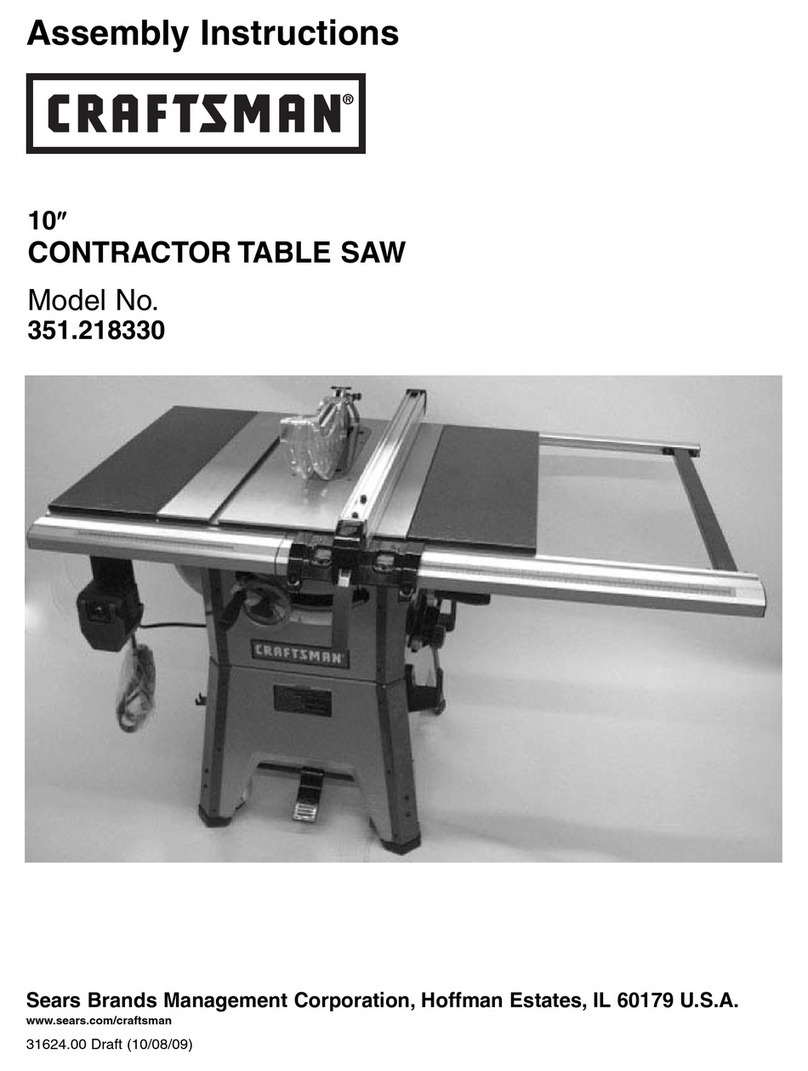

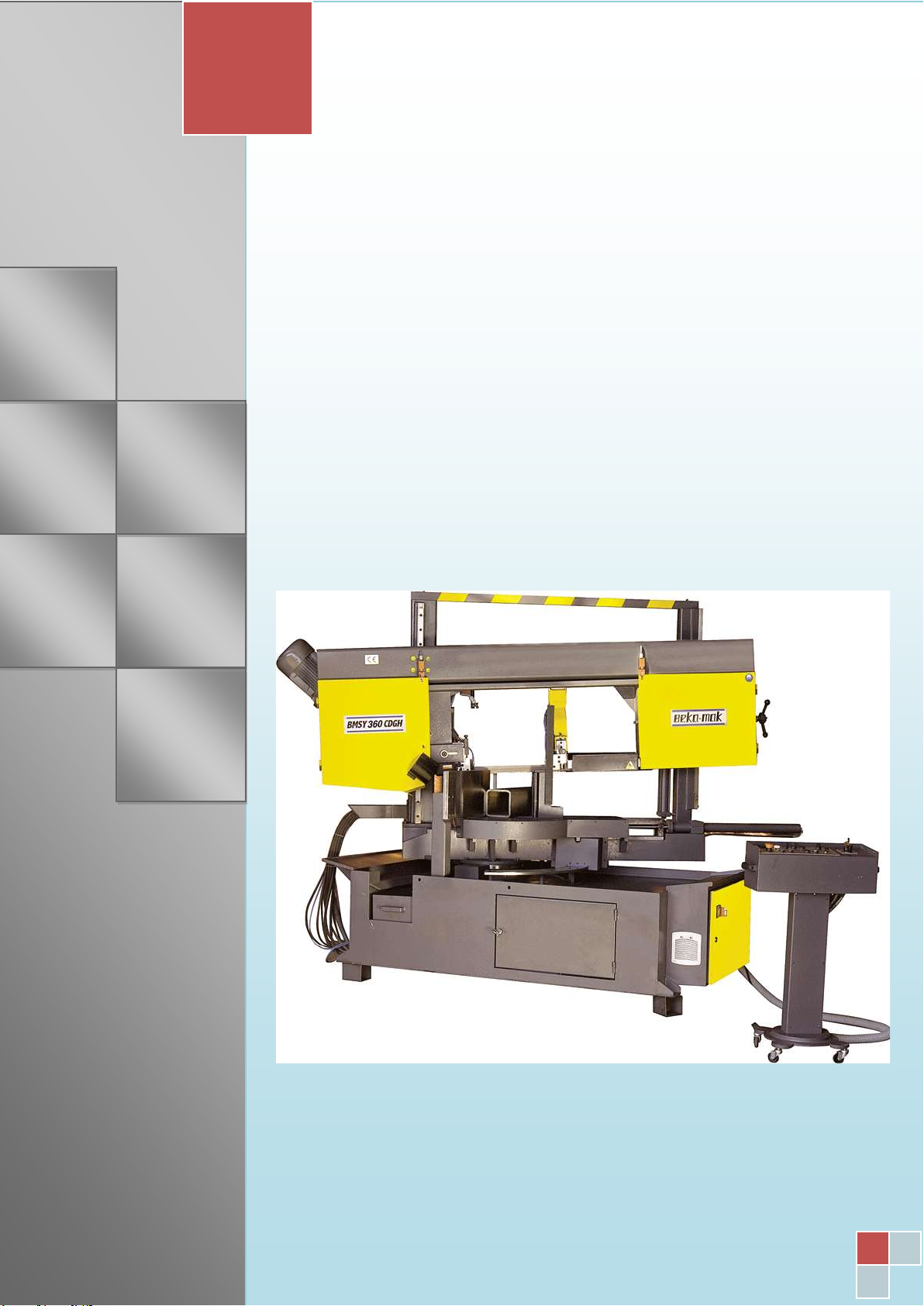

Beka-Mak BMSY 360 CDGH User manual

SEMI AUTOMATIC

TWIN PILLAR

BANDSAWING

MACHINES

BMSY 360CDGH

RUNNING VOLTAGE SERIAL NUMBER

WARRANTY

- THE FIRM GUARANTEES THE MACHINE DESCRIBED HEREBY, DESIGNED IN COMPLIANCE WITH

ALL REGULATIONS IN FORCE, IN PARTICULAR SAFETY AND HEALTH REGULATIONS; THE

MACHINE HAS UNDERGONE SUCCESSFUL TESTING.

- THE WARRANTY COVERS A PERIOD OF 12 MONTHS. IT DOESN’T COVER ELECTRICAL MOTORS

AND TOOLS.

- THE PURCHASER IS ENTITLED ‘REPLACEMENT OF FAULTY PARTS’. SHIPPING AND PACKING

COSTS ARE AT HIS EXPENSE.

