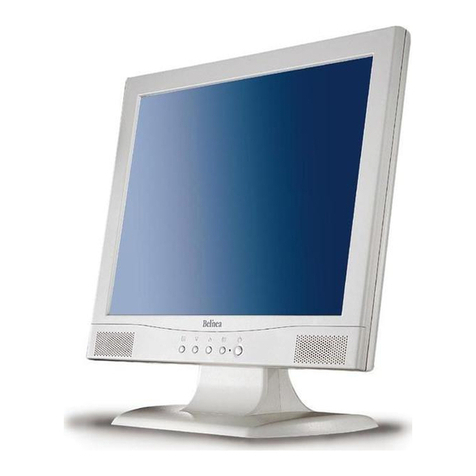

BELINEA 101830 User manual

18" LCD Colour Monitor - Maxdata(101830)

Horizontal frequencies

30-82kHz

Service

Service

Service

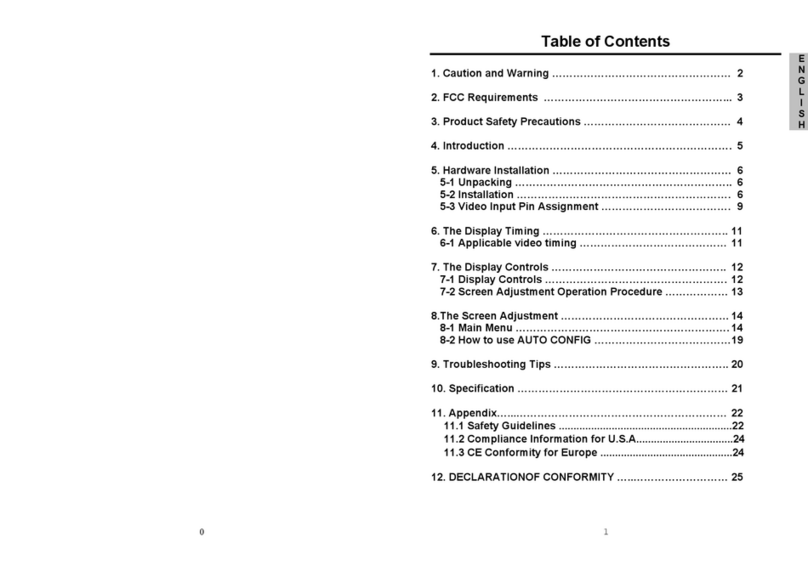

TABLE OF CONTENTS

Published by BCU Monitor Printed in Taiwan Copyright reserved Subject to modification Jul . 12 2002

DDC/Power saving/Auto Picture Adjustment

Description Page

Important Safety Notice ---------------------------------- 2

Technical Data ------------------------------------------ 3~4

Connection to PC, Front Control------------------------ 5

Setting using the OSD Menu----------------------------- 6

Failure Mode of LCD Panel-------- -- -------------------- 7

Clock&Phase Adjustments--------------------------------9

OSD Lock/Unlock--- --------------------------------------10

Aging Mode------------------------------------------------- 11

Factory Mode---------------------------------------------- 12

Warning and Notes----------------------------------------13

DDC Hex Data---------------------------------------- 21~22

Wiring Diagram-------------------------------------------- 23

Troubleshooting---------------------------------------------8

DDC Instructions------------------------------------- 14~20

Electrical Instructions-------------------------------- 24~25

Repair Flow Chart-------------------------------------26~28

Block diagram-------------------------------- --------------29

Power Diagram---------------------------------------------30

Power Panel (C.B.A.)-------------------------------------31

Description Page

Video Input Diagram---

Video & SW_DDC Diagram---------------------------- 33

Scaler Diagram------------------------------------------- 34

Frame_Beffer Diagram---------------------------------- 35

LVDS Diagram---------------------------------------------36

MCU Diagram---------------------------------------------37

Scaler Panel (C.B.A.)-------------------------------38~39

Inverter Diagram(AMBIT)-------------------------- 40~41

Inverter Panel(C.B.A.)------------------------------42~43

Control Diagram------------------------------------------44

Control Panel(C.B.A.)-----------------------------------45

Exploded View ------------------------------------------- 46

Recommended

CA110 Application----------------------------------51~59

General Product Specification--------------------61~83

Safety Test Requirements------------------------------84

Important Information-----------------------------------85

--------------------------------- 32

parts list--------------------------------47

Spare parts list-------------------------------------- 48~50

Repair Tips------------------------------------------------60

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

SAFETY NOTICE

GB 3138 106 10216

DL9B3L/00C

(LG PANEL)

Important Safety Notice

2

FOR PRODUCTS CONTAINING LASER :

DANGER- Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

CAUTION- Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

CAUTION- The use of optical instruments with this

product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITHTHEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Proper service and repair is important to the safe, reliable

operation of all Maxdata Company** Equipment. The service

procedures recommended by Maxdata and described in this

service manual are effective methods of performing service

operations. Some of these service operations require the use

of tools specially designed for the purpose. The special tools

should be used when and as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. Maxdata could not possibly know, evaluate

and advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, Maxdata has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by Maxdata must first satisfy himself

thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

* * Hereafter throughout this manual, Maxdata

Company will be referred to as Maxdata.

WARNING

Critical components having special safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Maxdada.

Maxdata assumes no liability, express or implied, arising out

of any unauthorized modification of design.

Servicer assumes all liability.

* Broken Line

Take care during handling the LCD module with backlight

unit

- Must mount the module using mounting holes arranged in four

corners.

- Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

- Do not scratch or press on the panel with any sharp objects, such

as pencil or pen as this may result in damage to the panel.

- Protect the module from the ESD as it may damage the electronic

circuit (C-MOS).

- Make certain that treatment person’s body are grounded through

wrist band.

- Do not leave the module in high temperature and in areas of high

humidity for a long time.

