Beissbarth Start Line MT 601 D User manual

Start Line MT 601 D

Radwuchtmaschinen

Wheel Balancers

de

Originalbetriebsanleitung

Radauswuchtmaschine

en

Original instructions

Wheel Balancing Machine

fr

Notice originale

Banc d‘équilibrage de roues

es

Manual original

Máquina de equilibrado de ruedas

it

Istruzioni originali

Equilibratrice per ruote

pt

Manual original

Máquina de balanceamento de rodas

1 695 600 538 2016-07-27|

| Start Line MT 601 D | 23 en

Contents English

1. Symbols used 24

1.1 In the documentation 24

1.1.1 Warning notices -

Structure and meaning 24

1.1.2 Symbols in this documentation 24

1.2 On the product 24

1.3 Safety Instructions 24

2. User information 25

2.1 Important notes 25

2.2 Safety instructions 25

2.3 Electromagnetic compatibility (EMC) 25

3. Product description 25

3.1 Intended use 25

3.2 Prerequisites 25

3.3 Device description 26

3.4 Accessories supplied 26

4. Initial commissioning 27

4.1 Unpack the MT 601 D 27

4.2 Setting up the MT 601 D 27

4.3 Fitting the wheel-guard hood 27

4.4 Power socket 28

4.5 Checking direction of rotation 28

4.6 MT 601 D calibration 28

5. Fitting and removing flange 29

5.1 Fitting flange 29

5.2 Removing flange 29

6. Fitting and removing wheel 29

6.1 Clamping the wheel 29

6.1.1 Clamping on correct side 29

6.1.2 Clamping on opposing side 30

6.1.3 Clamping with special flange 30

6.2 Removing the wheel 30

7. Program layout 31

7.1 Display 31

7.2 Control buttons 31

7.3 Keystroke combination for changing between

functions 32

7.4 Balancing programs 32

7.5 Standard program for input of rim data 32

7.6 Input of rim data for ALUS 34

8. Balancing the wheel 34

8.1 Occupied area 34

8.2 Measuring imbalance 35

8.3 Attaching balance weights 35

8.3.1 Standard procedures for clip-on weights

and adhesive weights 35

8.3.2 ALUS balancing mode 35

8.3.3 Splitting the balance weights (HID

program) 35

8.4 Attaching the clip-on weights 36

8.5 Attaching adhesive balance weights 36

9. Imbalance minimization 37

10. Adjustment 37

11. Faults 38

12. Service 39

12.1 Cleaning and Maintenance 39

12.2 Spare and wearing parts 39

12.3 Self-calibration 39

12.3.1 Self-calibration of system 39

12.3.2 Automatic self calibration of the rim-

distance gage 39

12.4 Self-inspection 40

12.5 Structure and setting of pressure sensor 40

12.6 Adjusting the belt tension 40

12.7 Changing the fuse 40

13. Decommissioning 41

13.1 Temporary shutdown 41

13.2 Change of location 41

13.3 Disposal and scrapping 41

13.3.1 Substances hazardous to water 41

13.3.2 MT 601 D and accessories 41

14. Technical parameters 41

14.1 MT 601 D 41

14.2 Size and weight 41

14.3 Operating range 41

14.4 Temperatures and operating range 41

1 695 600 538 2016-07-27|

24 | Start Line MT 601 D | Symbols useden

1.3 Safety Instructions

Please read the manual before operation.

Please wear eye protection.

Rotating equipment, exercise caution.

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices -

Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the con-

sequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of fail-

ure to observe action and information given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if in-

structions not observed

DANGER Immediate impend-

ing danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible inter-

mediate result.

"Final result There is a visible final result on com-

pletion of the instruction.

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible.

Information on the rating plate

Product designation, 10-digit material number; volt-

age (V), setting (Hz), installed load (kW); current (A),

maximum supply pressure (kPa), protection class (IP);

year of manufacture; CE mark; 13-digit material num-

ber and machine model; barcode.

Disposal

Dispose of used electrical and electronic

devices, including cables, accessories and

batteries, separately from household waste.

Prescribed voltage supply

Information on the voltage set and safety warning.

DANGER – Exposure of live parts on open-

ing the MT 601 D!

Risk of (fatal) injury or heart failure from

electric shocks on contact with live compo-

nents (e.g. master switch, printed circuit

boards).

¶Work on electrical installations or equip-

ment is only to be performed by qualified

electricians or trained personnel under the

guidance and supervision of an electrician.

¶Disconnect the MT 601 D from the mains

before opening.

Direction of wheel rotation

Wheel must turn in direction indicated.

(see chapter "Checking the direction of

rotation")

1 695 600 538 2016-07-27|

User information | Start Line MT 601 D | 25 en

2. User information

2.1 Important notes

Important information on copyright, liability and warran-

ty provisions, as well as on equipment users and com-

pany obligations, can be found in the separate manual

"Important notes on and safety instructions for Beissbarth

Tire Equipment". These instructions must be

carefully studied prior to start-up, connection and opera-

tion of the MT 601 D and must always be heeded.

2.2 Safety instructions

All the pertinent safety instructions can be found in

the separate manual "Important notes on and safety

instructions for Beissbarth Tire Equipment". These

instructions must be carefully studied prior to start-up,

connection and operation of the MT 601 D and must

always be heeded.

2.3 Electromagnetic compatibility (EMC)

The MT 601 D satisfies the requirements of the EMC

directive 2004/108/EG.

iThe MT 601 D is a class/category A product as

defined by EN 61 326. The MT 601 D may cause

high-frequency household interference (radio inter-

ference) so that interference suppression may be

necessary. In such cases the user may be required to

take the appropriate action.

3. Product description

3.1 Intended use

The MT 601 D is a wheel balancing machine featuring

mechanical wheel clamping for the balancing of car,

light van and motorcycle wheels with a rim diameter of

10" - 27" and a rim width of 1" - 20".

The MT 601 D is to be used exclusively for this purpose

and solely for the range of applications specified in

these instructions. Any other purpose is not consistent

with the intended use and is therefore not permissible.

iThe manufacturer cannot accept any liability for pos-

sible damage arising from improper use.

3.2 Prerequisites

The MT 601 D must be installed on a flat surface

made of concrete or similar material and anchored in

position.

!An uneven or vibrating surface can lead to inaccu-

rate unbalance measurements.

