MACHINE INFORMATION

MACHINE SPECIFICATIONS

Illumination Distance 5 Meters

Vibration Rating 20 G

Shock Rating 100 G

Frame And Body

Cab

Type FOPS (ISO 3449) / ROPS

(ISO 3471)

Principal Chassis Components

Type Front Chassis, Rear Chassis,

Male Oscillation Joint.

Materials

Type Structural steel and high

strength steel

Front Chassis Construction

Type I-section beams and boxed

transverse members

Rear Chassis Construction

Type Dual box-type longitudinal

beams, two boxed transverse

members and one transverse

tubular member

Bin

Type Ribless structure manufac-

tured from high tensile wear

and impact resistant, alloy

steels.

Retrieval Points (in conformance with ISO 10532) B35E,

B40E, B45E & B50E

Type Two points on the front chas-

sis and two points on rear

chassis.

Retrieval Points (in conformance with ISO 10532) B60E

Type Two points on the front chas-

sis and two points on rear

axle housing.

Tie-down Points (in conformance with ISO/DIS 15818)

B35E, B40E, B45E & B50E

Type Two points on the front chas-

sis, two points on the front of

the rear chassis and two

points at the rear of the rear

chassis.

Tie-down Points (in conformance with ISO/DIS 15818)

B60E

Type Two points on the front chas-

sis, two points on the front of

the rear chassis and two

points on the rear axle

housing.

Lifting Points (in conformance with ISO/DIS 15818)

Type Two points on front chassis

and two points on bin.

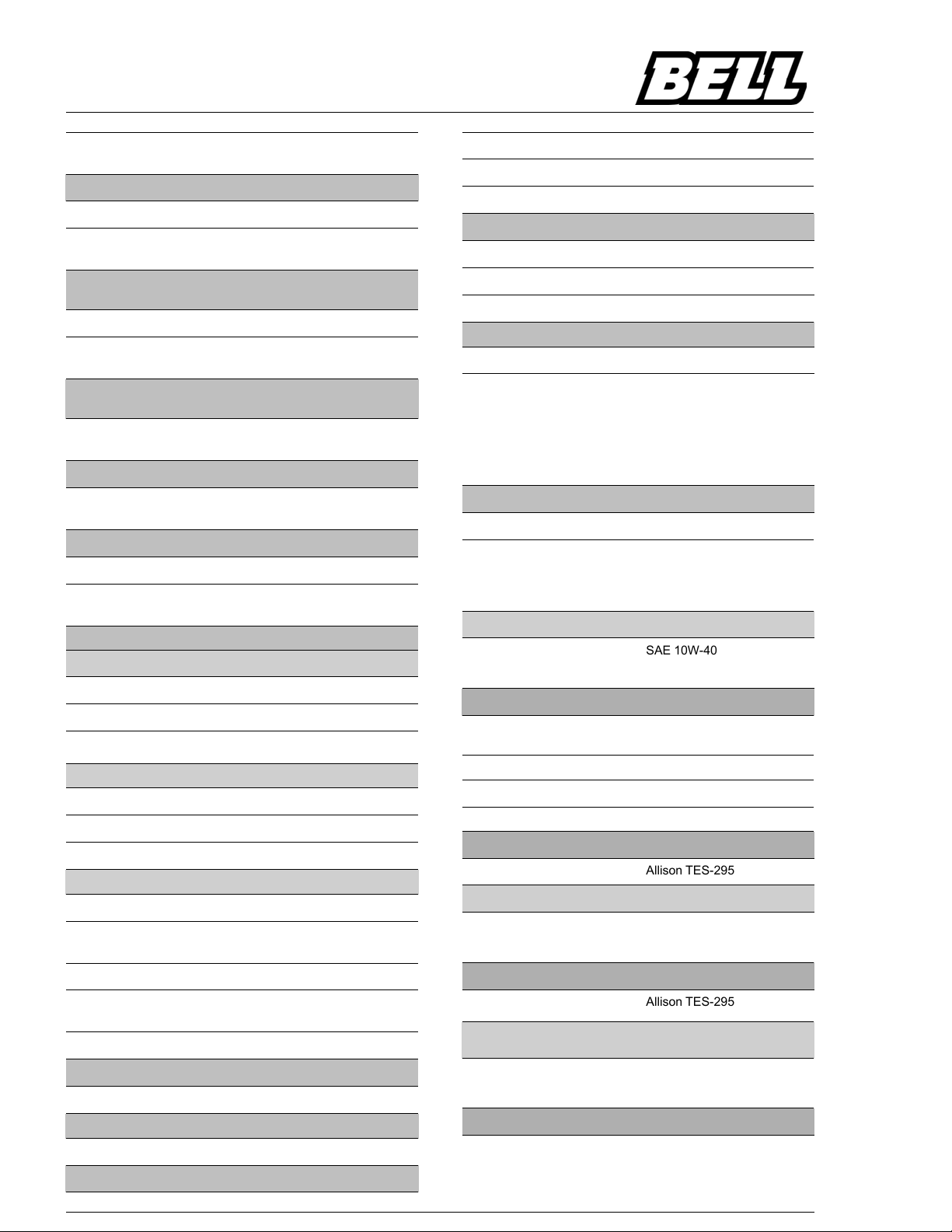

B35E

Rated payload 33 500 kg (73 855 lb.)

Capacity struck 16 m³ (20.9 yd.³)

Capacity heaped (SAE 2:1) 20.5 m³ (26.8 yd.³)

Capacity heaped (SAE 1:1) 24.5 m³ (32 yd.³)

B40E

Rated payload 39 000 kg (85 980 lb.)

Capacity struck 19 m³ (24.9 yd.³)

Capacity heaped (SAE 2:1) 24 m³ (31.4 yd.³)

Capacity heaped (SAE 1:1) 28.5 m³ (37.3 yd.³)

B45E

Rated payload 41 000 kg (90 390 lb)

Capacity struck 19.5 m³ (25.5 yd.³)

Capacity heaped (SAE 2:1) 25 m³ (32.7 yd.³)

Capacity heaped (SAE 1:1) 29.5 m³ (38.6 yd.³)

B50E

Rated payload 45 400 kg (100 090 lb)

Capacity struck 21.5 m³ (28.1 yd.³)

Capacity heaped (SAE 2:1) 27.5 m³ (36 yd.³)

Capacity heaped (SAE 1:1) 33 m³ (43.2 yd.³)

B60E

Rated payload 54 500 kg (120 152 lb)

Capacity struck 27 m³ (35.3 yd.³)

Capacity heaped (SAE 2:1) 35 m³ (45.8 yd.³)

Capacity heaped (SAE 2:1) 42 m³ (54.9 yd.³)

Tip Cylinders (B35E, B40E, B45E & B50E)

Tip cylinders 2 x single stage, double

acting

Tipping angle max. Can be

limited to any lower angle,

programmable on CDU.

70°

Tip Cylinders (B60E)

Tip cylinders 2 X two stage, double acting

telescopic

Tipping angle max. Can be

limited to any lower angle,

programmable on CDU.

55°

B35E, B40E & B45E