Beijing Arctic Star Technology BSM360 User manual

BSM360 Ultrasonic Flaw Detector

Operation Instructions

Beijing Arctic Star Technology NDT Co., Ltd.

Ultrasonic Flaw Detector BSM360 86+010—51658378

2

Content

Chaper I Overview........................................................................................................................................................6

1.1 How to Use the Operation Instructions..............................................................................................................6

1.1.1 Layout of Pages and Conventions of Expressions..........................................................................................6

1.2 Standard Configurations and Options................................................................................................................7

1.2.1 Standard Configuration...................................................................................................................................7

1.2.2 Options............................................................................................................................................................7

Chaper II Technical Parameters and Performance Features of the Instrument.............................................................8

2.1 Measuring Range and Measuring Error.............................................................................................................8

2.2 Operation Environment.....................................................................................................................................8

2.3 Power supply.....................................................................................................................................................8

2.4 Overall Dimension and Weight..........................................................................................................................8

2.5 Performance Features........................................................................................................................................8

2.6 Technical Parameters.........................................................................................................................................9

2.7 Model differences………………………………………………………………………………………… 11

Chaper I Operation...…………………………………………………………………………………………………...12

3.1 Overview of the Instrument ..........................................................................................................................12

3.1.1 Designation of the Instrument’s Components...............................................................................................12

3.1.2 Functional Keyboard....................................................................................................................................12

3.1.3 Using of Power Supply.................................................................................................................................13

3.1.4 Working with Battery....................................................................................................................................13

3.1.5 Connecting the Probe....................................................................................................................................14

3.2 Operation.........................................................................................................................................................14

3.2.1 Basic steps....................................................................................................................................................14

3.2.2 Starting the Instrument..................................................................................................................................15

3.2.3 Description about Screen Display.................................................................................................................15

3.2.3.1 Three Display Modes of BSM360 Screen.................................................................................................15

3.2.3.2 Function Displaying Items.........................................................................................................................17

3.2.3.3 Description about Symbols Displayed on Screen......................................................................................17

3.2.3.4 Display of echo times................................................................................................................................17

3.2.3.5 Description about other symbol.................................................................................................................18

3.2.4 Overview of All Functions.........................................................................................................................18

3.2.5 Basic Operation Way....................................................................................................................................20

3.2.5.1 Selection of Functions...............................................................................................................................20

3.2.5.2 Multipurpose Function Items.....................................................................................................................20

3.2.5.3 Rough and Fine Adjustment of Functions.................................................................................................21

3.2.5.4 Example of Function Operation.................................................................................................................21

Chaper IV Description of all functions and Basic Operation way.................................................................................22

4.1 Adjustment of BASE Group............................................................................................................................22

Ultrasonic Flaw Detector BSM360 86+010—51658378

3

4.1.1 Detection Range (RANGE)..........................................................................................................................22

4.1.2 Material velocity (MTLVEL).......................................................................................................................22

4.1.3 Display starting point (D-DELA Y)...............................................................................................................23

4.1.4 Probe delay (P-DELAY)...............................................................................................................................23

4.2 Adjustment of P/R Group................................................................................................................................24

4.2.1 Probe type (PROBE TYPE)..........................................................................................................................24

4.2.2 REJECT........................................................................................................................................................24

4.3 Adjustment of GATE Group............................................................................................................................25

4.3.1 GA TE LOGIC/ ALARM...............................................................................................................................25

4.3.2 Starting point of the gates (aSTART/bSTART)…………………………………………………………….26

4.3.3 Width of the gates (aWIDTH/bWIDTH).....................................................................................................26

4.3.4 Response and measurement threshold (aTHRESH/bTHRESH)...................................................................27

4.4 Adjustment of settings.....................................................................................................................................27

4.4.1 Setting NO...................................................................................................................................................27

4.4.2 Recall............................................................................................................................................................28

4.4.3 Save.............................................................................................................................................................28

4.4.4 Delete............................................................................................................................................................29

4.5 Adjustment of ANG Group.............................................................................................................................29

4.5.1 Probe Angle (ANGLE)/Probe K V alue (K-V ALUE)....................................................................................29

4.5.2 Thickness of workpiece (T-V ALUE)...........................................................................................................30

4.5.3 Probe’s Front Edge (X-V ALUE)/Coordinate mode (X-COORD)...............................................................30

4.5.4 Probe position/Part diameter.........................................................................................................................31

4.6 Adjustment of GainGroup...............................................................................................................................32

4.6.1 REF GAIN....................................................................................................................................................32

4.6.2 ADD REF.....................................................................................................................................................32

4.6.3 Gain Scan......................................................................................................................................................32

4.6.4 Auto Gain......................................................................................................................................................33

4.7 Adjustment of DAC1 Group............................................................................................................................33

4.7.1 DAC display control (DAC)/DAC Revise (REVISE)..................................................................................33

4.7.2 DAC Plotting Point (RECORD) /DAC Revise Position (REVISE POS).....................................................34

