BEINAT GS300-Mc User manual

Belonging to

Important: Assembly / maintenance of the appliance must be carried out by qualified personnel and in

accordance with applicable laws and regulations.

The manufacturer assumes no responsibility for the use of products that have to comply with particular

environmental and / or installation standards.

Importantnote

Before connecting the equipment, it is recommended that you read the instruction manual carefully and keep

it for future reference. It is also recommended to perform the electrical connections correctly as per enclosed

drawings, observing the instructions and the Standards.

N.B. Refer to the documentation in all cases where the symbol ison the side

Channel: Beinat gas solutions

Electricconnections alsoavailable on

CONFORMITY

Installation

and user guide

EN50194

EN 45544-1-3

EN 50270

EN 61010-1

Compliant EN 60079-29-1

Installation EN60079-29-2

Reports issued by TUV Italia

INSTALL IN SAFE

AREA, NO ATEX

Control Unit from 1 to 3 Conventional sensors GS300-Mc

Rev. 6

The GS300-Mc control unit has been designed and built according to European regulations to flexibly detect the

presence of toxic and/or explosive gas and OXYGEN, through the connection of 3 remote probes.

A microprocessor is used tocreate a complete surveillance and control system with maximum flexibility. Thanks to this

and its other features GS300-Mc is suitable for civil use, industrial use and small underground car parks.

The GS300-Mc control unit has three danger levels:

1st LEVEL, 1st Alarm. This was set to 8 % of L.E.L. (120ppm)

2nd LEVEL, 2nd Alarm. This was set at 13% of L.E.L. (200ppm)

3rd LEVEL, Main Alarm. This was set at 20 % of L.E.L. (300ppm)

For oxygen the centrol unit GS300-Mc presents three levels of danger which are:

1st Pre-Alarm. Both in deficiency and excess of Oxygen.

2nd Pre-alarm. Both in deficiency and excess of Oxygen.

Main alarm. Both in deficiency and excess.

To facilitate event readings, the control unit has a front panel with 4 LEDs indicating which probe is currently being

monitored in rotation, and a display showing the gas concentration measured.

Other technical features make this controlunit extremely versatile and reliable; for example, by using a series of micro-

switches it is possible to:

Select or disable the probe when not installed or faulty;

Select the type of gas to be detected (toxic or explosive);

Choose the relay functioning mode (pulsed or continuous);

Choose to enable or disable of the intrinsic safety.

The GS300-Mc has the prerequisite to be able to test "TEST" in two different ways:

1) System Test TEST. Pressing the TEST button tests the entire system,including the relays and accessoriesconnected

to it.

2) Maintenance TEST. With special arrangements (see page 8) you can enable the function of:

Exclusion of the general alarm relay for a maximum duration of 60 minutes.

The IP44 external structure was designed for installations onwalls, or on electricalpanels by means of special brackets.

In addition to the alarm signal light, it is fitted with an internal buzzer.

CHECK the integrity of the probe after having removed it from the box.

Check that the data written on the box correspond to the type of gas used.

When doing the electrical connections, follow the drawing closely.

Any use of the detector for purposes other than the intended one is considered improper, and as

a result of which BEINAT S.r.l. therefore disclaims any responsibility for possible damagescaused

to people, animals or objects.

IMPORTANT: The operation test should not be carried out with the gas tap as this does not guarantee

a sufficient concentration to activate the general alarm.

TERMS and EXPECTATIONS: The installation of the GS300-Mc probe, its ordinary and extraordinary maintenance,

and its out of service removal at the end of the functional life guaranteed by the manufacturer, must be carried out

by authorized and/or specialized personnel.

Do not allow it to become wet.

The probe can be seriously damaged when immersed in water. Remember that the probe has a protection degree IP44.

Do not drop it.

Heavy knocks or falls during transportation or installation can damage the appliance.

Avoid abrupttemperature fluctuations.

Sudden temperature variations can cause condensation and the probe could work poorly.

Cleaning

Never clean the device with chemical products. If necessary, wash with a moist cloth.

Absolutely avoid using any cloth dipped in thinners, alcohol and chemical detergents.

Precautions

Technical Specifications

Page 2

MAINTENANCE

The user periodically (every 6 months) must perform a check of the operation of the

control unit by spraying a suitable test gas at the base of the probes connected until the

alarm condition is reached.

• At least once a year make a more accurate check by a specialist technician.

• Disabling the detector must be carried out by qualified personnel.