- Avoid contact with water as it may a short circuit within the module.

- If the surface of panel become dirty, please wipe it off with a soft

material. (Cleaning with a dirty or rough cloth may damage the

panel.)

Go to cover page

Max 101830

3

Technical Data

Go to cover page

Technical Specifications Pin Assignment

D-Sub connector

Pin No. Assignment

1 Red video input

2 Green video input

3 Blue video input

4 Ground

5 Not connected

6 Red return

7 Green return

8 Blue return

9 + 5v DDC

10 Ground

11 Ground

12 SDA (DDC data)

13 Hor. Sync

14 Vert. Sync

15 SCL (DDC Clock)

The digital/analog DVI-I onnector contains 29 signal contacts

organized in three rows of eight contacts. Signal pin

assignments are listed in the following table:

1

5

6

10

11

15

Pin No. Description

1TMDS data2-

2TMDS data2+

3TMDS data2 shield

4NC

5NC

6DDC clock

7DDC data

8Not connected-

9TMDS data1-

10 TMDS data1+

11 TMDS data1 shield

12 NC

13 NC

14 +5V

15 Ground(return for +5V and H/Vsync)

16 Hot plug detect

17 TMDS data0-

18 TMDS data0+

19 TMDS data0 shield

20 NC

21 NC

22 TMDS clock shield

23 TMDS clock+

24 TMDS clock-

C1 Analog R

C2 Analog G

C3 Analog B

C4 Analog H-sync

C5 Analog Vert. Sync.

1.1 LCD

Type NR. : LM181E05-C3 (LG-Philips)

Outside dimensions : 389(w)317.2(h)27(d) (Typ) mm

Pitch ( mm ) : 0.2805 (per one triad) x 0.2805mm

Color pixel arrangement : RGB vertical stripes

Display surface : low reflection, antiglare with hard coating

Number of color : 256 gray levels(8 bits)

Backlight : CCFL edge light system

Active area(WxH) : 359x287.2mm (18” diagonal)

View angle : Horizontal & Vertical 160 degree (CR>=10)

Contrast ratio : 350:1

White luminance : 250 nits (Typ)

1.2 Scanning frequencies

Hor. : 30 82 K Hz

Ver. : 56 - 76 Hz

1.3 Video dot rate : < 140 MHz

1.4 Power input : 90-264 V AC, 50/60 2 Hz

1.5 Power consumption : < 60 W maximum ( exclude USB option )

1.6 Dimensions : 426 * 454 * 180 mm

1.7 Weight : 8.4 KGS

1.8 Functions :

D-shell analog R/G/B separate inputs, H/V sync separated,

Composite (H+V) TTL level,

DVI digital Panel Link TMDS input

1.9 Ambient temperature : 5 C - 35 C

2 Electrical characteristics

2.1 Interface signals

The input signals can be applied in three different modes :

1). D-shell Analog

Input signal : Video, Hsync., Vsync

Video : 0.7 Vp-p, input impedance, 75 ohm @DC

Sync. : Separate sync TTL level , input impedance 2k2 ohm

terminate

Hor. sync Positive/Negative

Ver. sync Positive/Negative

Composite sync TTL level, input impedance 2k2 ohm terminate

(Positive/Negative)

Sync on green video 0.3 Vp-p Negative (Video 0.7 Vp-p Positive)

2). Intel DVI Digital

Input signal : Single channel TMDS signal

2.1.1 Audio

Input signal level : 500mVrms

Headphone output signal level : 32ohm 0.7+0.7 Vrms

Input signal connector : 3.5 mm mini jack

Loud speaker : 2+2 W stereo firing

2.1.2 Microphone

Sensitivity: -65± 5 dB re 1V/ubar at 1khz

Output impendence : 600 ohm typical

Max 101830

Technical Data(Continued)

4

Go to cover page

Max 101830

Allowed 85 Hz overscan signal mode specified

Once the signal input of PC is 85Hz, this monitor is able to display

at least for 10 minutes . An attention signal appears and shows

“This is 85Hz overscan for 5 seconds, change computer display

input to 1024X768 @ 60 Hz “

Dot rate (MHz) H.freq (KHz) Mode Resolution V.freq (Hz)

36.000 43.269 VESA 640 * 480 85.008

56.250 53.674 VESA 800 * 600 85.061

94.500 68.677 VESA 1024 * 768 84.997

Input signal mode

Factory preset 16 modes (F)

PRESET VIDEO RESOLUTION

Pre-set 32 modes (P)

PRESET VIDEO RESOLUTION

Power management

The power consumption and the status indication of the set

with power management function are as follows,

Note : Disconnect DVI signal cable and audio module.

STATUS Horizontal Vertical Power Spec LED

On Pulse Pulse as normal on Green

Stand-by No Pulse Pulse < 2 W Amber

Suspend Pulse No Pulse < 2 W Amber

off No Pulse No Pulse < 2 W Amber

According to VESA power saving signaling.

TCO99 power saving requirement

EPA energy star requirement

(Power Switch Off)

for Digital input power consumption is less 2W

( In non-DMPM recoverable off mode)

# Resolution Frequency Pixel rate Sync Comment

1 640X350 31.5K/70HZ 25.175 (+/-) IBM VGA 10h

2 720X400 31.5K/70HZ 28.322 (-/+) IBM VGA 3h

3 640X480 37.5K/75HZ 31.501 (-/-)

4 640X480 35.0K/67HZ 30.24 (-/-)

5 640X480 31.5K/60HZ 25.175 (-/-)

6 800X600 35.2K/56HZ 36 (+/+)

7 800X600 46.9K/75HZ 49.498 (+/+)

8 800X600 37.9K/60HZ 40 (+/+)

9 832X624 49.7K/75HZ 57.28 (+/+) MAC

10 1024X768 60.0K/75HZ 78.75 (+/+)