4.7.3 Starting of the A gate (a START) / Width of the A gate (a WIDTH)……………………………………….34

4.7.4 Show Marks/DAC curve mode.....................................................................................................................35

4.8 Adjustment of DAC2 Group............................................................................................................................35

4.8.1 DAC evaluating line (DAC-EL)/ DAC-REF...............................................................................................36

4.8.2 DAC quantifying line (DAC-SL)…………………………………………………………………………..36

4.8.3 DAC reject-judging line (DAC-RL).............................................................................................................36

4.8.4 DAC correction (CORRECT).......................................................................................................................37

4.9 Adjustment of A VG1 Group………………………………………………………………………………….37

4.9.1 A VG mode/Chock vel...................................................................................................................................37

4.9.2 Probe name...................................................................................................................................................38

Ultrasonic Flaw Detector BSM360 86+010—51658378

4

4.9.3 Frequency/crystal diametre...........................................................................................................................38

4.9.4 REF type/REF size.......................................................................................................................................38

4.10 Adjustment of A VG2group............................................................................................................................39

4.10.1 Gate A start/A VG curve..............................................................................................................................39

4.10.2 Record ref...................................................................................................................................................40

4.10.3 Transfers/attenuation correct.......................................................................................................................40

4.11 Adjustment of B / V group.............................................................................................................................40

4.11.1 B san/A scan................................................................................................................................................41

4.11.2 scan direction/scan mode............................................................................................................................41

4.11.3 Recall frame/Recall speed...........................................................................................................................41

4.11.4 Video / DynamicRecall...............................................................................................................................42

4.12 Adjustment of screen savers group................................................................................................................42

4.12.1 Screen saver mode / Preview......................................................................................................................42

4.12.2 DERECTION/SCR DELAY.......................................................................................................................43

4.12.3 screen save text...........................................................................................................................................43

4.12.4 ABOUT/COLOR SET................................................................................................................................44

4.13 Adjustment of MEM Group..........................................................................................................................44

4.13.1 Function group MEM (DA TA NO.)...........................................................................................................45

4.13.2 Recalling a stored data set (RECALL)......................................................................................................45

4.13.3 Storing a data set (SA VE)..........................................................................................................................45

4.13.4 Deleting a data set (DELETE)...................................................................................................................46

4.14 Adjustment of CFG roup...........................................................................................................................46

4.14.1 Measuring way (DETECT) /RS232 SET...................................................................................................47

4.14.2 Coordinate grid (GRID)/ELD backlight (BRIGHTNESS)........................................................................47

4.14.3 Echo display mode (FILL)/Sound of the Buzzer (BUZZER)....................................................................48

4.14.4 Selecting the language (LANGUAGE)/Selecting the units (UNIT)..........................................................48

4.15 Adjustment of advanced group.....................................................................................................................49

4.15.1 Setup Date (DA TE)/Setup Time (TIME)...................................................................................................49

4.15.2 Starting of the A gate (a START) / Width of the A gate (a WIDTH).........................................................50

4.15.3 Calibration of straight probe (CSBT)........................................................................................................50

4.15.4 Calibrating of Angle Beam Probe(CABT).................................................................................................51

4.16 Adjustment of special functions.................................................................................................................52

4.16.1 Gain step.....................................................................................................................................................52

4.16.2 Gain value...................................................................................................................................................52

4.16.3 Full screen...................................................................................................................................................52

4.16.4 Freeze..........................................................................................................................................................53

4.16.5 Memorize peak value..................................................................................................................................53

4.16.6 Extend key..................................................................................................................................................53

4.16.7 Test data display..........................................................................................................................................54

4.16.8 shortcut key.................................................................................................................................................54

Ultrasonic Flaw Detector BSM360 86+010—51658378

5

4.16.9 Locking menus............................................................................................................................................54

4.16.10 Locking data group...................................................................................................................................54

4.16.11 Locking setting.........................................................................................................................................55

4.16.12 Resetting the Ex-factory Setting...............................................................................................................55

4.16.13 Instrument program upgrade.....................................................................................................................56

Chapter V Calibrating the Instrument and Measuring................................................................................................57

5.1 Calibrating of Single Probe.............................................................................................................................57

5.1.1 Calibrating with Known MTLVEL...............................................................................................................57

5.1.2 Calibrating with Unknown MTL VEL...........................................................................................................57

5.2 Calibrating of Double Probe............................................................................................................................59

5.3 Calibrating of Angle Beam Probe....................................................................................................................60

5.4 Application of DAC Curve..............................................................................................................................61

5.5 Contents of Measurement................................................................................................................................62

Chapter VI Communication for the Instrument.............................................................................................................64

6.1 Data Communication......................................................................................................................................64

6.1.1 Connecting PC..............................................................................................................................................64

Chapter VII Maintenance and Repairing.......................................................................................................................65

7.1 Requirement on Environment..........................................................................................................................65

7.2 Charging the Battery........................................................................................................................................65

7.3 Replacing the Battery......................................................................................................................................65

7.4 Tips on Safety..................................................................................................................................................66

Appendix.......................................................................................................................................................................67

Appendix I Notice to User………………………………………………………………………………………..67

Appendix II Terms……………………..…………………………………………………………………………68

Appendix III List of Operations …………………………………………………………………………………70

Ultrasonic Flaw Detector BSM360 86+010—51658378

6

Chapter I. Overview

This is a portable industrial non-destructive flaw detector, which can rapidly, easily and accurately inspect,

locate, evaluate and diagnose various defects (crack, inclusion and pinhole, etc.) in a workpiece without destruction.

