Beissbarth MT ZERO 6 LCD Quick guide

MT ZERO 6 LCD

MT ZERO 6 LCD OEM

MT ZERO 6 LCD BMW

Radauswuchtmaschinen

Wheel Balancers

Radauswuchtmaschinen Wheel balancer

Equilibratrici per ruote

de

Betriebsanleitung

en

Operating instructions

fr

Mode d’emploi

Equilibreuses de roue

es

Manual de istrucciones

Máquinas de equilibrado de ruedas

it

Istruzioni originali

Manuale operatore

Übersetzung der

Originalbetriebsanleitung

Translation of the original

operating instructions

Traduction du manuel d'utilisation

d'origine

Traducción de las instrucciones

originales

1 695 600 968 2019-01-28| Beissbarth GmbH

68 | MT ZERO 6 LCD |

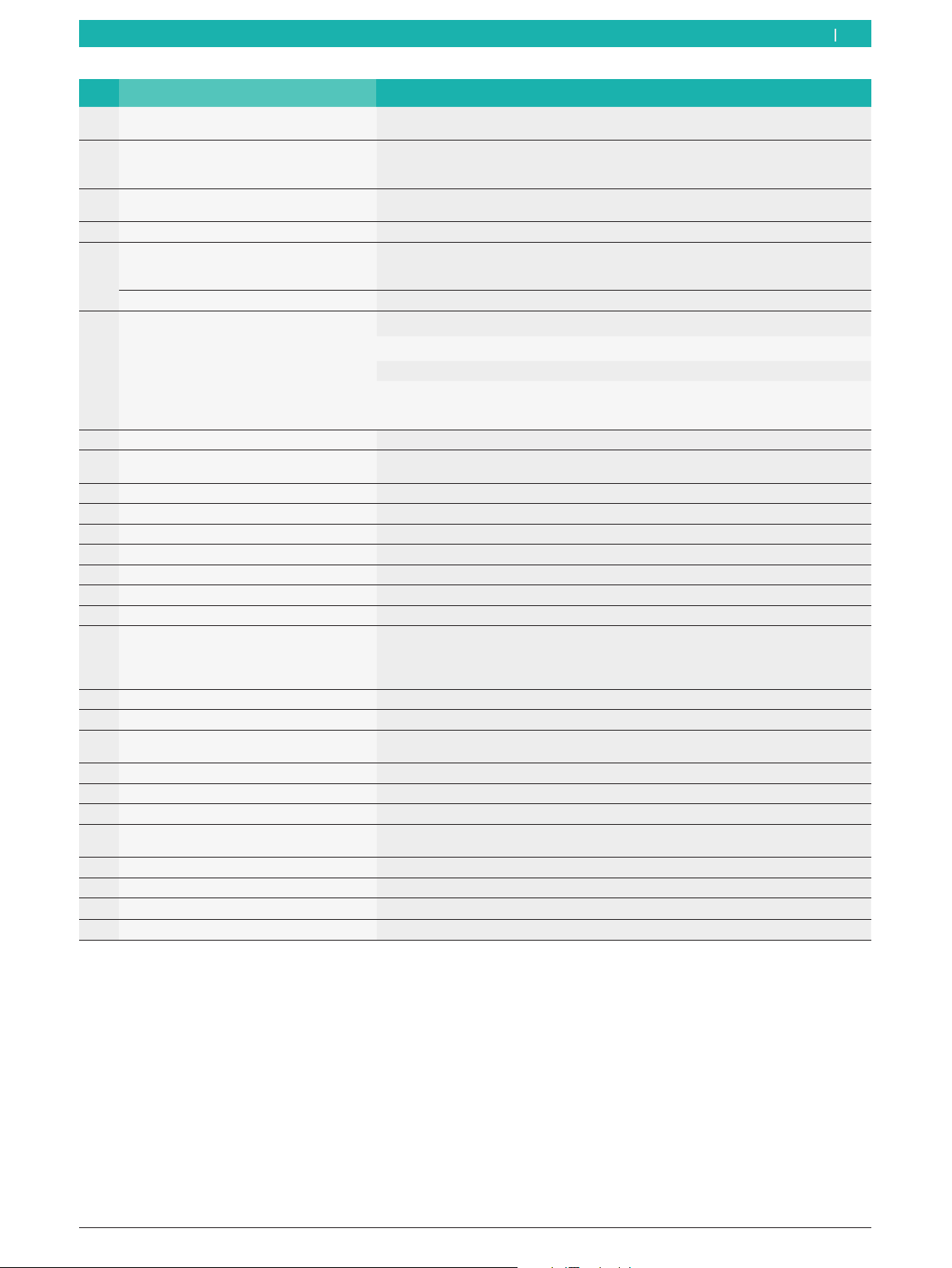

1. Symbols used 70

1.1 In the documentation 70

1.1.1 Warning notices -

Structure and meaning 70

1.1.2 Symbols in this documentation 70

1.2 On the product 70

1.2.1 Safety symbols 71

1.2.2 Certification symbols 71

1.2.3 Symbols on the product 72

2. User information 73

2.1 Important notes 73

2.2 Safety instructions 73

3. Product description 74

3.1 Intended use 74

3.2 Prerequisites 74

3.3 Scope of delivery 74

3.3.1 MT ZERO 6 LCD 74

3.3.2 Parts set, mechanical quick-action

clampxxx 75

3.3.3 Mechanical quick-action clamp (NA)

parts set 75

3.3.4 Parts set, pneumatic quick-action

clamp 75

3.3.5 Equipment 76

3.4 Special accessories 77

3.5 Component description 78

4. Initial commissioning 80

4.1 Unpacking 80

4.2 Transporting an handling the wheel balancing

machine 80

4.3 Floor mounting 81

4.4 Installing the wheel guard moving unit 81

4.5 Installing the support frame with sonar 83

4.6 Installing the wheel guard 84

4.7 Preparing the electrical connectors 84

4.8 Mounting the digital control panel 86

4.9 Digital control panel connections 87

4.10 Installing the clamping tool holders 88

4.11 Connecting the compressed air 88

4.12 Electrical connection 89

4.13 Ignition 89

4.14 MT ZERO 6 LCD calibration 89

5. Fitting and removing the flange 90

5.1 MT ZERO 6 LCD AWx 90

5.1.1 Removing the flange 90

5.1.2 Fitting the flange 90

5.2 MT ZERO 6 LCD AWxP 91

5.2.1 Removing the flange 91

5.2.2 Fitting the flange 91

6. Attaching and removing a wheel 92

6.1 MT ZERO 6 LCD AWx 92

6.1.1 Attaching a wheel 92

6.1.2 Removing a wheel 92

6.2 MT ZERO 6 LCD AWxP 93

6.2.1 Attaching a wheel 93

6.2.2 Removing a wheel 93

6.2.3 Wheel removal in the event of faults 93

7. Operation 94

7.1 Control keys 94

7.2 Display 94

7.2.1 Basic balancing screen 94

7.2.2 Data collection screen 95

8. Balancing the wheel 95

8.1 Important notes on balancing 95

8.2 Working range 96

8.3 Basic wheel balancing procedure 96

8.4 Selecting the type of vehicle 96

8.5 Balancing programs overview 97

8.6 Automatic balancing program selection 98

8.7 Manual balancing program selection 100

8.8 Acquiring rim data automatically 100

8.8.1 Standard, ALU1 (PAX1), ALU4, ALU5 and

all static balancing programs 100

8.8.2 ALU2 (PAX2) and ALU3 101

8.9 Manual rim data measurement 101

8.9.1 Standard, ALU1 (PAX1), ALU4, ALU5 and

all static balancing programsxxx 101

8.9.2 ALU2 (PAX2), ALU3 102

8.10 Measuring imbalance 103

8.11 Attaching balance weights 103

8.11.1 Overview of tools for attaching the

balance weights 103

8.11.2 Positioning the wheel 104

8.11.3 Splitting balance weights (split

program) 106

en

Contents English

1 695 600 968 2019-01-28|Beissbarth GmbH

| MT ZERO 6 LCD | 69

8.12 Attaching the clip-on balance weights 108

8.13 Attaching adhesive balance weights 109

8.13.1 Overview of tools used 109

8.13.2 With the electronic rim distance

gauge 109

8.13.3 With manual vernier caliper 110

8.14 Attaching adhesive balance weights by laser

indicator 111

9. Imbalance minimization 112

10. Menu navigation 114

10.1 Menu access 114

10.2 Settings menu 114

10.3 Calibration menu 114

10.4 Statistics menu 114

10.5 Aids menu 115

10.6 Service menu 115

10.7 User Diagnostics menu 115

11. Faults 116

12. Maintenance 118

12.1 Cleaning and maintenance 118

12.2 Service intervals 118

12.3 Spare and wearing parts 118

12.4 Maintenance work 118

12.4.1 Removing condensate 118

12.4.2 Recommended oil mist lubricator

lubricants 118

12.4.3 Topping up the oil in the oil mist

lubricator 118

12.4.4 Changing the oil in the oil mist

lubricator 119

12.4.5 Setting the lubricating oil flow 119

12.5 Diagnosis 119

12.6 Calibration 119

12.6.1 Calling up the calibration menu 119

12.6.2 Calibrating the flange 119

12.6.3 Calibrate the electronic rim-distance

gauge and the sonar probe. 120

12.6.4 Calibrating by wheel and balance

weight 121

12.6.5 Reference measurement 122

12.6.6 External laser indicator calibration 123

13. Decommissioning 126

13.1 Temporary shutdown 126

13.2 Change of location 126

13.3 Disposal and scrapping 126

13.3.1 Substances hazardous to water 126

13.3.2 MT ZERO 6 LCD

and accessories 126

14. Technical data 127

14.1 MT ZERO 6 LCD 127

14.2 Temperatures 127

14.3 Working range 127

14.4 Dimensions and weights 127

en

1 695 600 968 2019-01-28| Beissbarth GmbH

70 | MT ZERO 6 LCD | Symbols used

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible.