- THE WARRANTY DOESN’T COVER THE PARTS DAMAGED BY FALLS OR CARELESS HANDLING OF

THE MACHINE, INCORRECT OPERATION, NON-COMPLIANCE WITH THE MAINTENANCE RULES.

ANY TAMPERING WITH THE MACHINE, ESPECIALLY WITH THE SAFETY DEVICES

AUTOMATICALLY EXPIRES THE WARRANTY AND THE MANUFACTURER WILL BE FREED FROM

ANY RESPONSIBILITY.

- ANY KIND OF ALTERATION ON THE MACHINE ENDS THE WARRANTY AND THE MANUFACTURER

BECOMES FREE FROM EVERY KIND OF RESPONSIBILITY.

- NO CLAIM FOR DAMAGES SHALL BE ACCEPTED IN CASE THE MACHINE LAYS IDLE FOR A LONG

PERIOD OF TIME.

- MACHINE IS DESIGNED TO BE RUN INDOORS. IT IS NOT RECOMMENDED TO RUN THE MACHINE

OUTDOORS.

THE SERIAL NUMBER ON THE MACHINE IS A ‘MAIN REFERENCE FOR THE WARRANTY’,

INSTRUCTIONS MANUAL, AFTER SALE SERVICE AND IDENTIFY THE MACHINE IN CASE OF NEED.

IMPORTANT

UPON THE DELIVERY OF THE MACHINE, THE CONSUMER MUST MAKE HIMSELF

SURE THAT ALL THE DEVICES INDICATED IN THE PARAGRAPH OF THE SAFETY MANUAL

ARE PRESENT AND WORKING CORRECTLY. FURTHERMORE, HE MUST MOUNT IN

CONFORMITY WITH THE INSTRUCTIONS INDICATED THOSE DEVICES WHICH ARE NOT

MOUNTED AT THE TIME OF DELIVERY TO FACILITATE TRANSPORT.

WHEN ORDERING SPARE PARTS

IT IS NECESSARY TO STATE:

MACHINE MODEL

SERIAL NUMBER AND YEAR OF PRODUCTION

ITEM REFERENCE NUMBER

WITHOUT SERIAL NUMBER NO SPARE PARTS WILL BE DELIVERED

GENERAL INFORMATION

- THE MACHINES ARE MANUFACTURED IN COMPLIANCE WITH THE ACCIDENT

PREVENTION RULES IN FORCE.

- STRICTLY COMPLY WITH THE INSTRUCTIONS CONTAINED IN THIS MANUAL TO OBTAIN

THE BEST PERFORMANCE FROM THE MACHINE. STRICT COMPLIANCE WITH THE RULES

CONTAINED HEREWITH WILL ENSURE OPTIMUM RESULTS AND AVOID ANY

INCONVENIENCE CAUSED BY THE NON-COMPLIANCE OF OPERATION AND

MAINTENANCE INSTRUCTIONS.

- CLOSELY FOLLOW THE INSTRUCTIONS GIVEN BELOW TO AVOID CONTACTING THE

MANUFACTURER FOR THE PROBLEMS WHICH CAN BE EASILY SOLVED..

- IF AFTER HAVING STRICTLY COMPLIANCE WITH THE GIVEN INSTRUCTIONS, THE

PURCHASER STILL NEEDS THE HELP OF OUR TECHNICAL ASSISTANCE SERVICE, HE MUST

SUPPLY ALL THE TECHNICAL INDICATIONS NECESSARY TO DETERMINE THE TYPE OF

PROBLEM AND/OR THE PARTS WHICH ARE NOT FUNCTIONING CORRECTLY. THIS WILL

ENABLE OUR TECHNICAL ASSISTANCE SERVICE TO INTERVENE QUICKLY AND

EFFICIENTLY ON THE MACHINE.

COPIES OF THE INSTRUCTION MANUAL MAY BE REQUESTED UPON INDICATION OF THE

MACHINE SERIAL NUMBER.

GENERAL SAFETY NOTES

ALL INSTALLATION WORK INCLUDING THE ELECTRICAL CONNECTION MUST ONLY BE CARRIED

OUT BY QUALIFIED PERSONNEL.

THE MACHINE MUST ONLY BE OPERATED BY A TECHNICALLY TRAINED AND EXPERIENCED

OPERATIVE WHO IS ALSO INSTRUCTED IN ‘SAFETY AT WORK ’ PROCEDURES.

ANY ADJUSTMENTS, CLEANING, REPAIRS OR CHANGING OF THE SAW BLADE MUST UNDER NO

CIRCUMSTANCES BE PERFORMED UNLESS THE MACHINE IS FULLY ISOLATED FROM THE

ELECTRICAL POWER SUPPLY. ENSURE THE EMERGENCY STOP BUTTON ON THE CONTROL

BINNACLE IS PRESSED AND THE POWER SUPPLIES AT THE MAINS ARE DISCONNECTED.”

THE BAND SAW MUST BE REGULARLY INSPECTED AND MAINTAINED IN GOOD SERVICEABLE

CONDITION. EYE PROTECTION, EAR PROTECTION, GLOVES AND PROTECTIVE CLOTHING MUST BE

WORN WHEN ANY OF THE ABOVE PROCEDURES ARE BEING CARRIED OUT, AS WELL AS WHEN

CUTTING FLUID IS PREPARED, INTRODUCED OR DISPLACED FROM THE BAND SAW MACHINE (THE

RELEVANT ENVIRONMENTAL REGULATIONS MUST BE OBSERVED IN CASE OF THE USE AND

DISPOSAL OF CUTTING FLUID ETC.)

THE BAND SAW MUST BE INSTALLED ON GROUND. OBSERVE THE PERMISSIBLE FLOOR LOAD.

THAN THE BAND SAW MACHINE HAS BEEN PROPERLY BOLT TO GROUND SECURELY.

ALLOW SUFFICIENT WORKING SPACE AROUND THE BAND SAW OF AT LEAST 1 METER.

INSTALLATIONS OF STOCK ROLLER CONVEYORS REQUIRE ADDITIONAL SPACE AND POSSIBLY A

LIFTING MECHANISM FOR HEAVY WORK PIECES. ALWAYS ENSURE THAT THE WORKING AREA

AROUND THE BAND SAW IS WELL LIT.

SAFETY INSTRUCTIONS

BE SURE THAT ELECTRICAL CONNECTION IS MADE CAREFULLY. TO AVOID UNWANTED SITUATIONS LIKE ELECTRICAL SHOCK, PROTECT THE MAIN SUPPLY CABLE WITH A HOLSTER.

BEFORE RUNNING THE MACHINE, BE SURE THAT ALL OF THE PROTECTIONS ARE MOUNTED PROPERLY AND ALL THE COVERS ARE CLOSED.

AVOID FROM SMOKE AND MOISTURE.

PLEASE USE THE PARTS AND EQUIPMENTS WHICH ARE RECOMMENDED. USAGE OF UNSUITABLE PARTS AND MATERIALS WHICH ARE BIGGER THAN THE CAPACITY OF THE MACHINE CAN

CAUSE UNWANTED SITUATIONS.

CHECK THE MACHINE AND INFORM THE DEFECTS EVERYDAY.

DON’T LEAVE ANY MATERIAL AFTER CHANCING THE BAND.

DO NOT HOLD THE MATERIAL WHILE THE MACHINE IS CUTTING. ALWAYS TIGHTEN THE MATERIAL BY USING ESSENTIAL PARTS.