It can be used both in a lab and field. The instrument can be widely used in any fields that need defect inspection and

quality controlling e.g. manufacturing industry, iron & steel metallurgical industry, metalworking, chemical industry,

etc., also be broadly used in the active safety inspection and service-life evaluation in such fields as aerospace,

railway transportation and boiler pressure vessels, etc. It is an essential instrument for non-destructive inspection

industry.

When the ultrasonic wave propagates in a job, one can detect the defect in it by the influence on the propagation

of ultrasonic wave based on the acoustic characteristic demonstrated by the defect in the material. Based on this

principle, by using ultrasonic wave one can measure such defects as crack, pinhole and inclusion in such media as

metal, non metal and composite, etc.

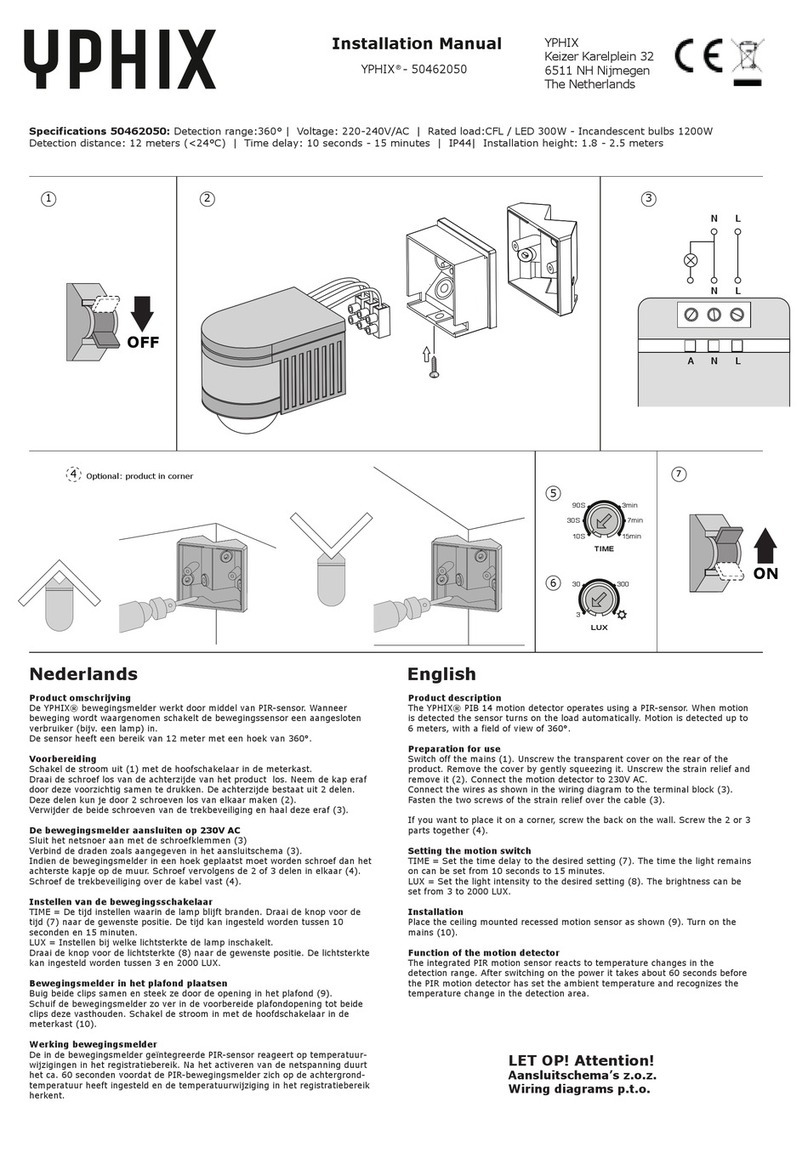

Fig. 1.1 Basic working principle for ultrasonic detection

1.1 How to Use the Operation Instructions

It is necessary to read chapter 1, 2, 3 and 4 of the Instructions before operating instrument for the 1st time. The

descriptions in the chapters are necessary preparation for operating the instrument, which will describe all keys and

displays on screen, and explain the operation principle.

By following the directions, you can avoid error or failure due to operation mistake and can have a clear concept

about all functions of the instrument.

1.1.1 Layout of Pages and Conventions of Expressions

In order that you can use the Instructions easily, all operation steps and matters needing attention are arranged in

a consistent way. This is helpful for getting each independent information. The structure of Contents for the

Instructions is as deep as up to the 4th level, and the items after the 4th level will be indicated in bold titles.