1. Symbols used

1.1 In the documentation

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people

in the vicinity. Warning notices also indicate the

consequences of the hazard as well as preventive action.

Warning notices have the following structure:

Warning

symbol KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of

failure to observe action and information

given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if

instructions not observed

DANGER Immediate impending

danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible

intermediate result.

"Final result There is a visible final result on

completion of the instruction.

en

1 695 600 968 2019-01-28|Beissbarth GmbH

Symbols used | MT ZERO 6 LCD | 71 en

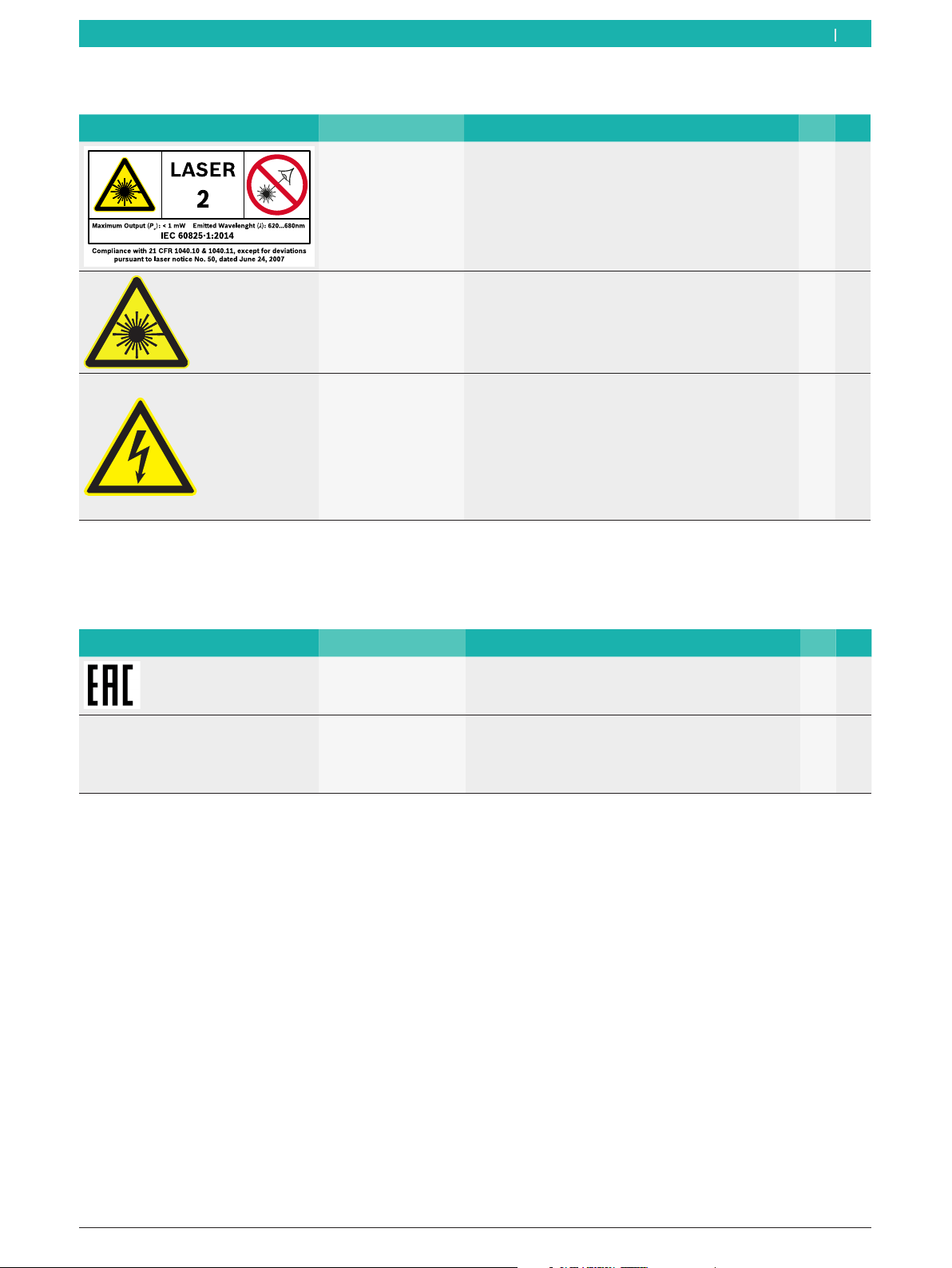

1.2.1 Safety symbols

Symbols Description Definition M1P2

WARNING

There are devices fit-

ted to the product

that use laser beams!*

Indicates the type and properties of the laser

equipment used on the product and the immediate

risks of exposure.

X X

WARNING

Source of the laser

beam!*

Indicates the positions of the laser devices. X X

DANGER – live parts

when opening the

MT ZERO 6 LCD!

Risk of injury, heart failure or death from electric shock

when touching live parts (e.g. main switch, circuit

boards).

RWork on electrical systems or equipment must only

be performed by qualified electricians or trained

personnel under the guidance and supervision of an

electrician.

RDisconnect the MT ZERO 6 LCD from the mains

voltage system before opening.

X X

* Version with positioning laser only

1M = MT ZERO 6 LCD AWx

2P = MT ZERO 6 LCD AWxP

1.2.2 Certification symbols

Symbols Description Definition M1P2

EAC identification Confirms the suitability of the machine for Russia. X X

Type plate Machine model, 10-digit ID number, voltage (V),

frequency (Hz), connected load (kW), amperage (A),

max. supply pressure (kPa), degree of protection

(IP), year of manufacture, CE mark, EAC mark, serial

number of the machine, barcode.

X X

1M = MT ZERO 6 LCD AWx

2P = MT ZERO 6 LCD AWxP

1 695 600 968 2019-01-28| Beissbarth GmbH

72 | MT ZERO 6 LCD | Symbols useden

1.2.3 Symbols on the product

Symbols Description Definition M1P2

Direction of wheel

rotation

The wheel must turn in the direction of rotation

indicated (see sec. "Checking the direction of

rotation").

X X

Compressed-air

supply

After the compressed-air supply has been

disconnected, the machine parts under pressure will

move to their resting positions automatically.

X

Start/stop balancing Adhesive label on the wheel protection casing.

Indicates the direction for starting and stopping the

rotation of the flange (wheel).

X X

Intended voltage

supply

Information on the voltage set and safety warning X X

Releasing the

pneumatic flange

In case of a faulty compressed-air valve, proceed as

specified to remove the wheel.

X

STOP! Using the pedal with

single function

Adhesive label on the body above the pedal.

Indicates the functions depending on how it is used.

RPedal down:

lock shaft/wheel.

X

STOP! Using the pedal with

double function

Adhesive label on the body above the pedal.

Indicates the functions depending on how it is used.

RPedal up:

lock/release the pneumatic flange.

RPedal down:

lock shaft/wheel.

X

1M = MT ZERO 6 LCD AWx

2P = MT ZERO 6 LCD AWxP

1 695 600 968 2019-01-28|Beissbarth GmbH

User information | MT ZERO 6 LCD | 73

2. User information

2.1 Important notes

Important information on copyright, liability and

warranty provisions, as well as on equipment users

and company obligations, can be found in the separate

manual "Important notes on and safety instructions

for Beissbarth Tire Equipment". These instructions must

be carefully studied prior to start-up, connection and

operation of the MT ZERO 6 LCD and must always be

heeded.

2.2 Safety instructions

All the pertinent safety instructions can be found

in the separate manual "Important notes on and

safety instructions for Beissbarth Tire Equipment". These

instructions must be carefully studied prior to start-up,

connection and operation of the MT ZERO 6 LCD and

must always be heeded.

Safety standards for the use of the position indicator

with laser beam

LASER RADIATION

DO NOT DIRECTLY LOOK INTO THE BEAM

LASER-CLASS-2 DEVICE

Function Specification

Radiated wave length 620 nm - 680 nm

Maximum laser radiation output < 1 mW

¶The laser beam of the lighting system and the

sonar probe only serves as a position indicator for

attaching the balance weights. Any use other than

the intended use will be considered non-compliant.

The manufacturer rejects any responsibility for

improper use of the device.

