Belle Group Premier XT User manual

1

- Spare Parts Book

Operators Manual

GB 4

16

870/00002/0

2

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature:

Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

Uunderskrevetaf: Administrerende direktør – På vegne af BELLE GROUP (SHEEN) UK.

PRODUCT TYPE ..................

MODEL .................................

SERIAL No............................

DATE OF MANUFACTURE...

SOUND POWER LEVEL.......

MEASURED

(GUARANTEED):

TYPE DE PRODUIT ..............

MODELE................................

N° DE SERIE ........................

DATE DE FABRICATION.......

NIVEAU DE ..........................

PUISSANCE SONORE

MESUREE (GARANTIE)

TIPO DE PRODUCTO ............

MODELO ................................

Nº DE SERIE ..........................

FECHA DE FABRICACIÓN....

NIVEL DE ...............................

POTENCIA ACÚSTICA

MEDIDO (GARANTIZADO)

TIPO DE PRODUTO: ...........

MODELO:.............................

NO. DE SÉRIE: ....................

DATA DE FABRIC................

NIVEL DE .............................

POTÊNCIA DE SOM

MEDIDO (GARANTIDO)

PRODUCTTYPE.....................

MODEL ..................................

SERIENUMMER ....................

FABRICAGEDATUM .............

GEMETEN ..............................

GELUIDSSTERKTENIVEAU

(GEGARANDEERD)

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an

authorised Belle Group dealer within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive

89/392/EEC), Electromagnetic Compatability Directive 89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, EN 292 Safety of

machinery and associated harmonised standards, where applicable. Noise emissions conform to directive 2000/14/EC Annex VI, for machines under article 12 the

notified body is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a

um distribuidor autorizado do Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta

directiva é uma consolidação da directiva de maquinaria original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas

92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, EN 292 Segurança da maquinaria e às normas harmonizadas afins se aplicáveis. As emissões de

ruído respeitam e estão dentro das directivas para máquinas 2000/14/EC Anexo VI, artigo 12, sendo o organismo notificado AV Technology Limited, AVTECH house,

Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB,verklaren hierbij dat als het product zoals beschreven in dit certificaat is

gekocht van een erkende Belle Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele

Machinerichtlijn 89/392/EEG), Electromagnetische Compatability Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn

72/23/EEG, EN 292 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde Standaarden, waar deze van toepassing is. Geluidsemissies volgens richtlijn

2000/14/EC Bijlage Vl. Het contactorgaan is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este certificado

es comprado a un distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva consolida la

directiva inicial sobre maquinaria 89/392/CEE), Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE), Directiva

sobre Bajo Voltaje 73/23/CEE, EN 292 de Seguridad de Maquinaria y Niveles armonizados estándares asociados donde sean aplicables. Emisión de Ruídos conforme

a la Directiva 2000/14/CE Anexo VI para máquinas bajo artículo 12 la mencionada unidad está AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 OXU, GB.

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un

distributeur autorisé Belle Group au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine

d'origine 89/392/CEE), Norme compatible pour l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, EN

292, Norme de sécurité des machines et des critères associés et configurés, si applicable. Les émissions de bruit sont conformes à la directive 2000/14/EC Annexe VI

pour machines , article 12, l’objet mentionné est

AV Technology Mimited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE /

DECLARACIÓN DE CONFORMIDAD CE / DECLARAÇÃO CE DE CONFORMIDADE /

EG-VERKLARING VAN OVEREENSTEMMING / EF

OVERENSSTEMMELSESERKLÆRING

Vi, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, erklærer hermed, at hvis det i dette certifikat beskrevne produkt er købt hos en autoriseret

Belle Group forhandler i EU, er det i overensstemmelse med følgende EØF-direktiver: 98/37/EF, 73/23/EØF (som ændret ved 93/68/EØF), 89/336/EØF (som ændret ved

92/31/EØF), 93/68/EØF og tilknyttede, harmoniserede standarder, hvor relevant. Støjniveauet er i overensstemmelse med direktiv 2000/14/EF, bilag VI gældende for

maskiner under paragraf 12. Det bemyndigede organ er AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritanien.

PRODUKTTYPE..................

MODEL ...............................

SERIENR. ...........................

FREMSTILLINGSDATO......

LYDEFFEKTNIVEAU .........

MÅLT (GARANTERET)

Ray Neilson

3

4

Engine Warranty

GB

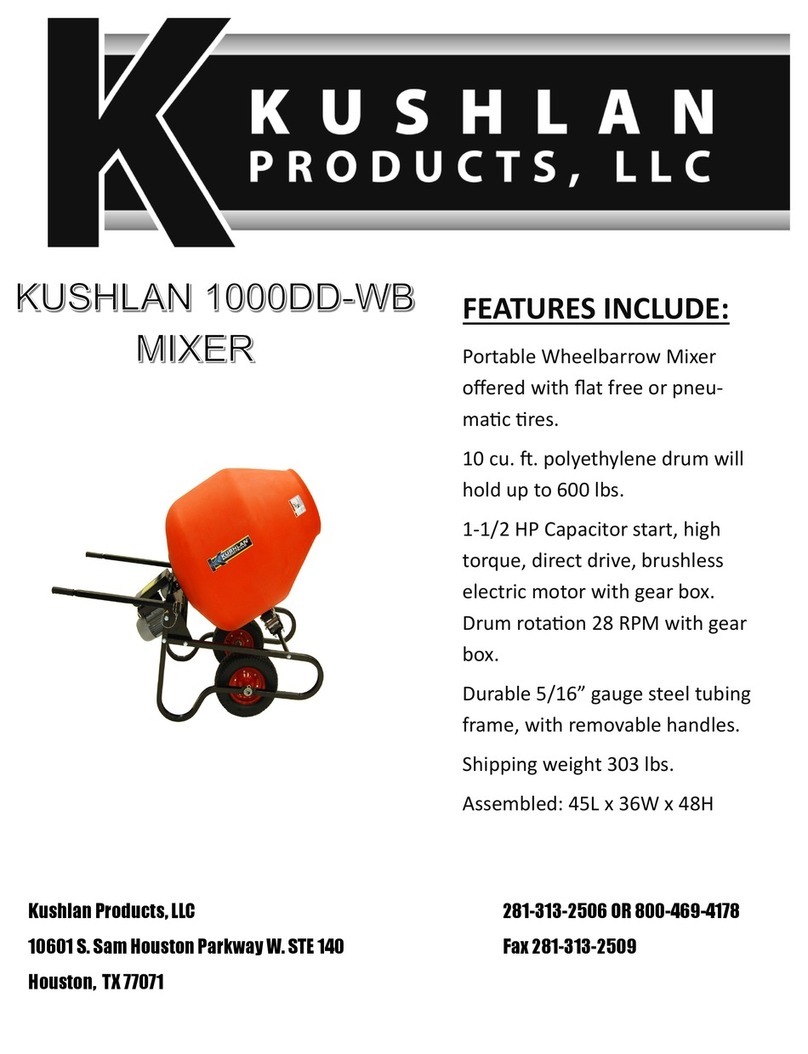

Congratulations on the purchase of this quality concrete mixer from the Belle Group range.

This machine is manufactured to conform to the EEC directives currently in force and is

issued with a declaration of conformity and therefore displays the CE mark, applicable in territories where they are enforced.

Read this manual carefully, observing all operating and safety instructions before, during and after using your machine. Maintain your

machine in good working order.

When maintaining this machine only the manufacturer’s original spare parts may be

used. The user will lose any possible claims if replacement parts used are other than the makers original spare parts.

Retain this manual with your machine for future reference.