PLEASE PAY ATTENTION TO CHOOSE THE AREA OF THE MACHINE WHICH DOESN’T INCLUDE ANYTHING THAT CREATES DIFFICULTIES TO CONTROL THE MACHINE

PLEASE BE SURE THAT THE TEETH OF THE BAND ARE LOOKING TO CORRECT DIRECTION.

DON’T LEAVE THE BAND ON THE GROUND OR ANY PLACE THAT IS DANGEROUS FOR OTHER PEOPLE.

BE CAREFUL WHEN USING THE MACHINE AND KEEP THE WORKING AREA CLEAN ( CLEAN THE SAW DUSTS AND OIL TRACES )

PAY ATTENTION TO SECURITY INSTRUCTIONS WHEN USING THE MACHINE.

DON’T WEAR LOOSE CLOTHS WHEN USING THE MACHINE.

REGARDLESS USE THE PROTECTIVE GLOVES WHEN USING THE MACHINE.

DON’T GET CLOSE TOO MUCH TO THE MACHINE WHEN RUNNING.

BEFORE CARRYING OUT ANY CLEANING OR MAINTENANCE PROCEDURE, DISCONNECT THE MACHINE FROM MAIN SUPPLY.

IN SOME CONDITIONS, NOISE LEVEL CAN BE ABOUT 85 DB. BAND CHOICE AND CUTTING SPEED IS IMPORTANT FACTOR FOR NOISE LEVEL.

ILLUMINATION IS AN IMPORTANT FACTOR FOR SECURITY.

RATIO OF COOLANT LIQUID IS IMPORTANT FOR OBTAINING OPTIMUM LUBRICATION.

NEVER USE THE MACHINE IF YOU NOTICE ANY FAULT OF THE MACHINE OR ABSENCE OF ANY PART OF THE MACHINE.

- CONTROL THE EMERGENCY BUTTON AT LEAST ONCE A WEEK AND BE SURE THAT IT IS WORKING PROPERLY.

RELATED DIRECTIVES AND STANDARDS

DIRECTIVES:

MACHINERY DIRECTIVE-/MAKINE DIREKTIFI 98/37/EC

LOW VOLTAGE DIRECTIVE/DÜŞÜK VOLTAJ DIREKTIFI 2006/95/EC

ELECTROMAGNETIC COMPATIBILITY DIRECTIVE/ELEKTRO MANYETIK UYUMLULUK DIREKTIFI- 2004/108/EC

STANDARDS:

EN ISO:13857:2008; SAFETY OF MACHINERY. SAFETY DISTANCES TO PREVENT HAZARD ZONES BEING REACHED BY UPPER AND LOWER LIMBS / MAKINELERDE GÜVENLIK-EL VE KOLLARIN TEHLIKELI

BÖLGELERE ERIŞMESINE KARŞI GÜVENLIK MESAFELERI

EN 982:1996: SAFETY OF MACHINERY - SAFETY REQUIREMENTS FOR FLUID POWER SYSTEMS AND THEIR COMPONENTS - HYDRAULICS / /MAKINALARDA GÜVENLIK- AKIŞKAN GÜÇ SISTEMLERI

VE BILEŞENLERI IÇIN GÜVENLIK KURALLARI – HIDROLIK

EN 954-1 (1996); SAFETY OF MACHINERY - SAFETY-RELATED PARTS OF CONTROL SYSTEMS - PART 1: GENERAL PRINCIPLES FOR DESIGN / MAKINELERDE GÜVENLIK - KUMANDA SISTEMLERININ

GÜVENLIKLE ILGILI KISIMLARI -BÖLÜM 1: TASARIM IÇIN GENEL PRENSIPLER

EN 13898:2003: MACHINE TOOLS - SAFETY - SAWING MACHINES FOR COLD METAL /TAKIM TEZGÂHLARI –GÜVENLIK - METALLERI SOĞUK IŞLEME IÇIN TESTERE TEZGAHLARI

ISO 14121-1:2007: SAFETY OF MACHINERY - RISK ASSESSMENT - PART 1: PRINCIPLES / MAKINALARDA GÜVENLIK-RISK ANALIZI-BÖLÜM 1: PRENSIPLER

EN ISO 12100-1:2003; SAFETY OF MACHINERY - BASIC CONCEPTS, GENERAL PRINCIPLES FOR DESIGN - PART 1: BASIC TERMINOLOGY, METHODOLOGY/ MAKINALARDA GÜVENLIK - TEMEL

KAVRAMLAR, TASARIM IÇIN GENEL PRENSIPLER - BÖLÜM 1: TEMEL TERMINOLOJI, METODOLOJI

EN ISO 12100-2:2003; SAFETY OF MACHINERY - BASIC CONCEPTS, GENERAL PRINCIPLES FOR DESIGN - PART 2: TECHNICAL PRINCIPLES/ MAKINALARDA GÜVENLIK –TEMEL KAVRAMLAR,

TASARIM IÇIN GENEL PRENSIPLER –BÖLÜM 2: TEKNIK PRENSIPLER

EN 60204-1:2006; SAFETY OF MACHINERY - ELECTRICAL EQUIPMENT OF MACHINES - PART 1: GENERAL REQUIREMENTS / MAKINELERIN EMNIYETI –MAKINELERIN ELEKTRIK DONANIMI –

BÖLÜM 1: GENEL GEREKLER

WARNING

THIS CHAPTER OUTLINING THE SAFETY DEVICES AND NORMS WAS DRAWN UP BEARING IN MIND

THE NORMAL USE OF THE MACHINE AS STATED IN THE CHAPTER ON THE OPERATION OF THE

MACHINE AND THE ADEQUATE PREPARATION OF THE OPERATORS AS REGARDS THE SPECIFIC

RISKS LINKED TO THE OPERATION OF THE MACHINE.

IF THE MACHINE ISN’T USED ACCORDING TO INSTRUCTION GIVEN IN THE ‘PURPOSE OF THE

MACHINE’ CHAPTER IN THIS MANUAL, THE MANUFACTURER ISN’T RESPONSIBLE FOR ANY

DAMAGE CAUSED TO PEOPLE AND THINGS.

FURTHERMORE, THE MANUFACTURER ISN’T RESPONSIBLE FOR ANY DAMAGE TO PEOPLE AND

THINGS AND THINGS RESULTING FROM THE NON-COMPLIANCE WITH THE FOLLOWING

WARNINGS.

A) ADOPT ALL THE NECESSARY PRECAUTIONS DURING LOADING, CALIBRATION, PART

REPLACEMENT, CLEANING, AND REPAIR OR MAINTENANCE OPERATIONS TO PREVENT

SOMEONE ELSE FROM TURNING THE MACHINE ON.

B) DO NOT TEMPER WITH THE SAFETY DEVICES AND GUARDS ON THE MACHINE.

C) DO NOT REMOVE ANY OF THE SAFETY DEVICES AND GUARDS ON THE MACHINE.

ALWAYS MAKE SURE THAT SAFETY DEVICES AND GUARDS ARE REMOUNTED AFTER THEIR

TEMPORARY REMOVAL FOR TECHNICAL REASONS ORDERED BY THE BOSS

CONNECTION TO THE ELECTRICAL SYSTEM

CONTROL PANEL IS MOUNTED ON THE ELECTRIC PANEL. MACHINE IS CONNECTED

TO THE MAIN SUPPLY IN THE ELECTRICAL PANEL. R, S AND T SHOWS THE PHASES, N IS

NEUTER AND PE IS GROUNDING. CONNECTION WILL BE FROM THE 13(L1) KLEMENS WHICH

IS AT RIGHT KLEMENS GROUP.