Main Power Supply

boxed version

................................................................ 110/230VAC 50/60Hz ±10%

Secondary Power Through Battery Max 2,2 Ah (Optional) ..................................................... 12 V ±10%

Battery Charger max 2.2 Ah .................................................................................................... Controlled

Power Demand ...........................................................................................................8,3W max @ 230V

Power Demand ................................................................................................................4W max @ 12V

Relay Contact Range ................................................................... 10A 250VAC resistive - 5A 30Vdc resistive

1st Pre Alarm ......................................................................................... Set to 8% of L.E.L. or 120ppm CO

2nd Pre Alarm ....................................................................................... Set to 13% of L.E.L. or 200ppm CO

Final Alarm ......................................................................................... Set to 20% of L.E.L. or 300ppm CO

..

Monitored Gas Indication ............................................................................... Through backlit color display

Number of Conventional Sensors that can be connected ....................................................................... 3

Micro-switches to include or exclude the probes ................................................................ 1 per each probe

Connectable probes ............................. Semi-conductor, Catalytic, Electrochemical cell, Pellistore, Infrared Rays

Type of faults detected by Fault Circuit ................................................... Interruption, short circuit, or wear

Input Signal ......................................................................................................... 4 ÷ 20 mA on 220 ohm

Device Accuracy ........................................................................................................................ 1% FS

Response Time ............................................................................................................................ < 2”

Control Unit .................................................................................................................... microprocessor

Functioning Temperature ................................................................................................... -10°C ÷ +60°C

Waiting, blinking period ........................................................................................................... 90 seconds

Manual Test ............................................................................................................................ Built in

Max. distance between probes and unit .......................................................................................... 100 m

Cable diameter for connecting probes ............................................................................................. 1 mm2

Connection: The cable of connection of the probe must not be installed together with the power cables.

Otherwise, make sure to use a shielded cable

Size DIN EN 50092 ........................................................................................................... 144*144*110

Degree of Protection ..................................................................................................................... IP44

Warranty.......................................................................................................................................3 years

WARNING! Actions to be taken in case of alarm

Gas

1) Put out all free flames.

2) Close the main gas tap or the LPG cylinder tap.

3) Do not turn any lights on or off; do not turn on any electrical device or appliance.

4) Open windows and doors in order to increase ventilation.

If the alarm stops, its cause must be found and the relevant consequent measures taken.

If the alarm continues and the cause of gas presence cannot be found or removed, abandon the building

and call the emergency services when outside (fire department, distributors, etc.)

IMPORTANT: The operation test should not be carried out with the gas tap as this does not guarantee a sufficient concentration

to activate the general alarm.

Warning !!

If you have the following symptoms: vomiting, sleepiness, or else, go to the closest first aid

station and inform the operators that you could have been poisoned by Carbon Monoxide, or

by an excess or deficiency of oxygen

Main Compatible Probes

140

140

140

108

77

Page 3

Screws5 ma

Brackets

144

144

GS300-Mc

000LEL

ppm

1 2 3

SG500 Catalytic IP30 Domestic Use CH4-LPG 0÷100% LEL 4÷20 mA ±5 % NO NO

SG544 Catalytic IP44 Tertiary CH4-LPG 0÷100% LEL 4÷20 mA ±5 % NO NO

SGM595 Catalytic IP55 Tertiary See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGM595/A Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGM533 Catalytic IP55 Tertiary See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SG800 Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes Yes

HCF100 SemiCondut IP55 Tertiary FREON 0÷300% ppm 4÷20 mA ±5 % NO Yes

SG895 Pellistor ATEX Zone 1 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SG580 Catalytic IP66 Zone 2 See catalogue 0÷100% LEL 4÷20 mA ±5 % Yes NO

SGF100 Catalytic IP64 Zone 2 Methane 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SGF102 Catalytic IP64 Zone 2 LPG 0÷100% LEL 4÷20 mA ±5 % Yes Yes

SGF104 Optical Fluores IP64 Zone 2 Oxygen In % 4÷20 mA ±5 % Yes Yes

SGF106 SemiCondut IP64 Zone 2 FREON 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF108 Elettrochimica IP64 Zone 2 H2S 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF110 Electrochemical IP64 Zone 2 C O 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SGF112 Catalytic IP64 Zone 2 Hydrogen 0÷100% LEL 4÷20 mA ±5 % Yes Yes

CO100r Electrochemical IP55 Tertiary CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

CO100Ar Electrochemical IP66 Zone 2 CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

SG800duct Catalytic IP66 Zone 2 CH4LPG 0÷100% LEL 4÷20 mA ±5 % Yes Yes

CO200duct Electrochemical IP66 Zone 2 CO 0÷300% ppm 4÷20 mA ±5 % Yes Yes

Application in:

Domestic: family accommodation. Local boilers up to 70 kW-h

Tertiary Areas: Large Rooms Boilers, Workshops, Material Deposits, Industrial Kitchens, Large Buildings, Buildings.