SAFETY AND ACCIDENT PROTECTION

Operating Instructions :

All persons who apply, assemble, operate, start, control, maintain or repair this machine must read and understand these operating

instructions.

Owner Responsibility :

The owner must ensure that only qualified persons operate, maintain, or repair this machine.

Storage :

When not in use, store in a dry, locked place. Keep away from children.

Operation for the Intended Purpose :

Mixers are intended for the production of concrete, mortar and plaster. The mixer must be used for its intended purposes and is not

suitable for the mixing of flammable or explosive substances. The mixers must not be used in an explosive atmosphere.

MAINTENANCE AND REPAIRS

Only authorised dealers should repair the mixer, and within the requirements of the CE mark (where applicable), where no deviation to

the original specification must take place.

Introduction

GB

REPLACEMENT PARTS

Contact your nearest Belle Group dealer. When ordering replacement parts, please quote the product type, serial number & engine/

motor model. Detail the part required in conjunction with the parts list provided, indicating the Page Number, Item Number and

quantity required.

Any maintenance and repairs carried out, to any of the electric motors components must be undertaken

by a qualified electrician.

WARNING

The engines installed in the Belle Premier XT range of mixers carry a 12 month warranty. Any problems encountered with the engine,

during the warranty period should be dealt with by the relevant approved engine dealer, nearest to yourself.

If you require the name of your nearest approved engine dealer, a full listing is available on request from Belle.

Serial Numbers

ATTENTION! Make a note of the serial numbers of your machine and always quote them in any communication with a

Belle Group Dealer.

MACHINE SERIAL NUMBER ENGINE / MOTOR SERIAL NUMBER

5

Warning Symbols

Contents

Belle Group reserves the right to change machine specification without prior notice or obligation.

GB

Page number

Engine Warranty......................................................................................................................................................................................... 4

Introduction ................................................................................................................................................................................................ 4

Warning Symbols ...................................................................................................................................................................................... 5

Plug Wiring ................................................................................................................................................................................................ 5

Safety Instructions ..................................................................................................................................................................................... 6

Transportation ........................................................................................................................................................................................... 7

Mixing Positions ........................................................................................................................................................................................ 7

Mixing Hints................................................................................................................................................................................................ 8

Functional Controls ................................................................................................................................................................................... 9

Operating Instructions - Electric Motors................................................................................................................................................... 10

Operating Instructions - Yanmar L40 ........................................................................................................................................................11

Operating Instructions - Lister Petter Build 10 & 32..................................................................................................................................11

Maintenance Instructions ......................................................................................................................................................................... 12

Lister Petter 10 & 32 Checks & Maintenance schedule ......................................................................................................................... 13

Yanmar L40 Checks & Maintenance schedule ....................................................................................................................................... 14

Technical Data.......................................................................................................................................................................................... 15

WEAR EAR PROTECTION

LIFTING POINT

READ OPERATOR

MANUAL

FIRE AND EXPLOSIVE RISK

WEAR PROTECTIVE

FOOTWEAR

WEAR EYE PROTECTION

WARNING - IMPORTANT

The Premier range of mixers are intended for industrial use, the following plug types are supplied fitted to the product:

110V motor - 32 amp rated BS4343 plug type.

230V motor - 16 amp rated BS4343 plug type.

415V motor - 32 amp rated BS4343 plug type.

Reference the 230V version, if the plug supplied with your product does not suit the supply outlet you are connecting too, it should be

removed and the appropriate plug fitted (3 pin BS1363 fused 13 amp for domestic household supplies).

Fitting a plug - WARNING THIS PRODUCT MUST BE EARTHED

IMPORTANT: The wires in the mains lead are coloured in accordance with the following code:

GREEN / YELLOW = EARTH, BLUE = NEUTRAL, BROWN = LIVE

The wire which is coloured Green and Yellow must be connected to the terminal in the plug marked E or coloured Green and Yellow.

The wire which is coloured Brown must be connected to the terminal in the plug marked L or coloured Red. The wire which is

coloured Blue must be connected to the terminal in the plug marked N or coloured Black.

Always ensure before connecting to the supply that the supply voltage is the same as the rated voltage marked on the motor.

GB

6

Safety Instructions

GB

READ THESE SAFETY INSTRUCTIONS

Please read and understand all running/safety instructions before operating this machine.

BEFORE STARTING THE MIXER

- Check that all guards are in position and correctly fitted.

-DO NOT wear loose clothing or jewellery that may become entangled in the workings of this machine.

- Suitable clothing as follows should meet relevant EEC/local safety standards: overalls, work boots, goggles, face mask, gloves

and ear defenders etc.

- On electric powered mixers, ensure that any trailing cable is protected against damage and not liable to be tripped over or trapped

- underneath the mixer.

-Belle strongly recommends the use of a Residual Current Device on 220/240v electrics.

- Remove all packaging material before operating.

WHEN OPERATING THE MIXER

- Keep engine housing lid closed whilst it is mixing.

- Keep unauthorised persons away from mixing drum.

- Keep area around the mixer clear of obstructions which could cause persons to fall onto moving parts.

- Always ensure mixer is on level ground before mixing.

- Ensure rear wheel brakes are applied before operating the mixer.

-DO become familiar with the controls before operating this machine.

-DO ensure plenty of ventilation when running the diesel engines in a confined area.

-DO replace any worn/damaged warning decals.

-DO ensure the drum is rotating while emptying the mixer.

-DO always switch off and remove the plug from the socket if leaving the machine unattended.

-DO NOT transport this mixer when mixing.

-BEWARE of the danger zones.

EMERGENCY STOP

See Operating Instructions Section for details.

FIRE FIGHTING

If your mixer catches fire, turn off the electric supply.

Using a dry powder or C02 fire extinguisher put out the fire. If the fire can not be put out, keep away and call the fire brigade.

If you are in any doubt about the safety condition of your machine, please consult your nearest Belle dealer or Belle direct.

DRUM ROTATES ANTI-CLOCKWISE

ALWAYS MIX ON LEVEL GROUND

ALWAYS MIX IN WELL VENTILATED

PLACES EXHAUST FUMES CAN KILL

ALWAYS WORK WITHIN THE

RATED CAPACITY

DO NOT PUT SHOVEL IN THE DRUM

DO NOT PUT ANY PART OF YOUR

BODY IN THE DRUM

DO NOT FILL WITH FUEL OR

LUBRICATION OILS WHILST

ENGINE IS RUNNING

LOAD AND UNLOAD FROM THE

TRANSPORT CORRECTLY

(See Transport Section in Manual)

7

Transportation

GB

LOADING BY FORK LIFT

- For normal site to site transporting, the usual method of loading into a pick-up truck or trailer should be used. A fork socket (Fig 3)

is located beneath the main frame to enable the mixer to be loaded using a forklift (Fig 1).

LOADING BY CRANE

- To expose the lifting eye, turn the drum so it is facing down, (Fig 2).

- Ensure the lifting ropes are inspected to the current Health and Safety guidelines and are sufficient to carry the total weight of the

mixer. See technical data. Ensure the lifting hook is correctly located prior to lifting the machine.

-DO NOT stand underneath the machine whilst it is being lifted.

TOWING

- These mixers are designed for on site towing only, maximum speed 5mph/8 kmh (Fig 4), for short periods of time.

-DO NOT tow on a public highway.

Fig 1

Fig 2

Fig 3

Fig 4

5mph

8kmh

If the fork is not the same depth

as the socket it may be necessary

to pack under the fork with wood to

keep the load stable.

Mixing Positions

GB

Fig 5 MIXING POSITIONS

Fig 6 STORAGE POSITIONS Fig 7 DISCHARGE POSITIONS

DRUM TILTING

The hand wheel gives an easy positive control of the drum which can be

locked in the stored, mix, and discharge position.