!Any uneven floors or that do not meet the previously

expressed safety requisites relieve the manufactur-

er from any liability for damages to persons and/or

property.

!1) * These dimensions refer to standard rims (A); for

rims with a special shape (B - C), special accesso-

ries should be used.

A

B

C

Fig. 1: Rim types

1 695 600 538 2016-07-27|

26 | Start Line MT 601 D | Symbols useden

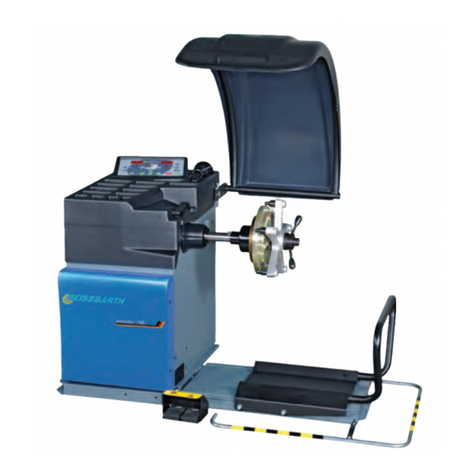

3.3 Device description

Fig. 2: Product introduction

Item Designation Function

1 Display panel Display of measuring results

2 Control panel Operation of the MT 601 D

3 Shelf Shelf for balance weights and accessories.

4 On/Off switch Switching power On/Off

5 Clamping tool holders Attaching spare parts and cones

6 Brake pedal Blocking of wheel while attaching or removing wheel weights

7 Retaining tabs For fastening to the floor

8 flange Fasten wheel.

9 Rim-distance gage

(electronic)

RRecords rim distance and rim diameter.

RDetermines positions for attachment of adhesive balance weights.

10 Wheel guard RProtects operator against flying particles (e.g. dirt, water).

RStarting and stoppin measurement

11 Cover plate Storing & reconditioning the weights

3.4 Accessories supplied

Name Order number

Large flange 0530201001

Small cone 0530201016

Cone 2 0530201037

Cone 3 0530201038

Cone 4 0530201039

Spacer plate, large 020601001

Quick-action clamping nut 020601003

Wrench, waf 12 022102001

Wrench, waf 6 022102002

Wrench, waf 4 022102003

Wrench, waf 3 022102004

Name Order number

Balance weight pliers 022102005

Spring 020701012

Weights100g 022102006

Weights50g 022102010

Weights35g 022102011

Weights10g 022102013

Weights5g 022102027

Measuring compass 020601004

Adhesive weights remover 020601105

Allen key 022102035

hexagon socket head bolt 030201064

1 695 600 538 2016-07-27|

Initial commissioning | Start Line MT 601 D | 27 en

4. Initial commissioning

4.1 Unpack the MT 601 D

1. Remove the steel band and fasteners.

2. Carefully lift off the packaging.

3. Remove the accessories and packaging material

from the packaging unit.

iCheck that the MT 601 D and the accessories are in

proper working order and that there are no visi-

ble signs of component damage. In case of doubt,

do not commission the unit and consult customer

service.

iDispose of the packaging material at an appropriate

collection site.

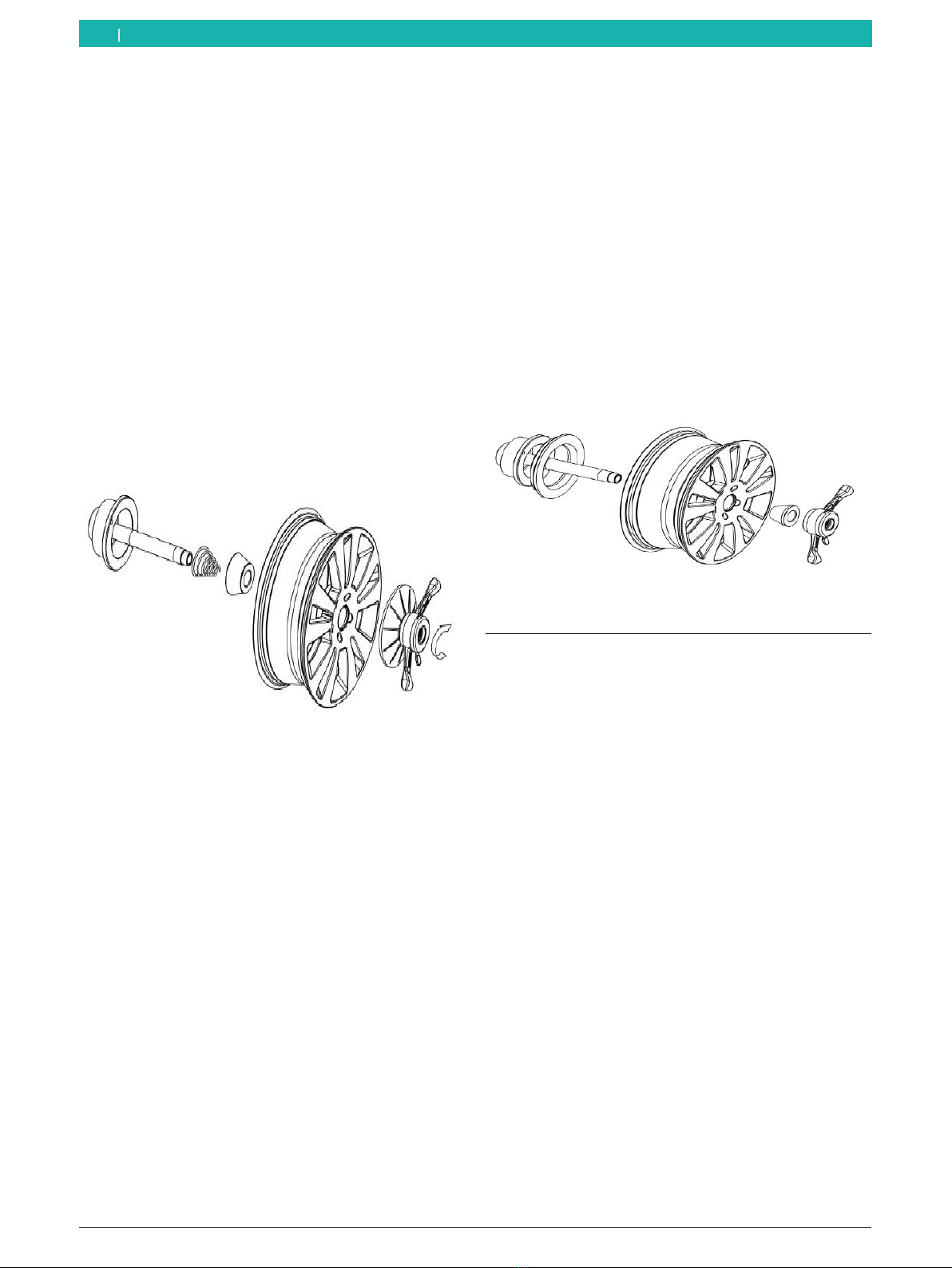

4.2 Setting up the MT 601 D

1. Unfasten locating screw on MT 601 D.

2. Attach hoisting strap as shown in illustration. The

hoisting strap must be at least the same length, and

must have enough load-bearing capacity (at least

100kg).