11 1024X768 48.4K/60HZ 65 (-/-)

12 1152X870 68.7K/75HZ 100 (-/-) MAC

13 1152X900 71.8K/76HZ 108 (+/+) SUN Mode II

14 1280X1024 64.0K/60HZ 108 (+/+)

15 1280X1024 80.0K/75HZ 135 (+/+)

16 688X556 31.3K/50HZ 27 (-/+) TV-PAL

#Resolution Frequency Pixel rate Sync Comment

1 640X350 31.5K/70HZ 25.175 (+/-) IBM VGA 10h

2 720X400 31.5K/70HZ 28.322 (-/+) IBM VGA 3h

3 640X480 37.5K/75HZ 31.501 (-/-)

4 640X480 43.3K/85HZ 36 (-/-)

5 640X480 37.9K/72HZ 31.5 (-/-)

6 640X480 35.0K/67HZ 30.24 (-/-)

7 640X480 31.5K/60HZ 25.175 (-/-)

8 800X600 35.2K/56HZ 36 (+/+)

9 800X600 46.9K/75HZ 49.498 (+/+)

10 800X600 37.9K/60HZ 40 (+/+)

11 800X600 53.7K/85HZ 56.251 (+/+)

12 832X624 49.7K/75HZ 57.28 (+/+) MAC

13 800X600 48.1K/72HZ 50 (+/+)

14 1024X768 60.0K/75HZ 78.75 (+/+)

15 1024X768 48.4K/60HZ 65 (-/-)

16 1024X768 56.5K/70HZ 75 (-/-)

17 1024X768 61.1K/76HZ 83.096 (+/+) IBM XGA-2

18 1024X768 68.7K/85HZ 94.5 (+/+)

19 1152X864 67.5K/75HZ 108 (+/+)

20 1152X864 63.9K/70HZ 94.5 (+/+) non-VESA

21 1152X864 54.0K/60HZ 79.9 (+/+) non-VESA

22 1152X870 68.7K/75HZ 100 (-/-) MAC

23 1152X900 61.8K/66HZ 92.94 serr- SUN Mode IV

24 1152X900 71.8K/76HZ 108 (+/+) SUN Mode II

25 1280X960 60.0K/60HZ 108 (+/+)

26 1280X960 75.0K/75HZ 129.895 (+/+) non-VESA

27 1280X1024 76.0K/72HZ 130.223 (+/+) DOS/V

28 1280X1024 64.0K/60HZ 108 (+/+)

29 1280X1024 80.0K/75HZ 135 (+/+)

30 1280X1024 81.1K/76HZ 135.008 (-/-) SUN Mode I

31 1280X1024 71.7K/67HZ 117 (+/+) SUN Mode V

32 688X556 31.3K/50HZ 27 (-/+) TV-PAL

Connection to PC,Front Control 5

Go to cover page

Connecting cables to the monitor

The monitor ports are protected by a cover.

1 = Power connector

2 = DVI-I connector

3 = D-SUB connector

The data cable supplied has two 15-pin D-SUB connectors for

the D-SUB connector of the monitor and of the computer.

Connect one of the D-SUB connectors of the data cable to the

D-SUB connector on the monitor (3) and secure the plug-in

connection by tightening the safety screws.

If instead of the data cable supplied you want to use a data cable

with DVI-I connector or if you want to connect the monitor to a

second computer, proceed as follows:

Connect the DVI-I connector of the data cable to the DVI-I

connector on the monitor (2) and secure the plug-in connection by

tightening the safety screws.

Data cables with DVI-I connectors are available from specialised

dealers.

After switching on the monitor you must select the desired input

with the OSD menu .

Switching the monitor on/off

The ON/OFF switch (1) is used for switching the monitor on and

off.

The power indicator (2) glows green when the monitor and

computer are switched on. The power indicator glows orange

when the monitor does not receive a video signal or is in the

energy-saving mode. The power indicator goes off when the

monitor is switched off.

3~8 = Buttons for the OSD menu(On-Screen-Display)

2 = Power indicator

1 = Power button

Monitor settings with the buttons of the control panel

With the buttons of the control panel, you can make the following

settings directly: auto-adjustment of the monitor, adjusting the

brightness and adjusting the contrast.

Other settings are carried out via an integrated OSD menu (On-

Screen Display).

Performing auto-adjustment of the monitor

Press the AUTO button.

The picture quality ( , ) and picture position will be

optimally adjusted for your system.

Press the MENU button to save the settings.

The brightness of the monitor is adjusted directly with the arrow

buttons.

PHASE CLOCK

Adjusting the brightness

Press the button or .

BRIGHTNESS

Press the or button to adjust

the brightness.

The setting window disappears after

approximately 60 seconds if no

further setting is made.

All changes are stored automatically.

BRIGHTNESS

50

The window with a setting scale is visualised.

Removing the monitor base

The monitor surface is susceptible to scratching!

Lay the monitor on its face on a soft surface.

Remove the four screws on the rear of the monitor.

123

Max 101830

Settings using the OSD menu

6

With the buttons on the control panel, call up and use the

integrated OSD (On-Screen Display) menu.

The OSD menu is available in different languages. The English

menu names are used in the following description (default setting).

With the OSD function you can select another

language.

The main menu appears on the screen with icons for the setting

functions.

LANGUAGE

The first symbol ( ) is

highlighted.

If necessary, press the or

button to mark another icon (e.g.

).

Press the MENU button to select

the highlighted icon.

LANGUAGE

ADJUST POSITION

Press the or button to

adjust the selected function

(here: HORIZONTAL).

Press the key or to

mark another function or press

the MENU key to return to the

main menu.

Select the symbol (EXIT

MAIN CONTROLS) in the

main menu and press the MENU

key to exit the OSD menu.

The corresponding setting window (here: )

is displayed.

ADJUST POSITION

Setting language for the OSD menu

Adjusting picture position

?