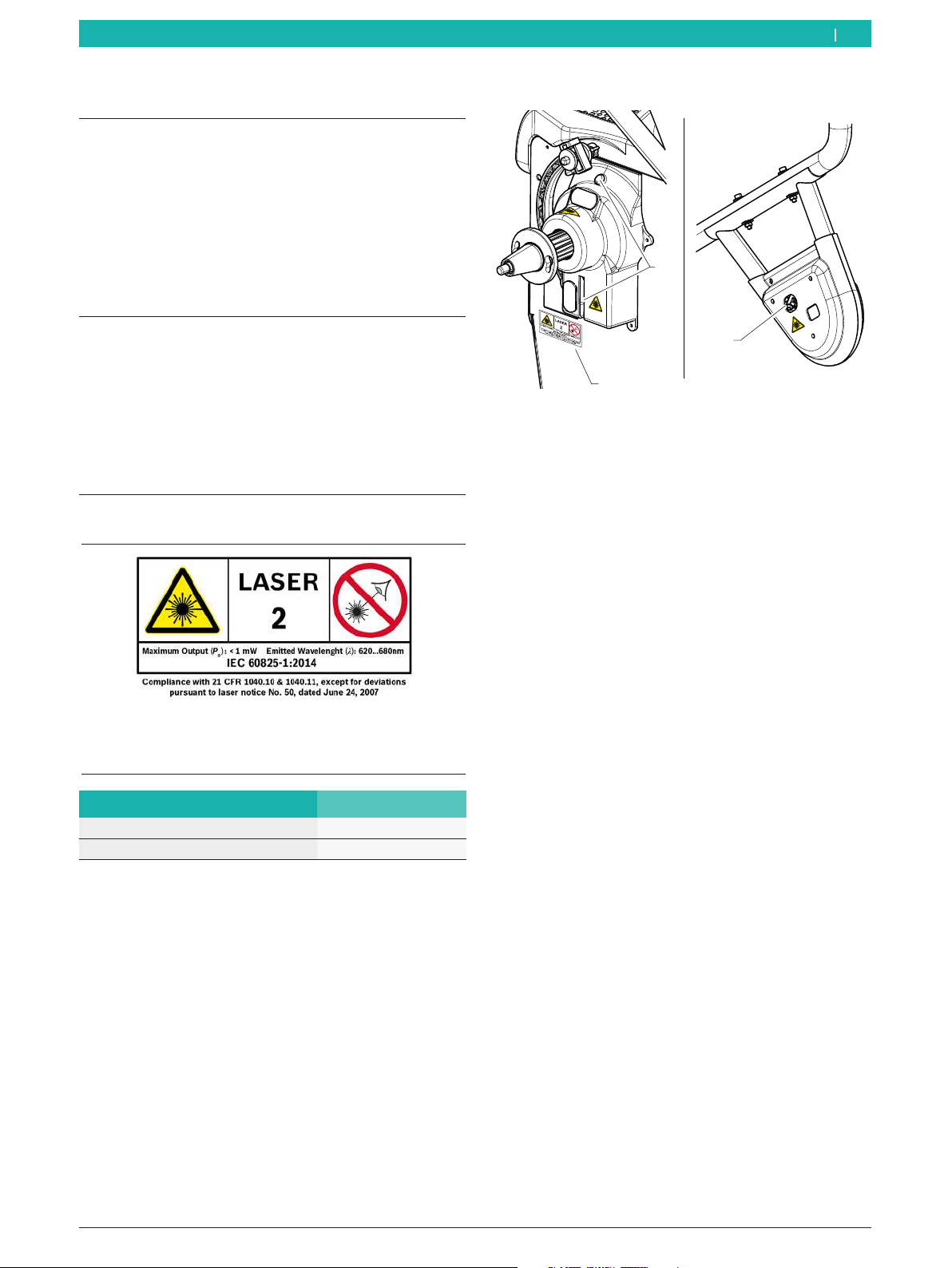

Positions of the laser sources

2

1

651127-45_BM

3

Fig. 1: Positions of the laser sources

1 Main information plate position

2 Laser sources on the lighting system

3 Laser sources on the probe

Safety instructions

¶Severe eye injury from exposure of the eyes to the

laser beam (more than 0.2 seconds).

Do not look directly into the laser source and do not

expose eyes to laser beam.

¶Never direct the laser beam toward people or

animals, and do not look directly into the laser beam

or its reflection.

The laser beam may blind people, resulting in

accidents or eye injury.

¶In case the laser beam hits your eyes, immediately

close your eyes and remove your head from the laser

beam.

¶Never use laser goggles as safety goggles.

Laser goggles are used to better visually detect

the laser beam and not as protection from laser

radiation.

¶Never use laser goggles as sun glasses or behind the

wheel when driving.

Laser goggles do not offer complete protection from

UV beams and limit the perception of differences in

color.

¶Do not modify the laser equipment.

¶Switch off the wheel balancing machine before

performing any maintenance work, particularly if

work is to be performed in the immediate vicinity of

the laser sources or of areas directly exposed to the

laser beams.

¶The laser equipment must be repaired by trained

and briefed personnel using only original spare

parts. This enables the laser equipment to be used

safely.

en

1 695 600 968 2019-01-28| Beissbarth GmbH

74 | MT ZERO 6 LCD | Product description

3.2 Prerequisites

The MT ZERO 6 LCD must be installed on a flat surface

made of concrete or similar material and anchored in

position.

!An uneven or vibrating surface can lead to

inaccurate imbalance measurements.

!Any non-contiguous floor covering or deviation from

the above-mentioned safety requirements releases

the manufacturer from all liability for damage to

objects and/or personal injury.

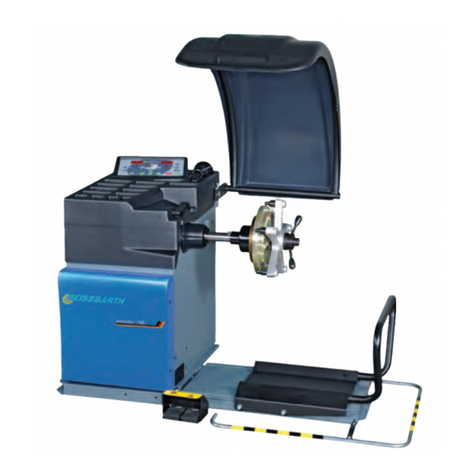

3. Product description

3.1 Intended use

The MT ZERO 6 LCD is a wheel balancing machine

with mechanical (MT ZERO 6 LCD AWx) or pneumatic

(MT ZERO 6 LCD AWxP) wheel clamping. The

MT ZERO 6 LCD can be used to balance passenger

car, small van and motorcycle wheels with a rim

diameter between 10'' - 30'' and a rim width between

1'' - 15''1) .

The MT ZERO 6 LCD is to be used exclusively for

this purpose and solely for the range of applications

specified in these instructions. Any other purpose is not

consistent with the intended use and is therefore not

permissible.

iThe manufacturer does not accept any liability for

possible damage arising from improper use.

!1) * These dimensions refer to standard rims (A);

for rims with a special shape (B - C), special

accessories should be used.

A

B

C

Fig. 2: Rim types

¶Do not use the laser equipment in areas exposed to

explosion hazards or environments with flammable

liquids, gases or dust.

Sparks may form in the laser equipment and ignite

dust or vapors.

¶Protect the laser equipment from warmth as well as

continuous solar irradiation, fire, water and moisture.

Explosion hazard.

en

3.3 Scope of delivery

3.3.1 MT ZERO 6 LCD

651127-04_BM

41

7

2

3

5

6

Denomination Order

number

Qty.

1 Wheel guard 1 695 600 809 1

2 Wheel guard moving unit - 1

3 Mechanical quick-action clamp

parts set1)

1 695 602 400 1

3* Mechanical quick-action clamp

(NA) parts set1)

1 695 655 837 1

3** Parts set, pneumatic quick-action

clamp 1)

1 695 655 602 1

3*** Pneumatic quick-action clamp

parts set, L = 130mm1)

1 695 601 006 1

4 Support frame with sonar - 1

5 Digital control panel - 1

6 Holder for digital control panel - 1

7 Equipment - 1

Operating instructions 1 695 600 968 1

Instructions for tire service devices 1 695 000 006 1

¹)May be included in the scope of delivery depending on the version

ordered

1 695 600 968 2019-01-28|Beissbarth GmbH

Product description | MT ZERO 6 LCD | 75

3.3.2 Parts set, mechanical quick-action clampxxx

Designation Order number Qty.

1 Quick locking nut 1 695 616 200 1

2 Spacer ring 1 695 616 100 1

3 Concave socket 1 695 616 500 1

4 Basic centering flange - 1

5 Allen key 1 695 635 000 1

6 Centering cone 42 – 65mm 1 695 632 500 1

7 Centering cone 54 - 80mm 1 695 652 862 1

8 Centering cone 75 - 110mm 1 695 605 600 1

3.3.4 Parts set, pneumatic quick-action clamp

651115-17_BM

1

23

4

5

6

7

8

9

10

11

Designation Order number Qty.

