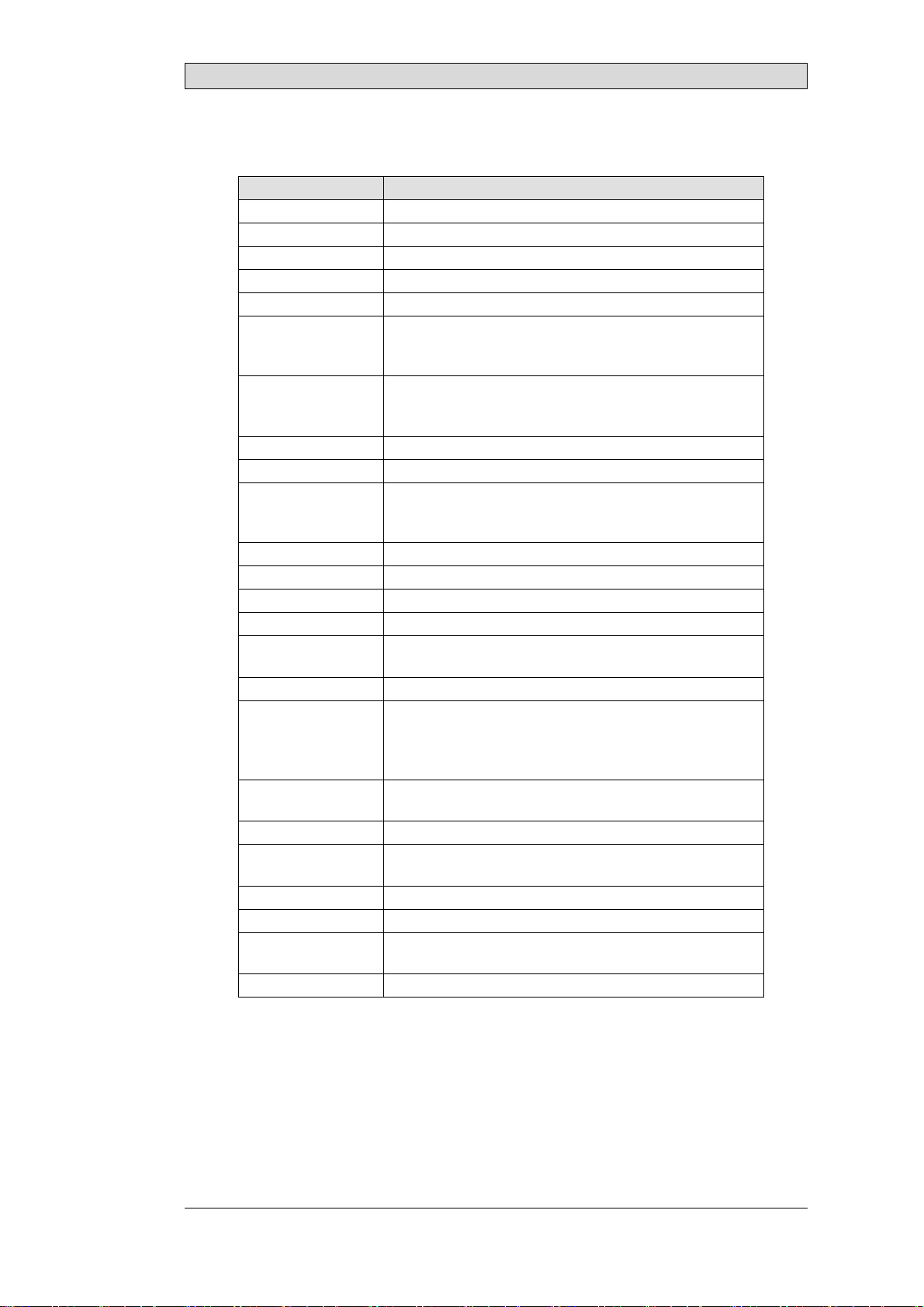

3TechnicalData

Parameter BoX2 base

Dimensions,W×H×D 130×89×35mm

Sealing IP20

Framematerial Plastic(PC+ABS)

Weight 0.3kg

CPU 400MHzARM9

SerialportCOMA StandardD-sub(9Pin,female)