The drum is locked in position by a self locating plunger which

engages into the handwheel. To move the drum the locating plunger must be

dis-engaged, this is done by pressing down on the footpedal (this is situated

just above the pivoting front axle), the handwheel will now move freely allowing

the re-positioning of the drum, to relock the drum in position, release the footpedal

and rotate the handwheel until the self-locating locking plunger engages into the

handwheel ring.

-DO NOT put your hand through the

hand wheel.

-ALWAYS keep both hands on the

hand wheel.

8

Mixing Hints

GB

Mix Ratios

The correct mix ratio (cement:sand:stone) depends on the type of application; harder concrete requires more cement, rougher

applications require more aggregate. The ratios given below are guidelines: best proportions may depend on the quality of sand/stone

used.

First put in the water - around 7 litres (1½ gallons), using more or less depending on the type of mix required. Add some aggregate

before adding cement, to avoid sticking. Work consistently to the ratio of ingredients for whatever type of concrete mix you are

working to.

Getting A Good Mix

The approximate mixing time for concrete is 2-4 minutes from when all the material (including the water) has been added - over-

mixing can reduce strength and cause segregation of the coarser aggregates.

Beware of low grade aggregates; these will only lead to trouble later on with sinking and frost spoiling the appearance of the pour.

Also do not get the concrete mix too wet as this can reduce strength and make it less able to withstand weathering.

Looking After Your Mixer

Never throw material into the mixer - trickle it steadily over the rim or it will stick firmly to the back of the drum and can only be

dislodged by stopping the mixer.

Keep your mixer clean - material left in the drum will harden, and attract more on each use until the mixer is useless.

Do not throw bricks into a mixer drum to clean it out. The best method is a mix of 1” (2½cm) gravel and clean water - use plenty of it,

as this will do the job in half the time.