1 Wheel locking sleeve

L=100mm1)

1 695 653 212 1

1* Wheel locking sleeve

L=130mm1)

1 695 600 999 1

2 Spacer ring 1 695 616 100 1

3 Concave socket 1 695 616 500 1

4 Rubber cap 1 695 624 800 1

5 Basic centering flange - 1

6 Centering cone 42 – 65mm 1 695 632 500 1

7 Centering cone 54 - 80mm 1 695 652 862 1

8 Centering cone 75 - 110mm 1 695 605 600 1

9 Centering cone 120 - 174mm 1 695 606 300 1

10 Basic centering flange 1 695 653 255 1

11 Hexagon bolt ISO 4017 MA8x30 1 695 020 514 2

¹)May be included in the scope of delivery depending on the version

ordered

en

3.3.3 Mechanical quick-action clamp (NA) parts set

651113-46_BM

1 2 3 4 5

67 8 9 10

11 12

Denomination Code for

ordering

No.

1 Basic centering flange - 1

2 Rubber cap 1 695 624 800 1

3 Spacer ring 1 695 655 316 1

4 Concave sleeve 1 695 616 500 1

5 Quick-locking nut - 1

6 Centering cone, 42–65mm 1 695 632 500 1

7 Centering cone, 60–74mm 1 695 655 841 1

8 Centering cone, 72–94mm 1 695 655 840 1

9 Centering cone, 89–132mm 1 695 653 449 1

10 Centering cone, 90–112mm 1 695 655 839 1

11 Spacer ring 1 695 654 895 1

12 Allen key 1 695 635 000 1

1 695 600 968 2019-01-28| Beissbarth GmbH

76 | MT ZERO 6 LCD | Product descriptionen

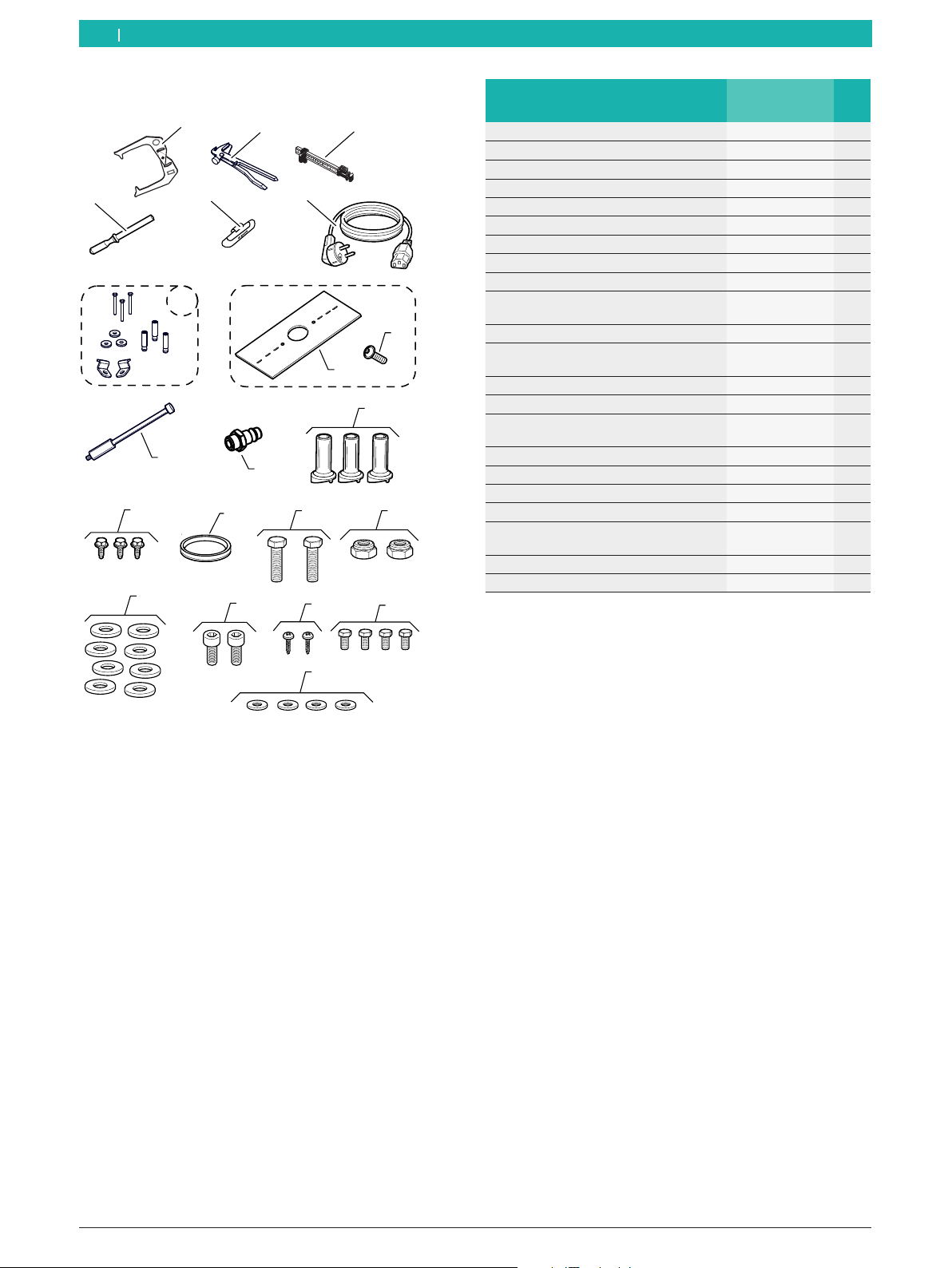

3.3.5 Equipment

8

9

7

45

32

1

11

12

13

10

15 16

17 18 19 20

21

14

6

651127-57_BM

Denomination Code for

ordering

Qty.

1 Measuring compass 1 695 602 700 1

2 Balance weight holder 1 695 606 500 1

3 Weight positioning gauge 1 695 629 400 1

4 Plastic spatula 1 695 656 585 1

5 60-g balance weight 1 695 654 377 1

6 230-V power supply cable1) 1 695 652 991 1

6* 110-V power supply cable1) 1 695 042 146 1

7 Floor mounting parts set 1 695 655 582 1

8 Calibration plate 1 695 600 938 1

9 Hex socket head cap screw

ISO7380 M8x20

1 695 042 418 1

10 Calibrating pin 1 695 656 719 1

11 Quick-release coupling –

MT ZERO 6 LCD AWxP1)

1 695 042 398 1

12 Cone holder 1 695 627 500 3

13 Self-tapping screw 6.3x16 1 695 041 397 3

14 Rubber cap –

MT ZERO 6 LCD AWx1)