CHECK THE VOLTAGE WHICH IS MENTIONED AT THE FIRST PAGE OF THE MANUEL BEFORE

SETTING THE ELECTRICAL CONNECTION OF THE MACHINE.

IF THE CABLE PHASE LINE IS CORRECT PHASE CONTROL LED LIGHTENS IN THAT WAY IT IS

PREVENTED TO MOTORS MOVE ON WRONG WAYS. BE SURE THAT THE OUT-PUT VOLTAGE AT

THE POWER SUPPLY IS 22 ~ 28 VDC.

THE MACHINE IS PROTECTED AGAINST SHORT CIRCUIT WITH INTERRUPTERS AND AGAINST

HIGH VOLTAGE WITH THERMAL RELAYS. GROUNDING AND NEUTRALIZING HAVE TO BE DONE

TO PROTECT THE MACHINE .

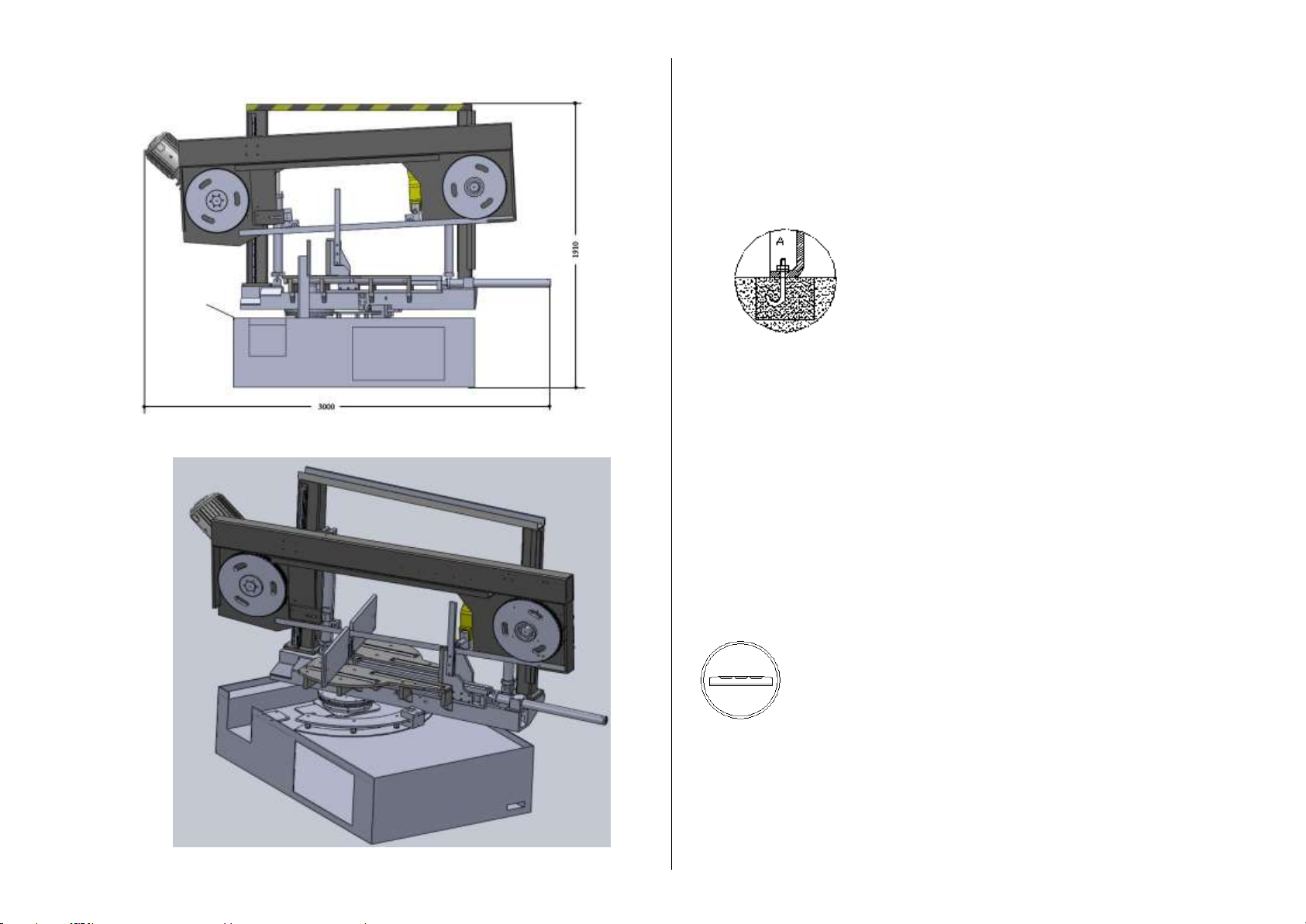

TECNICAL DATA

BMSY 360CDGH

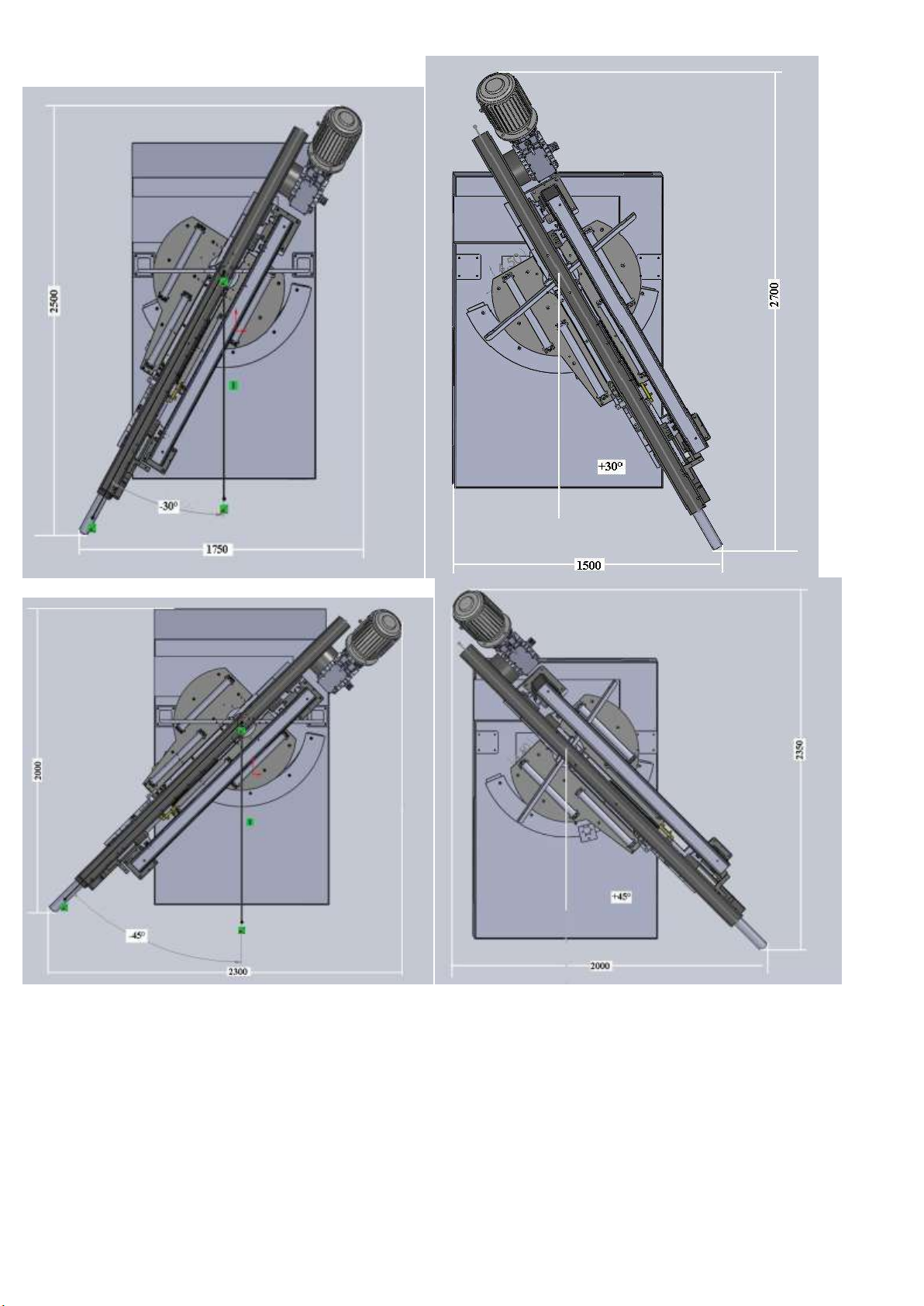

CUTTING CAPACITY

ROUND

mm

360

0°

FLAT

mm

640 X 360

SQUARE

mm

360

CUTTING CAPACITY

ROUND

mm

360

+30°

FLAT

mm

510 X 360

SQUARE

mm

360

CUTTING CAPACITY

ROUND

mm

360

+45°

FLAT

mm

390 X 360

SQUARE

mm

360

CUTTING CAPACITY

ROUND

mm

310

+60°

FLAT

mm

250 X 360

SQUARE

mm

270

CUTTING CAPACITY

ROUND

mm

360

-30°

FLAT

mm

510 X 360

SQUARE

mm

360

CUTTING CAPACITY

ROUND

mm

360

-45°

FLAT

mm

390 X 360

SQUARE

mm

360

MAIN DRIVE MOTOR

kw

3

HYDRAULIC MOTOR

kw

1,1

COOLANT MOTOR

kw

0,12

CUTTING SPEEDS

m/min

20 - 100

BAND DIMENSIONS

mm

5000 X 41 X 1,3

WORKING HEIGHT

mm

800

WEIGHT

kg

1630

DIMENSIONS

LENGTH

mm

3000

WIDTH

mm

1200

HEIGHT

mm

1910

TRANSPORTATION AND CARRYING OF MACHINE

IMPORTANT

CARRY WELL-BALANCED WITH A STRONG ROPE WHICH WILL BE HOOKED TO CARRYING RINGS

FIXING

AREA THAT MACHINE WILL BE FIXED SHOULD BE FLAT AND BOWLESS. MACHINE BASE

SHOULD BE PLACED PROPERLY , LINEAR AND DIAGONAL WAY . GET THE MACHINE TO

BALANCE WITH 4PCS M12 SCREWS THAT ARE ON THE LEGS, YOU SHOULD FIX IT WITH

Ø13 STEEL PINS.

BALANCING THE MACHINE

BALANCING THE MACHINE CAN BE ACHIEVED BY USING THE HEIGHT