Calling the ADJUST POSITION setting window

Horizontal picture position ( HORIZONTAL

the picture to the left or to the right

Vertical picture position ( VERTICAL ): Shifting

the picture down or up

): Shifting

Adjusting the brightness and contrast

Calling the BRIGHTNESS & CONTRAST setting window

Setting the brightness of the display(BRIGHTNESS)

Setting the contrast of the display ( CONTRAST )

Setting the colour temperature

The "warmth" of the screen colours is set using the colour

temperature. The colour temperature is measured in K (= Kelvin).

Setting the picture quality

Eliminating picture interference (VIDEO NOISE )

Eliminating picture noise and horizontal interference

(PHASE)

Eliminate vertical interference with local fuzziness

(CLOCK)

Calling the ADJUST COLOR setting window

ORIGINAL PANEL COLOR = Setting for general

applications (default setting)

9300K FOR CAD/CAM = Setting for CAD/CAM programmes

6500K FOR IMAGE MANAGEMENT = Setting, for example,

for image processing or playing DVDs

USER PRESET = User -defined setting

In the user -defined setting you can change the colour

ratios of the basic colours (red, green, blue) as required.

Setting position for the OSD menu

Calling the OSD SETTINGS setting window

You can shift the OSD menu up, down, to the left or to the

right.

Displaying monitor data

You will find the serial number and the current resolution

of this screen in PRODUCT INFORMATION

.

i

Activating the factory settings

Activating the factory settings(RESET TO FACTORY

NO = retain own settings

YES = Activating the factory settings

WithYES all monitor settings are reset to the factory settings.

SETTINGS)

Selecting input signal

The monitor can be operated with analog or digital signals. Withthis

function you can (depending on the graphics card you use) switch over

between the analog and the digital mode.

Calling the INPUT SELECTION setting window

Switch on the analog mode ( ANALOG DSUB ).The monitor

processes the signals of the analog port (VGA/D

-SUB).

Switch on the digital mode ( DIGITAL DVI ). The monitor

processes the signals of the digital port (DVI-I).

Switch on analog mode via digital port ( ANALOG DVI ).

The monitor processes the analog signals of the digital

port (DVI -I).

Locking the OSD menu (OSD Lock)

The OSD menu can be locked to prevent accidental or

unauthorised changes to the monitor settings.

Press the MENU button and hold it for approx. 10 seconds.

Please proceed in the same manner to release the locked OSD

menu again.

Setting language for the OSD menu ( )

You can choose from English (default setting), German,

French, Spanish, Italian, and Japanese.

LANGUAGE

Go to cover page

Max 101830

7

Go to cover page

Max 101830

Failure Mode of LCD panel

Quick reference for failure mode of LCD panel

This page presents problems that could be made by LCD panel. It is

not necessary to repair circuit board. Simply follow the Mechanical

instruction o n this manual to eliminate failure by replace LCD panel

or backlight tubes.

Failure description Phenomenon

Vertical dim lines

Vertical block defect

Vertical lines defect

(Always bright or dark)

Horizontal block defect

Horizontal dim lines

Horizontal lines defect

(Always bright or dark)

Has bright or dark pixel

.

..

.

.

.

.

..

.

.

.

Bright pixel

Dark pixel

..

....

Polarizer has bubbles

Polarizer has bubbles

Foreign material inside

polarizer. It shows linear or

dot shape.

....

Concentric circle formed

Bottom back light of LCD is

brighter than normal

Backlight un-uniformity

Backlight has foreign

material. Black or white

color, linear or circular type

8Trouble Shooting

Go to cover page

Trouble shooting

Should an error occur, first check the following points. If the distortion is still not eliminated, the monitor should, if possible,

be checked on another computer and/or with another data cable.

Having this problem? Check the following points:

No display (power indicator does

not light)

Check whether the monitor is

switched on.

Check whether the power cable

on themonitor is connected

correctly.

Check whether the computer is

switched on.

Having this problem? Check the following points:

No display (power indicator lights) Check whether the computer is

switched on.

Check whether the data cable for

the monitor is

correctly attached

to the monitor port on the computer.

Press any key on the computer

keyboard the computer may be in

Alter the brightness and/or contrast

until you get apicture.

Check whether the data cable for

the monitor is correctly attached to

the monitor port on the computer.

Check whether the computer is

switched on.

The input signal (horizontal

frequency and refresh rate) at the

displayed input does not correspond

to the technical monitor data.

Adjust the video frequency range

using the computer sof tware (safe

Picture position is not correct The monitor recognises an

undefined mode (see

").

Press the AUTO button to conduct

the

Technical

data

auto-adjustment of the screen.

Set the picture position with the

OSD menu .

Picture is shaking Check whether the data cable for

the monitor is correctly attached to

the monitor port on the computer.

Having this problem? Check the following points:

Picture disturbances (vertical lines) Press the AUTO button to conduct

the auto-adjustment of the screen.

Set the picture quality in VIDEO

NOISE(CLOCK ).

Picture disturbances (horizontal

lines, picture noise) Press the AUTO button to conduct

the auto -adjustment of the screen.

Set the picture quality in VIDEO

NOISE(PHASE ).

The screen becomes darker The background lighting has a

limited lifetime.If your monitor

display should become too dark,the

exchanged.

background lighting will have to be

Image of last screen display still

visible

If you switch from a high

-contrast

display (for example black lines/

characters on a white background)

to a picture of medium brightness,

you may be able to see a faint

image of the previous display for a

time. This phenomenon is not due

to a monitor defect but to the

technology used (IPS display with

large viewing angle, IPS = In Plane

Switching).

Permanently unlit or lit pixels The standard of production

techniques today cannot guarantee

an absolutely fault -free screen

display. A few isolated constant lit

or unlit pixels may be present.

The maximum permitted number

of pixels faults is stipulated in the

stringent international standard

ISO 13406 -2 (Class II).

