Page 4SKU 47211 For technical questions, please call 1-800-444-3353.

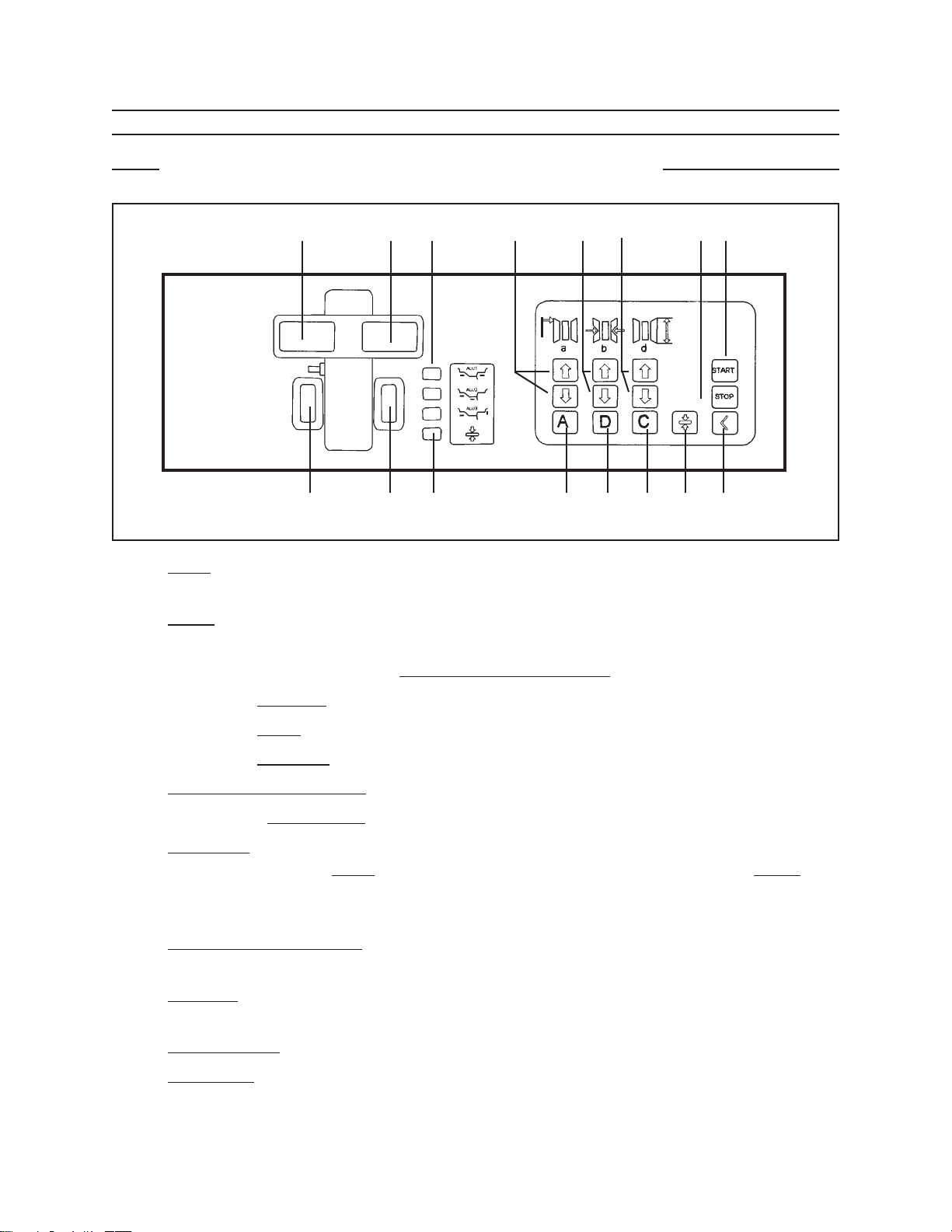

BEFORE EACH USE, ALWAYS EXAMINETHEWHEEL BALANCER FOR STRUC-

TURAL CRACKS AND BENDS, DAMAGE TO THE SAFETY GUARD (504) AND

ELECTRICAL WIRING, AND ANY OTHER CONDITION THAT MAY AFFECT THE

SAFE OPERATION OF THE MACHINE. Do not use the Wheel Balancer even if

minor damage appears. (See Figure E.)

MAINTAIN A SAFEWORKING ENVIRONMENT. Keep the work area well lit. Make

sure there is adequate surrounding workspace. Always keep the work area free of

obstructions, grease, oil, trash, and other debris. Do not use the Wheel Balancer

in a damp or wet location. Do not use the Wheel Balancer in areas near flammable

chemicals, dusts, and vapors.

THIS WHEEL BALANCER IS DESIGNED FOR USE WITH MOST PASSENGER

CAR AND LIGHT DUTYTRUCKWHEELS. Do not attempt to exceed this machine’s

maximum wheel diameter capacity of 31-1/2” or the maximum wheel width capacity

of 20”.

PRIOR TO BEGINNING A JOB, MAKE SURE THE SAFETY GUARD (504) IS IN

THE PROPER LOWERED POSITION. DO NOT RAISE THE SAFETY GUARD

UNTIL THE SPINNING WHEEL COMES TO A COMPLETE STOP.

(See Figure E.)

ALWAYS KEEP HANDS, FINGERS, AND FEET AWAY FROMTHE MOVING PARTS

OF THE WHEEL BALANCER WHILE THE MACHINE IS IN USE. Remain clear of

the spinning wheel while it is being balanced.

NEVER LEAVE THE WHEEL BALANCER UNATTENDED WHEN IT IS RUNNING.

After completing a wheel balancing job, always turn the Power Switch (523) to its

“OFF” position, and wait until the machine comes to a complete stop before leav-

ing. (See Figure E.)

MAKE SURETO READ AND UNDERSTAND ALL INSTRUCTIONS AND SAFETY

PRECAUTIONS AS OUTLINED IN THE MANUFACTURER’S MANUAL FOR THE

WHEEL YOU ARE BALANCING, AND THE VEHICLE THE WHEEL IS TO BE

USED ON.

BEFORE TURNING THE MACHINE ON, MAKE SURE TOOLS, TOOL TRAYS,

WHEELWEIGHTS, AND ALL OTHER PARTS AND EQUIPMENT ARE REMOVED

FROMTHE IMMEDIATELY VICINITY OF THE MOUNTED WHEEL THAT ISTO BE

BALANCED.

NEVER STAND OR ALLOW AN OBSERVER TO STAND IN LINE WITH THE

SPINNING WHEEL.

THE WHEEL BALANCER DOES NOT COME EQUIPPED WITH AN ELECTRI-

CAL POWER PLUG. Prior to using, this machine requires the attachment of a

grounded, 3-prong, 220 volt, Power Plug to its Power Cord (519). For your safety,

only a qualified, certified electrician should attach the Power Plug onto the Power

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Brought to You By Augusta Flint