Signs for Notes and Remarks

Ultrasonic Flaw Detector BSM360 86+010—51658378

7

Note: the sign of “Note” indicates the features and special aspect that may influence the accuracy of result

during operation.

Remarks: explanation, may include reference to other chapters or special introduction on a certain function.

List of item

The list of item is expressed in the following way

Item A

Item B

…

Operation procedure

The expressing way for operation procedure is as that shown in the following example

l By <Page up> key switch the function page.

l By <F1> key you select BASE functional group, and by <Menu> key, you select the functional menu for

RANGE, and then adjust parameters for RANGE by key + or -.

l You can shift the Rough and Fine adjusting mode by Enter key .

1.2 Standard Configurations and Options

1.2.1 Standard Configuration

Table 1.1 List of standard configurations

Designation Quantity

Main unit 1

4A/9V power adaptor 1

probe connecting cable 2

Carrying case 1

Instruction manual 1

Straight probe 20mm 2.5MHz (One)

Angle probe 10×10 K2 2.5MHz (One)

1.2.2 Options

Table 1.2 List of options

Designation Quantity

Serial cable 1 (9 pin)

Communication software for PC 1 set

Ultrasonic Flaw Detector BSM360 86+010—51658378

8

Chapter II Technical Parameters and

Performance Features of the Instrument

2.1 Measuring Range and Measuring Error

Range of scanning: 0 mm ~10000 mm

Resolution for scanning: 0.1mm (2.5mm ~100mm)

1mm (100 mm ~5000mm)

Range of gain: 0dB ~110 dB

D-Delay: -20µs~+3400µs

P-Delay: 0µs~99.99µs

Sound speed : 1000 m/s~15000m/s

2.2 Operation Environment

Temperature: -10℃~40℃

Humidity: 20%~90%RH

Free of strong magnetic field and corrosion.

2.3 Power supply

Li battery 7.4V 4800mAh

2.4 Overall Dimension and Weight

Overall dimension: 240mm×180 mm×50 mm

Weight: 1.8kg

2.5 Performance Features

l Automated calibration of transducer Zero Offset and/or Velocity ;

l Automated gain、Peak Hold and Peak Memory;

l Automated display precise flaw location(Depth d、level p、distance s、amplitude、sz dB、ф);

l Automated switch three staff gauge ((Depth d、level p、distance s);

Ultrasonic Flaw Detector BSM360 86+010—51658378

9

l Ten independence setup, any criterion can be input freely, we can work in the scene without test block;

l Big memory of 300 A graph and 30000 thickness value.

l Gate and DAC alarm;Acoustic-Optical alarm;

l RS232 port,communication with pc is easy;

l The embeded software can be online updated;

l Li battery, continue working time up to 7 hours;

l Other assistant function;

l Display freeze;

l Automated echo degree;

l Angles and K-value;

l Lock and unlock function of system parameters;

l Dormancy and screen savers;

l Electronic clock calendar ;

l Two gates setting and alarm indication;

l High-speed capture and very low noise;

l DAC、AVG、B Scan (no in BSM360B) ; Solid metal housing (IP65);

l Automated make video of test process and play; (no in BSM360B)

l Provides high contrast viewing of the waveform from bright, direct sunlight to completae darkness and easy to

read from all angles;

l Powerful pc software and reports can be export to excel;

2.6 Technical Parameters

Designation Technical Data

Range of scanning (mm)

Range of scanning (mm):0~10000

Steps: 2.5,5,10,20, 30,40,50,60,70,80,90, 100,150,200, 250, 300, 350, 400,

450,500,600,700,800,900,1000,2000,3000,4000,5000,6000,7000,8000,10000

Adjusting step: 0.1mm(2.5 mm~99.9mm) ,1mm(100mm~10000mm)

D-delay ( s)

D-delay ( s):-20~+3400

Steps: -20,-10,0.0, 10, 20, 50,100,150,200,250,300,350,400,450,500, 600,

700,800,900,1000,1500,2000,2500,3000,3400.

Adjusting steps: 0.1(-20 s~999.9 s) ,1(1000 s~3400 s)

P-delay ( s) P-delay:0.0~99.99

Adjusting steps: 0.01

MTLVEL(m/s)

MTLVEL:1000~15000

7 fixed levels: 2260,2730,3080,3230,4700,5920,6300,12000

Adjusting steps: 1

Ultrasonic Flaw Detector BSM360 86+010—51658378

10

Working mode Single probe (receiving and sending), double probe (one for receiving and

another for sending), transmission (transmission probe)

Frequency Range (MHz) 0.5–15

Gain adjustment (dB) 0~110

Adjusting step: 0.0,0.2,0.5,1,2,6,12

Reject 0%~80% of screen height, step: 1%

V ertical linear error V ertical linear error is not more than 3%

Horizontal linear error Not more than 0.2% in the scanning range

Sensitivity Leavings ≥62 dB

Dynamic range ≥34dB

Alarm Three modes, i.e. forbidden wave, loss wave and auto

Monitoring door

2, expressed by bold transverse line, whose start, width and height are

adjustable.