Example: a 17" or 18" flat- screen

monitor with a resolution of

1280 x 1024 has 1280 x 1024 =

1310720 pixels.

Each pixel consists of three

subpixels (red, green and blue), so

there are almost 4 million dots in

total.

According to ISO 13406-2 (Class II),

a maximum of 6 pixels and 7

subpixels may be defective, i. e.

a total of 25 faulted dots.

This corresponds to approx.

0,0006 % of the entire screen

surface!

energy saving mode.

Mode ) or Using another CRT

monitor.

Max 101830

CLOCK & PHASE Adjustments 9

Step 1 : Click on the Start button (Win95, Win98 or Win NT)

and choose " Shut Down...". as shown in Fig. 2.

Step 2 : The menu of " Shut Down Windows " is as shown in Fig. 3

Step 3 : Retain Shut Down Window on the screen , follow

the CLOCK and PHASE adjustment instructions for the

optimal video display.

PHASE phenomenon

Due to the different quality of video signal generated from graphics

cards. By press AUTO button for

t is necessary to adjust

CLOCK and PHASE functions for the optimal video display of LCD

monitor by manual. Following steps will guide you to make correct

adjustment of CLOCK and PHASE.

However, CLOCK and PHASE functions are only available while analog

video signal is supplied. Operating unit under digital signal state, the

video clock information can be obtained from graphics cards directly.

Therefor, it is unnecessary to adjust these functions.

CLOCK and PHASE adjustment

automatically. Sometimes, the deviation of video signal which generated

from graphics cards is out of control, then i

Manual adjustment

If the quility of display still poor or flicker, you may also improve it by

manual adjust CLOCK and PHASE functions to eliminate the flicker.

Step 4 : Press the MENU button to bring up MAIN CONTROLS

(OSD menu).

Step 8 : Press or to adjust PHASE. The picture will

be adjusted as following figure, adjust PHASE and check the

picture, stop at the point that without any vertical jitter bar

remaining on the screen.

button

Step 5 : Select Video Noise by press button.

Step 6 : Press to bring up it s submenu.button

Step 7 : Press or to adjust CLOCK. The picture will

be adjusted as following figure, adjust CLOCK to fine-tune the

video until optimal display is obtained.

button

Step 9 : Quit OSD menu by press button to save the settings.

CLOCK Phenomenon

Video Noise

(Auto adjustment hotkey)

Front control panel

1 = Buttons for the OSD menu (On-Screen-Display)

2 = Power indicator

3 = Power button

23

1

AUTO MENUINPUT

AUTO button

MENU

MENU

MENU

The monitor has build-in a auto adjustment hotkey on the front panel,

you may obtained a optimal video display by simply press the

button and save the settings. CLOCK, PHASE, Vertical position, and

Horizontal position are adjusted automatically.

AUTO

Fig. 1

Fig. 2

(Before)

(Before)

(After)

(After)

Fig. 3 (Win 98)

MENU

MENU

Go to cover page

Max 101830

10

OSD Lock/Unlock, Attention signal, Service Mode

Go to cover page

Front control panel

ATTENTION

OSD MAIN CONTROLS LOCKED

ATTENTION

OSD MAIN CONTROLS UNLOCKED

ATTENTION

ATTENTION SIGNAL OFF

ATTENTION

ATTENTION SIGNAL ON

To Lock/Unlock OSD function (User Mode)

The OSD function can be locked by pressing button for more than

10 seconds, the screen shows following windows for 3 seconds.

Everytime when you press or button, this message appears

on the screen automatically. The & (brightness) ,

(input) hotkey are still functional for brightness and input signal

selection while OSD locked.

Switch ON/OFF attention signals (User Mode)

All attention signals can be by keep pressing button

for more than 10 seconds if there is no video signal supplied.

Step 1: Disconnect signal cable (Monitor & PC are still ON.)

Step 2: Press "AUTO" button for more than 10 seconds, bring up

message as below.

switched off

Recover attention signals by pressing button for more than 10

seconds without video signal input.

Step 1: Disconnect signal cable (Monitor & PC are still ON.)

Step 2: Press "AUTO" button for more than 10 seconds again,

bring up message as below.

Access Service Mode (in USER MODE)

Method 1:

Leave service mode by either re-feed video signal or simply turn off

and on the power of monitor.

Step 1: Disconnect signal cable on Rear side of monitor.

Don't disconnect signal cable on PC side, because CPU will

detect pin-9 of D-SUB (15 pin connector).

(Monitor & PC are still ON.)

Bring up "CHECK CABLE CONNECTION" screen.

Step 2: Press MENU" " button for more than 15 seconds.

Bring up message as below.

Access Service Mode (in USER MODE)

Method 2:

Leave service mode by either re-feed video signal or simply turn off

Step 1:

- Turn off monitor.

- Disconnect signal cable on PC side.

- Turn on monitor.

(After 3 seconds)

Bring up "NO VIDEO INPUT"

Step 2: Press MENU" " button for more than 15 seconds.

Bring up "SERVICE MODE".

Access Service Mode (in USER MODE)

Method 3:

Leave service mode :simply turn off and on the power of monitor.

Step 1:

-PCoff.

- Signal cable connect to rear side of Monitor only.

- Turn on monitor.

Bring up "NO VIDEO INPUT"

Step 2: Press MENU" " button for more than 15 seconds.

Bring up "SERVICE MODE".

AUTO

AUTO

AUTO

MENU

MENU

Locked OSD function can be released by pressing button for

more than 10 seconds again. While press "MENU" button for OSD

unlocked purpose, the screen will keep showing OSD MAIN

CONTROLS LOCKED u ntil OSD function unlocked and screen

automatically shows following window for 3 seconds.