ADJUSTABLE SCREWS. THE MACHINE MUST BE BALANCED ON BOTH DIRECTIONS.

IMPORTANT : BALANCE OF THE MACHINE IS ONE OF THE MOST IMPORTANT

FACTORS FOR THE CORRECT WORKING OF THE MACHINE.

OPERATION PANEL

EMERGENCY STOP

BUTTON:PREVENTS ACCIDENTS

AT UNEXPECTING SITUATIONS.

START BUTTON : START THE CUTTING

STOP BUTTON :STOPS THE

CUTTING

SIGNAL BUTTON : SHOW SIF THERE IS A

PROBLEM AT THE MACHINE.

COOLANT BUTTON : IT IS USED

TOL ET THE COOLANT LIQUID

FLOW.

BOW UP BUTTON: MOVES THE BOW UP

MANUALLY AND STOPS CUTTING.

BOW DOWN BUTTON: MOVES

DOWN THE BOW MANUALLY.

START(READY)BUTTON:ENERGISESPOWERCIRCUITOF

THE MACHINE

VICE PRES BUTON:IT IS USED TO

PRESS THE MATHERIAL

BLADE TIGHTENING BUTTON: TIGHTEN THE

BLADE.

MITRE LOCK SELECTOR: LOCKS

OR UNLOCKS THE BOW FOR

MITRE ADJUSTMENT

TOP CLAMPING SELECTOR(OPTIONAL): THIS

OPTION IS FOR TIGHTENINK THE MATERIAL

VERTICALLY FOR BUNDLE CUTTING

ANGLE DISPLAY: DISPLAYS THE

POSITION OF BOW IN DEGREES

BETWEEN 0° AND +60°

DOWN FEED SPEED ADJUSTMENT: ADJUST

SPEED ACCORDING TO HARDNESS OF MATERIAL

TO BE CUT. WHEN BLADE BECOMES BLUNT

CHOOSE A LOWER SPEED TO HAVE A BETTER

CUT.

SPEED CONTROL POTMETER :

CONTROLS THE INVERTER TO

ADJUST THE TURNING SPEED OF

BLADE

THE INDICATOR OF MANOMETER MUST BE IN THE GREEN AREA (AREA II). IF THE INDICATOR IS IN

ONE OF THE RED AREA, THIS MEANS THAT THE TENSION OF THE BLADE IS NOT IN THE

ACCEPTABLE LEVEL AND IT MAY CAUSE UNWANTED RESULTS.

AREA I : THIS SHOWS THAT THE TENSION OF THE BLADE IS LESS THAN IT MUST BE. ADJUST

THE BLADE TENSION.

AREA II : THIS SHOWS THAT THE TENSION OF THE BLADE IS NORMAL

AREA III : THIS SHOWS THAT THE TENSION OF THE BLADE IS MORE THAN IT MUST BE. THIS

MAY BREAK THE BLADE. REDUCE THE TENSION.