Fig. 3: Lifting the wheel balancer

Warning of damage or wrong lifting gear

Risk of injury if MT 601 D falls.

¶Please check hoisting strap before

attaching it.

¶Secure the hoisting strap.

¶Lift the MT 601 D carefully.

3. MT 601 D must never be lifted by the flange shaft.

After lifting, set down at prepared installation lo-

cation and pay attention to the minimum specified

distance.

Fig. 4: Wheel balancer installation location

iFor safety reasons, the installation location must be

500mm away from the wall.

4. MT 601 D must be secured to the ground with ex-

pansion bolts. Measuring errors will occur if it is not

fixed firmly.

4.3 Fitting the wheel-guard hood

1. Remove nut from support bracket on the 2 wheel-

guard hoods, then remove the support bracket.

Fig. 5: Unfastening the guard hood

1 695 600 538 2016-07-27|

28 | Start Line MT 601 D | Initial commissioningen

4.4 Power socket

!MT 601 D must not be connected to the power

supply unless its voltage is the same same as that

specified on the rating plate.

1. Check to ensure that power supply is at the same

voltage as specified on the rating plate.

2. Check the usual standard for machines and ensure

that the power connector and power port on cus-

tomer premises both comply with that standard.

3. Connect up to power supply.

4. Connect switch connector of wheel-guard cover.

Fig. 8: Connect switch connector of wheel-guard cover

2. Attaching the wheel-guard hood and hood bracket.

Fig. 6: Fitting the wheel-guard hood

3. Install wheel-guard hood in support and tighten the

screw.

4. Install support bracket 2, then install the plate as

shown in the following Figure.

Fig. 7: Installing the support bracket

4.5 Checking direction of rotation

1. Check whether the MT 601 D is properly connected

to the mains.

2. Switch on the MT 601 D at the on/off switch.

3. Close the wheel-guard hood.

Flange shaft rotates.

!If flange shaft does not rotate, press button <???>.

iIf the direction of rotation is incorrect the MT 601 D

comes to an immediate halt and the error message

ERR 3 is displayed.

4. Check direction of rotation of flange shaft.

iThe correct direction of rotation is indicated by a label

on the right side of the MT 601 D.

4.6 MT 601 D calibration

!Calibration must be performed after initial commis-

sioning.

1. Calibrate the flange.

2. Calibrate rim-distance gage.

3. Calibrate MT 601 D.

4. Perform reference measurement.

iThe calibration is described in the section "Calibra-

tion".

1 695 600 538 2016-07-27|

Fitting and removing flange | Start Line MT 601 D | 29 en

5. Fitting and removing flange

5.1 Fitting flange

1. Actuate pedal.

Flange shaft blocked.

2. Screw lead screw into flange shaft.

3. Install the M14 screw.

Fig. 9: Installing the lead screw

4. Use Allen key to tighten until there is no clearance

between lead screw and flange, i.e. until tight.

"Screw connection established

iInstall until "0" marks on flange shaft and lead screw

are aligned.

5.2 Removing flange

1. Actuate pedal.

Flange shaft blocked.

2. Turn wrench anti-clockwise until lead screw and

flange shaft disconnect from one another.

Fig. 10: Removing flange

6. Fitting and removing wheel

WARNING - wheel may slip!

Risk of crushing of fingers and other body

parts when attaching and removing wheel.

¶Wear protective gloves.

¶Wear safety shoes

¶Do not place finger(s) between wheel and

flange shaft.

¶Heavy wheels should always be handled

by two people.