Zone 2 - Mixed IP66 ATEX: High probability of escape, high risk locations, premises for which applicable regulations apply.

Zone 1 - Hazardous Area, High Risk Hazards, Rooms for Which Regulations, Tanks, Control Valves are in force.

Probe Sensor Degree Suitable for Gas Range Output Precis. Calibration Relay

Protec. Detected Working Automatic

Sensor

Page 4

Componentsand commands

1) LED ON. It blinks for about 2 minutes (warm up time) when the mains power is supplied. When ready, the

LED stays on without blinking.

Note: during warm up the control unit is not able to detect the presence of gas.

2) BATTERY LED. It lights up (fixed) when no mains power is present and the control unit is supplied by a 12Vdc

battery. It blinks when the battery is flat.

3) OVER LOAD PROBES LED. If this LED turns on, it means there is a short circuit or high current absorption

in the probes.

4) OVER LOAD BATTERY LED. If this Led turns on, it means the battery is not connected properly, or it has

an anomalous voltage absorption.

5) TEST BUTTON. Pressing and holding down this button, you can obtain a gas leakage simulation. In order

to perform this operation no failures or alarms should be present.

6) RESET BUTTON. This button is pressed to clear all memories, or to restore the control unit after a failure.

7) 1st Alarm LED. This LED will light up when the gas concentration level has reached 8% of LEL, or 120ppm

(ref. CO), and the 1st threshold relay contact is closed. The relay disenergizes when the 13% of LEL, or 200ppm

CO, threshold is exceeded.

8) 2nd Alarm LED. This LED will light up when the gas concentration level has reached 13% of LEL, or 200ppm

(ref. CO), and the 2nd threshold relay contact is closed. The buzzer will issue a low frequency sound. The relay

disenergizes when dropping below the 13% of LEL, or 200ppm CO, threshold.

9) MAIN ALARM LED. This LED will light up when the gas concentration level has reached 20% of LEL, or

300ppm (ref. CO), and the MAIN ALARM relay contact is closed. The buzzer will issue a high frequency sound.

10) FAULT LED. This LED blinks when one of the connected probes is faulty, if there is an interruption in the

cable connection, or if an error was made during wiring. When this LED is blinking, the device is no longer

capable of detecting. To reactivate the device, the damaged probe must be repaired or disabled using the

internal micro-switch (see chapter 6 paragraph A) and then the RESET button must be pressed.

11) DISPLAY backlight colours. The symbols are illustrated in the draw.

a) The symbol of the battery light on when the GS300-Mc is powered with an external battery.

The drawn battery indicates the state of load of the battery and when it blinks it means that the battery is low.

b) The number on the display indicates the concentration of gas detected.

The exchange of data of every connected probe is every about 4 seconds.

c) The letters ppm means when the connected probe detects Toxic gas.

The letters LEL means when the connected probe detects Explosive gas.

d) The numbers in the rectangle “1 2 3 “: are the probe connected; They lidht up in sequence and identify

the monitored zone.

e) The timing symbol lights when GS300-Mc is in warm up phase, the same time its begins the count down

Main Alarm

2 Alarm

1 Alarm

Fault

O N

Battery

Test

Reset

Over Load

Battery

Over Load

Probes

(1)

(2)

(3)

(4)

(5)

(6)

(11) (7)

(8)

(9)

(10)

GS300-Mc

100ppm

1 2 3

%LEL

Switch1

Intrinsic safety selection

Switch 2

Main alarm relay functioning mode

Switch 3

Maintaining of the memory of alarm,only when

you set the CO gas

Switch 4

Selecting OXYGEN mode

Power terminal block Sensors terminal block

S1 S2 S3 S4 1 2 3 4

Deleting or disabling the probes

monitored gas type selection

Page 5

Components and Commands continue

11) DISPLAY. The display below is represented with all its segments and indications

a) The number on the display indicates the concentration of gas detected.

b) The number drawn on the display indicates which probe is monitored

The exchange of data of every connected probe is every about 4 seconds.

c) The letters ppm means when the connected probe detects toxic gas.

The letters LEL means when the connected probe detects explosive gas.

d) The timing symbol lights when the control unit is in warm up phase, the same time its begins the count

down.

c

000

a

d

LEL

ppm

1 2 3 b

IMPORTANT NOTE

The installation of the detector is not exempt from ...… The compliance with all regulations concerning the characteristics,

installation and use of gas appliances. The ventilation of the spaces and the elimination of combustion products are described

in the UNI norms according to ART. 3 LAW 1083 / 71 and relevant legal provisions.

