- T e mac ines are manufactured in compliance wit t e accident prevention rules in

force.

- Strictly comply wit t e instructions contained in t is manual to obtain t e best

performance from t e mac ine. Strict compliance wit t e rules contained erewit will

ensure optimum results and avoid any inconvenience caused by t e non-compliance of

operation and maintenance instructions.

- Closely follow t e instructions given below to avoid contacting t e manufacturer for t e

problems w ic can be easily solved..

- If after aving strictly compliance wit t e given instructions, t e purc aser still needs

t e elp of our tec nical assistance service, e must supply all t e tec nical indications

necessary to determine t e type of problem and/or t e parts w ic are not functioning

correctly. T is will enable our tec nical assistance service to intervene quickly and

efficiently on t e mac ine.

Copies of t e instruction manual may be requested upon indication of t e mac ine serial

number.

All installation work including t e electrical connection must only be carried out by qualified

personnel.

T e mac ine must only be operated by a tec nically trained and experienced operative w o is

also instructed in ‘safety at work ’ procedures.

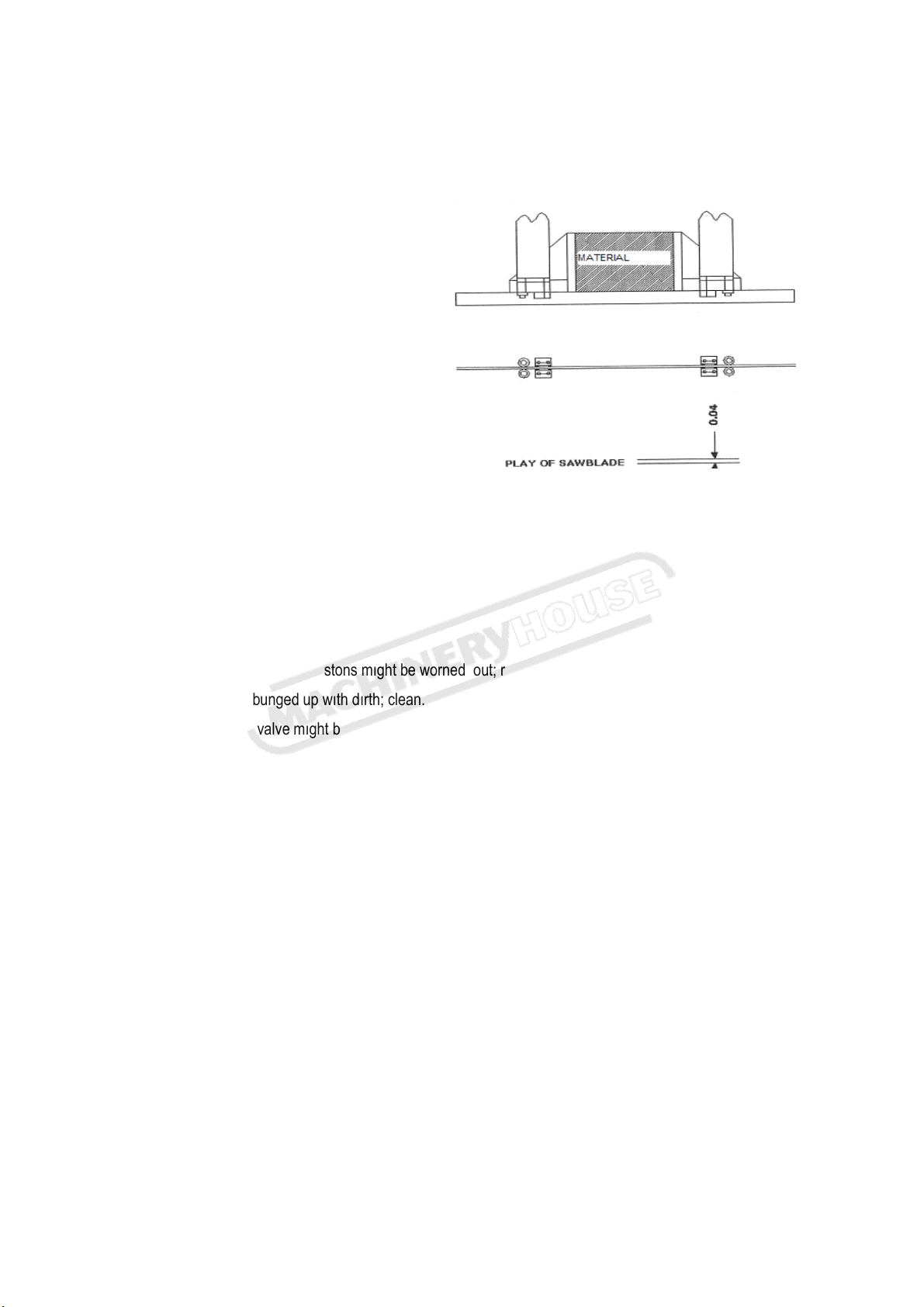

Any adjustments, cleaning, repairs or c anging of t e saw blade must under no circumstances be

performed unless t e mac ine is fully isolated from t e electrical power supply. Ensure t e

emergency stop button on t e control binnacle is pressed and t e power supplies at t e mains are

disconnected.”

T e band saw must be regularly inspected and maintained in good serviceable condition. Eye

protection, ear protection, gloves and protective clot ing must be worn w en any of t e above

procedures are being carried out, as well as w en cutting fluid is prepared, introduced or displaced

from t e band saw mac ine (t e relevant environmental regulations must be observed in case of

t e use and disposal of cutting fluid etc.)

T e band saw must be installed on ground. Observe t e permissible floor load. T an t e band

saw mac ine as been properly bolt to ground securely.

Allow sufficient working space around t e band saw of at least 1 meter. İnstallations of stock roller

conveyors require additional space and possibly a lifting mec anism for eavy work pieces.

Always ensure t at t e working area around t e band saw is well lit.