APPLICATIONS QUANTITIES

CEMENT SAND STONE

MOST ORDINARY 1 2 4

FOUNDATIONS 1 3 6

ROUGH MASS CONCRETE 1 4 8

WATERTIGHT FLOORS,TANKS PITS ETC. 1 1.5 3

9

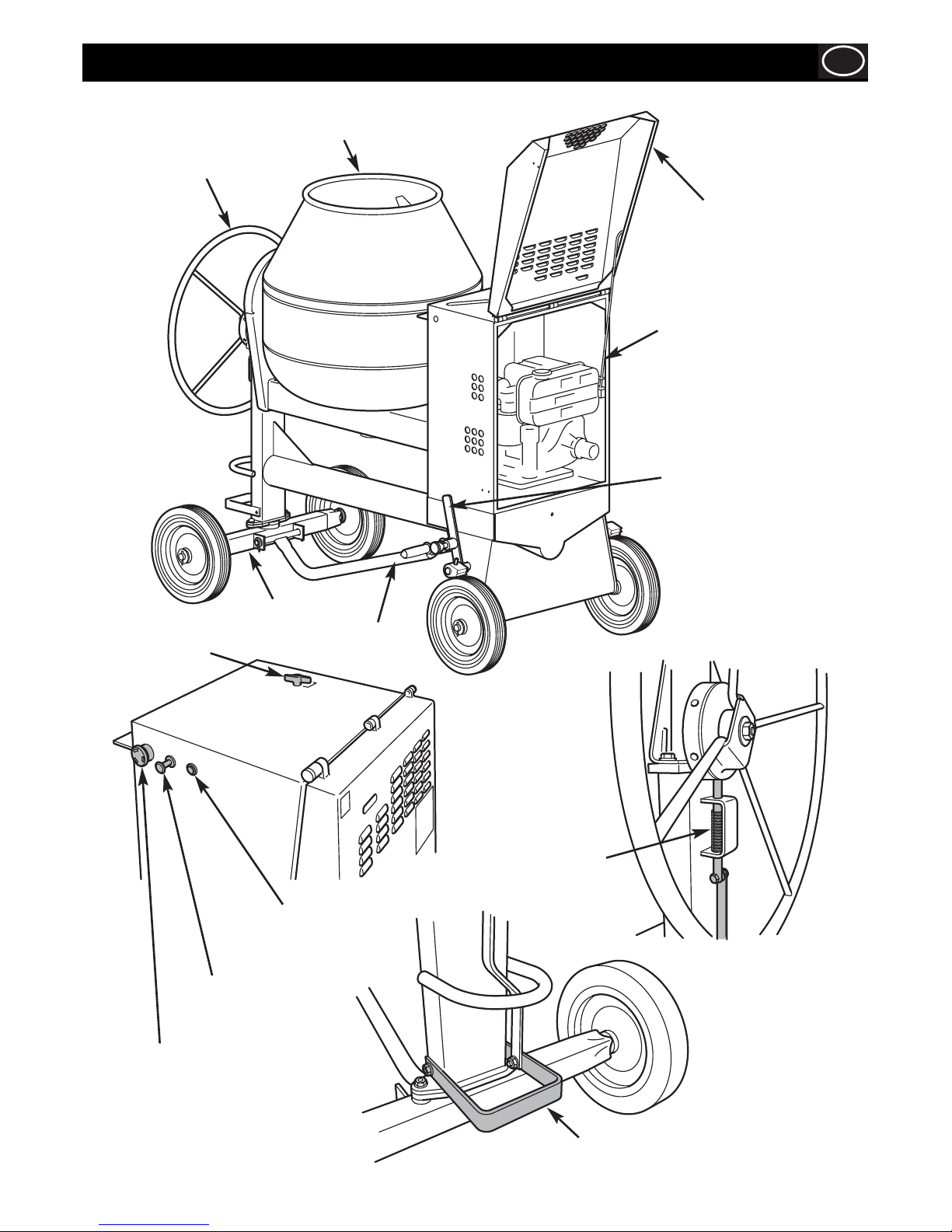

Functional Controls

GB

Mixing Drum

Rear Opening

Door

Door Stay

Park Brake

Lever

Handwheel

Towbar

Pivoting Axle

Handwheel

Locking Plunger

Foot Pedal

Lister Emergency

Stop

Electric

Emergency

Stop

Yanmar

Emergency

Stop

Yanmar Engine

Charge Light

10

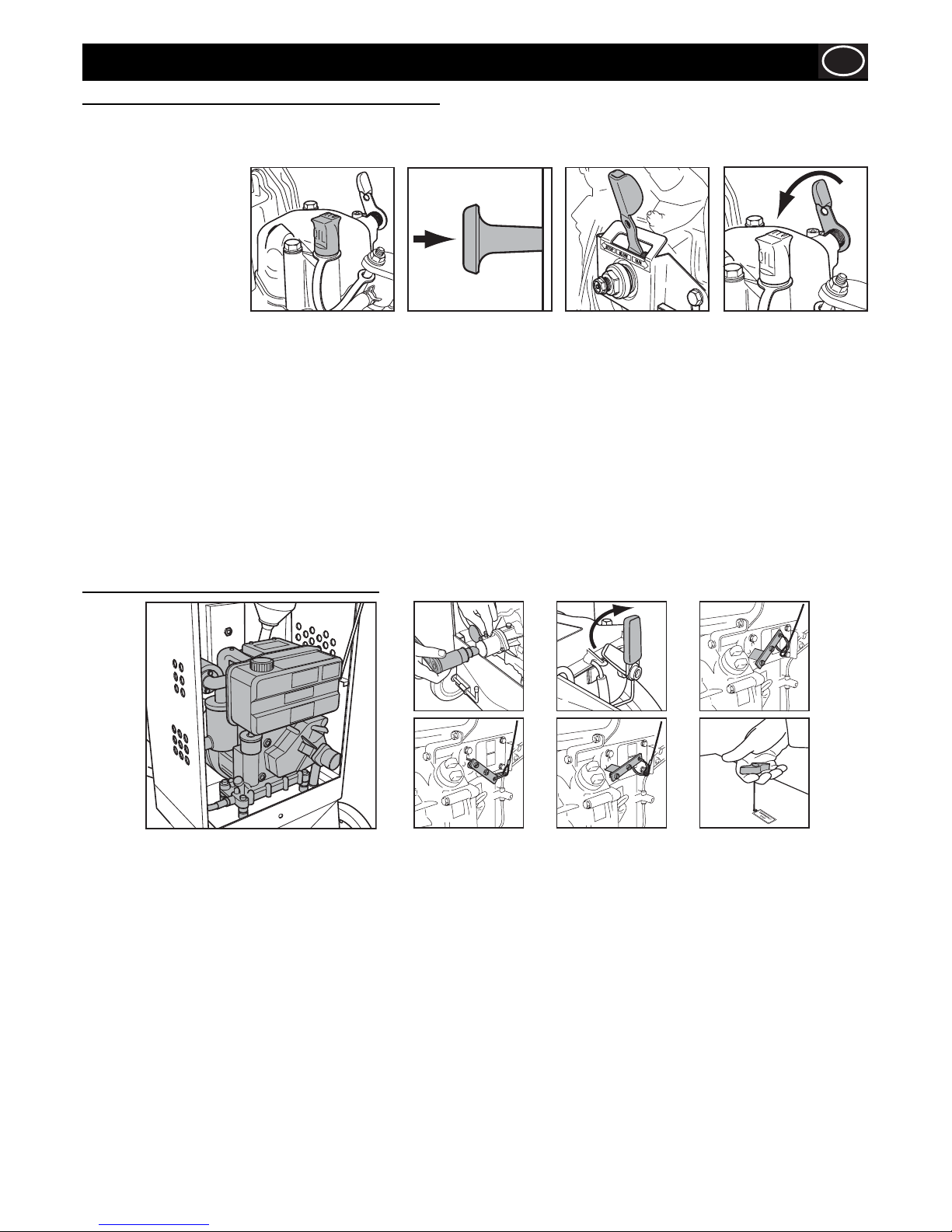

Operating Instructions

GB

STOPPING

1.1 Depress RED Button

(or on/off toggle

switch if fitted to the Off

position) to stop mixer

(Fig B).

STARTING

1.2 Lift rear door.

1.3 Feed supply cable out

through the rear of the

mixer and plug into

power supply.

1.4 Depress GREEN

Button (or on/off toggle

switch if fitted to the On

position) to start mixer

(Fig A).

- Ensure supply cable is safely stored before moving mixer.

- Keep rear door shut when mixer is running

EMERGENCY STOP

1.5 Depress large RED Button, situated on top left hand side of power unit housing (Fig C).

- 110V & 415V (Brook Hansen) motor, Start / Stop using a control box situated on inside left of power unit housing.

2. YANMAR (ELECTRIC START)

STOPPING

2.1 Press Red Lever (Fig D).

- Note: Red indicator light

glows when engine charging

system fails.

-Ensure that when machine

is not in use that ignition is

switched OFF, or battery

failure may occur.

EMERGENCY STOP

2.2 Pull the handle on the

side of the power unit box to

STOP the machine (Fig E).

COLD STARTING

2.3 Lift rear door.

- Open fuel cock if fitted (Fig F).

2.4 In cold starting situations the engine requires 2cc of engine oil (10w-30) to be applied using oil applicator. The oil

should be inserted into the engine byremoving the rubber plug on thepriming port, ensure the plug isreplaced (Fig G).

2.5 Ensure the Emergency Stop Button is pushed in (Fig H).

2.6 Set the engine speed lever (situated on the left hand side of engine) to the run position (Fig I).

2.7

Turn ignition key clockwise untilengine turns over, release key whenengine starts. If engine fails to start, repeat process of cold start.

- Note: Once an attempt to start the engine has failed, before re-trying the key must be turned back to the OFFposition.

-DO NOT operate with rear door open.

WARM STARTING

2.8 Repeat process above from 2.5.

1. ELECTRIC MOTOR : VARIANTS

AB

C

D

PULL

TO

STOP

E

Open

Closed

F

11

3. YANMAR (RECOIL START) Back Up to Electric Start

STOPPING

3.9 Press red lever (Fig D).

EMERGENCY STOP

3.10 Pull the handle on

the side of the

power unit box to

STOP the

machine (Fig E).

COLD STARTING

3.11 Lift rear door.

Open fuel cock if fitted (Fig F).

3.12 In cold starting situations the engine requires 2cc of engine oil (10w-30) to be applied using oil applicator. The oil should be

inserted into the engine by removing the rubber plug on the priming port, ensure the plug is replaced (Fig G).

3.13 Ensure the Emergency Stop Button is pushed in (Fig H).

3.14 Set the engine speed lever (situatedon the left hand side of engine) to the run position (Fig I).

3.15 Pull out the recoil starting handle tothe point where you feel a strongresistance, then return back theinstall position. Push over

the decompression lever (top right hand side of engine) this will return automatically when the recoil handle is pulled for

the second time.

3.16 Apply both hands to the recoil starting handle and pull briskly, if engine does not start repeat from 3.15.

- DO NOT operate with rear door open.

WARM STARTING

3.17 Repeat process above from 3.14.

4. LISTER PETTER : CRANK HANDLE START

Operating Instructions

GB

- Caution should be taken when starting unit, always use Anti-Kick Back Starting Handle.

- Ensure handle is correctly engaged in crank barrel (Fig J) before cranking engine.

- Ensure Oil & Fuel levels are checked daily before starting engine.

- Ensure rear door stay is correctly engaged before working in power unit area.

- Keep rear door closed when mixer is running.

4 STOPPING

4.1 Open rear door and move Start / Stop lever to the STOP position (Fig L).

COLD STARTING

4.2 Lift rear door.

4.3 Lift Safety Button up, locate Starting Handle in crank barrel and turn until handle engages (Fig J).

4.4 Engage Start / Stop lever into START position (Fig K).

4.5 Push decompression lever into vertical position and hold (Fig L).

4.6 Crank the engine as fast as possible and move the de-compressor lever into the running position whilst continuing to crank briskly

until the engine starts.

4.7 Once the engine starts remove handle and place back in storage, then move Start/Stop lever into the RUN position(Fig M).

WARM STARTING

4.8 Follow the above instructions from 2.2 to 2.6, however start engine with the Start / Stop lever in the RUN position.

EMERGENCY STOP

4.9 Pull handle on top of power unit box (Fig O).

K M O

J L N

GHI

12

Maintenance Instructions

GB

Before starting any maintenance or repairs, stop engine or switch off motor, and isolate from the main power supply.

On completion of maintenance, check that the mixer functions correctly and that all guards are correctly fitted.

ELECTRIC MOTORS

All portable electric appliances are dangerous if abused. This machine will only operate on one voltage. Check the power supply to

ensure it corresponds to the voltage as stamped on the motor. Make sure that the motor is switched off before you plug it into the

power supply.

220/240v -Always use a Residual Current Device (“RCD”), (earth leakage trip), plugged directly into the 220/240v socket. If using an

extension cable, plug it directly into the

RCD. 110v -When using a portable transformer it must have a minimum output of 6.3kw and be continuously rated.

- DO NOT use an extension cable between the transformer and the power supply.

The symbols on the ON/OFF switch are 0=OFF and I=ON in accordance with international standards.