MENU

1 = Buttons for the OSD menu (On-Screen-Display)

2 = Power indicator

3 = Power button

23

1

AUTO MENUINPUT

INPUT

ATTENTION

CHECK CABLE CONNECTION

ATTENTION

NO VIDEO INPUT

ATTENTION

NO VIDEO INPUT

MENU

MENU

SERVICE MODE

SERIAL NO. : YEKA105542

HOURS OF OPERATION: 000222

MENU

SERVICE MODE

SERIAL NO. : TW211P0022

HOURS OF OPERATION: 000205

SERVICE MODE

SERIAL NO. : TW211P0022

HOURS OF OPERATION: 000205

Max 101830

11

Go to cover page

AGING Mode

Bring up :

After 15 seconds, bring up :

After 15 seconds, bring up :

After 15 seconds, bring up :

----------

----------

repeatly

Connect signal cable again => go back to normal display.

Front control panel

Access Aging.. Mode (Method 1)

(Monitor & PC are ON for Step 1.)

Step 1: Disconnect signal cable on Rear side of monitor.

Bring up "CHECK CABLE CONNECTION" screen.

or

Disconnect signal cable on PC side.

Bring up "ENTERING SLEEP MODE" about 3 seconds,

then disappear.

Step 2:

Turn off LCD monitor.

Push AUTO " " & " " & " " buttons simultaneously

,then release Power buttun only, untill picture comes on the screen.

Bring up "AGING ...".

1 = Buttonsfor the OSDmenu (On-Screen-Display)

2 = Power indicator

3 = Power button

23

1

AUTO MENUINPUT

ATTENTION

CHECK CABLE CONNECTION

ATTENTION

ENTERING SLEEP MODE

AUTO

A G I N G. . .A G I N G. . .

A G I N G. . .A G I N G. . .

Method 2:

Leave AGING mode :connect signal cable to PC,

then turn on PC.

Step 1:

- PC off and Monitor off.

- Signal cable connect to rear side of Monitor only.

- Connect Power Cord to rear side of monitor, then insert the plug

into a properly grounded electrical outlet.

(Power LED of monitor is off now.)

Step 2:

Push AUTO " " & " " & " " buttons simultaneously

,then release Power buttun only, untill picture comes on the screen.

Bring up "AGING ...".

---------

---------

repeatly

AUTO

A G I N G. . .A G I N G. . .

Max 101830

12

Go to cover page

Factory Mode

Access Factory Mode

Factory Mode:

How to Get into Factory Mode Menu

Turn off LCD monitor.

Push AUTO " " & " " & " " buttons simultaneously

,then release Power buttun only, untill picture comes on the screen.

Press MENU " " button, bring up Factory mode indication as

shown in Fig 2.

Fig. 2

Factory Mode indication==>

MAXDATA 180P V1.88 02-04-17

Contrast adjustment (Sub-Contrast). Use this menu item to

adjust the contrast gain of pre-amp ranges from 0 to 255.

(For

9 3 0 0 K R G B

6 5 0 0 K R G B

Color temperature gain adjustment. Use these menu items to

adjust the RGB gains of pre-amp for different color

temperatures, ranges from 0 to 255.

OFFSET R G B

Sub-Brightness adjustment. Use this menu item to adjust

the brightness level (DC-level) of pre-amp range from 0 to

255.(R/G/B ANALOG DC -level).

example: of Sub-Contrast in factory mode is

preset for 100%(Maximum Value) of Contrast Value in user

mode).

GAIN R G B

R/G/B GAIN adjustment. Use this menu item to adjust

the R/G/B (GAIN) of Amp. range from 0 to 255.(R/G/B

ANALOG GAIN Values).

AUTO SUB:

AUTO Colour to Adjust OFFSET R/G/B & GAIN R/G/B

automatically by LCD MONITOR CPU.

RESERVE1: NO FUNCTIONED, RESERVED ONLY.

RESERVE2: NO FUNCTIONED, RESERVED ONLY.

RESERVE3: NO FUNCTIONED, RESERVED ONLY.

AUTO SUB:

Use button to select factory adjustment indication (for example:

MAXDATA 180P V1.88 02-04-17), which is the entrance of the factory

adjustment menu, press MENU " " button to access it. The

window shows as below.

(PS: The “Offset R G B” function can be used on reduce or eliminate

snowy noise on the background when the resolution of video signal is

1280 X 1024 vertical 60Hz. Slightly increase or decrease the value

until snowy noise completely disappear.)

Default values (example) are as below.Default values (example) are as below.

Leave Factory Mode

Turn off monitor, then turn on monitor again => go back

to User mode directly.

Leave Factory Mode

Turn off monitor, then turn on monitor again => go back

to User mode directly.

SUB BRI:SUB BRI:

-

-

OKOK

255255

255255

-

SUB CON:SUB CON:

NO FUNCTIONED,”DIGITALDC-Level” RESERVED

for LCD MONITOR 150P usage ONLY.

AUTO

MENU

Fig. 1

1 = Buttonsfor the OSDmenu (On-Screen-Display)

2 = Power indicator

3 = Power button

23

1

AUTO MENUINPUT

MENU

9300K R G B9300K R G B

6500K R G B6500K R G B

OFFSET R G BOFFSET R G B

SUB CON:SUB CON:

SUB BRI:SUB BRI:

-

-

AUTO SUB:AUTO SUB:

-

OKOK

GAIN R G BGAIN R G B

RESERVE1:RESERVE1:

RESERVE3:RESERVE3:

RESERVE2:RESERVE2:

MAXDATA 180P V1.88 02-04-17

0000

Fig. 3

AUTO

Use or buttons to select SUB-CON, 9300K R G B,..etc.

Use or buttons to decrease/increase the value of each item.

Press " " => go back to MAIN CONTROLS.

All the default values are invisible. Press " " => appear.

To press AUTO " " button on this screen, the values of

OFFSET and GAIN will be adjusted by CPU automatically.