COM1: 1×RS-232Rx/TxwithRTS/CTS

COM2: 1×RS-422

SerialportCOMB StandardD-sub(9Pin,female)

COM3: 1×RS-232Rx/TxwithRTS/CTS

COM4: 1×RS-485

Ethernet 10/100MbitBase-T(shieldedRJ45withLEDs)

USB SupportsuptoUSB2.0HighSpeed

Flashmemory

(application

memory)

256MBSSD(NANDFlash)

Applicationmemory200MB

MemoryRAM 128MB(DDR2)

NVRAM N/A

Realtimeclock Yes

Battery Lithiumion,3V/200mAh

Powerconsumption

atratedvoltage 3W

Fuse InternalDCfuse,2.0AT

Powersupply CE:Thepowersupplymustconformwiththerequirements

accordingtoEN/IEC60950andEN/IEC61558-2-4.

ULandcUL:Thepowersupplymustconformwiththe

requirementsforclass2powersupplies.

Operating

temperature -10°Cto+50°C

Storagetemperature -20°Cto+60°C

Relativehumidityin

operation 5%–85%non-condensation

Vibration 1g,accordingtoEN/IEC60068-2-6,TestFc

Mechanicalshock 15g,half-sine,11msaccordingtoEN/IEC60068-2-27

Approvalsand

certifications CE/FCC/KC

Informationisavailableonwww.beijerelectronics.com

ULapproval Yes,informationavailableatUL.com

BeijerElectronics, MAEN274 15

Technical Data

16 BeijerElectronics, MAEN274

Chemical Resistance

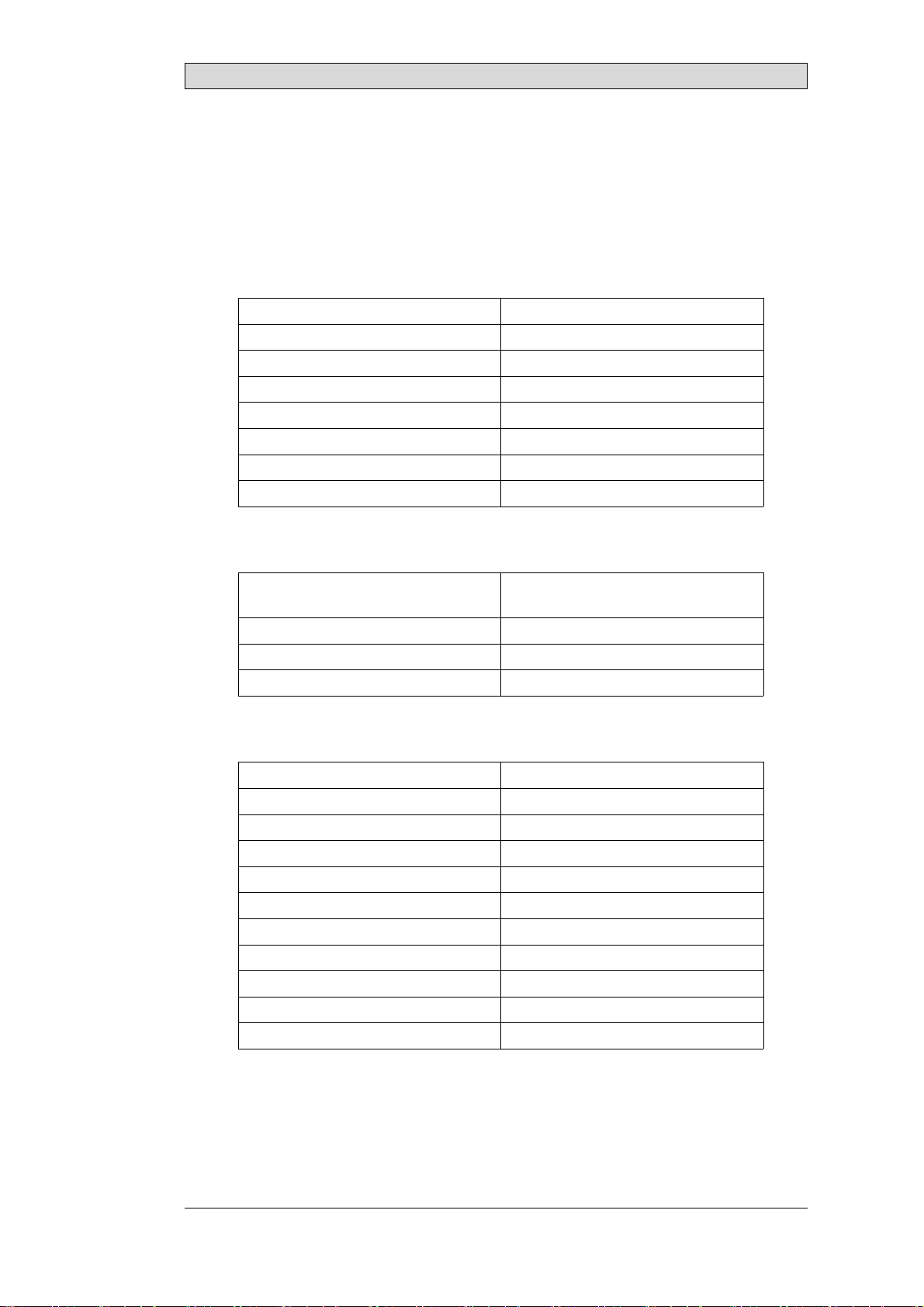

4 ChemicalResistance

4.1 PlasticCasing

The frame and casing material is plastic (PC+ABS). This material withstands

exposure to the following chemicals without visible change:

Aceticacid10% Nitricacid10%

Baysilon®M300 Phosphoricacid30%

Citricacid10% Seawater

Cleaningagent,Dor®Sodiumhypochlorite

Curdsoapsolution2% Sodiumthiosulphate

Hydrochloricacid20% Sulphuricacid30%

Hydrogensuperoxide30% Urea

Lacticacid10% -

The material shows limited resistance to the following chemicals at room