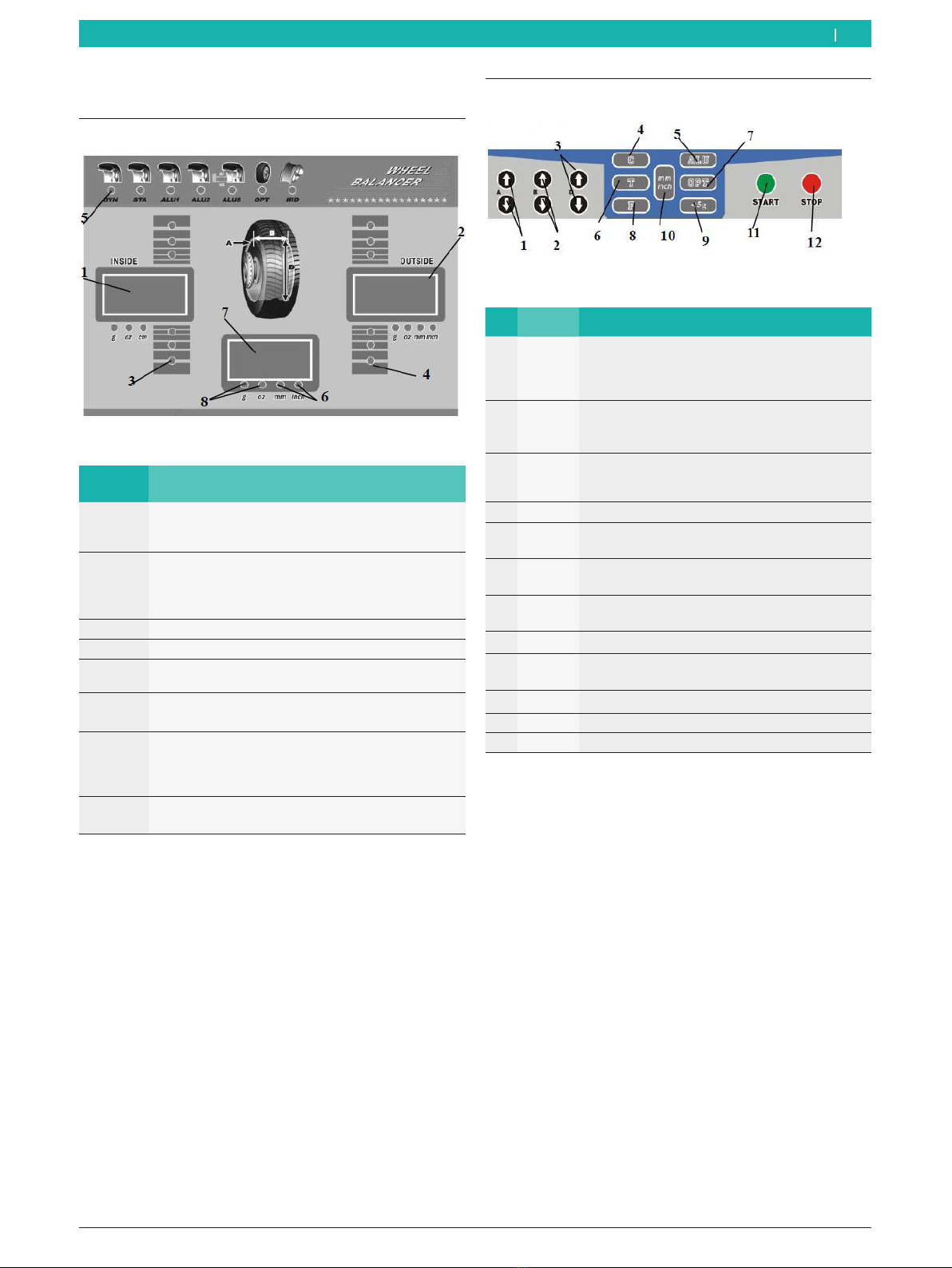

6.1 Clamping the wheel

6.1.1 Clamping on correct side

iThe usual clamping method is with aligned sides, a

quick and easy operation suitable for normal steel

rims. This method can only be used on steel rims

where distortion is not serious.

1. Push wheel onto flange shaft with internal face onto

lead screw.

2. Fit suitable cone (small surface facing inwards).

3. Press quick-locking nut, then rotate quick locking

nut on the flange shaft.

4. Release clamping device, then rotate quick locking

nut clockwise.

Fig. 11: Install wheel on correct side

1 695 600 538 2016-07-27|

30 | Start Line MT 601 D | Initial commissioningen

6.1.2 Clamping on opposing side

iChoose opposing side for clamping if the wheel is

badly distorted outside its central holder because

this process assures precise clamping action be-

tween the internal face of the steel rim mounting

and the flange shaft. It is also suitable for alloy rims,

especially for thick rims.

1. Attach spring to flange shaft.

2. Install a suitable cone (small surface facing out-

wards).

3. Install tire on flange shaft (locating surface of wheel

rim facing outwards).

4. Install with quick locking nut and big spacer plate.

5. Press down quick clamping tool, and rotate quick

locking nut onto lead screw.

6. Release clamping device, then rotate quick locking

nut clockwise.

Fig. 12: Clamping with spacer plate (large)

6.1.3 Clamping with special flange

iThe clamping method is suitable for wheels on

which the centre bore diameter is larger than the

diameter of the shaft flange.

1. Secure the flange to the lead screw (in any posi-

tion).

2. Fit tire to lead screw (locating surface of wheel rim

facing inwards).

3. Install a suitable cone (small surface facing out-

wards).

4. Press down quick clamping tool, and rotate quick

locking nut onto lead screw.

5. Release clamping device, then rotate quick locking

nut clockwise.

Fig. 13: Locating the wheel with a special flange

6.2 Removing the wheel

1. Turn quick locking nut anti-clockwise.

2. Loosen and remove quick locking nut while holding

the tire.