MECANICAL TENSIONING:MIN:320 BAR MAX.320 BAR

HYDRAULIC MAIN PRESSURE:60 BAR

VICE PRESSURE:20 BAR

LOCKING PRESSURE:60 BAR

HYDRAULUIC TENSIONING:50 BAR

LIFTING PRESSURE:60 BAR

BOW DOWN PRESSURE:60 BAR

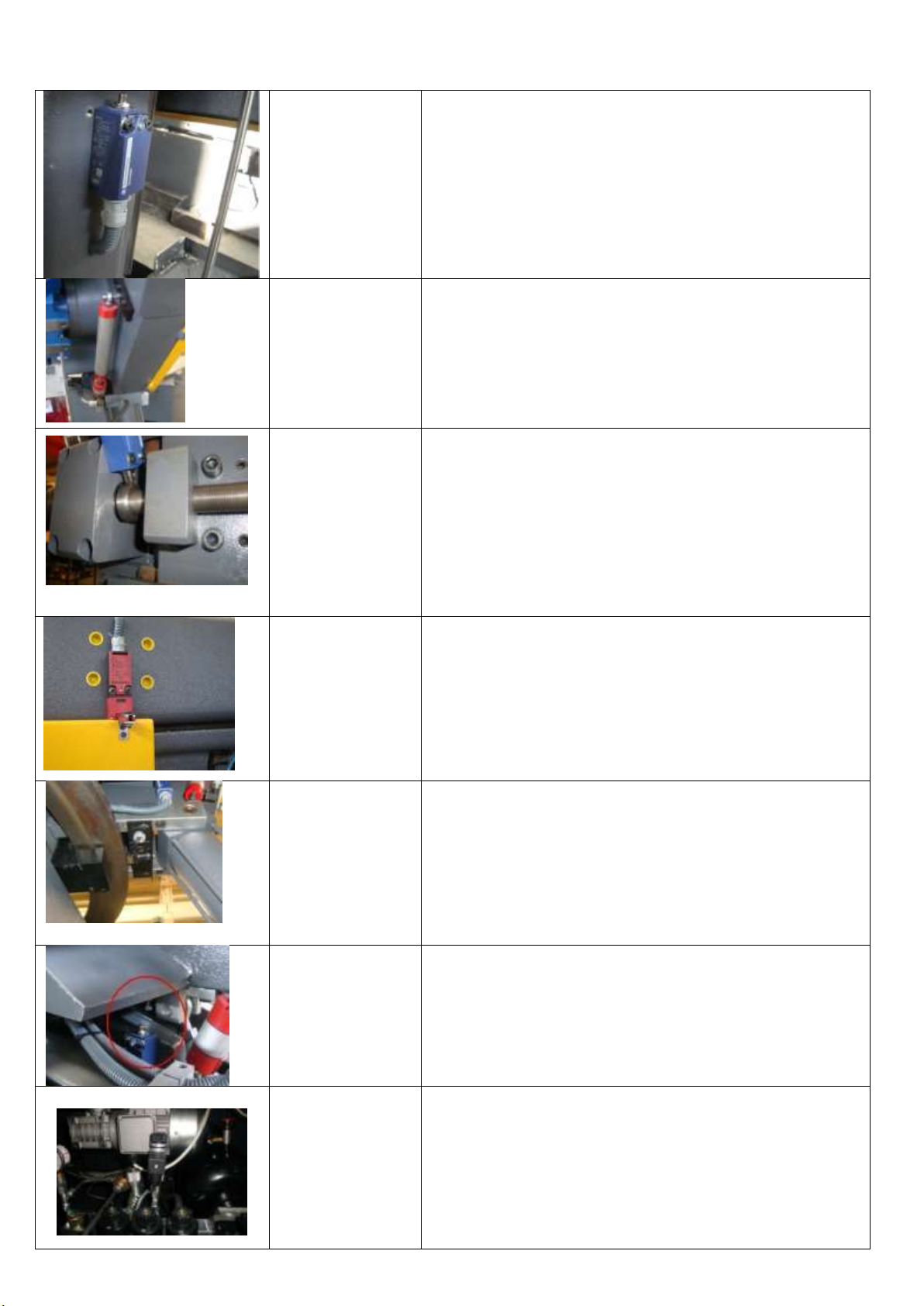

LIMIT SWITCHES

LOWER LIMIT

SWITCH

BY THIS SWITCH BOW MOVES UP AFTER CUTTING PROCESS

UPPER LIMIT

SENSOR (PISTON

TYPE-DIGITAL

ENCODER)

AFTER CUTTING PROCESS BOW GOES UP TO THE VALUE THAT

ADJUSTER FROM PANEL. UPPER LIMIT MAY CHANGE MAY CHANGE

FROM PANEL

BLADE BREAK

PROTECTION

SWITCH

WHEN BLADE BREAKS OR LOSES TENSION MAIN MOTOR STOPS FOR

SAFETY MACHINE AND OPERATOR.

WHEN THIS SWITCH IS OPERATING BOW MAY ONLY MOVE UP OR

DOWN

SAFETY SWITCHES

FOR COVERS

BY THIS SWITCH MACHINE DOES NOT START IF COVERS ARE LEFT

OPEN

(INCREMENTAL

TYPE- DIGITAL

ENCODER):

READS THE ANGLE OF BOW.

MAX. LIMIT SWITCH

THIS SWITCH SHOULD BE PRESSED FOR CHANGING THE ANGLE.

VICE PRESSURE

SWITCH

THIS SWITCH SENSES THE MATERIAL IS TIGTHENED WELL AND DOES

NOT LET THE BOW GO DOWN DOWN UNTIL THE MATERIAL IS

TIGHTENED

MANUAL CUTTING OPERATION

1-ADD COOLANT TO THE TANK

2-CHECK LEVEL OF HYDRAULIC OIL(ISO 32)

3-SWITCH ON MAIN SWITCH

4-SEE ENERGY ON LIGHT ON THE CONTROL PANNEL

5-IF THERE IS NO LIGHT CHANGE PLACES OF INPUT PHASES

6-PRESS MACHINE READY BUTTON

7- PUSH BOW UP TILL IT’S ENOUGH FOR MATERIAL TO BE CUT

8-OPEN THE VICE BY TURNING THE RELATED BUTTON.

9-PLACE THE MATERIAL. ADJUST THE LENGHT TO BE CUT BY LEAN SHAFT AND CLOSE VICE JAWS AND FIX THE MATERIAL.

10-THE SAW WILL NOT START UP UNLESS THE MATERIAL IS NOT CLAMPED WIT APPROPRIATE PRESSURE.

11-START THE SAW BY PRESSING START BUTTON.

12-DETERMINE THE APPROPRIATE SAW CUTTING SPEED AND TURN ON THE COOLANT ACCORDING TO YOUR NEED.

13-DUE TO THE MATERIAL DETECTION SENSORS ON THE MACHINE APPROACHED TO THE MATERIAL FASTLY AND THEN PASSES TO

THE SPEED WHICH IS ADJUSTED BY THE VALVE.

14-WHEN THE MACHINE RUNS TO THE CUTTING SPEED , THE COOLANT STARTS AS WELL.

15-CUTTING SPEED OF THE MACHINE SHOULD BE ADJUSTED ACCORDING TO THE MATERIAL AND CHIP AFTER CUTTONG PROCESS.

FOR EXAMPLE; IF THE CHIP IS BURNT AFTER THE CUTTING THAT MEANS THE SPEED IS TOO FAST. THAT IS NOT PROPER FOR THE

MACHINE AND THE BLADE.

16-AFTER CUTTONG PROCESS THE BALDE WILL RISE UP AND STOP AUTOMATICALLY.

17-THE SAME SHOULD BE DONE FOR THE SECOND CUTTNG.

18-DURING THE TIME THERE MIGHT PILE UP CHIP INFRONT OF THE SENSORS , THIS MIGHT CAUSE WORKING PROBLEM TO THE

MACHINE; TO AVIOD THAT , THE WHEEL COVERS SHOULD BE OPENED REGULARLY AND CHIP SHOULD BE CLEANED.

INSTRUCTIONS FOR MAINTENANCE

DAILY MAINTENANCE

1-REMOVE THE CHIPS ON WHEEL

2-CLEAN THE HYDRAULIC DRAWER

3-REMOVE THECHIPS AT SHAFT AND FLAT

4.MANOMETER SHOULD BE BETWEEN 190-210 BAR.

5-CLEAN THE TENSIONING SLIDE FLATS.

6. CLEAN THE CHIPS IN THE BORON OIL TANK

PUMP AIR TO REMOVE THE DIRTH IN HOSES

A-CHECK THE CHIP BRUSH.

B-FILL GREASE OIL FROM THE HOLE ON THE TENTIONING SHAFT.

C- CHECK THE TIGHTNESS OF WHEEL BOLTS.