Description of Display

The BX444Mc is equipped with a display backlight color to facilitate the recognition of the state of the probe

monitored.

The data exchange for each probe connected happens every 4 seconds.

00LEL

300ppm

The blu display shows

the percentage of

oxygen. normal

condition

20.6

%

20LEL

FAU

The green display

shows an absence of

leakage of gas, normal

conditione

The display shows with

red color a concentration

of explosive gases in

% LEL greater than a

threshold alarm.

The display shows with

red color a concentration

of toxic gases ppm

greater than a threshold

alarm.

The yellow display shows

a fault of one or more

probes.

< 19.9 %

> 21.9 %

< 19.5 %

> 22.5 %

< 18.5 %

> 23.5 %

1st Pre-Alarm

2nd Pre-Alarm

Main alarm

< Oxygen deficienty

> Excess Oxygen

The BX444-Mc presents three

levels of danger which are:

Page 6

Legend setting switches

S1) switch group reserved to the probe N° 1

S2) switch group reserved to the probe N° 2

S3) switch group reserved to the probe N° 3

1) Selection of positive safety

2) Operating mode of the main alarm relay.

3) Selection of MEMORY.

N.B. You can remove the selection of memory

when the gas CO is selected.

4) Selection for oxygen detection

Diagram of the terminal block relay

WARNING.

Before connecting to the mains power, ensure the voltage is correct.

Carefully follow the instructions and the connections according to Regulations in force, keeping in

mind that the signal cables should be laid separate from the power cables.

An automatic cut-off switch (appropriately identified as devicesectioning of the detector) should be

incorporated in the electrical system, adequatelylocated and easily accessible.

Electrical Connections

Power supply

230VAC

PH N 4 5 6 7 8 9 10 11 12

CNC

NO

CNC

NO

CNC

NO

CNC

NO

Fault 1st threshold 2nd threshold Main alarm

PLEASE NOTE!

All relays are free of voltage

Connection of probes and eventual battery

12V

1 2 3 4 5 6 7

+ +

Optional

3 2 1

Probe 1 3 2 1

Probe 2 3 2 1

Probe 3

R1 R2 R3

Switch1

Intrinsic safety selection

Switch 2

Main alarm relay functioning mode

Switch 3

Maintaining of the memory of alarm,only when

you set the CO gas

Switch 4

Selecting OXYGEN mode

Power terminal block Sensors terminal block

S1 S2 S3 S4 1 2 3 4

Deleting or disabling the probes

monitored gas type selection

Page 7

Connections of a solenoid valve Normally Closed with Positive Safety

Connections of a solenoid valve Normally Closed without Positive Safety

Control unit power supply and connection of a solenoid valve with sirens to 12 VDC trough

an alternative source and recharge battery.

NC NA

Ph

N

PH N 4 5 6 7 8 9 10 11 12

Power supply

230 VAC

CNC

NO C

NC

NO

CNC

NO

CNC

NO

Fault 1°Threshold 2° Threshold Alarm Solenoid valves

Ph

N

PH N 4 5 6 7 8 9 10 11 12

Power supply

230 VAC

CNC

NO C

NC

NO

CNC

NO

CNC

NO

Fault 1°Threshold 2° Threshold Alarm Solenoid valve

Connection examples

Power supply 230/12V

Diode

1N 5406 3 2 1

Probe 1 3 2 1

Probe 2 3 2 1

Probe 3

Solenoid valve GAS and Sirens 12 VDC

1 2 3 4 5 6 7

+ + R1 R2 R3

12 V

It's not possible to connect directly solenoid

valves or sirens 12V.dc. to the GS300-Mc

Page 8

Components and Commands continue

Description of Micro-switches

Installing, uninstalling or disabling probe

Through the Micro switches (see drawing below) on the control unit, you can to activate or to deactivate 3

Zones.

You can connect 3 probes to the GS300-Mc. The control unit is tested with the probes connected

In some installations, you may need only one probe. In this case we will proceed to disable a probe, to do this

select the switch of the probe (zone) concerned.

These micro-switches are also used to disable one or all probes in case of failure

N.B. The microswitches are also used for switching off in case of failure

A row of LEDs numbered from 1 to 3 and called PROBES has been fitted on the GS300-Mc. These LEDs are

lit with a 4 second frequency representing the connected probes, and indicate the probe being read on the

display.

In case of alarm: The LED that represents the probe stops for about 15 seconds. This is done in order to

identify the relevant zone or zones easily.

The gas percentage measured by the probe appears on the display and is maintained for 15 seconds. On the

next pass, the LED (probe) will be maintained again and the alarm will be issued.