MENU

9300K R G B9300K R G B

6500K R G B6500K R G B

OFFSET R G BOFFSET R G B

SUB CON:SUB CON:

SUB BRI:SUB BRI:

-

-

AUTO SUB:AUTO SUB:

-

OKOK

GAIN R G BGAIN R G B

RESERVE1:RESERVE1:

RESERVE3:RESERVE3:

RESERVE2:RESERVE2:

MAXDATA 180P V1.88 02-04-17

0000

8484

188188

5050

182182

8686

181181

8383

251251

228228

255255

252252

255255

205205

255255

255255

226226

Max 101830

13

Go to cover page

Warning and Notes

Fig.1

V

Warnings

1. Safety regulations require that the unit should be returned

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol .

2. In order to prevent damage to ICs and transistors, all

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is 0 V (after approximately

30 seconds).

3. ESD

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

4. When repairing a unit, always connect it to the AC Power

voltage via an isolating transformer.

5. Be careful when taking measurements in the high-voltage

section and on the picture tube panel.

6. It is recommended that saferty goggles be worn when

replacing the picture tube.

7. When making adjustments,use plastic rather than metal tools.

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

8. Never replace modules or other components while the

unit is switched on.

9. Together with the defleciton unit, the picture tube is used

as an integrated unit. Adjustment of this unit during repair

is not recommended.

10. After repair, the wiring should be fastened in place with

the cable clamps.

11. All units that are returned for service or repair must pass

the original manufactures safety tests.

Notes

1. The direct voltages and waveforms are average voltages.

They have been measured using the Service test software

and under the following conditions :

- Mode : 640 * 480 (31.5kHz / 60Hz)

- Signal pattern : grey scale

- Adjust brightness and contrast control for the

mechanical mid-position (click position)

2. The picture tube panel has printed spark gaps.

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

3. The semiconductors indicated in the circuit diagram(s)

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

(CRT ONLY)

Max 101830

DDC Instructions

General

Pin assignment

1

10

6

11 15

5

Assignment Assignment

Pin No. Pin No.

Ground

No Connected

Ground

Blue video input

2

7

6

8

4

5

3

19

12

11

14

13

15

10

Red video ground

Blue video ground

Green video ground

+5V

Ground

Data clock line(SCL)

V.Sync(VCLK for DDC)

H.Sync

Serial data line(SDA)

Green video input

Red video input

A. 15-pin D-Sub Connector

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed.

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this

case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For Analog interface: Standard Version 3.0

Structure Version 1.2

For Digital inferface: Standard Version 3.0

Structure Version 1.3

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98.

3. EDID301.EXE program (3138 106 10103) as shown in Fig. 1

4. A/D Alignment kits (3138 106 10079):

inclusion : a. Alignment box x1 (as Fig. 2)

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

d. (DVI-D) to (D-Sub) cable x1 (as Fig. 3)

Note: The EDID301.EXE (Release Version 1.58 20000818)is a

windows-based program, which cannot be run in MS-DOS.

Diskette with EDID301.EXE

EDID301.EXE

Ver:1.58

(DVI-D) to (D-Sub) cable

Note: The alignment box has already build-in a batteries socket for

using batteries (9V) as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

To Monitor

DC 8V~12V

Video CardVideo Card

To Printer

Power

indicator

A/D Alignment Kits - Analog connectionA/D Alignment Kits - Analog connection

A/D Alignment Kits - Digital connectionA/D Alignment Kits - Digital connection

Fig. 2Fig. 2

Fig. 1Fig. 1 Fig. 3Fig. 3

To Monitor

(Digital port)

DC 8V~12V

To Printer

Power

indicator

14

Go to cover page

Max 101830

Go to cover page

15

DDC Instructions (Continued)

Step 3: Installation of EDID301.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID301.EXE program into floppy disk

drive.

2. Click , choose Run at start menu of Windows 95/98 as

shown in Fig. 4.

Fig. 4

4. Click OK button. The main menu appears (as shown in Fig. 6).

This is for initialize alignment box.

Fig. 6

Fig. 5

Fig. 7

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 7) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this time,

please make sure all cables are connected correctly and fixedly,

and the procedure has been performed properly.

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID301 (for example, A:\EDID301, as shown in Fig. 5).

Method 2: After create a shortcut of EDID301.EXE

: Double click EDID301 icon (as shown in Fig. 8) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 9.

This is for initialize alignment box.

Fig. 9

Note 2: During the loading, EDID301 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Fig. 8

1

Configuration and procedure

There are 2 chips contained OSD string, serial number..etc

on the circuit board,

main EEPROM which storage all factory settings,OSD string.

DDC IC which storage 128byte EDID data(serial number ..etc.).

Following descirptions are the connection and procedure for Analog

and Digital DDC application, the main EEPROM can be

re-programmed along with Analog/Digital IC by enable “factory memory

data write” function on the DDC program (EDID301.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID301.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

Step 2: Connecting printer cable and video cable of monitor as Fig. 3

Fig. 3

Rear view of hp L1815

12 3

1=Power connector

2=DVI-I connector

3=D-SUB connector

~

~

PC

To printer port (LTP1)

DC Power

8~12 V

Printer

Port

To video card

To

Monitor

To PC

Max 101830

16

Go to cover page

DDC Instructions (Continued)

Max 101830

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all cables and

box as shown in Fig. 10

Fig. 11

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 12.

Step 3: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Step 4: Modify DDC data (Monitor Serial No.)

1. Click Next , bring up Fig. 15.

2. Click Next , bring up Fig. 16.

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 15

Fig. 16

Fig. 12

2. Select the DDC2B as the communication channel.

Select "Enable" & fill out "F0" for Mapped EDID page address

as shown in Fig. 12.