EXTENSION CABLES

If you need to use an extension cable it must be no longer than 30 metres (100 feet) in length. The wire section for 220/240v must be

2.5mm2. The wire section for 110v must be 4mm2 on 100T and 6mm2 on other models. Ensure that the extension cable is

carefully laid out avoiding liquids, sharp edges and places where vehicles might run over it. Unroll it fully or it will overheat and could

catch fire. Make sure that any extension cable connections are dry and safe.

COMBUSTION ENGINES

- Be aware of exhaust venting directions.

The engine needs a regular oil check.Try not to run low on fuel as this may result in sediment from the bottom of the tank doing

damage to the injector and pump. Repairs and rectification of pipework and components affected by contaminants in fuel

cannot be accepted as warranty, neither will faults caused or contributed to by the machine running out of fuel. You may

need to bleed the fuel system free of air before starting. For initial engine fill or top up use a suitable engine oil of a 10W/30 grade. In

your own interests read the makers instruction leaflet issued with the machine before starting up.

DRUM (Removal and Fitment)

This can be instantly removed by unscrewing it counter clockwise in the vertically up position. Lift the drum off the machine using a

fork lift, with the forks under the base of the drum. When replacing make sure that the drum shaft is greased before it is fully

screwed down on to the shoulder of the shaft, ensure the drum is fully screwed down on to the shoulder or damage will occur. Take

care when screwing on the drum, spinning on fast may damage the gearbox.

CLEANING

Wipe off any external material. DO NOT use petrol, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products. Never

let any liquids near the engine/motor. Use 1” gravel and clean water to clean the inside of the drum.

- DO NOT use bricks etc. as this will damage the drum.

DRIVE BELT

- DO NOT try to adjust with the engine / motor running.

- DO NOT run slack.

- DO NOT operate machine with guards removed.

The drive belt is under constant even tension by a spring loaded jockey, this requires no attention. The bearings are sealed for life.

GEARBOX OIL

Note: The original gearbox oil is a synthetic oil and must not be mixed with a mineral oil.

Full gearbox fill 1.0 ltrs, check regularly.

The gearbox was originally filled with: Total :- Transmission W 75W/90 viscosity

Equivalent oils:

Shell :- Tivela SA, Tivela WA, Dentax W Mobil :- Glygoyle 22

Texaco :- Synlube 90 Castrol :- WM or Alpha SN150

Esso :- GX 75W/90 Caltex :- Synthetic gear lubricant

LUBRICATION AND RUNNING

See Maintenance Schedule Section and Operating Instructions.

Remember that diesel engines vibrate more, so regularly check all nuts and bolts are tight.

13

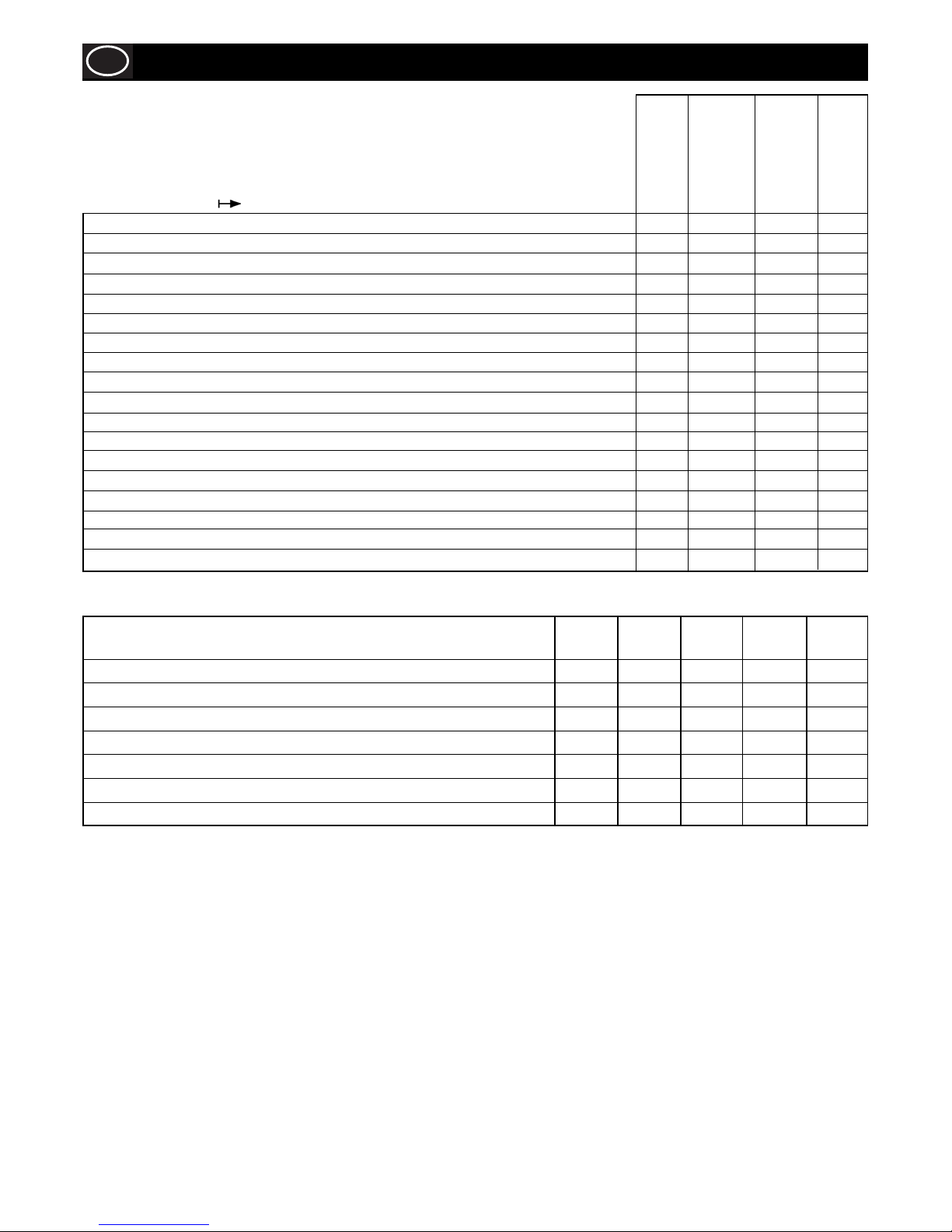

Check the fuel & lubricating oil levels 9

Check for oil & fuel leaks 9

Clean, or replace, the air cleaner element under very dusty conditions 9

Check the condition of the battery, if fitted 9

Clean or replace the air cleaner element under moderately dusty conditions 9

Drain the sump and refill with new oil of the correct type and specification as given in 9 9

engine handbook

Clean or replace the injectors if the exhaust is dirty 9

Renew the fuel filter element if the fuel being used is not perfectly clean 9

Replace the air cleaner element 9

Examine exhaust & induction systems for leaks, damage or restrictions 9

Renew the fuel filter element 9

Check the battery charge winding system; refer to Workshop Manual 9

Check the valve clearances 9

Decarbonise if the engine performance has deteriorated 9

Clean the cylinder barrel and head fins 9

Clean the banjo union at the cylinder head end of oil feed pipe 9

Drain, flush and refill the fuel tank 9

Daily

Every 125 Hrs

Every 2000

Hrs

Every 1000

Hrs

Every 500 Hrs

Every 250 Hrs

To help assist engine running-in, all engines are despatched with an initial fill lubricating

oil which must be changed after 100 hours.

All subsequent oil changes must be as specified below.