In case of fault: The LED of the relevant probe starts blinking and remains lit. The display will show the “FAU”

(Fault) fixed indication, and the buzzer will issue a continuous sound until:

1) The repair has been carried out;

2) The relevant probe has been disabled using the micro-switch.

Probe indication

Leds from n°1 to n°3

Zone 1 Zone 2 Zone 3

Micro-switch (1) to enable or to disable the probe.

Position ON enabled - In position OFF disabled

000LEL

ppm

1 2 3

The simultaneous and prolonged pressure for 5 sec of the "TEST" and "RESET" buttons enables the test-on mode in

which the control unit does not switch the general alarm relay fora period of 15 minutes; Not evenpressing the external

manual button.

A further keypress in the same mode extends the time of 15 minutes to a maximum of 60 minutes.

In this mode, before the passage from the current channel to the next, the "TESt-On" string is displayed followed

by the minutes of the general alarm relay being switched off.

You can terminate this mode before the natural deadline by resetting the control unit by pressing 3 consecutive

times and within 5 seconds the RESET button.

Mantinance Test

Page 9

Components and Commands continue

Selection of the type of gas monitored by each probe

The control unit if fitted with four micro-switches in order to select the type of gas that the connected probes

should monitor.

The LEL reading is obtained by shifting the switch to ON. Explosive gas (see display)

The ppm reading is obtained by shifting the switch to OFF. Toxic gas (see display)

Relay’s working mode and the memory of the Main alarm

Switch 1 – Selection of the positive safety

In the ON position, the positive safety function is enabled.

The relay is energized after performing the waiting phase and switches when the GS300-Mc is in main alarm

In the OFF position, the positive safety function is disabled.

The relay is energized only when the GS300-Mc enters the state of main alarm

Switch 2 – Functioning Mode of main alarm relay.

In the ON - Continuous function, the relay remains closed until the RESET button is pressed.

In the OFF - Impulse function, the relay remains closed for 5 seconds, and then disenergizes afterwards.

Zone 1 Zone 2 Zone 3

Micro-switch (2) to select the type of gas monitored

Position ON lreading in LEL - Explosive gas

Position OFF reading in ppm - Toxic gas

Zone 1 Zone 2 Zone 3

Micro-switch 1Positive Safety

Micro-switch 2working mode of the Main

Alarm relay

Page 10

When all else fails, read instructions

30 cm Light Gases

30 cm Heavy Gases

Middle Height Volatile Gases

SENSOR INSTALLATION INFORMATION

Installation and positioning of the probe

The GS300-Mc control unit belongs to group II and must be installed in a safe area;

Outside the ATEX zone, however, not in boiler rooms or engine room.

The control unit must be accessible and visible to the user.

The GS300-Mc is designed so that it can be mounted externally or built into electrical panels.

The Control Unit complete cabinet is an equipment suitable for wall mounting and is powered by 110/240 VAC with

IP44 protection

When installing, it is good to use the normal care that an electronic equipment requires:

- Install the equipment away from excessive heat sources.

- Avoid liquids coming into contact with the control unit, remembering that its external structure has IP20 degree of

protection if installed on the Boxed version (cabinet) supplied to the source is IP44.

The Sensor must be selected with an IP degree depending on the area to be controlled (Kitchens, Boiler

Rooms, Laboratory, etc.) by selecting one of the probes from Beinat from IP30 to ATEX. see page 3

Position of thedetection sensors

You can connect many types of remote probes to this unit. Therefore, they should be positioned at different heights

depending on the type of gas to be detected.

These heights are:

- 30 cm from the lowest point of the floor in order to detect: Heavy gases (L.P.G. etc.)

- 30 cm from the highest point of the ceiling in order to detect: light gases (Methane, etc.)

- 160 cm from the lowest point of the floor in order to detect: volatile gases (CO, etc.)

It is importanttonote that the remote probes should be installed according to the following restrictions:

1) The probes should not be placed near the appliances to be controlled (boilers, burners, industrial kitchens, etc.)

but on the opposite side.

2) The sensors should not be affected by smoke, vapour, and moving air, as they could distort their measurement.

3) The sensors should not be placed near sources of heat, ventilators or fans.

It should be noted that the internal GAS sensors of the probe are perishable components with a variable average

life span from 5 to 6 years (you can request the relative table). Therefore, after this period of time has elapsed it

is advisable to replace them.

4) The control of operation and maintenance and / or extraordinary must be carried at least once a year. good

to keep

When turning on leds fault is necessary make the replacement of the probe by a specialized technician.

Page 11

Turning on the GS300-Mc

1) Apply power using the proper switch. This switch should be fitted with protection fuses.