1 695 624 800 1

15 Screw M8x50 ISO4017 1 695 040 041 2

16 Low nut M8 EN ISO10511 1 695 002 003 2

17 Washer M8 ISO7089 1 695 002 101 8

18 Screw M8x25 ISO4762 1 695 030 504 4

19 Self-tapping screw 4.2x16

UNI6947

1 695 000 307 4

20 Screw M5x12 ISO4017 1 695 000 410 4

21 Washer M5 ISO7089 1 695 040 163 4

¹)May be included in the scope of delivery depending on the version

ordered

1 695 600 968 2019-01-28|Beissbarth GmbH

Product description | MT ZERO 6 LCD | 77

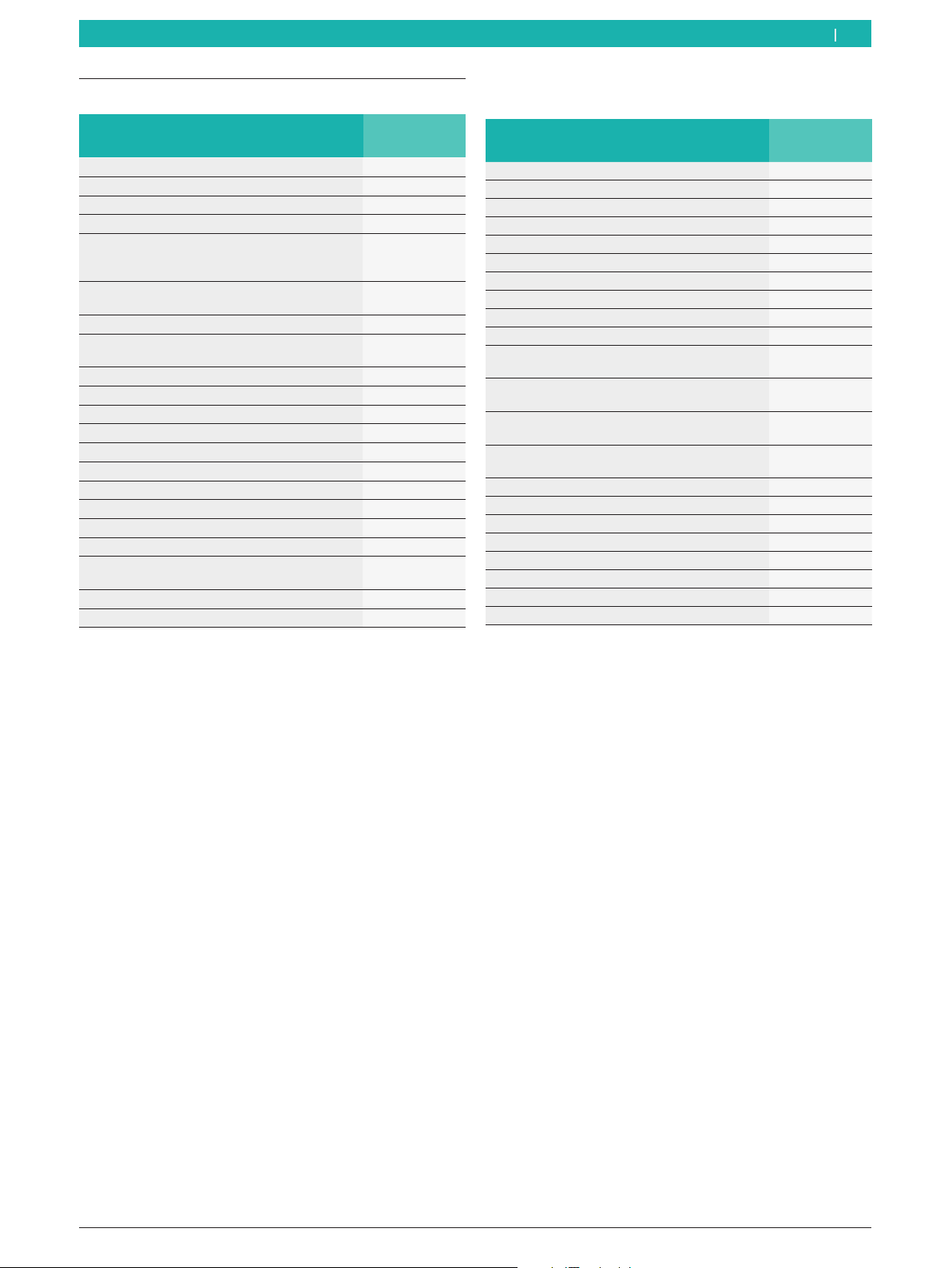

3.4 Special accessories

Designation Code for

ordering

Cone ø 89–132 inside 40mm 1 695 653 449

Fourth centering cone Ø 120 to 174mm

1 695 606 300

Rim spacer ring 1 695 606 200

Three-arm flange for light commercial vehicles

1 695 653 420

Infinitely variable universal flange for

passenger cars

(3-4-5-hole flange)

1 695 654 043

Quick-release coupling for flange (3-4-5-hole)

kit

1 695 612 100

60-g balance weight, Zn-certified 1 695 654 376

Duo Expert centering system (3 sleeves in

carrying case, 54–78mm)

1 695 656 698

Adapter for standard rims kit 1 695 655 294

Adapter for standard rims with 4 holes 1 695 655 295

Adapter for standard rims with 5 holes 1 695 655 296

Adapter for standard rims with 6 holes 1 695 655 297

Adapter mount 1 695 655 298

DEMOBOX KIT FOR PASSENGER CARS 1 695 656 570

Quick release motorcycle wheel flange 1 695 654 039

Clamping kit for swinging arms (Ø 19mm) 1 695 654 060

Wheel lift 1 695 911 173

Positioning laser with light ring 1 695 654 994

Adapter kit for Daimler Sprinter and VW

Crafter

1 695 000 074

Centering kit for light trucks 1 695 656 783

Weight scraper 1 695 656 585

Designation Code for

ordering

Spacer plate 1 695 600 061

Large-diameter spacer plate 1 695 653 888

Rubber ring 1 695 624 800

Centering kit for GM/Opel 1 695 655 323

Centering kit for GM/Opel Expert 1 695 655 324

Three-way centering kit (42–111.5mm) 1 695 654 851

Four-way centering kit (42–111.5mm) 1 695 655 293

Centering kit for Daimler/Smart 1 695 655 326

Centering kit for BMW 1 695 656 822

Centering kit for Daimler 1 695 654 919

Centering cone for Peugeot and others

(58/65mm)

1 695 655 780

Centering cone for PSA/Renault and others

(50/60/65mm)

1 695 655 781

Centering cone for Mini Countryman and

others (72.5mm)

1 695 000 007

Centering cone for VW and others (65–

84mm)

1 695 000 073

Centering cone (50–60 / 66 / 71mm) 1 695 656 571

Centering cone for light trucks (122–174mm) 1 695 654 627

Centering cone for light trucks (88–174mm) 1 695 654 849

Spacer sleeve for off-road wheels 1 695 901 667

Printer 1 695 042 875

Shelf for printer and special accessories 1 695 656 409

Bike ECO centering kit 1 695 654 718

Clamping tool holder 1 695 107 499

en

1 695 600 968 2019-01-28| Beissbarth GmbH

78 | MT ZERO 6 LCD | Product descriptionen

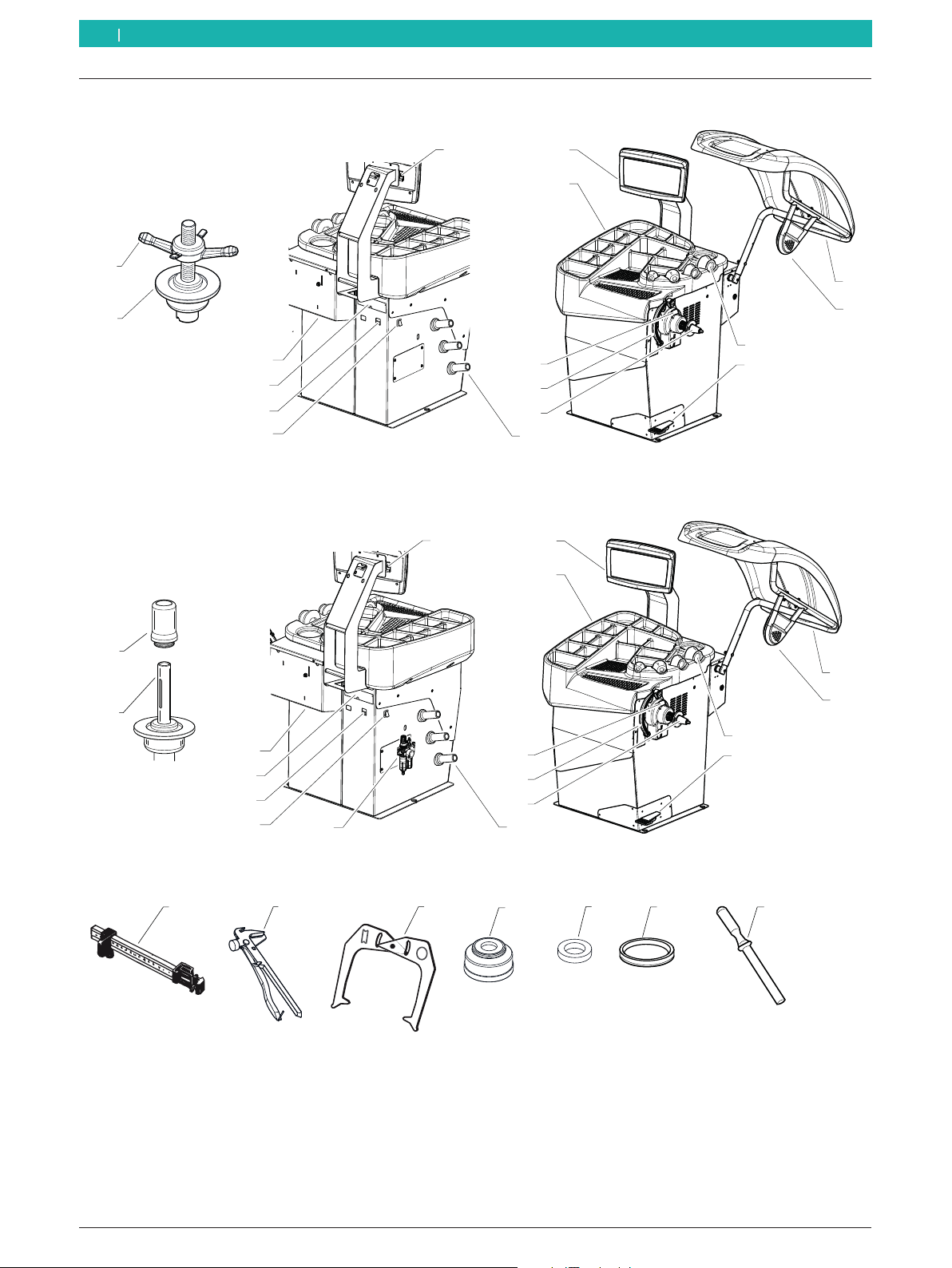

3.5 Component description

12

13

1

3

2

6

14

651127-05_BM

5

7

4

8

9

10

11

15

27

26

Fig. 3: MT ZERO 6 LCD AWx

1

3

2

6

14

651127-06_BM

5

7

4

8

9

10

11

1516

17

18

26

27

Fig. 4: MT ZERO 6 LCD AWxP

19 2120 2522

23

24

651127-07_BM

Fig. 5: Accessories

1 695 600 968 2019-01-28|Beissbarth GmbH

Product description | MT ZERO 6 LCD | 79 en

Item Denomination Function

1 Wheel guard RProtecting the operator from ejected objects (e.g. dirt, water).

RStarting and stopping measurement.