Fig. 10

Rear view of hp L1815

12 3

1=Power connector

2=DVI-I connector

3=D-SUB connector

~

~

PC

To video card

To printer port (LTP1)

DC Power

8~12 V

Printer

Port

To

Monitor

To PC

Fig. 13

Fig. 14

<- - -

<- - -

For AnalogFor Analog

select and fill out,

if necessary.

select and fill out,

if necessary.

Don't close this screen. --->

Go to cover page

17

DDC Instructions (Continued) Max 101830

Fig. 17 Fig. 20

Fig. 21

Fig. 18

Fig. 19

3. Click Next , bring up Fig. 17. 6. Click Next , bring up Fig. 20.

7. Click Next , bring up Fig. 21.

(Serial number can be filled up or be changed at this moment.

4. Click Next , bring up Fig. 18.

5. Click Next , bring up Fig. 19.

Fig. 22

8. Click Next , bring up Fig. 22.

- Click Finish to exit the Step window.

18

Go to cover page

DDC Instructions (Continued)

Max 101830

Fig. 25

Fig. 26

Fig. 27

Step 8: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 25.

The file type is EDID301 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes,

hex code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into DDC IC

& EEPROM for DDC Data application.

Step 9: Load DDC data

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig. 26.

3. Click Open.

2. Click Save.

Step 9: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 27.

Step 5: Access Factory Mode for DDC data writing

Factory Mode:

How to Get into Factory Mode Menu

Turn off LCD monitor.

Push AUTO " " & " " & " " buttons simultaneously

,then release Power buttun only, untill picture comes on the screen.

Press MENU " " button, bring up Factory mode indication as

shown in Fig 23.

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

(0% ~ 100%, -> READY)

2. Click (Read EDID) to re-confirm (check contents) it.

Step 7: Reconfirm Monitor Serial Number in User Mode

1. Turn off monitor, then turn on monitor again => leave factory mode

and return to User Mode directly.

2. Press "MENU" button -> select "PRODUCT INFORMATION" ->

press "MENU" button -> bring up Fig. 24.

Fig. 24

Fig. 23

2 3

1

AUTO MENUINPUT

AUTO

MENU

Factory Mode indication==>

PRODUCT INFORMATION

SERIAL NO. : TY 123456

RESOLUTION : 1024x768@60HZ

VIDEO INPUT : ANALOG (D-SUB)

MENU BACK TO MAIN CONTROLS

MAXDATA 180P V1.88 02-04-17

19

Go to cover page

DDC Instructions (Continued) Max 101830

Re-programming Digital DDC IC (User mode)

Connecting all cables and alignment box as shown in

Fig. 28.

Step 1:

After connection for Digital DDC application, if it is still in Analog DDC

application of EDID301.

Exit EDID301 program before Digital DDC application.

Fig. 29

Fig. 30

Step 2: Initialize alignment box

(Shortcut of EDID301.EXE on

Double click EDID301 icon (as shown in Fig. 29) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 30.

Windows Wallpaper already.)

Step 3: Read DDC data from monitor

1. Click icon from the tool bar to bring up the Channels

Configuration Setup windows as shown in Fig. 30.

2. Select the DDC2B as the communication channel.

Disable "Factory memory data write" for Digital DDC

application as shown in Fig. 31.

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 32.

Fig. 31

Fig. 32

Step 4: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 (Digital) as shown in Fig. 33 .

EDID30 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 34 Fig. 35

Fig. 28

Rear view of hp L1815

12 3

1=Power connector

2=DVI-I connector

3=D-SUB connector

~

~

PC

To video card

To printer port (LTP1)

DC Power

8~12 V

To

Monitor

To PC

Printer

Port

D-Sub connector

1

1

Fig. 33

<- -<- -

For DigitalFor Digital

select and fill out,

if necessary.

select and fill out,

if necessary.

20

Go to cover page

DDC Instructions (Continued)

Max 101830

Step 5: Modify DDC data (Monitor Serial No.)

Monitor Serial No. can be filled up or be changed (for example,

TY 123456) as shown in Fig. 40.

Click Finish to exit the Step window as shown in Fig. 41.

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

2. Click (Read EDID) to re-confirm (check contents) it.

The 128bytes DDC data which had been written into DDC IC of

Digital Mode.

Fig. 36 Fig. 37

Fig. 43

Fig. 44

2. Click Save.

Step 9: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 27.

Step 7: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 43.

Step 8: Load DDC data

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig 44.

3. Click Open.

Fig. 38

Fig. 41

Fig. 40

Fig. 39

The display of SERIAL NO. by OSD can be change/update by

Analog Mode only.

It means "Analog Mode and Digital Mode are using same EEPROM

for display of SERIAL NO. by OSD" as shown in Fig. 42.

Fig. 42

PRODUCT INFORMATION

SERIAL NO. : TY 123456

RESOLUTION : 1024x768@60HZ

VIDEO INPUT : ANALOG (D-SUB)

MENU BACK TO MAIN CONTROLS

Table of contents

Other BELINEA Monitor manuals

BELINEA

BELINEA CRT-Monitor User manual

BELINEA

BELINEA 2080 S2 User manual

BELINEA

BELINEA 101536 User manual

BELINEA

BELINEA 10 30 50 User manual

BELINEA

BELINEA 15 User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 10 User manual

BELINEA

BELINEA 101715 User manual

BELINEA

BELINEA Belinea 2025 S1W User manual

BELINEA

BELINEA 101735 User manual

BELINEA

BELINEA 101927 User manual

BELINEA

BELINEA 10 20 05 User manual

BELINEA

BELINEA 101730 User manual

BELINEA

BELINEA 10 80 80 User manual

BELINEA

BELINEA 101901 User manual

BELINEA

BELINEA 1705 S1 User manual

BELINEA

BELINEA 102035W User manual

BELINEA

BELINEA 1945 G1 User manual

BELINEA

BELINEA 102015 User manual

BELINEA

BELINEA 10 30 55 User manual