3. Remove wheel.

1 695 600 538 2016-07-27|

Program layout | Start Line MT 601 D | 31 en

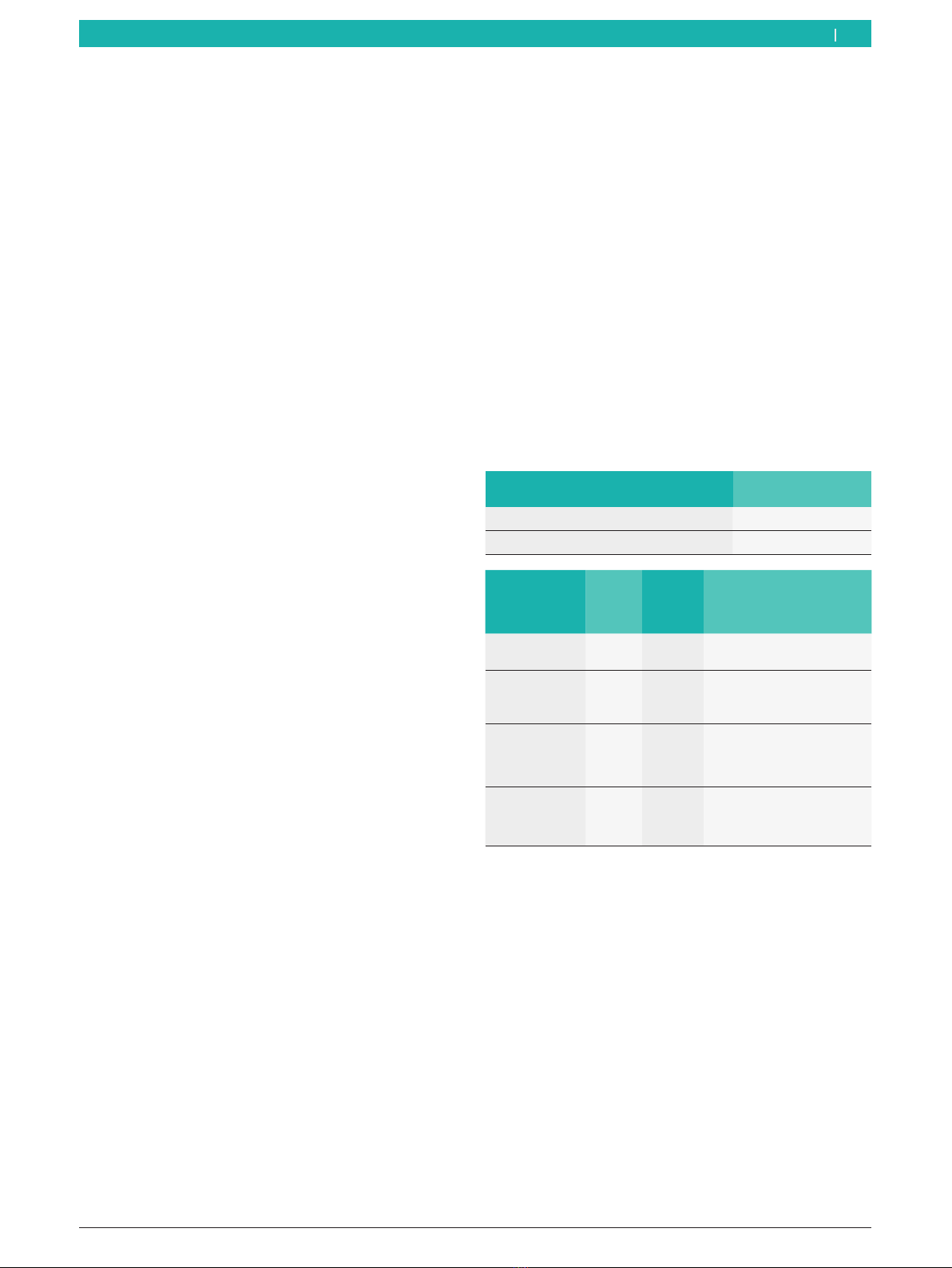

7.2 Control buttons

Fig. 15: Control buttons

No. Name Description

1 A Enter distance of wheel from MT 601 D by hand.

RArrow upwards, increase value,

RArrow downwards, reduce value.

2 B Enter rim width manually:

RArrow upwards, increase value,

RArrow downwards, reduce value.

3 D Enter rim diameter manually:

RArrow upwards, increase value,

RArrow downwards, reduce value.

4 C Calibration/reset button

5 ALU Dynamic imbalance measurement for alloy rims

(optional)

6 T Starting the self test to check the mainboard

(PCB)

7 OPT Starting the optimization process of tires and

rims

8 F Changeover between static / dynamic balancing

9 <5g Precision display of imbalance value below 5g

(0.3ounces)

10 mm/inch Changeover between millimetres/inches

11 START START button, start of measurement

12 STOP STOP button, stop measurement

!Only press key by hand. Do not press using sharp

objects.

7. Program layout

7.1 Display

Fig. 14: LED screen

No. Description

1 Left display panel A:

RDistance of rim to MT 601 D

RValue of imbalance on 1st balancing plane (inner)

2 Right display panel D:

RDiameter of rim

RValue of imbalance on 2nd balancing plane (out-

er)

3 Display of 1st balancing plane (inner)

4 Display of 2nd balancing plane (outer)

5 Display of balancing function and balancing method

6 Display of set unit

(millimetre or inch)

7 Average display panel B:

RWidth of rim

Rthe static value

RInstructions about the balancing weights

8 Display of set unit

(grams or ounces)

iAfter starting MT 601 D the screen displays the

machine code and three display windows show "8.0

5.7 14.0".

1 695 600 538 2016-07-27|

32 | Start Line MT 601 D | Program layouten

7.3 Keystroke combination for changing

between functions

Keystroke combination Description

+

Changing between grams and ounces

+

Automatic start of measurement

when closing the wheel-guard hood

+

Calibration, internal scales, A and D

values

+

Weight calibration

+

Calling up the "Attaching concealed

weights" program

iAfter the selected function has ended, the data are

retained.

7.4 Balancing programs

Symbol Description

DYN: Dynamic clip weights, on both

sides of the rim.

For the balancing of steel rims.

STA: Choose static balancing if no bal-

ancing weights are fitted to both sides

of a wheel or to the wheel(s) on a mo-

torbike.

ALU1: Balancing of light alloy rims by

attaching adhesive balance weights to

the inner and outer side of a rim.

ALU2: Attach clip-on balance weights

and adhesive balance weights to inside

of rim.

ALUS: Adhesive balance weights to any

locations on inside of rim

iWe recommend using the static balancing program

for wheel widths of less than 3.5inches (8.9cm).

For static balancing, to eliminate static imbalance,

adhesive balance weights can be attached to one

side of the rim or or adhesive balance weights can

be attached to the center of the rim. Only the di-

ameter is relevant to the imbalance result. No other

parameters are relevant.

iPress "F" to choose static balancing mode. Press

"ALU" to choose a different balancing mode.

"An LED displays the status of the balancing program.

iIn accordance with standard practice, the inside of

the tire faces the machine while the outside of the

tire faces away from the machine.

7.5 Standard program for input of rim

data

iThe form of input for rim data depends on the

choice of balancing program.

To balance a wheel successfully, please enter the fol-

lowing parameters:

¶Rim distance: Distance between wheel and

MT 601 D.

¶Rim diameter: The nominal diameter of the rim.

¶Rim width: In the standard program, to be read from

or measured on the rim.

1 695 600 538 2016-07-27|

Program layout | Start Line MT 601 D | 33 en

Automatic measurement of distance & diameter

1. Retract the rim-distance gage until the gage head is

close to the inner rim, and hold it there.

2. Whenever the warning tone sounds, return the

rim-distance gage to its starting position.

3. Read out test result from display window.

Fig. 16: Setting gage head for automatic measurement

iThe warning tone confirms the position.

"Left window shows A value (distance).

"Right window shows D value (rim diameter).

iEnter value for rim width manually.

Manual input of rim data.

1. Pull rim-distance gage onto rim.

2. Read off the scale value.

3. Using the "↑↓" keys, enter the relevant rim data for

A, B and D.

Fig. 17: Reading off scale value A (rim distance)

iThe rim width and rim diameter can also be read off

the rim.

Fig. 18: Measuring the rim diameter

iThe rim width and rim diameter can also be mea-

sured using a measuring compass.

Fig. 19: Measuring the rim width

"All data required are established and are keyed in.