Adjusting range of start (mm): horizontal pixel 0~208, the displayed value is

relative with the scanning range.

Step: value in mm corresponding to a pixel (relative with the scanning range)

Adjusting range of width (mm): horizontal pixel 4~212, the displayed value is

relative with the scanning range.

Step: value in mm corresponding to a pixel (relative with the scanning range)

Adjusting range of height: 2%~90% of vertical graduation

Step graduation: 1%

Display

Display: high-brightness graphic lattice

A-Scan display area

Full screen or local

A-Scan display freezing and de-freezing A-Scan filling

Data save 300 A-Scan images (including setting of instrument)

30000 values of thickness (300 sets)

Standard communication

interface with PC RS232

Measuring unit mm/inch

Battery Li battery 7.4V 4800mAh

Power adaptor Input 100V~240V/50Hz~60Hz

Output 9VDC/1.5A

Working temperature -10℃~40℃

Working humidity 20%~90%

Port type BNC

Ultrasonic Flaw Detector BSM360 86+010—51658378

11

Overall dimension (mm) 240×180×50

Weight (kg) 1.8

Ultrasonic Flaw Detector BSM360 86+010—51658378

12

Chapter III Operation

3.1 Overview of the Instrument

3.1.1 Designation of the Instrument’s Components

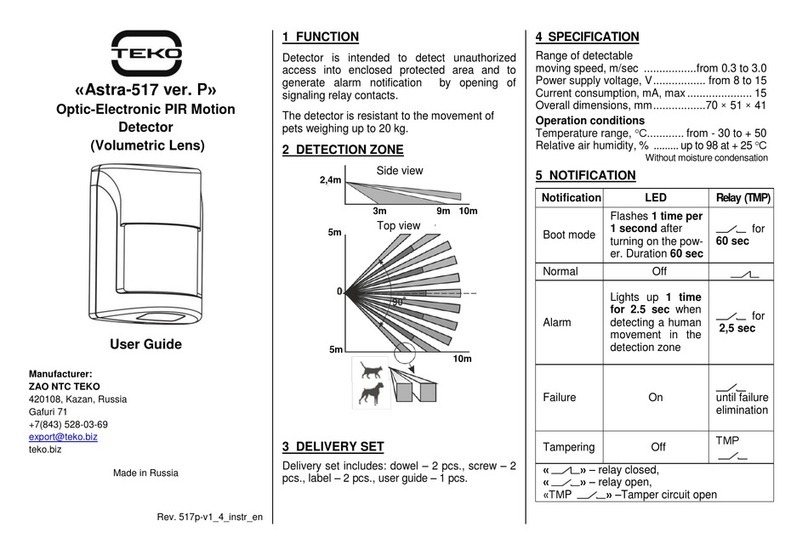

Fig.3.1 Outside Drawing of the Instrument

3.1.2 Functional Keyboard

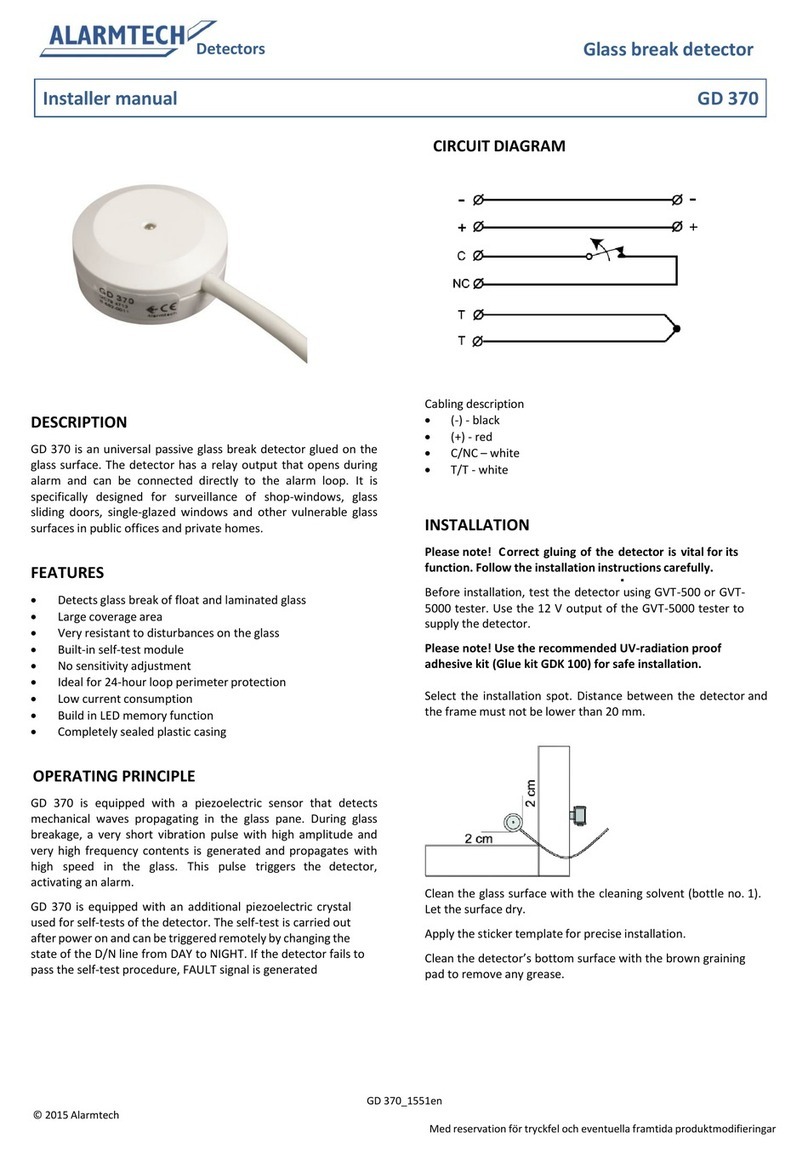

Keys of BSM360 are included in three groups: Function group, usual key group and special function group.