temperature:

Cleaner’snaphtha,freefromaromatic

hydrocarbons Heatingoil

Ethylalcohol96% Isopropanol

Glycerin N-hexane

Glycol Persilpowderinsolution

The material shows little or no resistance to the following chemicals at room

temperature:

Acetone Methylisobutylketone

Ammoniasolution,diluted Naphthalene

Aniline Nitrobenzene

Aromatichydrocarbons Oleicacid

Benzene Oliveoil

Bromin Phenol

Butter Potassiumcarbonate,sat.

Chlorine Sodiumhydroxidesolution10%

Diethylether Soyaoil

Iodine Toluene

Lard Trichloroethylene

BeijerElectronics, MAEN274 17

Chemical Resistance

18 BeijerElectronics, MAEN274

Operator Panel Drawings

5 OperatorPanelDrawings

5.1 Connectors

1234

Pos. Connector Description

1 Powersupply +24VDC(18–32VDC)

2 COMA Serialcommunicationport

3 LAN 1×10/100Base-T(shieldedRJ45)

4 COMB Serialcommunicationport

5.1.1 CommunicationPorts

Serialport,9-pinfemale Serialport,9-pinfemale

Pin COM1 COM2 COM3 COM4

1- RS422Tx+

RS485Tx+/Rx+ -RS422Tx+

RS485Tx+/Rx+

2 RS232RxD - RS232RxD -

3 RS232TxD - RS232TxD -

4- RS422Rx+ - -

5 GND GND GND GND

6- RS422Tx-

RS485Tx-/Rx- -RS422Tx-

RS485Tx-/Rx-

7RS232RTS - - -

8 RS232CTS - - -

9- RS422Rx- - -

BeijerElectronics, MAEN274 19

This manual suits for next models

1

Table of contents

Other Beijer Electronics Media Converter manuals

Beijer Electronics

Beijer Electronics JetCon 1701GP-U User manual

Beijer Electronics

Beijer Electronics BoX2 extreme User manual

Beijer Electronics

Beijer Electronics BoX2 extreme User manual

Beijer Electronics

Beijer Electronics BoX2 base v2 Instruction sheet

Beijer Electronics

Beijer Electronics BoX2 pro User manual