Aston Technologies Inc. www.astontechusa.com

- 10 -

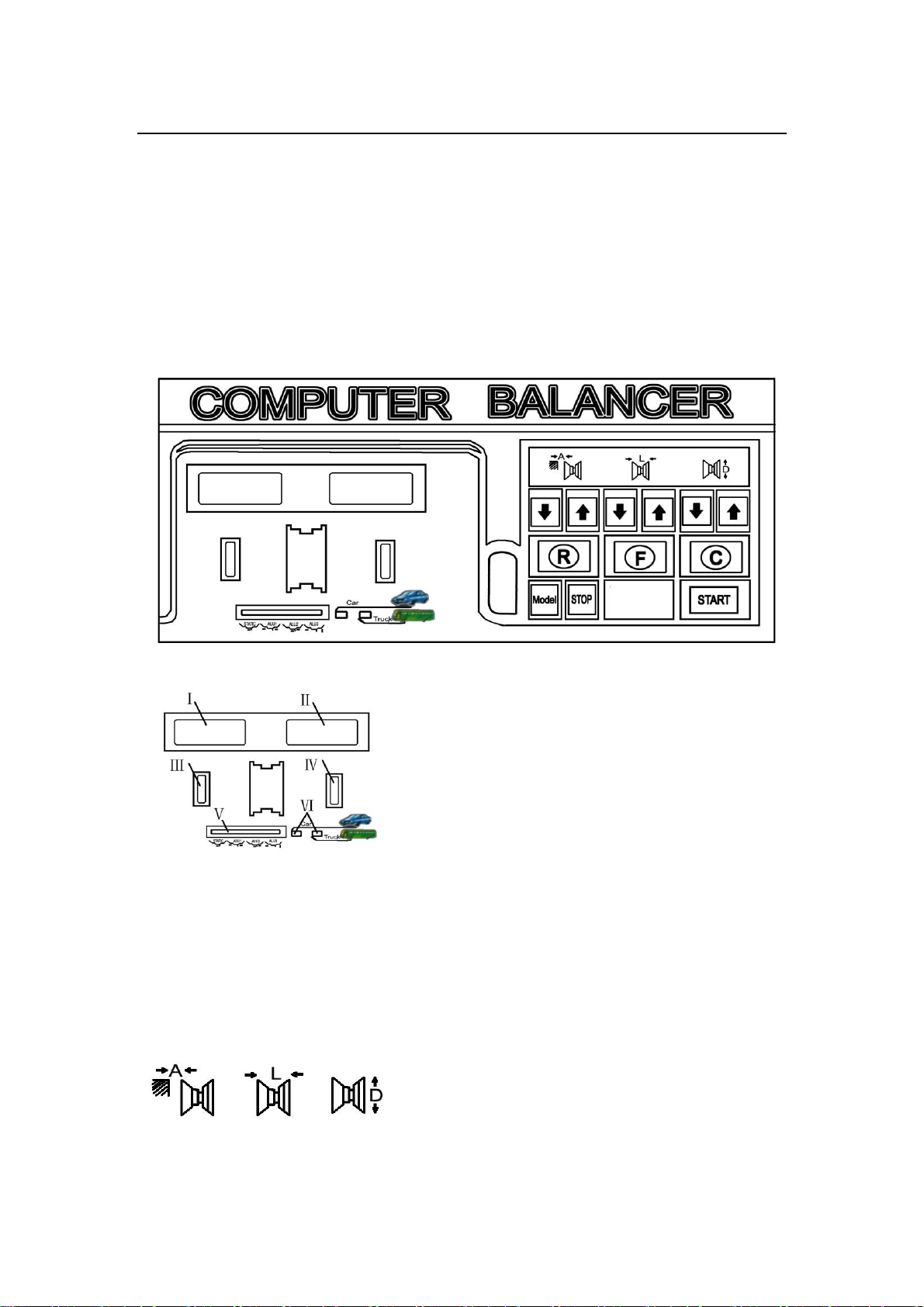

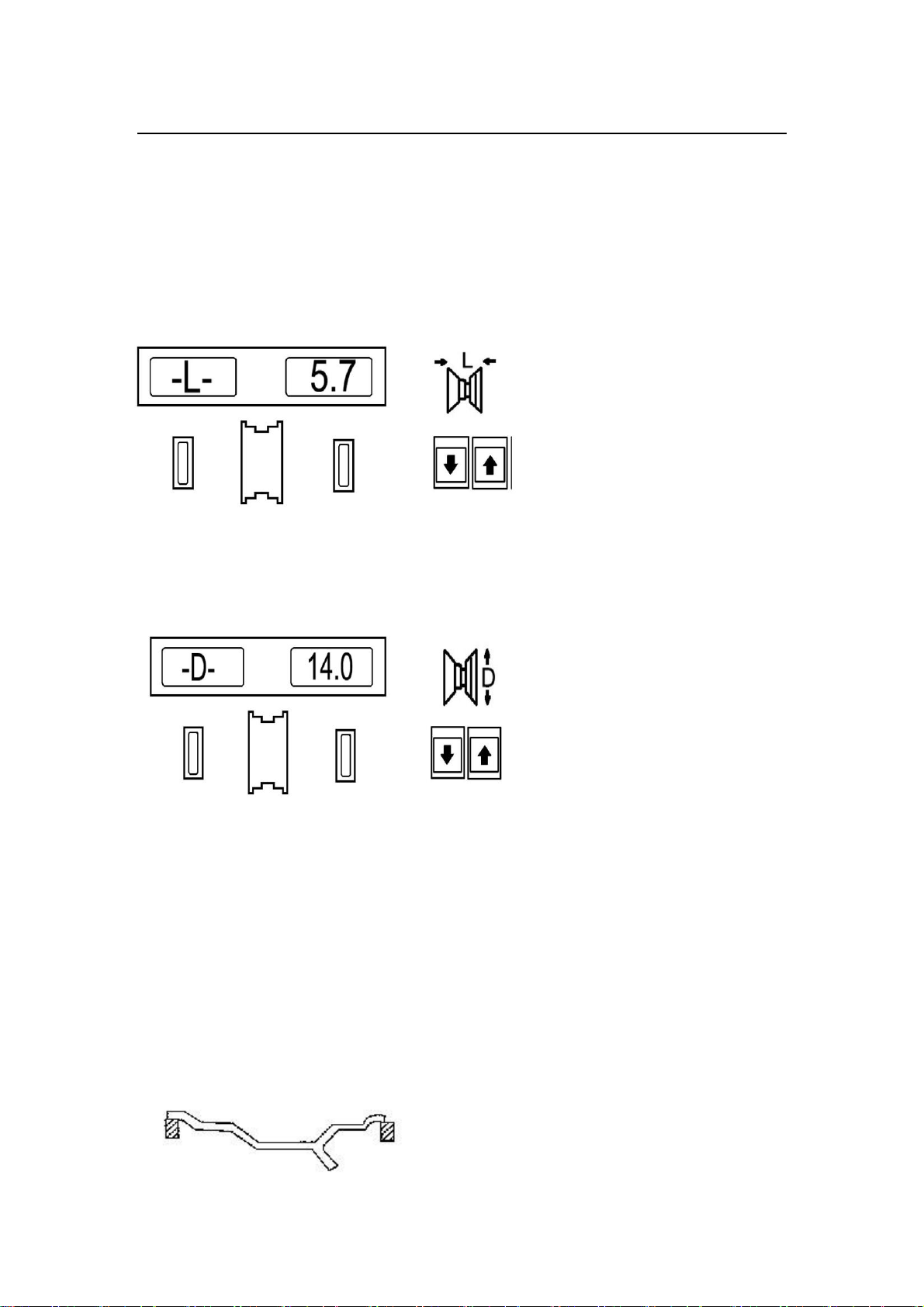

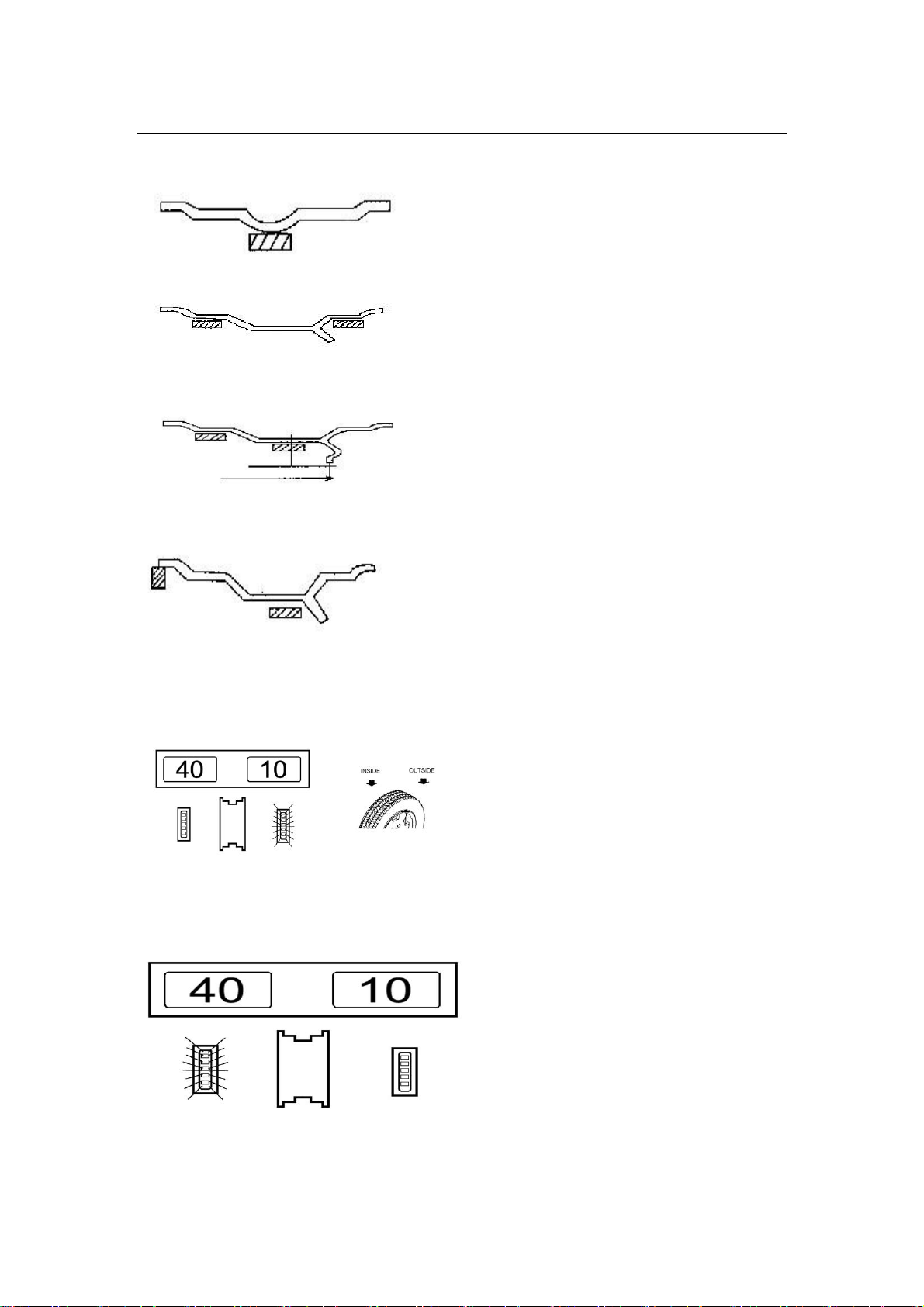

3. Rotate the tire slowly,

when all the outer indicator

LEDs light, shown in Fig.4,

place 10g lead block at twelve

o’clock position on the outside

of rim.

4. Continue to rotate the

tire again until a zero (0)

appears in the outer LEDs

window. After balancing

ends, demount the tire. If

testing the tire again, do not

turn off power supply.