2 Sonar probe RDetermines the rim width by means of the probe.

RLaser beam for indicating where to attach the clip-on balance weight on the

outside of the wheel.

3 Rim-distance gauge (electronic) RRecords rim distance and rim diameter.

RDetermines the positions for attaching the adhesive balance weights.

4 Cone of drive shaft Flange mount

5 Laser If the Easyfix® function is switched off, the position of the adhesive balance

weights is indicated by a laser beam as soon as the correct balancing position is

reached

Lighting Always switched on whenever the electronic rim-distance gauge is in use.

6 Pedal MT ZERO 6 LCD AWx

Locking the shaft/wheel

MT ZERO 6 LCD AWxP

Pedal up

Pedal down

Locking/releasing the pneumatic flange

Locking the shaft/wheel

7 Digital control panel Command interface for use of the wheel balancing machine.

8 Shelf RStorage of cones and tools.

RShelf for balance weights and accessories.

9 Mains socket Connection for power supply cable.

10 On/off switch Switching the wheel balancing machine on and off.

11 Interface card Internal interface card for connecting the measurement system.

12 Quick-locking nut MT ZERO 6 LCD AWx: centering and securing the wheel on the cone

13 Centering flange MT ZERO 6 LCD AWx: centering and securing the wheel on the cone

14 Securing cone Centering the wheel on the flange shaft.

15 Clamping tool holder Storing accessories

16 Oiler regulator filter unit for processing

the compressed air with pneumatic

connection

MT ZERO 6 LCD AWxP:

RChecking/setting the operating pressure

RRemoving dirt

RSupplying oil to compressed-air system

17 Spacer plate MT ZERO 6 LCD AWxP: centering and securing the wheel on the cone.

18 Centering flange with tie rod MT ZERO 6 LCD AWxP: centering and securing the wheel on the cone

19 Weight positioning gauge Manual measurement of the width and positioning of the adhesive balance

weights with the programs ALU2, ALU3, adhesive balance weight statics, PAX2.

20 Balance weight holder Removing the wheel weights from the rim.

21 Measuring compass Manual measurement of rim width and rim diameter.

22 Concave socket For use with quick-locking nut with outside cone attachment.

23 Spacer ring Used in combination with the quick-locking nut to secure the wheels if a cone is

used on the flange.

24 Rubber cap For protective purposes when clamping aluminum rims.

25 Plastic spatula For removing adhesive balance weights

26 USB port For updating the software.

27 Connector plate For protecting the connections used to connect the digital control panel

1 695 600 968 2019-01-28| Beissbarth GmbH

80 | MT ZERO 6 LCD | Initial commissioning

4.1 Unpacking

1. Place the packed goods near the installation

location.

iUse an appropriate fork lift or a pallet truck (with

a minimum load capacity of 400kg) to move the

packed machine. Insert the forks between the

support legs of the palette and lift the packaging.

2. Remove the strap and retaining clamps from the

pallet and the packaging carton.

3. Carefully lift off the packaging.

4. Take the standard accessories and the packaging

material out of the transport crate.

iCheck if the MT ZERO 6 LCD and the accessories

are in proper working order and that there are

no visible signs of component damage. In case of

doubt, do not commission the device and consult

customer service.

iDispose of the packaging material at an appropriate

collection site.

4.2 Transporting an handling the wheel

balancing machine

iOn delivery, the machine is fastened to the pallet.

651127-08_BM

Fig. 6: MT ZERO 6 LCD on pallet

1. Remove fastening screws.

2. Move the machine from the pallet to a suitable

position intended for installation.

iAt least 2 people are needed for this job.

!Do not lift the machine for transport by the shaft

or measurement system. That area must not be

subjected to impacts or potential damage.

651127-01_BM

Fig. 7: Places by which the machine must not be lifted for

transport

!Do not hold the machine by the plastic covers

for moving or lifting. Otherwise, there is a risk of

damage during handling or transport.

3. Carefully position the first side of the machine and

make sure that the machine is in balance and cannot

tip over.

651127-02_BM

Fig. 8: First step of setup

4. Pull out the pallet from under the machine, and

position the machine carefully.

651127-03_BM

Fig. 9: Second step of setup

en

4. Initial commissioning

1 695 600 968 2019-01-28|Beissbarth GmbH

Initial commissioning | MT ZERO 6 LCD | 81

3. The wheel balancing machine must be secured to

the ground at a minimum of 3 places with screws

and dowels.

1

2

M8x70

8,5x24x4

n°3

n°3

3

Ø8

n°3

651127-11_BM

1

2

3

1

2

3

Fig. 12: Securing the MT ZERO 6 LCD

4. Insert the dowels provided, insert the washers

in between, and fully tighten them with a torque

wrench at a tightening torque of 25Nm.

5. Set up the machine in the intended area, paying

attention to the specified safe distances.

iFor safe and ergonomic operation of the wheel

balancing machine, it is advisable to set it up at a

distance of 500mm from the nearest wall.

500 mm

500 mm

651115-08_BM

Fig. 10: Safe distances

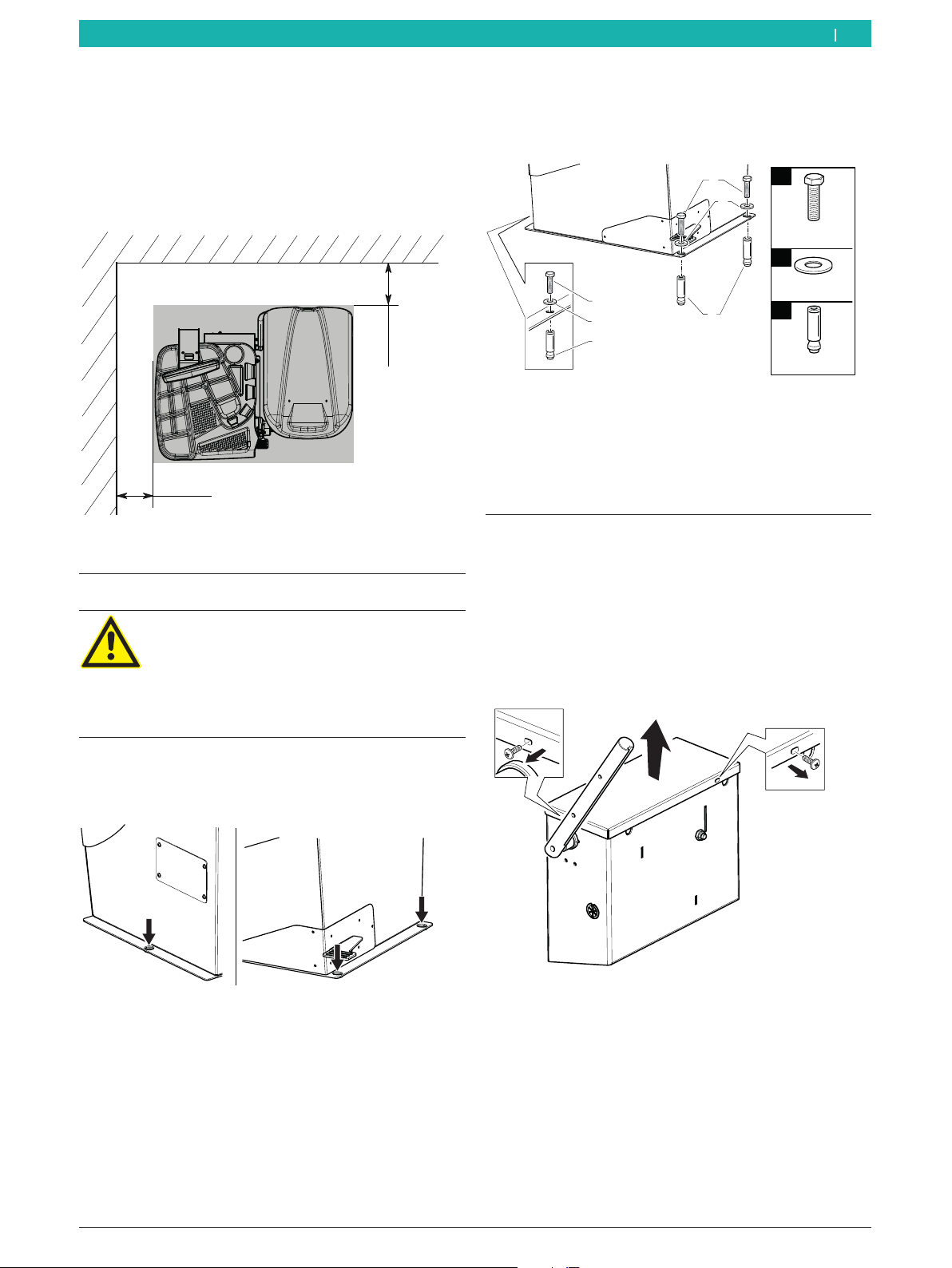

4.3 Floor mounting

Warning – danger of tipping!

Considerable forces are involved in the wheel

balancing process.

¶Before using the machine, it is essential

to fasten it to the ground according to the

manufacturer's specifications.