There are 6 keys in Functional group, in which F1, F2, F3, F4, F5 are corresponding with the 5 functional groups on

screen, and the key <> is used for switching of pages; Usual key group comprises 9 key: Up,down, dB+, dB-,+,-,

gain step key, freeze key, Enter key. they are used for usual operating; and special function group consists of 9

keys: on/off key, full screen key, detection zone,gate A,gate B,Auto gain, extend keypeak

memory and measure display. Overall arrangement of the whole face is as following picture.Overall

Ultrasonic Flaw Detector BSM360 86+010—51658378

13

arrangement of the whole face is as following picture.:

Fig.3.2 Functional Keyboard

Particular Operation Instructions of keys refer to appendix II.

3.1.3 Using of Power Supply

BSM360 can work with plug-in power supply (AC, DC adaptor) or battery.

The detector will switch the power supply to adapter automatically when the power supply adapter is used.

The detector will switch the power supply to battery automatically when the power supply adapter is turned off.

The batteries will be charged automatically When BSM360, which is equipped with battery , is power supplied with

adapter.

3.1.4 Working with Battery

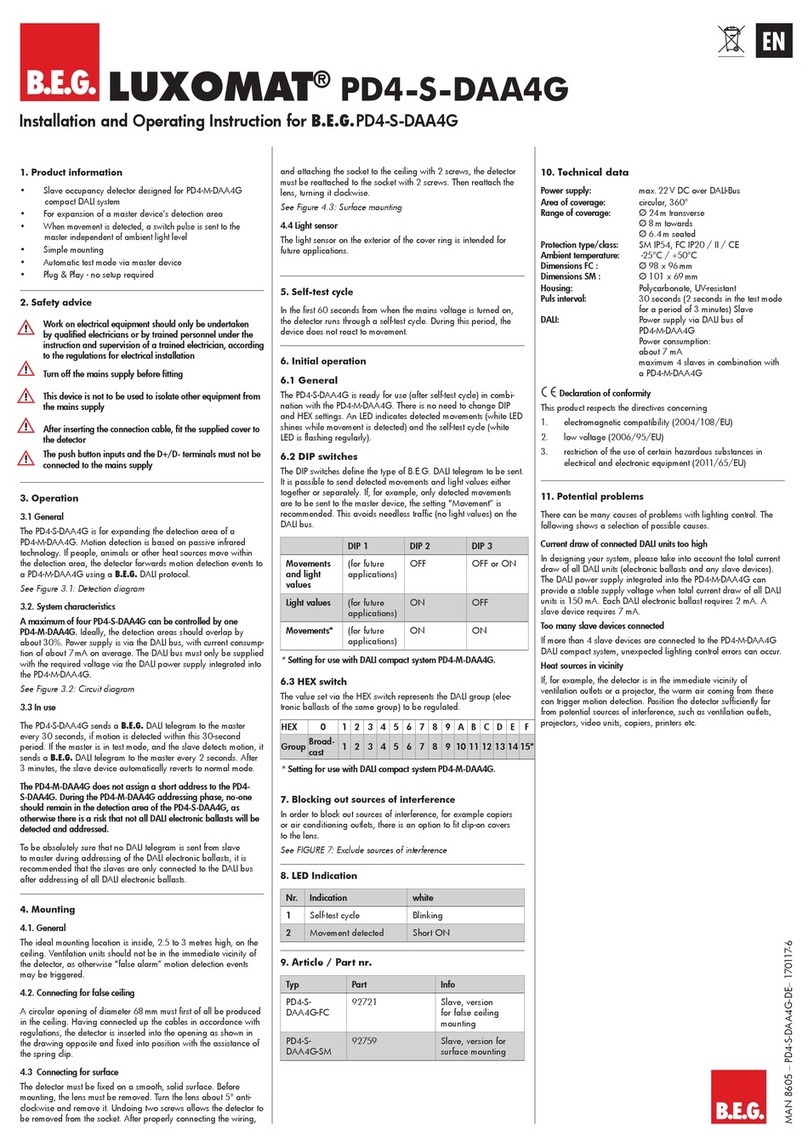

Indicator for charging

At lower right corner of BSM360 horizontal scale, there are symbols for battery voltage:

Battery voltage high Battery voltage drops Battery voltage low

Fig.3.3 Battery status display

If it shows the symbol for low voltage, you must stop detection immediately and use adpter or charge it.