1 695 600 538 2016-07-27|

34 | Start Line MT 601 D | Balancing the wheelen

7.6 Input of rim data for ALUS

iThe type of input for tire data depends on the choice

of balancing program. To balance a wheel success-

fully, please key in the following parameters.

RRim distance: Distance between wheel and machine

body.

RRim diameter: Nominal diameter of rim.

RRim width: The distance between inner and outer

balancing points.

!The balancing point depends on the choice of bal-

ancing program.

Automatic entry in ALUS balancing mode

1. Pull the rim-distance gage to inside of first adhesive

balance weight position and wait for warning tone to

confirm.

2. Pull in rim-distance gage to second inner adhesive

balance weight position and hold it there. After the

warning tone, return rim-distance gage to its starting

position.

Fig. 20: Automatic input in ALUS balancing mode

iAfter completing the process described above, the

ALUS balancing mode is selected automatically.

iThe ALUS balancing mode can also be selected

using the ALU key.

8. Balancing the wheel

WARNING – Incorrectly balanced wheels!

Risk of injury due to change in handling charac-

teristics of vehicle.

¶MT 601 D must stand on a flat surface and

must be secured.

¶Specified flange must be mounted on a

clean and grease-free flange shaft.

¶Use the specified accessories (cone, spac-

er rings).

¶Rim must contact flange accurately, re-

move any dirt.

¶Perform a reference measurement after

attaching balance weights.

8.1 Occupied area

CAUTION – Danger of injury if the wheel is

turning!

Danger of crushing of limbs when wheel is

turning for persons in the restricted area.

¶When the wheel is turning the operator

must stay in the work area.

¶There must be no persons in the restricted

area when the wheel is turning.

Fig. 21: Definition of working range

1 Area which can be occupied during the measurement

2 Area which must not be occupied during measurement

1 695 600 538 2016-07-27|

Balancing the wheel | Start Line MT 601 D | 35 en

8.2 Measuring imbalance

iThis measurement can be stopped at any time.

$Press the stop button.

$Raise wheel-guard hood.

iBefore measuring the imbalance, remove old bal-

ance weights, dirt etc. from the tire. Check to

ensure that tire is at its specified pressure. Check

locating surface of rim and distortion of installation

hole. Remove old balance weights.

1. Close the wheel-guard hood.

The dynamic mode is selected automatically.

Once the measurement is over, the value for im-

balance of the 1st balancing plane is displayed in

the left-hand display panel A and the 2nd balanc-

ing plane is displayed in the right-hand display

panel B.

2. Raise the wheel-guard hood once the measurement

process has ended.

8.3 Attaching balance weights

iAfter the balance weights have been attached, the im-

balance must be measured again to check the balance.

8.3.1 Standard procedures for clip-on weights and

adhesive weights

Attach balance weights to inside of rim, facing the ma-

chine.

1. Turn tire by hand.

The relevant indicator lights up and the warning

tone sounds once the balancing position has been

reached.

2. If a clip-on balance weight is selected, a balance

weight is fitted in the 12 o"clock position (see left-

hand display panel A for value). For adhesive balance

weights, use the automatic rim-distance gage.

Fit balance weights to outside of rim.

1. Turn tire by hand.

The relevant indicator lights up and the warning

tone sounds once the balancing position has been

reached.

2. Attach clip-on weight or adhesive balance weight in

the 12 o"clock position (see right-hand display panel D

for value).

Fig. 22: Attaching balance weights

8.3.2 ALUS balancing mode

iThe position of the adhesive balance weights is de-

termined by the automatic rim distance gage.

iThe left-hand display panel A shows the 1st bal-

ancing plane, while display panel D shows the 2nd

balancing plane.

1. Turn tire by hand.

The relevant indicator lights up and the warning

tone sounds once the imbalance point is reached.

2. Actuate pedal to hold the flange shaft.

3. Fit the required adhesive balance weights to the

head of the rim-distance gage.

4. Pull out the rim-distance gage.

5. If the left-hand window displays "――口" and if the

warning tone sounds, the point directly on the head

of the rim-distance gage is the balancing position.

iIn this way, attach weights to both balancing planes

of the wheel. The pedal light lights up while the ped-

al is being depressed to hold the flange shaft firmly.

8.3.3 Splitting the balance weights (HID program)

iFor ALUS, the balance weights can be split to con-

ceal them behind the spokes.

iAfter measurement, to split the balance weights,

please press "T+OPT". If Hide lights up, this means

that the HID function can be used.

1. Press the "T+OPT" key.

Indicator panel B displays 12o"clock.

2. Rotate tire until corresponding position on outer

side lights up. Press "ALU" key for confirmation

purposes.

3. Indicator panel B displays "-1-". Rotate tire, move

left-hand spoke with imbalance point to 12o"clokc

position on the flange shaft. To confirm, press "ALU"

key.

4. Indicator panel B displays "-2-". Rotate tire, move

left-hand spoke with imbalance point to 12o"clokc

position on the flange shaft. To confirm, press "ALU"

key.

5. Indicator panel B displays "SPD". On the outside of

the tire are two split balancing points. Correspond-

ing position on the outer side lights up, actuate

pedal to hold flange shaft in place.

6. Fit the required adhesive balance weights to the

head of the rim-distance gage.

1 695 600 538 2016-07-27|

36 | Start Line MT 601 D | Balancing the wheelen

8.4 Attaching the clip-on weights

iTo attach the clip-on weights, you need to use coun-

terweight pliers.

Fig. 23: Balance weight pliers

a. Balance hammer jaw

b. Hammerhead

c. Hook rolling groove

d. Metal shears for removal of metal

1. Find balancing position, then take off clip-on

weights.

2. Fixed the clip-on weights to rim with hammerhead.

iThe pliers end of the counterweight pliers is needed

to remove balance weights.

iCarefully remove the tire on completion of all bal-

ancing work to prevent collision impact with flange

shaft.

8.5 Attaching adhesive balance weights

!Remove all weights using adhesive balance weight

remover. To prevent damage to the rim, do not use

any other sharp objects for this job.

1. Set required number of balance weights on head of

rim-distance gage.

2. Extract rim-distance gage once window B displays

"――口" and the warning tone sounds.

3. Rotate rim-distance gage, fit it closely to the tires,

then attach weights to the rim.

4. Repeat process for the adhesive balance weight and

repeat the 2nd balancing plane.