Lister-Petter 32 & 10 Engines

Checks and Maintenance

GB

Mixer Daily 50 250 500 1000

Hours Hours Hours Hours

Grease Yoke Pivot 9

Grease Tipping Gear (10 Operations of Grease Gun) 9

Remove Drum and Grease Shaft 9

Check Nuts and Bolts 9

Check Gearbox Oil 99

Grease Layshaft, Grease Nipple 9

Check Components for Leaks 9

14

Checks and Maintenance

GB

Items marked “99“ should be serviced by an authorized YANMAR

dealer, unless the owner has proficient mechanical ability and the proper tools.

Parts with an asterisk mark “ * “ are related to the CARB ULG rules.

Yanmar L48 Engine April ‘04

Every 3 months or

Every 200 Hrs

Every month or

Every 500 Hrs

Every 6 months or

Every 400 Hrs

Every year or

Every 1000 Hrs

Check the fuel level and refill. - Before Operation

Drain the fuel tank 9

* Clean the fuel filter 9

* Replace the fuel filter 9

Check for fuel / oil leakage - After Operation

* Fuel injection nozzle, Check the injection condition 99

* Check the fuel injection timing 99

* Check the fuel injection pump 99

Check the lube oil level in the oil pan and refill - Before Operation

Replace the lube oil 1st time 2nd & after

Clean lube oil filter 1st time 2nd & after

Check for lube oil leakage - After Operation

Check the valve clearances 9

* Check the air cleaner element 9

* Replace the air cleaner element 9

Check the battery liquid level and refill - Before Operation

Check the warning lamps - When Engine Is Started

Adjusting the intake and exhaust valve clearance 99

Mixer Daily 50 250 500 1000

Hours Hours Hours Hours

Grease Yoke Pivot 9

Grease Tipping Gear (10 Operations of Grease Gun) 9

Remove Drum and Grease Shaft 9

Check Nuts and Bolts 9

Check Gearbox Oil 99

Grease Layshaft, Grease Nipple 9

Check Components for Leaks 9

15

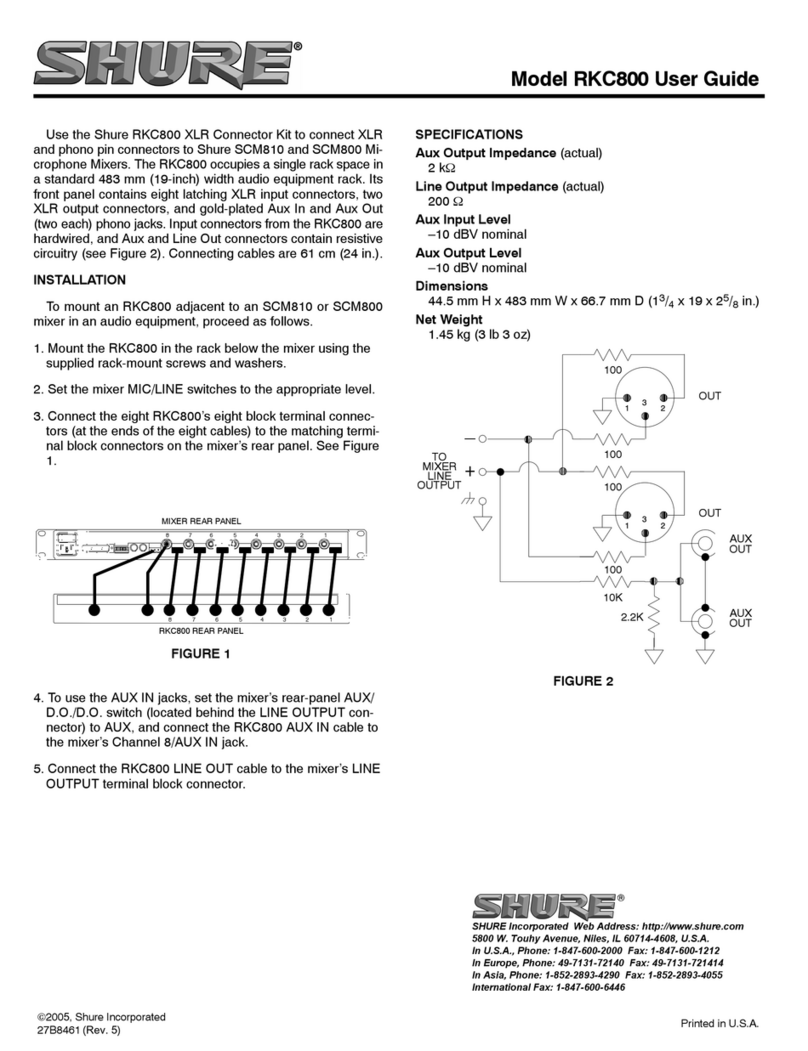

Technical Data

GB

100XT 150XT 175XT 200XT

A - OVERALL LENGTH (MM) 1665 1665 1890 1890

B - OVERALL WIDTH (MM) 900 900 900 900

C - OVERALL HEIGHT (MM) 1468 1568 1049 1077

D - LOADING HEIGHT (MM) 613 607 713 680

E - DISCHARGE HEIGHT (MM) 350 350 350 350

F - DIAMETER OF WHEELS (MM) 2100 2100 2200 2200

G - OVERALL LENGTH - DOOR OPEN (MM) 1950 1950 1950 1950

H - OVERALL HEIGHT - DOOR OPEN (MM) 1120 1120 1520 1520

J - WHEEL BASE 1120 1120 1520 1520

CUBIC FEET IN/OUT 5/3.5 7/5 8/6 10/7

MIXED BATCH OUTPUT (LTR) 110 160 180 220

MAX DRUM CAPACITY (LTR) 250 300 350 400

MAX DRY MIX DRUM CAPACITY IN (LTR) 160 220 250 310

DRUM SPEED (RPM) 19 19 19 19

D

E

A

JB

C

F

H

G

ELECTRIC RANGE

100XT 150XT 175XT 200XT 100XT 150XT 175XT 200XT 100XT 150XT 175XT 200XT

UNLADEN WEIGHT (Kg) 305.5 314.5 322.5 325 303.5 312.5 320.5 323 305.5 314.5 322.5 325

NOMINAL VOLTAGE (V)

NOMINAL CURRENT (Amp)

NOMINAL POWER

VOLTAGE FREQUENCY (Hz)

MOTOR RPM

MOTOR PROTECTION

POWER CONSUMPTION (Kwh)

SOUND POWER LEVEL (LWA)

DIESEL RANGE

100XT 150XT 175XT 200XT 100XT 150XT 175XT 200XT

UNLADEN WEIGHT (Kg) 367 376 392.5 395 334.5 343.5 350.5 353.5

ENGINE MODEL

NOMINAL POWER (KW)

STARTING METHOD

FUEL CAPACITY

SOUND POWER LEVEL (LWA) 99 dB(A)

5

Thermal / NVR

1.5

87dB(A)

415240

110

13.7 6.6 3.6

1.5

50

1350 1430 1500

2.5

Hand Crank Electric / (Recoil Backup)

0.75 1.9 2.3

LT1 (Build 32) LT1 (Build 10)

