DEMOUNTING

- Clamp the whell on the self-centering chuck

and raise it until the rim flange touches the bead

breaking tool. Using the control and selector

deflate the tyre and begin the bead breaking

operation ( Fig. 19 or Fig. 16 ). Use the pedal

and selector to graudally advance the bead

breaking roller turning the spindle continuously.

- Lubricate the bead and the rim flange with the

special lubricant keeping the wheel in movement.

When the operation is finished rotate the tool by

180º, removing the pin. Repeat the bead

breaking on the other side of the tyre in the same

way.

- Tilt the toll arm and move it back of the tyre

pressing the pedal. Using the lever swing the tool

into position 2 then re-attach the tool arm to the

trolley. Use the control to move the tool againts

the tyre with the control until the bead is hooked

on Fig. 20. Put the tyre into tension moving the

rim away from the tool so that the bead enters

the channel.

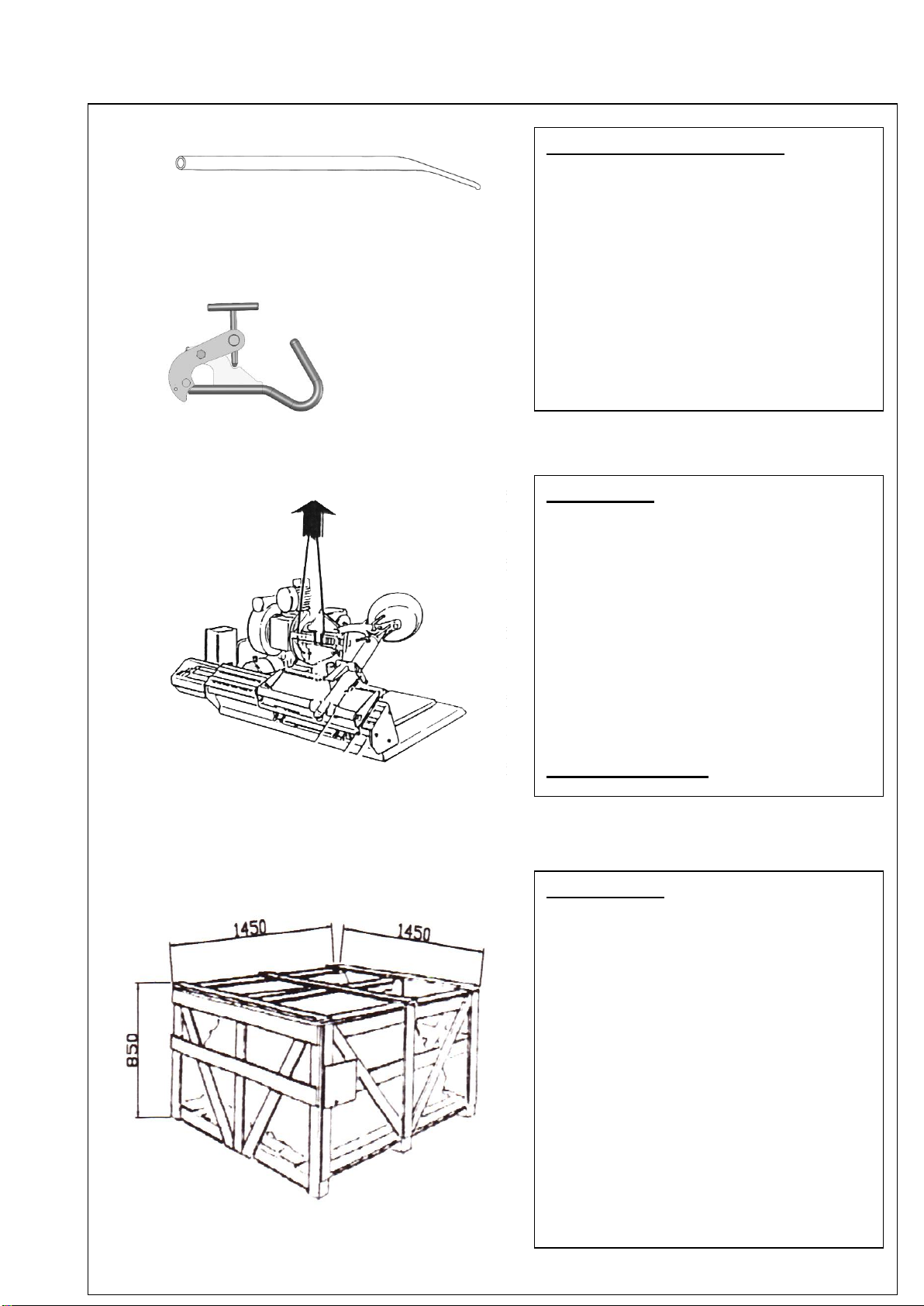

- Insert the special lever ( Fig.21/Fig. 8 ) between

the rim and bead to the right of the tool to ensure

that the bead remains on the tool. Move the rim

towards the tool again ( Fig. 21 ) until the front

bead has completely come out. Rest the wheel

on the trolley platform to obtain working space for

the easy removal of the inner tube.

- To demount the back bead proceed as shown

in Fig. 12 rotate the tool by 180º, insert it

between the rim and the bead, move it against

the rim flange and insert the lever ( Fig 20 ) and

then rotate the spindle in clockwise direction until

the operation is complete.

MOUNTING

- Place the tyre on the rim, clamp the special

pincers( Fig. 18/Fig. 9 ) on the front rim flange

and position the tool with reference to the edge

of the rim flange.

- Rotate the spindle in a clockwise direction until

the back rear bead is fully mounted.

- İnsert the inner tube and support the wheel on

the trolley platform ( Fig. 18 ) to assist the

operation.

- Re-position the tool near to the valve with the

relevant referance point on the edge of the rim.

Clamp the pincers ( Fig.18/Fig. 9 ) to the left of

the tool and rotate the wheel clockwise making

sure that the bead is inside the rim channel.