Fig. 24: Balancing plane 1 – Attach the adhesive balance weights

Fig. 25: Balancing plane 2 – Attach the adhesive balance weights

7. Pull out the rim-distance gage. If window B displays

"――口" and if the warning tone sounds, the point

directly on the head of the rim-distance gage is the

balancing position.

8. Continue rotating tire manually to secure other bal-

ance weights behind the spokes.

Repeat steps 5 and 6.

1 695 600 538 2016-07-27|

Imbalance minimization | Start Line MT 601 D | 37 en

9. Imbalance minimization

If great wheel imbalance is measured (e.g. static im-

balance greater than 50g), it is advisable to perform

wheel matching by using the imbalance of the rim to

provide compensation for the static imbalance of the

tire (imbalance minimization). The first step involves

rotating the tire 180 degrees on the rim. Additional

minimization can then be achieved by rotating the tire

further. The matching program provides assistance with

this minimization process.

!Work as accurately as possible throughout the entire

procedure.

1. After measurement and running a balance cycle, if

the result is over 50g, press "OPT" button to call up

the function.

2. Rotate wheel to inner imbalance position, press

"OPT" button, then monitor displays "180".

3. Make double mark, on tire and rim (external side 12

o"clock position).

4. To achieve even greater precision, also make marks

on cone and shaft at 12 o"clock position.

5. Remove wheel.

6. Pull tire off rim using tire changing machine.

7. Mount tire again, but this time with mark on tire in

position 180 degrees directly opposite to the mark

on the rim.

8. Inflate tires and clamp back onto MT 601 D.

9. This time, marks on rim, cone and flange shaft

should all be at 12 o"clock position while mark on

tire should be at 6 o"clock position.

10.Switch on MT 601 D by pressing START button, or by

lowering the wheel-guard hood.

11.If MT 601 D stops rotating, turn wheel to position of

inner imbalance and only apply a mark to the rim.

Outer face at 12 o"clock position.

12.Rotate wheel to outer imbalance position, make an-

other new mark, this time only on the tire, outer side

at 12 o"clock position.

13.Remove wheel.

14.Pull tire off rim using tire changing machine.

15.Mount tire again but this time with new mark on tire

precisely aligned with new mark on rim.

"Minimization of imbalance is now finalized.

10. Adjustment

Operator error or other reasons may give rise to a

fault or malfunction. With the following adjustments,

theMT 601 D can be put back into service.

iTo set up MT 601 D, the correct parameters must

be used to assure the balancing precision of the

MT 601 D.

1. Press and hold down the C-key then, half a second

later, also press the T-key. The indicator panel dis-

plays "CAL CAL CAL", and the LED for the relevant

window flashes. If LED stops flashing, release the

keys.

2. Press A key "↑", A key "↓", and ALU key, window

now shows "re""05".

"Left and right windows now display symbols and

values.

Function Key

Change of setting/value B-key "↑""↓"

Perform next setting A-key "↑"

Adjustment Left-

hand

window

Right-

hand

window

Description

Residual imbal-

ance

re 05 Setting of residual imbal-

ance not displayed

External gage

On/Off

aut On or

Off

Adjustment of external

gage On/Off

Compensation,

internal gage

da-1 000 Adjustment of compensa-

tion value on internal gage

Compensation,

external gage

db-1 000 Adjustment of compen-

sation value for external

gage

iThe value displayed in the right-hand window is the

normal stored value.

iIn the event of data loss or replacement of the

computer PCB, the standard memory must always

be calibrated in accordance with the details on the

label inside the machine.

!If above operation is not successful, please contact

Customer Service.

1 695 600 538 2016-07-27|

38 | Start Line MT 601 D | Faultsen

11. Faults

!If the error message persists, contact customer service.

iOther possible malfunctions are primarily of a technical nature and are to be checked and if necessary recti-

fied by a qualified engineer. Please always contact the Customer Service of the dealer authorized to trade in

Beissbarth-workshop equipment.

iFor rapid assistance it is important to quote the details on the rating plate (label on MT 601 D) and the nature

of the problem when calling.

Fault Cause Remedy

No display when powering up RFuse defective

RSwitch defective

RChanging the fuse

RReplace switch

"Err1" appears on screen display Press START key and keep it held down Contact customer service

"Err2" appears on screen display RNo wheel installed in machine

RMount flange and check lead screw for back-

lash.

RWheel incorrectly installed and not secured.

RMotor belt too loose or too tight

RClamp tire and try once again

RReinstall flange

RReinstall the wheel according to 6.1

"Err3" appears on screen display Imbalance value of tire is too high To check, replace wheel and, if necessary,

perform a self check.

"Err4" appears on screen display Position sensor error Contact customer service

"Err5" appears on screen display Wheel-guard hood not closed Close wheel-guard hood

"Err7" appears on screen display Stored data missing Enter memory values and repeat self-calibra-

tion

Only 00-00 is displayed. No other

value.

RSensor head wire is broken or has a loose

contact

RStored data missing

Contact customer service

Every rotational value range has

been exceeded

RThe tire is dirty or the center contact surface

on the rim is distorted

RThe sensor head has become damp

RThe quick locking nut is not securely mount-

ed

RPower supply is too weak

RTire pressure is too low

RMachine not fixed

RReplace wheel

RReset sensor head

RUse stable power supply

RInflate tire to correct pressure.

RSecure machine to a flat concrete floor

with an expansion bolt.

Powers down within 10 seconds. RPower supply connection is loose

RFault

RCheck power connector

RRestart after powering down

The imbalance value is not correct.

Faults on left and right and very dif-

ficult to achieve imbalance of 00.

RSensor head defective

RProgram error

RRepeat self-calibration

Does not brake as soon as value is

displayed

RBrake system defective

RExternal fault

RRestart the machine

Second imbalance value exceeds 10g. RInside of rim hole not regular.

RLead screw incorrectly installed.

RTo check, replace wheel

RReinstall flange (see Chapter 5.1)

Self-calibration shows "Err8" RNo 100g self-calibration weight

RPower wire on pressure sensor is broken

RComputer PCB is defective

RPower supply PCB is defective

RAdd 100g weights

RCheck cable and connect it securely

100g is displayed as an error value RStored parameter is impaired.

RTire error value is too high

RKey in data again from label inside ma-

chine.

