8

4. Cleaning, Disinfection and Sterilization

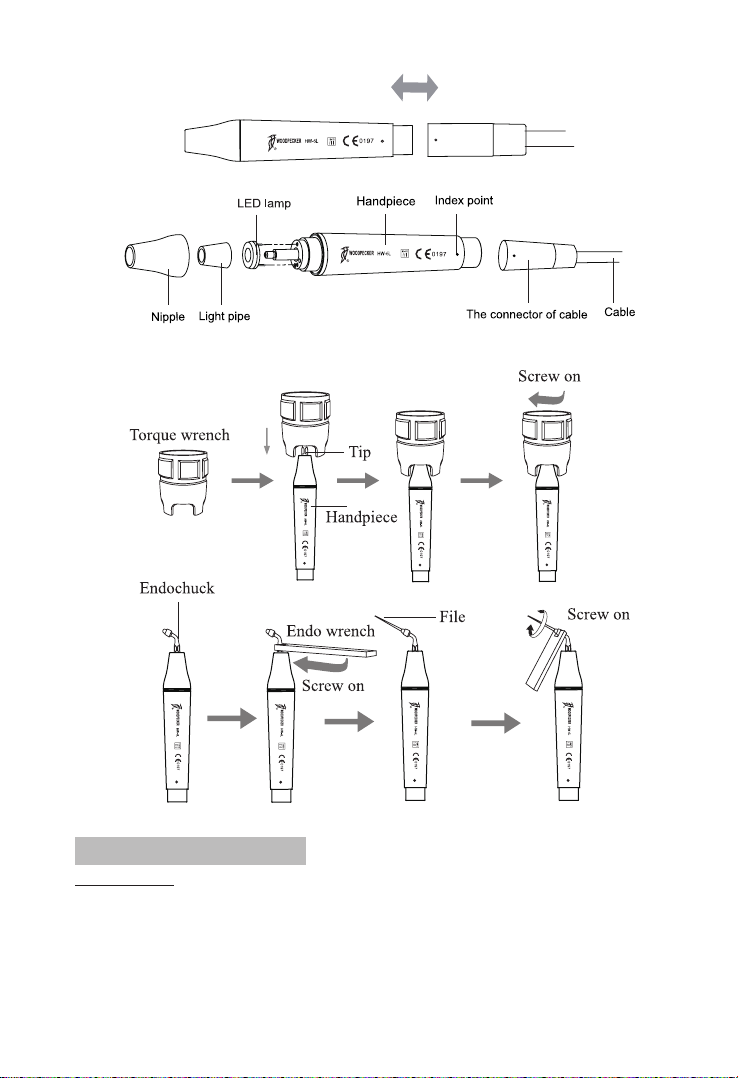

The cleaning, disinfection and sterilization of handpiece, tip, and

wrench (include torque wrench and Endo wrench) are as follow.

Unless otherwise stated, they will be hereinafter referred to as

“products”.

Warnings

The use of strong detergent and disinfectant (alkaline pH>9 or acid

pH <5) will reduce the life span of products. And in such cases, the

manufacturer takes no responsibility.

Do not clean the handpiece with ultrasound cleaning machine.

This device shall not be exposed to high temperature above 138℃.

Processing limit

The products have been designed for a large number of sterilization

cycles. The materials used in manufacture were selected accordingly.

However with every renewed preparation for use, thermal and chemical

stresses will result in ageing of the products. The maximum number of

sterilizations for handpiece is 600 times. For tips, it is 300 times. And for

wrench, it is 1000 times.

4.1 Initial processing

4.1.1 Processing principles

It is only possible to carry out effective sterilization after the

completion of eective cleaning and disinfection. Please ensure that, as

part of your responsibility for the sterility of products during use, only

sufficiently validated equipment and product-specific procedures are

used for cleaning/disinfection and sterilization, and that the validated

parameters are adhered to during every cycle.

Please also observe the applicable legal requirements in your country

as well as the hygiene regulations of the hospital or clinic,especially with

regard to the additional requirements for the inactivation of prions.

4.1.2 Post-operative treatment

The post-operative treatment must be carried out immediately, no

later than 30 minutes after the completion of the operation. The steps are

as follows:

1. Let the Ultrasonic scaler works for 20-30 seconds under irrigation

mode to ush the handpiece and tip;

2. Remove the handpiece from the Ultrasonic scaler, and rinse away

the dirt on the surface of product with pure water (or distilled water/

deionized water);