L40 AE

LISTER YANMAR

16

6

2

5

7

24

25

4

5

27

7

8

15

13

16

19

19

26

23

22

17

18

21

20

9

1

14

1-01

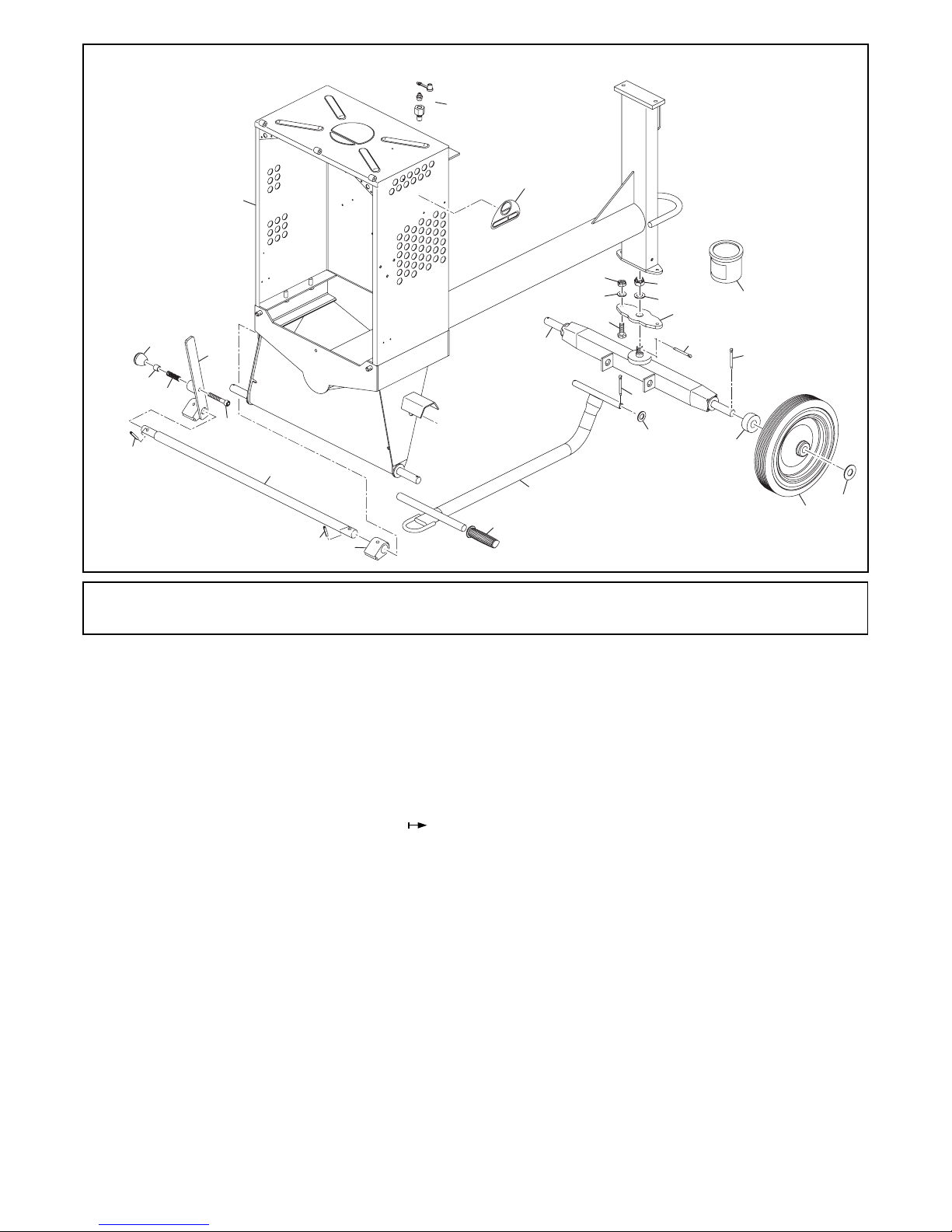

FRAME ASSEMBLY - 100-150XT

(CORRECT AT 05/04)

1-01

Frame Assembly - 100-150XT

1 909-19700.............1 ..........Frame (100/150XT)

2 909-12300.............1 ..........Axle

3

4 8-20002.................1 ..........Nut (M20)

5 4-2001...................3 ..........Washer (M20)

6 909-11100 ...........1 ..........Towbar

7 3-0006...................6 ..........Split Pin

8 4-0009...................4 ..........Washer (M26)

9 XS35 ....................2 ..........Handle Grip

10

11

12

13 60-0284.................4 ..........Wheel

14 909-20000.............1 ..........Grease Nipple Assembly ( June’04)

15 909-99996.............4 ..........Spacer

16 909-17402.............1 ..........Brake Bar

17 909-99998.............1 ..........Lever

18 7-10015.................1 ..........Screw (M10x65)

19 3-0044...................2 ..........Spirol Pin

20 2-0027...................1 ..........Spring

21 909-99997.............1 ..........Spacer

22 74-0001.................1 ..........Knob

23 909-17401.............1 ..........Brake Cam

24 800-22600.............1 ..........Decal Kit (100XT)

24A 800-22700.............1 ..........Decal Kit (150XT)

24B 800-22800.............1 ..........Decal Kit (175XT)

24C 800-22900.............1 ..........Decal Kit (200XT)

25 1-0519.................A/R ........Orange Paint (Tin)

25A 1-0507.................A/R ........Orange Paint (Spray)

26 3-0049...................1 ..........Split Pin

27 3-4034...................1 ..........Cap

17

14

6

2

5

7

24

25

4

5

12

11

10 3

7

8

15

13

16

19

19

26

23

22

17

18

21

20

9

1

1-02

FRAME ASSEMBLY - 175-200XT

(CORRECT AT 05/04)

1-02

Frame Assembly - 175-200XT

1 909-11600 ............. 1 .........Frame (175/200XT)

2 909-12300.............. 1 ......... Axle

3 909-99935.............. 1 ......... Plate

4 8-20002.................. 1 ......... Nut (M20)

5 4-2001.................... 3 ......... Washer (M20)

6 909-11100 ............. 1 .........Towbar

7 3-0006.................... 6 ......... Split Pin

8 4-0009.................... 4 ......... Washer (M26)

9 XS35 ..................... 2 .........Handle Grip

10 7-10010.................. 2 .........Screw (M10x30)

11 4-1005.................... 2 .........Washer (M10)

12 8-10001.................. 2 .........Nut (M10)

13 60-0284.................. 4 .........Wheel

14 909-20000.............. 1 ......... Grease Nipple Assembly ( June’04)

15 909-99996.............. 4 .........Spacer

16 909-17402.............. 1 .........Brake Bar

17 909-99998.............. 1 .........Lever

18 7-10015.................. 1 .........Screw (M10x65)

19 3-0044.................... 2 .........Spirol Pin

20 2-0027.................... 1 .........Spring

21 909-99997.............. 1 .........Spacer

22 74-0001.................. 1 .........Knob

23 909-17401.............. 1 .........Brake Cam

24 800-22600.............. 1 ......... Decal Kit (100XT)

24A 800-22700.............. 1 .........Decal Kit (150XT)

24B 800-22800.............. 1 .........Decal Kit (175XT)

24C 800-22900.............. 1 .........Decal Kit (200XT)

25 1-0519.................... A/R ..... Orange Paint (Tin)

25A 1-0507.................... A/R ..... Orange Paint (Spray)

26 3-0049.................... 1 .........Split Pin

18

8

1

1A

14

5

15

4

3

6

7

2

9

10

12

6

18 19

16

17 8

3

11

13

11

2-01

(CORRECT AT 07/03)

2-01

Door Assembly

1 909-10400............. 1 .......... Cover

1A 909-19700............. 1 ..........Hewden Rear Door Assembly

2 800-99903............. 1 .......... Decal

3 PS071 .................. 2 ..........Cap

4 3-0008................... 8 .......... Rivet

5 908-10700............. 2 .......... Catch

6 3-0003................... 2 .......... Split Pin

7 909-17600............. 1 .......... Door Stay

8 4-10001................. 2 .......... Washer (M10)

9 3-0013................... 2 .......... Spirol Pin

10 8-8002.................. 3 .......... Nut (M8)

11 4-8006................... 6 ..........Washer (M8)

12 909-99959............. 1 ..........Bracket

13 7-8008................... 3 ..........Screw (M8x16)