1. Place the MT ZERO 6 LCD on the ground at the

intended final location. Use the bore holes in the

base of the machine for orientation.

651127-10_BM

Fig. 11: Overview of mounting holes

2. Position a power drill with a 14-mm bit, and drill

holes 65mm deep.

!We recommend cleaning the hole carefully before

inserting the dowel.

4.4 Installing the wheel guard moving

unit

iThe screws for securing the unit are already

attached to the MT ZERO 6 LCD.

1. Remove the screws for securing the cover of the

unit's casing.

2. Remove the cover.

651127-12_BM

Fig. 13: Removing the cover

en

1 695 600 968 2019-01-28| Beissbarth GmbH

82 | MT ZERO 6 LCD | Initial commissioning

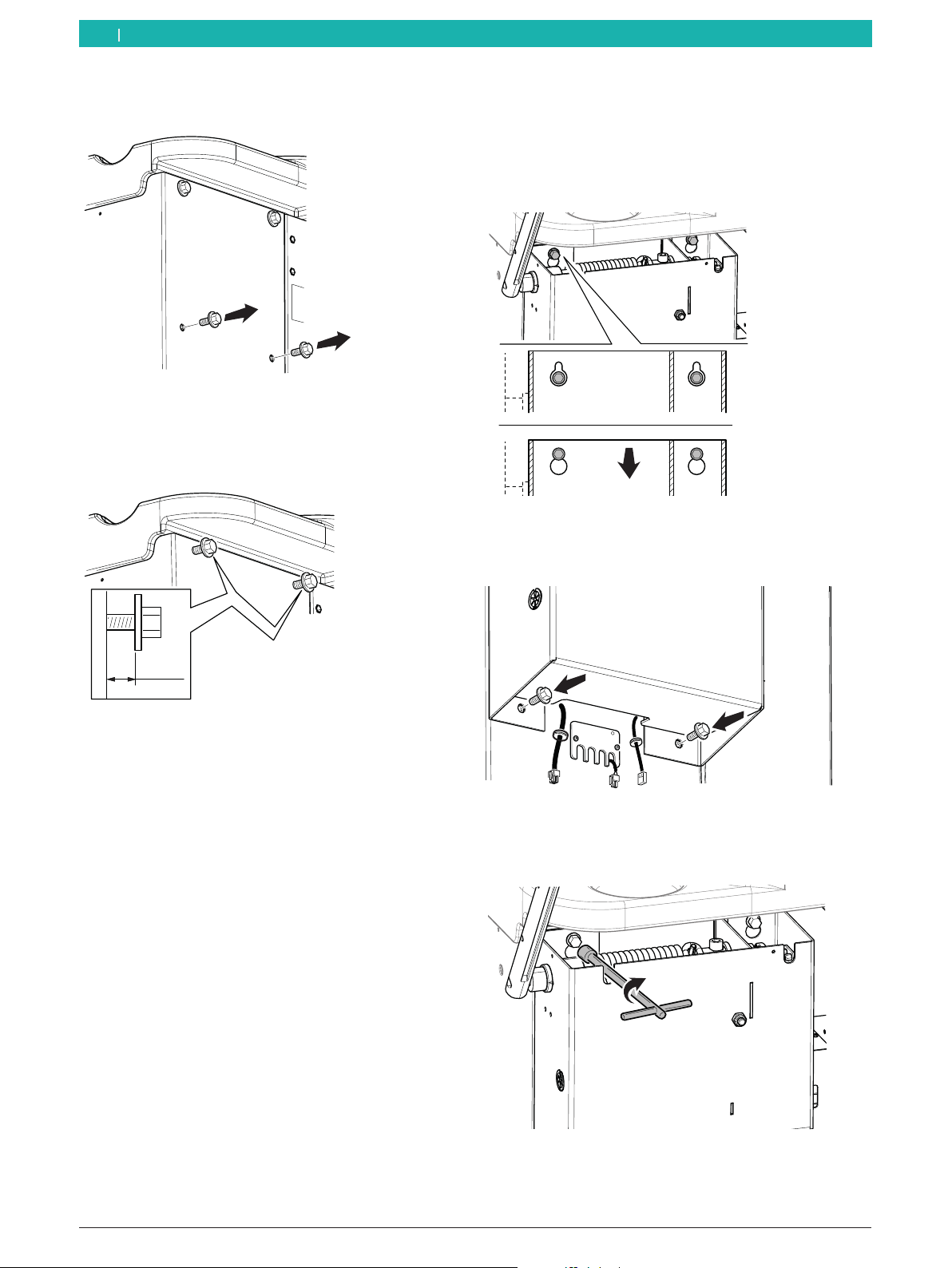

3. Remove the screws from the bottom holes on the

back of the casing.

651127-42_BM

Fig. 14: Removing the bottom screws

4. Position the screws and washers on the top

holes leaving at least 5mm of space between the

structure's wall and the washer.

≥5mm

651127-13_BM

Fig. 15: Positioning the top screws

5. Anchor the protective hood of the moving unit by

aligning the top holes of the unit with the screws

previously put in place.

!Make sure not to crush the cables extending from

the bottom of the unit.

6. Push the unit down, and make sure the screws are

positioned correctly and as far in the holes as they

will go.

iThe unit must be parallel to the structure.

651127-14_BM

Fig. 16: Anchoring the moving unit

7. Position the screws and washers previously removed

on the bottom holes, but do not tighten them yet.

651127-15_BM

Fig. 17: Positioning the bottom screws

8. Tighten the top screws on the holes in the unit with

the tool.

651127-16_BM

Fig. 18: Tightening the top screws

en

1 695 600 968 2019-01-28|Beissbarth GmbH

Initial commissioning | MT ZERO 6 LCD | 83

9. Tighten the bottom screws.

!Make sure the unit is parallel to the structure.

"This concludes the installation of the moving unit of

the protective hood.

4.5 Installing the support frame with

sonar

1. Remove the support frame taking care not to

damage the cables extending from it.

iThe number of cables extending from the frame

varies depending on the machine's version. On the

wheel balancing machine with sonar functions and

laser, 2 cables are routed from the frame, while

there is just one cable on the version with sonar

only.

2. Position the support frame on the machine shaft

extending from the wheel guard moving unit.

3. Position the extending cables inside the receptacle

of the machine shaft extending from the unit.

651127-17_BM

Fig. 19: Preparation for installation

4. Connect the frame to the machine shaft. Proceed

with caution.

!Make sure not to crush the cables between the

machine shaft and the frame.

651127-18_BM

Fig. 20: Installing the support frame

5. Attach the screw set included in the scope of

delivery to the bottom hole.

iSee the figure for the direction of installation.

651127-20_BM

1

2

M8x50

Ø8

n°1

1

n°1

2

Fig. 21: Fitting the bottom screw

en

1 695 600 968 2019-01-28| Beissbarth GmbH

84 | MT ZERO 6 LCD | Initial commissioning

6. Screw the screw set included in the scope of

delivery into the threaded bore hole at the top.

iSee the figure for the direction of installation.

651127-19_BM

1

2

M8x50

Ø8

n°1

1

n°1

2

Fig. 22: Fitting the top screw

7. Fit the screw set included in the scope of delivery

for attaching the frame on the machine shaft, but do

not tighten it yet.

651127-21_BM

1

2

M8

Ø8

n°2

1

1

n°2

2

2

Fig. 23: Fitting the fastening screws

!Perform a visual inspection to make sure the

support frame is parallel to the floor of the

structure.

Fig. 24: Ensuring the parallel alignment of the support frame

iThe coupling for attaching the frame has some play.

If necessary, use it to set the correct position.