Ultrasonic Flaw Detector BSM360 86+010—51658378

14

Charging the Li Battery.

You can charge the Li battery by using an external battery charger. It is recommended to charge by using the

power adaptor in the standard kit of BSM360. Before using the charger, please read carefully the Operation

Instructions for it. The continuous charging time for Li (4.8Ah) battery is about 4h~5h.During the charging, Rapid

Charging indicator lamp (green) will light up; when the charging completes, the Rapid Charging indicator lamp goes

out.。

3.1.5 Connecting the Probe

Proper probe shall be connected when using BSM360 to inspect. So long that you have a proper cable, and the

working frequency is within proper range, any probe made by our company is suitable for BSM360.The probe

connector for BSM360 is BNC.

The probe shall be connected to the socket at top of the instrument casing. Both connector sockets , have

different function, sending socket at left (with red mark) and receiving socket at right (with blue mark) .With

Single-Probe mode, the sending socket can be used only. When connecting a double-wafer (TR) probe (one wafer for

sending, another for receiving) or two probes (one for sending, another for receiving), take care that the sending

probe shall be connected to the sending socket and receiving probe to the receiving socket .Otherwise, it may result in

loss or disorder echo waveform.

3.2 Operation

3.2.1 Basic steps

a) Get ready the job;

b) Insert the probe plug into the probe socket of the host, rotate tightly the locking nut;

c) press, turn on the instrument;

d) It will carry out self test;

In normal case, when you turn on the unit, it will automatically enter into the status that it is in during last

turning off. The instrument parameters are consistent with last turning off, but the waveform during last turning

off will not display.

e) Check voltage of the battery; If the power monitor shows that the voltage is low, it will turn off

automatically 1 min after alarming bell.

f) According to your application ,Ten independence setups can be applied, any criterion can be input freely,

we can work in the scene without test block.

Whether it needs to calibrate the instrument, if yes, ask a professional technician to calibrate it (refer to

chapter IV);

g) Measure;

Ultrasonic Flaw Detector BSM360 86+010—51658378

15

h) Save the results, big memory of 300 A graph and 30000 thickness value.

i) Turn off the instrument;

3.2.2 Starting the Instrument

press, turn on the instrument,it will carry out self test.After five seconds, the instrument come into operation

mode。

Remarks:

Press “Combined Key ” as startup and loading of the program to execute some special

functions, Particular Operation Instructions of Combined keys refer to appendix II.

3.2.3 Description about Screen Display

Fig. 3.4 Description about screen

3.2.3.1 Three Display Modes of BSM360 Screen,

A-scan at normal mode

Ultrasonic Flaw Detector BSM360 86+010—51658378

16

Fig. 3.5 A-scan at normal mode

A-scan at Enlarged mode

You can activate Enlarge mode by . The gain and selected dB step value will be always displayed on the

screen. And at the same time, all other functions are locked.

Fig. 3.6 A-scan at Enlarged mode

Manual B-scanning (no in BSM360B)

Ultrasonic Flaw Detector BSM360 86+010—51658378

17

Fig. 3.7 B-scan mode

3.2.3.2 Function Displaying Items

The 15 functional groups are displayed at lower part of the screen in three pages. The current functional group

will be highlighted, as that shown in fig. 2-4. and at the same time, the current function in the current functional

group will also be highlighted, as that shown in fig.2-4. Under Enlarged mode, the display of functional groups

disappear.

3.2.3.3 Description about Symbols Displayed on Screen

In the fig left, echo amplitude H=84%, depth

to the reflector=1.57mm, surface distance=25.14mm, echo times is 2, start of range=0.0mm, end of range=40.0mm

In the fig left, echo amplitude(pixels) H=148,

Angular distance=27.68mm.

Fig. 3.8 Description about the display field in screen

3.2.3.4 Display of echo times

When the angle of probe is not zero and the measured echo is multi-echo, the echo times will be drew on the

status column as the following.

\ one time echo

\/ two times echo

Ultrasonic Flaw Detector BSM360 86+010—51658378

18

/\/ three times echo

/\/\ four times echo

/\/\- five and more times echo

3.2.3.5 Description about other symbol

There some other symbols above functional menu,Freeze and Communication symbol is beside the battery

status symbol.

symbol

name Description

Freeze Freeze state。

Communication The instruments is communicating with PC.

Angular distance distance from the incidence point to the reflecte point.

Depth to reflector depth from the incidence point to the reflecte point.

Surface distance surface distance from the incidence point to the reflecte point.

Echo amplitude The amplitude value of max echo within the gate.

Edge sampling It show that the instrument is in “Edge sampling”mode,depth and angular distance

is the measure value of the first echo which is above the gate and within the gate.