2) You will notice that some LEDs will light up in turn for about 20 seconds, so as to test the LEDs.

3) The Led ON continues to blink about 1.30 minutes after which remains steady light.

This indicates that the control unit is ready to detect.

4) By pressing the MANUAL TEST button, you get the simulation of a gas leak and the unit carries out the

following:

a) The 1st Pre-alarm LED lights up calibrated to 8% LEL or 120 ppm (referred to CO) switching the reference

relay.

b) The 2nd Pre-alarm LED lights up calibrated to 13% LEL or 200 ppm (referred to CO) switching the relay

the buzzer will issue a low frequency sound

c) The Main alarm LED lights up calibrated to 20% LEL or 300 ppm (referred to CO) switching the relay.

The Main alarm LED starts flashing; the buzzer will issue a hight frequency sound

When releasing the MANUAL TEST button, you will see the opposite: Only the Main Alarm LEDs and the Led

of 20% remain ON

The main alarm will persist as long as you do not press the RESET button, so canceling the alarm memory.

5) To complete the test please read the manual of the probe and perform sensor test by emitting gas with a

pre calibrated bottle.

6) to simulate the fault zone you only need to disconnect the probe return cable, the central will perform the

following actions:

-it lights in blinking mode the FAULT and the MAIN ALARM LED

- the buzzer sound continuously;

- the fault relay and the main alarm relay will switch.

Reconnect the return cable and press the RESET button to restore the control unit functioning

Troubleshooting and solutions before calling a technician

-If the device does not start up.

Check that the 240VAC mains power is correctly connected. If powered by the battery, check that the 12Vdc

power is correctly connected.

-If the Fault LED lights up.

Check that the probe cables are connected as in the drawing, they have not pinched the insulating sheath

Check that the voltage at the terminals 3-4, is greater than 11 VDC and less than 25 VDC

Check that at the terminals 3 and 5- (6-7) is present a voltage from a minimum of 0,8 VDC at a maximum

of 1,1 VDC

-If the Over Load Probe LED lights up.

Check: that the power polarity has not been inverted,that no short-circuit ispresent, that the probeswere not damaged

during installation, that no excessive current absorption is present.

-If the Over Load Battery LED lights up.

Check that the connection cables are not short-circuited, that the polarity has not been inverted, or that the battery

is not damaged

-If the Control Unit is repeatedly issuing an alarm.

Check that there are no gas leaks.

Check that together with the alarm signal is not also turn on the FAULT indicator, in this case, control the probes.

-If the Control Unit is issuing an alarm and does not shut off the devices connected to it.

Check that the wiring is correct and that the jumper that carries power to the relay has been set properly.

NOTA: All relays are voltage free; Check the connection drawing.

- If a 12Vdc solenoid valve, which does not work well,.

Direct connection of 12VDC solenoid valves or sirens to the control unit is not possible, having absorption in excess

of 100mA.

To connect a solenoid valve with superior absorption you must resort of an external battery.

The control unit gives a max current of 100mA.

Check the connection design.

013

2

1,1

V.

Voltmeter

WARNING.

This measurement should

be performed in clean air.

1 2 3 4 5 6 7

+ +

3 2 1

Probe 1 3 2 1

Probe 2 3 2 1

Probe 3

If other problems arise, a specialised and/or authorised technician and/or the Distributor of

BEINAT S.r.l. should be contacted directly.

BE - V 6 34 17

Control Unit GS300-Mc Lo styling è della b & b design

Dealer stamp

Purchase date:

Serial number:

Beinat S.r.l. following the purpose of improving its products, it reserves the right to modify the technical, aesthetic and functional characteristics

at any time and without giving any notice.

INSURANCE. This device is insured by the SOCIETÀ REALE MUTUA for the PRODUCT'S GENERAL LIABILITY

up to a maximum of 1,500,000.00 EURO against damages caused by the device in case of failures in functioning.

WARRANTY. The warranty term is 3 years from manufacturing date, in agreement with the following

conditions. The components acknowledged as faulty will be replaced free of charge, excluding the replacement

of plastic or aluminium cases, bags, packing, batteries and technical reports.

The device must arrive free of shipment charges to BEINAT S.r.l.

Defects caused by unauthorized personnel tampering, incorrect installation and negligence resulting from

phenomena outside normal functioning shall be excluded from the warranty.

BEINAT S.r.l. is not liable for possible damage, direct or indirect, to people, animals, or things; from product

faults and from its enforced suspension of use.

DISPOSAL OF OLD ELECTRICAL & ELECTRONIC EQUIPMENT.