8. Tighten the screw set.

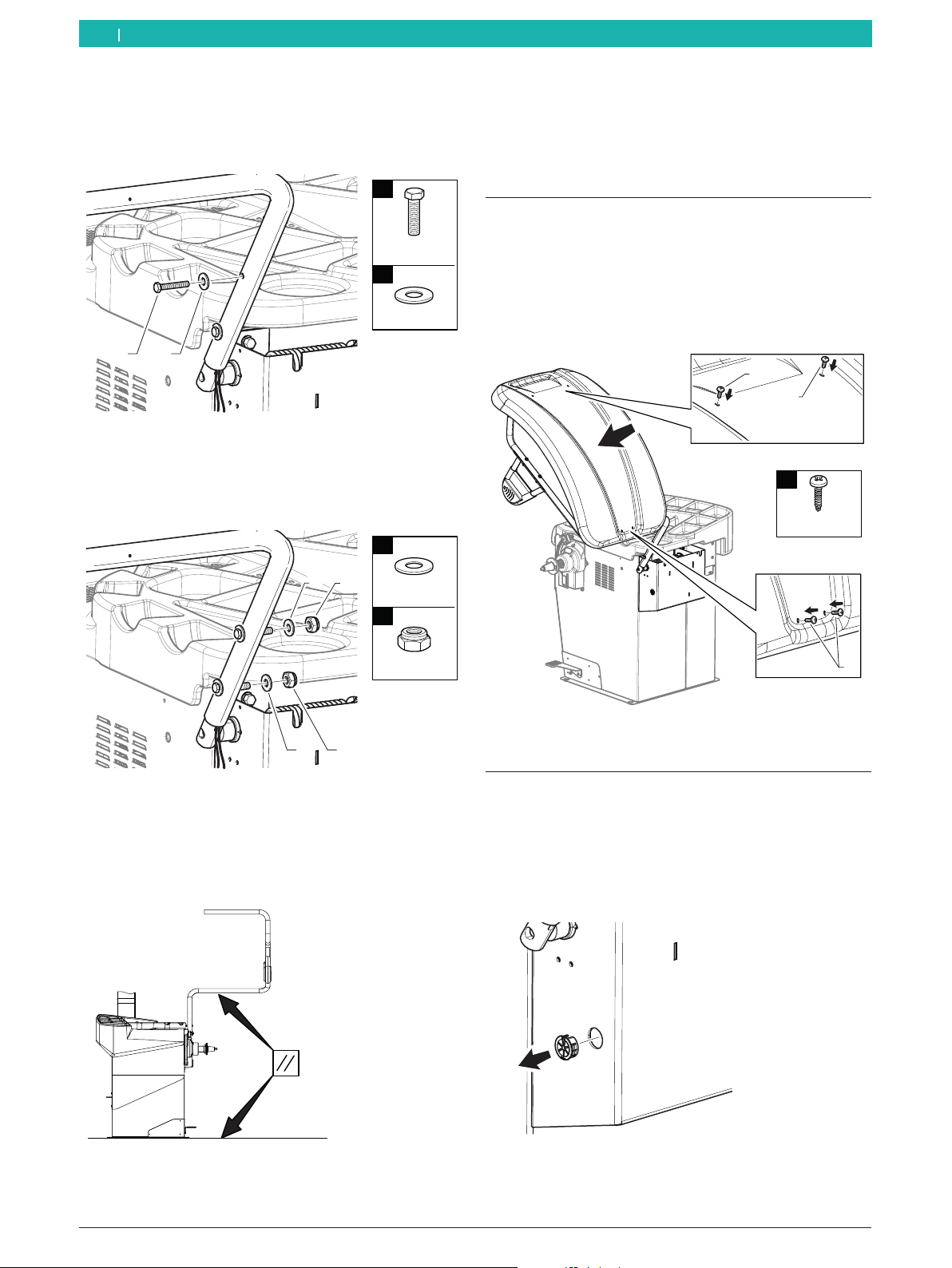

4.6 Installing the wheel guard

1. Remove the wheel guard.

2. Position the wheel guard on the frame in such a way

that the holes in the protective hood are aligned

with the holes in the frame.

3. Use the screw set included in the scope of delivery

to secure the wheel guard.

651127-22_BM

1

4,2x16

1

n°4

1

1

Fig. 25: Installing the wheel guard

4.7 Preparing the electrical connectors

iDuring this phase, the machine must not yet be

connected to the voltage supply.

1. Remove the grommet from the wheel guard moving

unit.

651127-23_BM

Fig. 26: Position of the grommet

en

1 695 600 968 2019-01-28|Beissbarth GmbH

Initial commissioning | MT ZERO 6 LCD | 85

2. Place the cables extending from the support frame

into the receptacle of the grommet, and position the

grommet as specified by the dimensions listed here.

651127-24_BM

200 mm

Fig. 27: Dimensions for positioning the grommet

3. Position the cables in the receptacle of the

grommet, and guide them towards the bottom until

they extend from the casing of the unit.

4. Position the grommet in its receptacle again.

651127-25_BM

Fig. 28: Routing the cable through the unit

5. Uninstall the plate of the interface card.

Fig. 29: Uninstalling the plate of the interface card

6. Connect the connectors shown in this figure, and

position the cables in the notches on the interface

card plate.

iInsert the washers for routing the cables into the

notches of the plate.

651127-37_BM

1 2 3

3

2

1

Fig. 30: Interface card connections

1 Micro-switch cable

2 Magnetic-sensor cable

3 Sonar cable

iIf present, connect the laser cable to the extension

inside the machine.

7. Connect the laser cable.

651127-63_BM

Fig. 31: Connecting an external laser cable

8. Position the washer for routing the cable in the

notch of the plate.

651127-64_BM

Fig. 32: Positioning the laser cable

en

1 695 600 968 2019-01-28| Beissbarth GmbH

86 | MT ZERO 6 LCD | Initial commissioning

9. Install the interface card plate on the machine.

Proceed with caution.

!Make sure not to crush the cables between the

structure and the plate.

651127-38_BM

Fig. 33: Installing the interface card plate

!To avoid damaging the cables, make sure the

cables are not excessively taut and have freedom of

movement in their notches.

10.After completion of the connections described,

install the cover of the wheel guard moving unit.

651127-27_BM

Fig. 34: Installing the cover

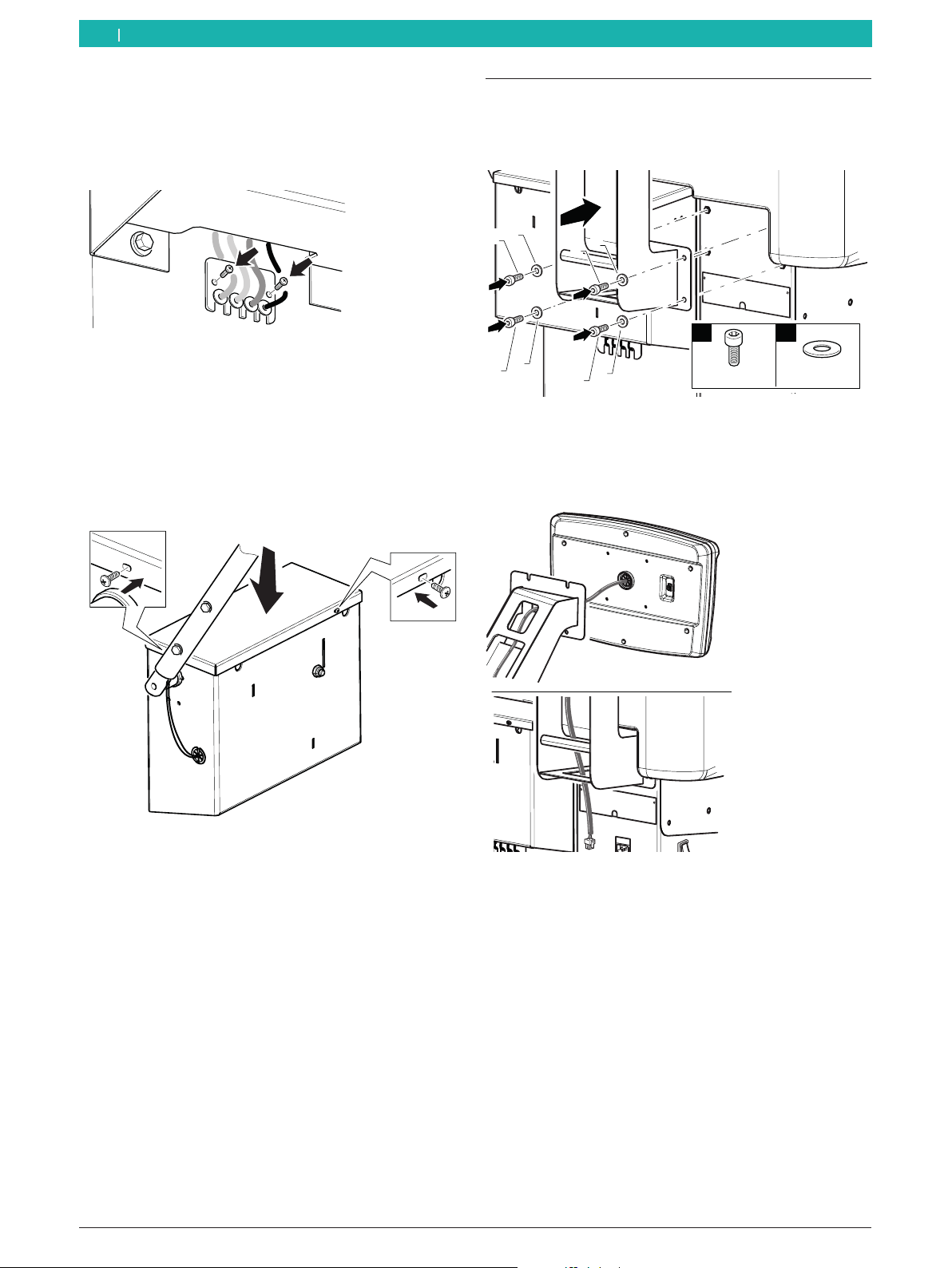

4.8 Mounting the digital control panel

1. Remove the holder for the digital control panel.

2. Use the screw set included in the scope of delivery

to install the mount on the back of the casing.

651127-28_BM

12

M8x25 Ø8

n°4

n°4

1

1

2

12

2

12

Fig. 35: Mounting the holder for the digital control panel

3. Remove the digital control panel.

4. Insert the cable into the holder and route it out of

the base.

651127-29_BM

Fig. 36: Cable penetration

en

This manual suits for next models

2

Table of contents

Other Beissbarth Wheel Balancer manuals