D.CONTROL THE OIL LEVEL IN HYDRAULIC TANK

E. FILL GREASE OIL FROM THE HOLE ON THE TENSIONING SLIDE

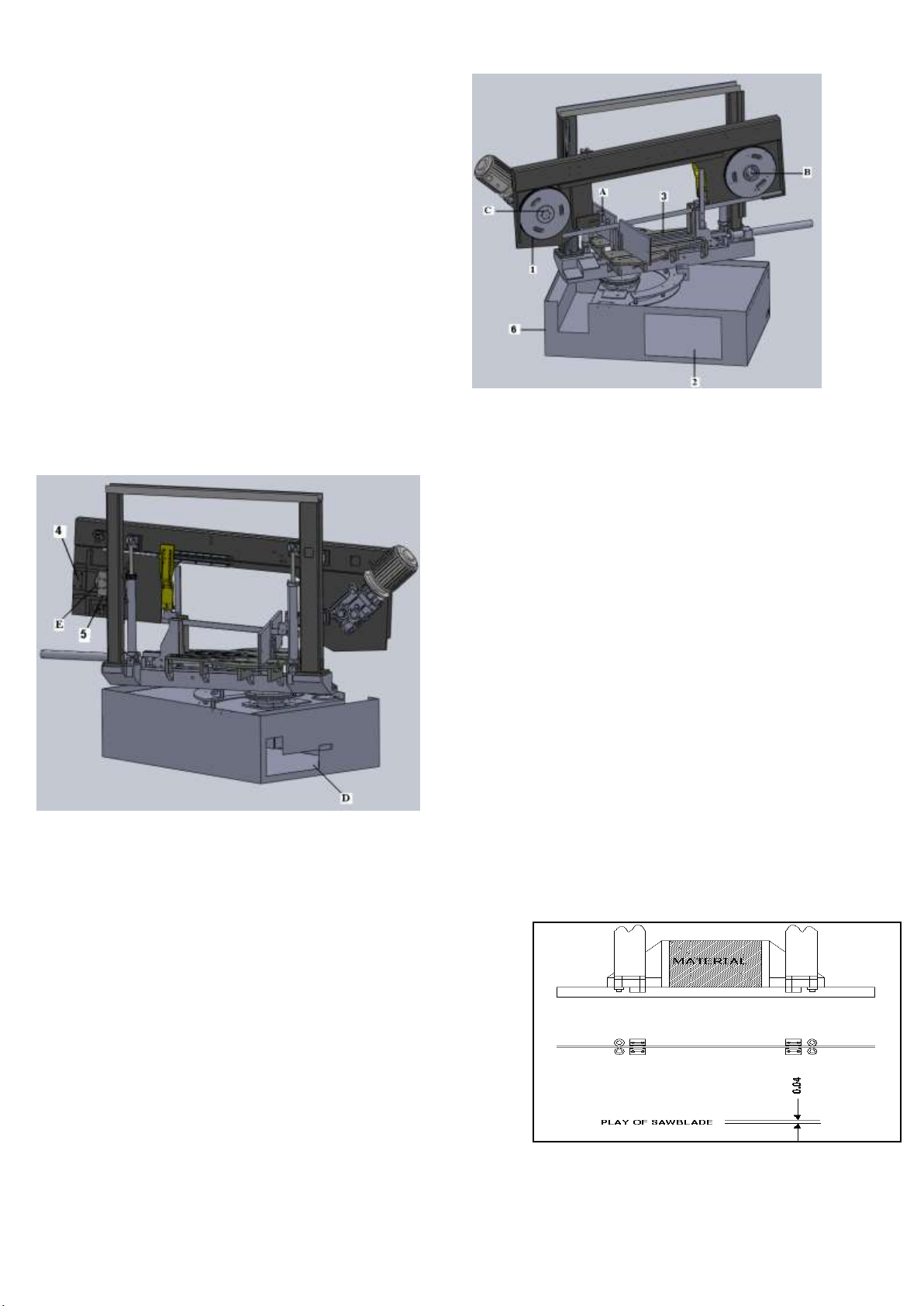

BLADE GUIDANCE

FOR AN ACCURATE GUIDACE OF THE BANDSAW BLADE THERE ARE TWO

RIGID AND PRECISE VERTICAL GUIDE ARMS FITTED WITH ROLLERS FOR

TWISTING PRETWISTING AND CARBIDE INSERTED PLATES FOR THE FIANL

AND EXACT BLADE GUIDE. PUT THE BLADE ARMS ALWAYS AS CLOSE AS

POSSIBLE TO THE MATERIAL TO BE CUT AND TIGHTTEN THEM.

THE PLAY OF THE BLADE CAN BE RE-SET BY ALTERING THE POSITION OF A

CARBIDE INSERTED GUIDE PLATE.

THE MINIMUM PLAY SHOULD BE 0.04 MM.

CHANGING THE HYDRAULIC OIL

POURING OUT THE HYDRAULIC OIL

LOWER DOWN UNTIL IT RECEIVES THE CUTTING

HEAD.

REMOVE HYDRAULIC HOSE UNION AT HEAD LIFTING

PUT THE REMOVED HYDRAULIC END OF THE HOSE

INTO A CONTAINER.

EMPTY THE OIL BY PRESSING HEAD LIFTING BUTTON

AT CONTROL PANEL.

AFTER EMPTING THE OIL, FIX THE HYDRAULIC HOSE UNION TO

THE SAME PLACE.

REFILLING THE HYDRAULIC OIL

THE HYDRAULIC OIL FILLING

REMOTE THE BOLTS OF HYDRAULIC DRAWER, THEN

PULL IT OUT.

OPEN THE STORE COVER.

POUR 32 NUMBERED ISO HYDRAULIC OIL INTO

TANK. (4LT CAPACITY.)

CLOSE THE TANK COVER AND MOVE THE DRAWER

INTO THE BODY

FASTEN THE SCREWS TO THE BODY AGAIN WITH THE HELP

OF HYDRAULIC DRAWER.

FILLING OF COOLANT

CONSISTING OF A MIXTURE OF LIQUID AND WATER COOLANT LIQUID SHOULD BE USED FOR STEEL CUTTING. COOLANT

SHOULD NOT BE USED FOR CUTTING CASTING. SPECIFIC PERIODS OF TIME (AT LEAST ONCE A MONTH) , COOLANT SHOULD BE

DRAINED AND CLEAN CHIPS. IF AMOUNT OF COOLANT IS NOT ENOUGH, ADD TO THE TANK. (4 LITERS OF TANK CAPACITY. COLLANT

MIXING RATIO 1/10)

WORKING PRINCIPLE OF THE BOW

THE HYDROLIC PUMP STARTS AS THE HYDROLIC ENGINE IS TURNED ON. THE HYDROLIC PUMP ABSORBES THE OIL FROM THE TANK

AND GIVES IT TO THE CLOSED CENTERED DIRECTION CONTROL VALVE. THE DIRECTION CONTROL VALVE TAKES THE LEFT POSITION

FOR THE BOW’S UPWARDS MOVEMENT AND PUMPS THE OIL TO PISTON’S SIDE OF CYLINDER AND THE PISTONS STARTS TO MOVE

UPWARDS. THIS IS HOW THE BOW’S UPWARDS MOVEMENT IS PROVIDED. THE BOW MOVES DOWNWARDS BY ITS OWN WEIGHT. FOR

THIS MOVEMENT THE DIRECTION CONTROL VALVE TAKES THE RIGHT POSITION AND THE OIL TURNS BACK TO THE TANK BY PASSING

THROUGH THE OIL THROTTLER. BY THIS METHOD THE BOW’S DOWNWARDS MOVEMENT IS BEING PROVIDED.