Peak sampling It show that the instrument is in “Peak sampling”mode,depth and angular distance

is the measure value of the echo with the max amplitude within the gate。

Memory peaks peaks memory function is enabled.

Making video Dynamic Record function is enabled.

Operation error Operation error last time.

Radian revise Abscissa and measure result is revised according to radian.

3.2.4 Overview of All Functions

The functions of BSM360 are included in 15 functional groups and several special functions.

The functional groups include BASE, P/R, GA TE, CHAN, AGLEY , GAIN DAC1, DAC2, A VG1,

A VG1,BSCAN, SCR, MEM, CFG, ADV they will be introduced in the following table.

No.

group Functions Description

1 BASE RANGE, MTL VEL, D-DELAY , P-DELA Y Basic

adjustment

items necessary

for the display

range

1 P/R PROBE TYPE, , REJECT Sending and

receiving the

Ultrasonic Flaw Detector BSM360 86+010—51658378

19

adjustment items

needed

1 GA TE GA TE LOGIC/ALARM, aSTART/bSTART, aWIDTH/bWIDTH,

aTHRESH/bTHRESH

Relative items for

gate configuration

1 SET SETTING NO.,RECALL、SAVE、DELETE Relative items for

independence setups

1 ANG ANGLE/K-V ALUE, T-V ALUE, X-V ALUE/X-COORD, PROBE

POS/P ART DIA

Setting relative with

angle probe

2 Gain REF GAIN、ADD REF、SCAN DB、AUTO-80 Relative items for

gain

2 DAC1 DAC/REVISE, RECORD/REVISE POS, aSTART/aWIDTH, SHOW

MARK/DAC MODE

Plotting DAC curve

2 DAC2 DAC-EL/ERS-REF, DAC-SL, DAC-RL, CORRECT Setting relative with

DAC curve

2 AVG1 AVG MODE/CHOCK VEL、 PROBE NAME、 FREQUENCY/DIAMETER、 REF TYPE/REF

SIZE

2 AVG2 A START/AVG CURVE、RECORD REF、TEST ATTN/CORRECT

3 B / V B-SCAN /A-SCAN、SCAN WAY/SCAN MODE、RE-FRAME/RE-SPEED、

REVIEW/VIDEO

3 SCR SCR TYPE/PREVIEW、DIRECTION/SCR DELAY、SCR TEXT、ABOUT/COLOR

SET

Screen saver

3 MEM DA TA NO, RECALL, SA VE, DELETE Setting of data

memory

3 CFG DETECT/RS232 SET, GRID/BRIGHTNESS, FILL/BUZZER,

LANGUAGE/UNIT

Setting of relative

state

3 ADV DA TE/TIME, aSTART/ aWIDTH,CSBT,CABT Advanced function

Other special functions can be realized by Special Function (SF) keys. The functions of each SF keys are

introduced in the following table.

Special Functions Description of function

Gain step To adjust the gain step

dB+、dB- To adjust the gain

Full-screen To switch over in full screen

Freeze To freeze waveform

Dynamic record On/off Dynamic record

Memory Peaks Capture the max value of echo on the screen

Measure display Select the display mode of measure result on the screen

Enter Switch of multi-menu, parameters, confirmation of functions

Page up Switch function page

Ultrasonic Flaw Detector BSM360 86+010—51658378

20

3.2.5 Basic Operation Way

You can select a functional group by <Fn> key; select certain function by <Menu> key and ; at this time, you

can modify parameters of this current menu by Coder And for some functional menus, they are shared by two

functions, when you have selected such a function, by pressing or the corresponding <Menu> key, it can be

shifted to another function.

3.2.5.1 Selection of Functions

There are 5 functional groups displayed below the A-scan zone, which can be selected by the corresponding

<Fn> key, and the selected one will be highlighted. The four corresponding function items will be displayed closely

next to the right of A-scan zone, which can be selected by press “↑” or “↓” key key.

3.2.5.2 Multipurpose Function Items

In some cases, a functional item has two functions. thus they can be shifted by pressing down the press “↑” or

“↓” key key again or striking key. The symbol “>” displayed behind the function name means that it is a

multipurpose function item.

Function I Function II Functional group to which

GA TE LOGIC

ALARM

G

A TE

aSTART

bSTART

G

A TE

aWIDTH

bWADTH

G

A TE

aTHRESH

bTHRESH

G

A TE

ANGLE

K

-

V ALUE

ANG

X

-

V ALUE

X

-

COORD

ANG

PROBE POS PART DIA ANG

RECORD REVISE POS DAC1

aSTART aWIDTH DAC1

SHOW MARK DAC MODE DAC1

DAC-EL ERS-REF DAC2

A VG MODE CHOCK VEL A VG1

FREQUENCY DIAMETER A VG1

REF TYPE REF SIZE A VG1

A START A VG Curve A VG2

CORRECT TEST A TTN A VG2

B-scan A-scan B/V

SCAN W AY SCAN MODE B/V

RE-FRAME RE-SPEED B/V

DIRECTION SCR DELAY SCR

Table of contents