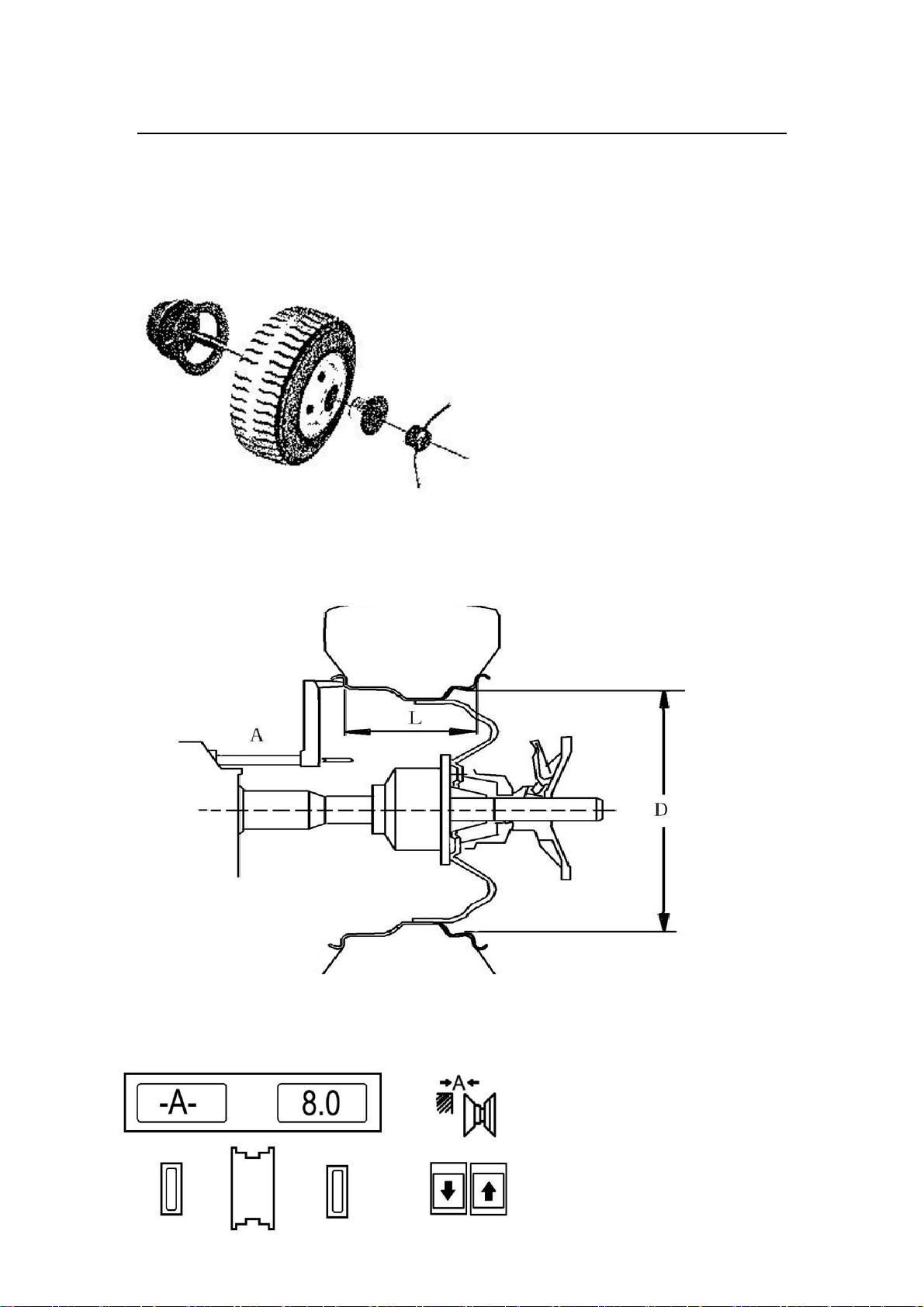

Caution: 1. when the single-phase power is turned on, rotate the tire by hand

to extend the motor life.

2. Check whether input dimension is wrong, press the key R to

automatically defect the value A, L, D.

3. Check whether balancing modes accord with the tire structure.

(See detailed 4.4 balancing modes)

4. Check whether the lock washer nut is tightened.

5. When dismount the tire, care is taken to carry the tire lightly and

do not impact the main shaft.

6. When balancing using balancing block with clamp, nail lightly with

balance weight on the tire edge. After balancing ends, knock it on

the floor and do not knock hard on the main shaft to avoid

damaging the sensor.

5. MAINTENANCE

5.1 Self-calibration

Self-calibration is completed in the factory. When using the machine many

years later and replace the parts of machine or doubt that balancing error is

much greater, self-calibrate over again. Select a medium-sized tire (13 inches

or 14 inches), install it on the main shaft, input the value A, L, D of this tire.

Caution: Select the better tire to self-calibrate, input the correct dimension,

or else result in calibrating inaccurately.