RTo check, replace wheel

1 695 600 538 2016-07-27|

Service | Start Line MT 601 D | 39 en

12. Service

12.1 Cleaning and Maintenance

!Before cleaning and servicing, switch off the

MT 601 D and disconnect mains plug.

!Do not use any solvent-based cleaning agents. Use

alcohol or similar cleaning agents to clean plastic

parts.

For perfect operation and to guarantee the perfor-

mance capability of MT 601 D, the following work must

be carried out at the intervals indicated:

Scope of service work

Weekly

Semi-annually

Treat and clean moving mechanical parts with spray oil

or kerosene and lubricate with engine oil or a suitable

grease.

x

Performing the check measurement x

Tab. 1: Maintenance and calibration intervals

12.2 Spare and wearing parts

The manufacturer cannot accept any liability for dam-

age arising from the use of non-genuine replacement

parts.

Designation Order number

Centering flange 1 695 602 400

Centering cone 42 - 65mm 1 695 632 500

Centering cone 54 - 80mm 1 695 652 862

Centering cone 75 - 110mm 1 695 605 600

Balance weight pliers 1 695 606 500

Manual vernier caliper 1 695 629 400

Measuring compass 1 695 602 700

Balance weight 1 695 654 377

Balance weights, calibrated 1 695 654 376

Label, electrical power supply 230 V 1 695 101 269

Label, electrical power supply 110 V 1 695 100 854

Direction of wheel rotation label 1 695 653 878

Tab. 2: Spare and wearing parts

12.3 Self-calibration

12.3.1 Self-calibration of system

1. Press and hold down the C-key then, half a second

later, also press the T-key. The indicator panel dis-

plays "CAL CAL CAL". All LEDs light up and flash. If

LED stops flashing, release the keys.

2. Press START key and start the test. When the indi-

cator panel displays "ADD" "12H", then press ALU to

confirm.

3. Whenever the indicator panel displays "100" "ADD",

then attach 100g weights to any desired positions

on outside face of wheel.

4. Start test run by pressing START key.

5. Whenever the indicator panel displays "ADD" "100",

then attach 100g weights to any desired positions

on inside face of wheel.

6. Press START key and start the test. Indicator panel

displays "END" "CAL".

7. Press START key and start the test.

8. Check result.

Description Result

Value is dis-

played

If "00""100" is displayed, ±4g deviation is

allowed.

Phase differ-

ence

All outside indicators light up, 100g

weights underneath flange shaft, ±4° error

is permitted.

"System self-calibration is now finalized.

iAfter replacement of computer PCB or pressure

sensor, the system must be recalibrated.

12.3.2 Automatic self calibration of the rim-distance

gage

1. Ensure that rim-distance gage is in starting position.

Press STOP and "<5g". The indicator panel displays

"CAL" "100".

2. Extract rim-distance gage 100mm. Press ALU key to

confirm. Indicator panel displays "CAL" "215".

3. Pull rim-distance gage out to 215mm, let head of

rim-distance gage make contact with top of inside of

tire. Press ALU key to confirm.

4. Check the result.

Description Result

The values "000" "000" "000"

are displayed

Calibration successful

"CAL" "100" is displayed Repeat self-calibration

1 695 600 538 2016-07-27|

40 | Start Line MT 601 D | Faultsen

12.4 Self-inspection

1. Press T-key. Displays light up one after the other,

from left to right. After the system test of the LEDs,

[ ][POS][ ] appears on the display screen.

2. Rotate tires until LED starts to flash. If the single

tooth on the flange shaft passes the sensor, the

display screen shows [ ][POS][ 0 ].

3. With each round, [ 0 ] appears once in the right-

hand window. When rotated in the opposite direc-

tion, the ALUS LED starts to flash.

iThe self-test program tests the position sensor and

checks that the LED is functioning normally.

12.5 Structure and setting of pressure

sensor

1. Unfasten nuts 2, 3, 4 and 5.

2. Unfasten nut1, unscrew and remove vertical rod.

3. Remove or replace pressure sensor for checking

purposes.

4. Place the measuring sensors longitudinally on the

vertical rod and transversely on the horizontal rod.

The positive terminals on both measuring sensors

should point downwards.

5. After connecting horizontal and vertical rods, screw

vertical rod into iron beam 1-1.5cm.

6. Visually check to ensure that flange shaft and ma-

chine body are perpendicular. If necessary, use nut 2

or 3 to adjust its position.

7. Tighten nut 4 by hand, then tighten for one half turn.

Then tighten nut 5 with a wrench.

8. Tighten nut 2 by hand, then tighten for one half turn.

Then tighten nut 3 with a wrench.

9. After installation, use an iron wire to short-circuit

connector on pressure sensor to discharge it.

12.6 Adjusting the belt tension

1. Remove the cover panel.

2. Unfasten motor screw, turn motor until belt tension

is OK, at which point it should be possible to press

down belt by up to 4mm.

3. Retighten motor screw then install cover.

12.7 Changing the fuse

iInstall two fuses in the power supply board and

always replace them after every malfunction.

iBefore maintenance on the pressure sensor, the ma-

chine must be powered down because the computer

PCB may otherwise burn out during removal of the

sensor head. After maintenance work on the pres-

sure sensor, perform an endurance test.

iIf the size of the clamped tire exceeds 15", bridge

pins 1 and 4 on the computer PCB. Let the machine

run continuously in extended automatic operating

mode for about 15 minutes. Then turn off the power

for about 30 minutes. Then switch the machine back

on again. Perform the endurance test 5 times or

more.

Table of contents

Other Beissbarth Wheel Balancer manuals

Popular Wheel Balancer manuals by other brands

Unitrol

Unitrol AT-26 Instruction booklet

John Bean

John Bean B 2000P Operator's manual

Snap-on Equipment

Snap-on Equipment JohnBean B2000P Series Operator's manual

Aston Global

Aston Global ADP-2000L user manual

Mondolfo Ferro

Mondolfo Ferro MT 2450 Operator's manual

Sicam

Sicam SBM V655 Original instructions

M&B Engineering

M&B Engineering WB 355 Original instruction manual

Central Machinery

Central Machinery 47211 Assembly and operation instructions

Atlas Equipment

Atlas Equipment Edge 401 unpacking instructions

Endo

Endo SBS3W instruction manual

Cormach

Cormach TOUCH MEC 1000 SONAR Technical support manual

Eagle

Eagle EB-1200 Instruction & maintenance manual