WORKING PRINCIPLES OF THE VICE

THE HYDROLIC PUMP ABSORBES THE OIL FROM TEHE TANK AND GIVES IT TO OPEN CENTERED DIRECTION CONTROL VALVE. THE

VALVE TAKES THE LEFT POSITION FOR VICE’S FORWARDS MOVEMENT AND PUMPS THE OIL TO THE PISTON SIDE OF THE CYLINDER.

AS THE MATERIAL IS CLAMPED, LOCKING VALVE TAKES ACTION AND KEEPS THE MATERIAL CLAMPED IN A STABLE PRESSURE. AFTER

CUTTING PROCESS FINISHES THE DIRECTION CONTROL VALVE TAKES THE RIGHT POSITION, TURNS OFF THE LOCKING VALVE AND

THE BACKWARDS MOVEMENT OF THE VICE BEGINS AS THE OIL IS PUMPED TO THE INVERSE SIDE OF THE PISTON. THIS IS HOW THE

VICE GETS OPENED.

TROUBLE SHOOTING

THE BOW COMES DOWN OUT OF CONTROL;

THE SEALS INSIDE OF THE HYDROLIC PISTONS MIGHT BE WORNED OUT; REPLACE.

CHECK VALVE MIGHT BE BUNGED UP WITH DIRTH; CLEAN.

CENTER OF THE DIRECTION VALVE MIGHT BE BUNGED UP WITH DIRTH; CLEAN.

THE O-RINGS OF PRESSURE ADJUSTING VALVEMIGHT BE WORNED OUT; REPLACE.

SOUNDS COMING FROM THE FRONT PULLEY

THE BEARINGS MIGHT BE WORNED OUT; REPLACE.

THE BLADE IS LEANING TO ONE SIDE WHILE CUTTING

CARBIDES MUST BE WORNED OUT; REPLACE,

BLADE GUIDING BEARINGS MIGHT BE WORNED OUT; REPLACE

THE WARNING LAMP ON THE CONTROL PANEL IS ON,

CHECK THE BLADE THIGHENING SWITCH

CHECK THE DRIVE SWITCH

CHECK THE UPPER LIMIT SWITCH

SETTING NEW BLADE

FIRST OF ALL BOTH GUARD FLAPS AND THE GUARDS WHICH ARE ON THE GUIDE ARMS HAVE TO BE OPEN UPWARDS.

LOOSEN THE BLADE BY THE HAND LEVEL SO FAR THAT THE BLADE CAN BE EASILY TAKEN OFF AROUND THE PULLEYS

THE SAME WAY BUT VIC AVERSE, FIT AND TIGHTEN THE NEW BLADE. THERE IS ALSO POSSIBILITY TO TIGHTEN THE BLADE

BY TORQUE METER.

ALWAYS PAY ATTENTION TO THE TEETH OF THE BLADE’S DIRECTION IS CORRECT. IF NOT CORRECT IT.

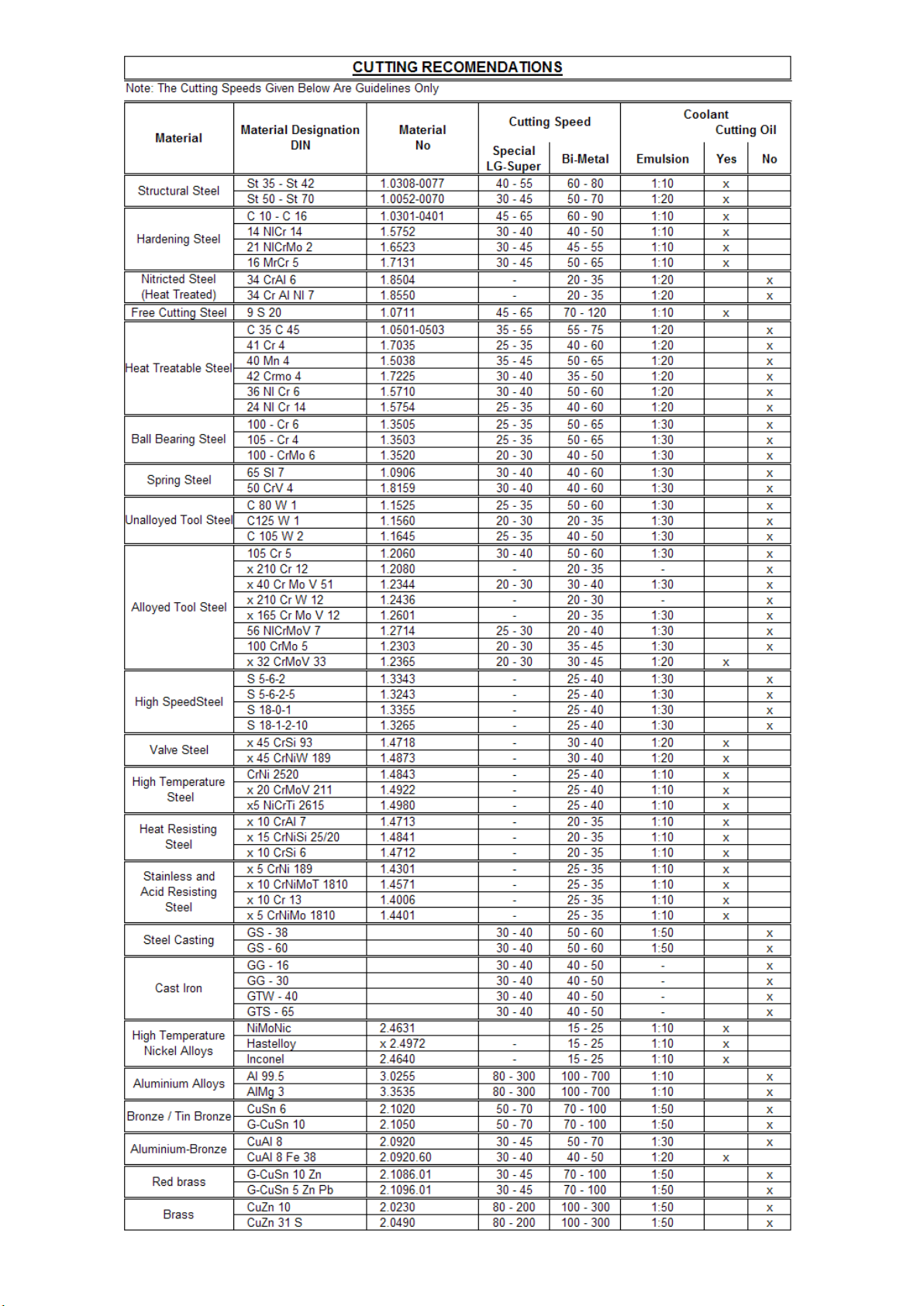

CUTTING SPEEDS

THE MACHINE HAS TWO PRE-SELECTED CUTTING SPEEDS OF 20 AND 100 M/SEC. CUTTING SPEEDS HAS TO BE SELECTED

ACCORDING TO THE GRADE AND DIMENSIONS OF THE MATERIAL. IF ANY VIBRATION AND/OR NOISE RAISES FROM THE BLADE,

CHANGE THE SPEED.

ALL THE DETAILS ABOUT THE CUTTING OF VARIOUS MATERIALS AND DIMENSIONS ARE GIVEN BELOW

CUTTING RECOMENDATIONS

SEMI AUTOMATIC

TWIN PILLAR

BANDSAWING

MACHINES

BMSy 360CDGH

SPARE PART TABLES

Table of contents

Other Beka-Mak Saw manuals