14 1-01 & 1-02 .................(Item 24)

15 3-3000................... 2 ..........Pad

16 915-00131............. 2 ..........Stud

17 909/99806 ............ 1 ..........Infil Plate

18 4-8006................... 2 ..........Washer (M8)

19 8-8002................... 2 ..........Nut (M8)

19

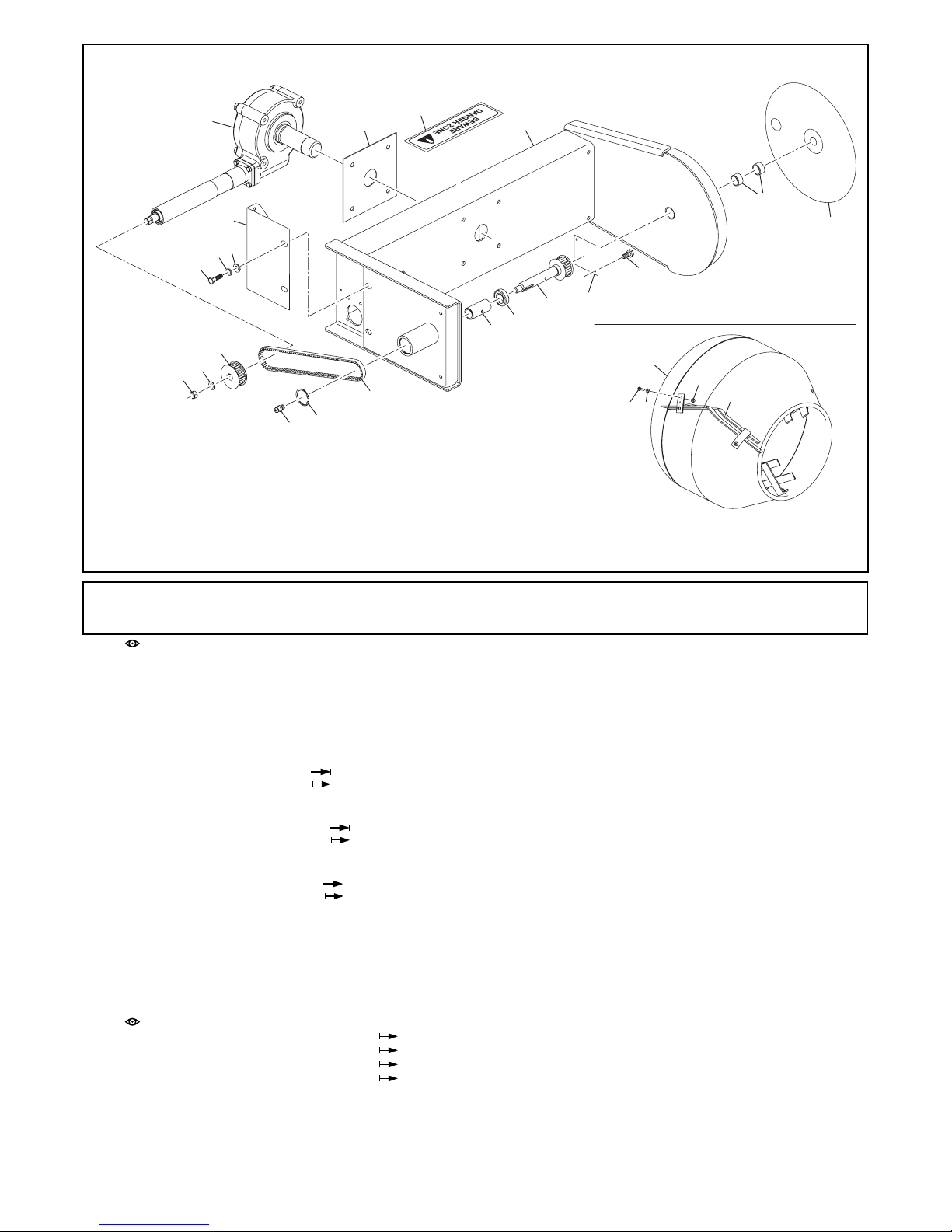

3-01

(CORRECT AT 07/03)

1

2

3

7

6

9

4

13

18 19

12 12

14

16

15

17

11

5

5

8

4

4

10

5

3-01

Wheel Assembly

1 4-1601................... 1 .......... Washer (M16)

2 2-0029................... 1 .......... Spring

3 909-99910............. 1 .......... Plunger

4 8-10001................. 3 .......... Nut (M10)

5 4-1005................... 7 .......... Washer (M10)

6 7-10010................. 1 .......... Screw (M10x30)

7 909-99926............. 1 .......... Plunger Link

8 9-10015................. 1 .......... Bolt (M10x150)

9 909-99929............. 1 .......... Foot Pedal

10 9-10004................. 1 .......... Bolt (M10x35)

11 909-14800............. 1 ..........Pivot

12 50-000016............. 2 .......... Composite Bush

13 909-14900............. 1 .......... Tip Gear

14 7-12013................. 2 .......... Screw (M12x35)

15 8-12001................. 2 .......... Nut (M12)

16 4-1204................... 4 ..........Washer (M12)

17 909-10500............. 1 .......... Hand Wheel

18 4-1607................... 1 ..........Washer (M16)

19 8-16003................. 1 .......... Nut (M16)

20

4-01

(CORRECT AT 05/04)

1

3

2

9

8

7

11

12

6

13

17

18

19

14

15 16

10

4

55

20

21

25

22

2423

4-01

Yoke Assembly

1 5-01 ............... 1 ..........Gearbox

2 909-99942............. 1 .......... Guard

3

4

5 7-6032................... 5 .......... Screw (M6x12)

6 909-10700............. 1 .......... Yoke (100/150XT)

6A 909-12200............. 1 ..........Yoke (175/200XT)

7 8-12003................. 1 .......... Nut (M12)

8 4-1205................... 1 .......... Washer (M12)

9 908-15700............. 1 .......... Pulley ( May’04)

9A 909-99807............. 1 ..........Pulley ( May’04)

10 500-06100............. 1 ..........Grease Nipple

11 PS022 .................. 1 ..........Circlip

12 908-15500............. 1 .......... Drive Belt ( May’04)

12A 21-0163................. 1 .......... Drive Belt ( May’04)

13 909-99932............. 1 ..........Spacer

14 PS074 .................. 2 .......... Bearing

15 909-13100............. 1 ..........Layshaft ( May’04)

15A 909-19900............. 1 ..........Layshaft ( May’04)

16 908-15900............. 1 ..........Cover

17 50-000016............. 2 ..........Bush

18 908-21200............. 1 ..........Cover

19 909-18300............. 1 .......... Drum (c/w Paddles) (100XT)

19A 909-18400............. 1 ..........Drum (c/w Paddles) (150XT)

19B 909-18500............. 1 ..........Drum (c/w Paddles) (175XT)

19C 909-18600............. 1 ..........Drum (c/w Paddles) (200XT)

20 800-10441............. 2 .......... Decal Danger Zone

21 5-01 ............... 1 ..........Plate

22 909-19100............. 1 .......... Paddle Kit (100XT) ( July’02)

22A 909-19200............. 3 ..........Paddle Kit (150XT) ( July’02)

22B 909-19300............. 3 ..........Paddle Kit (175XT) ( Oct’02)

22C 909-19400............. 3 ..........Paddle Kit (200XT) ( Aug’02)

23 7-12017................. 9 .......... Screw (M12 x 30))

24 4-1201................... 9 ...........Washer (M12)

25 8-12001................. 9 ..........Nut (M12)

Table of contents

Other Belle Group Mixer manuals