This symbol on the product or its packaging to indicates that this product shall not be treated as household waste. Instead, it shall be handed over to

the applicable collection point for the recycling of electrical and electronic equipment, such as for example:

- sales points, in case you buy a new and similar product

- local collection points (waste collection center, local recycling center, etc...).

By ensuring this product is disposed of correctly, you willhelpprevent potential negative consequence for the environment and human health, which could

otherwise be caused by inappropriate waste handing of this product. The recycling of materials will help to conserve natural resources. For more detailed

information about recycling of this product, please contact your local city office, your household waste disposal service or the shop where you purchased

theproduct.

Attention: in some countries of the European Union, the product is not included in the field of application of the National Law that applies the European

Directive 2002/96/EC and therefore these countries have no obligation to carry out a separate collection at the “end of life” of the product.

Madein Italy

IP44

Technical support - laboratorio@beinat.com

BEINAT S.r.l.

Via Fatebenefratelli 122/C 10077, S. Maurizio C/se (TO) - ITALY

Tel. 011.921.04.84 - Fax 011.921.14.77

http:// www.beinat.com

Table of contents

Popular Controllers manuals by other brands

Baker

Baker Becker VRP-CH Series instruction manual

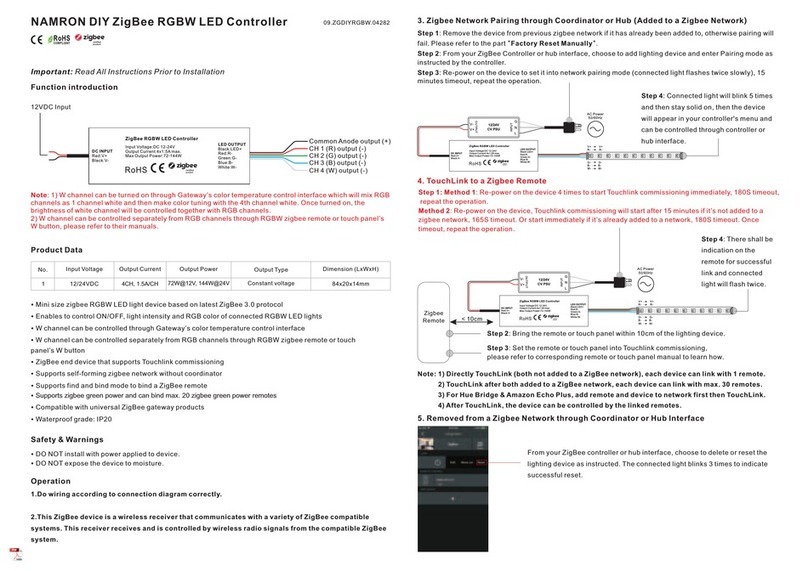

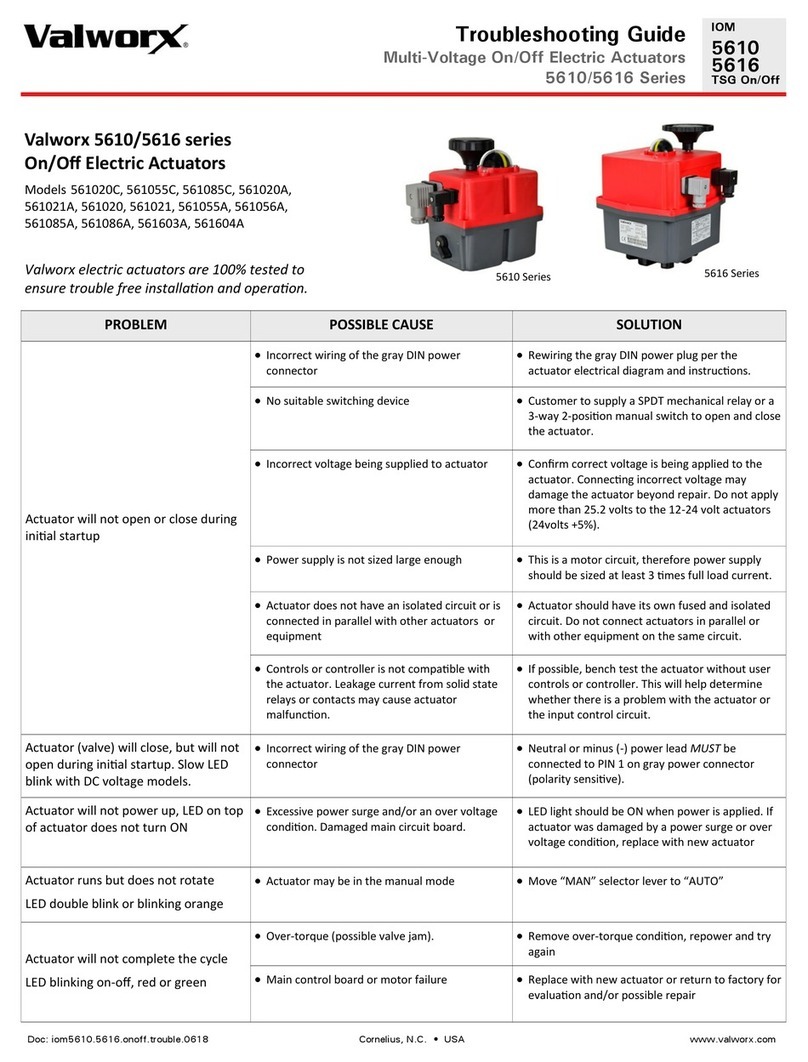

Valworx

Valworx 561020C troubleshooting guide

Mitsubishi Electric

Mitsubishi Electric MELSEC FX2NC-16MT-D/UL Hardware manual

Belimo

Belimo FSNF instruction sheet

Telcoma Automations

Telcoma Automations FM420 Operation and Programming Instructions

Emerson

Emerson Fisher Accu-Pressure Y693 instruction manual

Control Microsystems

Control Microsystems SCADAPack Micro 16 quick start guide

MR

MR TAPCON 230 Expert operating instructions

Hardie

Hardie Lawn Genie L30000W Installation and operation guide

Woodward

Woodward 2301E Installation and operation manual

AMX

AMX DAS-D-0404 installation guide

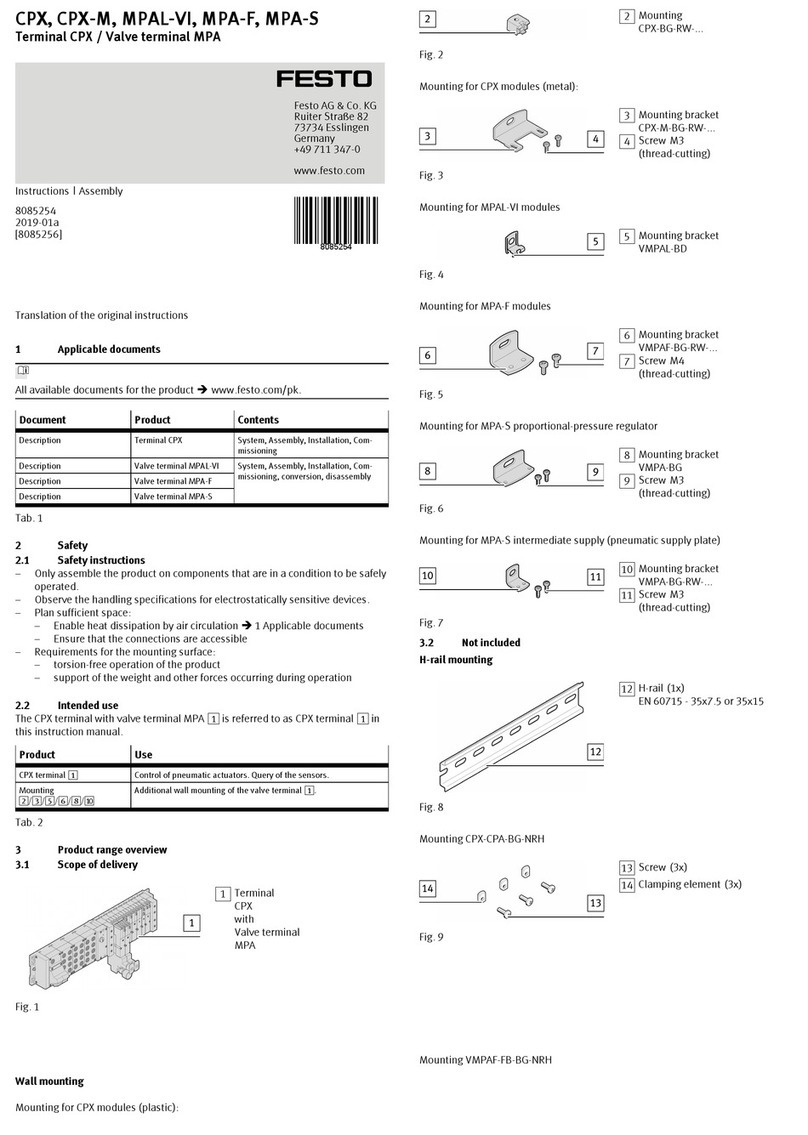

Festo

Festo CPX Instructions and Assembly