BC 350 Operators ManualBC 350 Operators Manual 4

Technical Data

GB

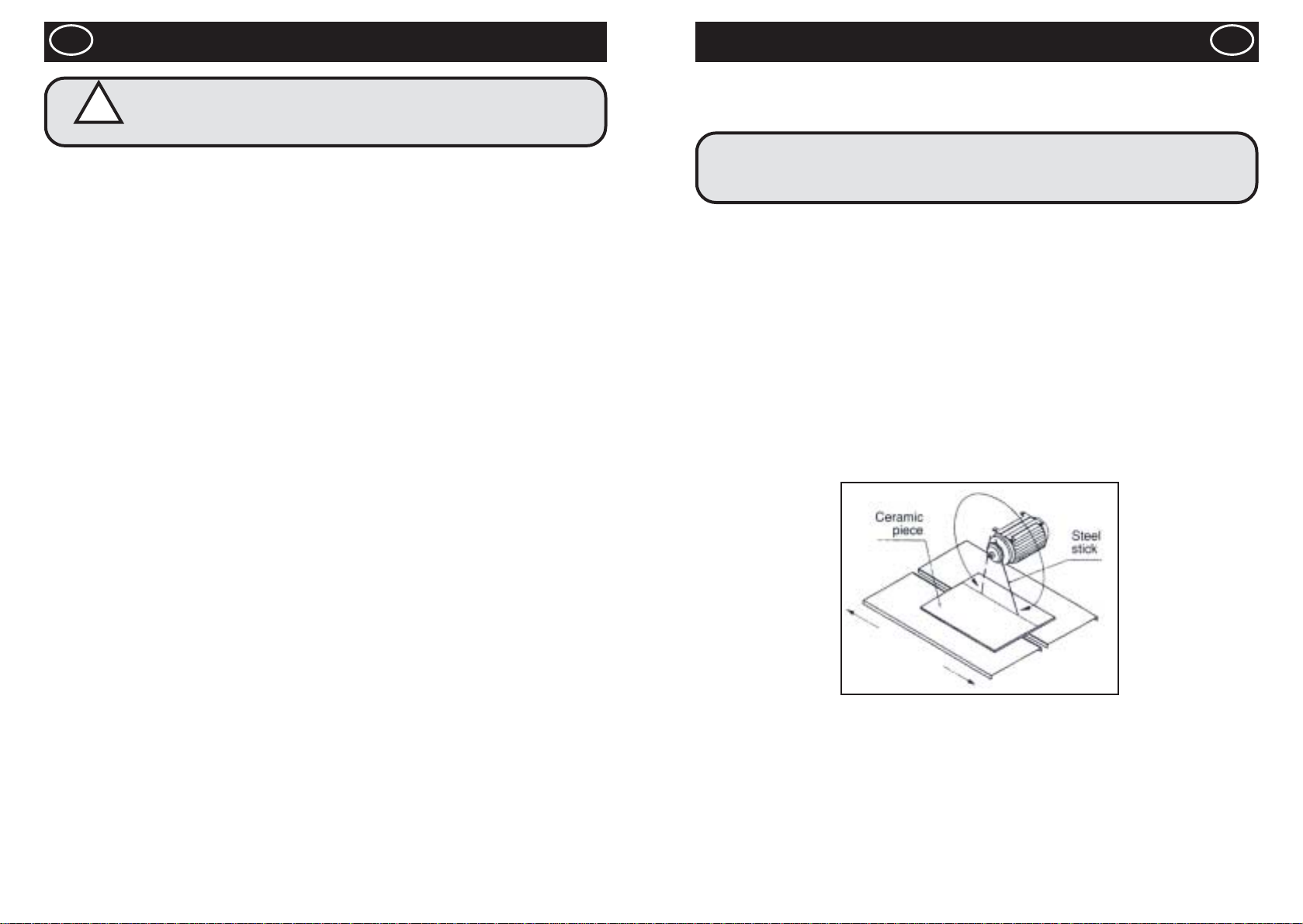

* The Sound Power Level was recorded on a machine using a 300mm Blade on 8mm

thick stoneware

Model Single Phase Three Phase

Height (mm) 500 500

Length (mm) 1100 1100

Width (mm) 530 530

Motor Power (kW / Hp) 2.2 / 3 3 / 4

Motor Voltage (V) 230 or 110 230-380

Pump Voltage (V) 230 or 110 230

Blade Diameter (mm) 300 300-350

Maximum Cut Length (mm) 65 65

Maximum Cut Height (mm) 75 75-100

R.P.M 3000 3000

Net Weight (Kg) 78 78

Water Volume (Ltr) 70 70

Sound Power Level (dB(A)) 99.7 99.7

13

Signed by: Managing Director - On behalf of BELLE GROUP (SHEEN) UK.

Signature: Le Directeur Général - Pour le compte de la SOCIETE BELLE GROUP (SHEEN) UK.

Medido por: Director Gerente - En nombre de BELLE GROUP (SHEEN) UK.

Assinado por: Director-Geral - Em nome de BELLE GROUP (SHEEN) UK.

Getekend door: Algemeen Directeur - Namens BELLE GROUP (SHEEN) UK.

852/10004/2

Ray Neilson

EC DECLARATION OF CONFORMITY / DECLARATION CE DE CONFORMITE / DECLARACIÓN DE CONFORMIDAD CE /

DECLARAÇÃO CE DE CONFORMIDADE / EG-VERKLARING VAN OVEREENSTEMMING

We, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, hereby certify that if the product described within this certificate is bought from an authorised Belle Group dealer

within the EEC, it conforms to the following EEC directives: 98/37/EC (This directive is a consolidation of the original machinery directive 89/392/EEC), Electromagnetic Compatability Directive

89/336/EEC (as amended by 92/31/EEC & 93/68 EEC). The low voltage directive 73/23/EEC, EN 292 Safety of machinery and associated harmonised standards, where applicable. Noise emissions

conform to directive 2000/14/EC Annex VI, the notified body being AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

PRODUCT TYPE ......................

MODEL .....................................

SERIAL No................................

DATE OF MANUFACTURE.......

SOUND POWER LEVEL...........

MEASURED (GUARANTEED):

TYPE DE PRODUIT ..................

MODELE....................................

N° DE SERIE ............................

DATE DE FABRICATION..........

NIVEAU DE ...............................

PUISSANCE SONORE

MESUREE (GARANTIE)

TIPO DE PRODUCTO ..............

MODELO ...................................

Nº DE SERIE .............................

FECHA DE FABRICACIÓN.......

NIVEL DE ..................................

POTENCIA ACÚSTICA

MEDIDO (GARANTIZADO)

TIPO DE PRODUTO: ................

MODELO:..................................

NO. DE SÉRIE: .........................

DATA DE FABRIC.....................

NIVEL DE ..................................

POTÊNCIA DE SOM

MEDIDO (GARANTIDO)

PRODUCTTYPE........................

MODEL .....................................

SERIENUMMER .......................

FABRICAGEDATUM ................

GEMETEN .................................

GELUIDSSTERKTENIVEAU

(GEGARANDEERD)

O signatário, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK 0EU, GB, pelo presente, declara que se o produto descrito neste certificado foi adquirido a um distribuidor autorizado do

Belle Group em qualquer país da UE, está em conformidade com o estabelecido nas seguintes directivas comunitárias: 98/37/EC (esta directiva é uma consolidação da directiva de maquinaria

original 89/392/EEC), Directiva de Compatibilidade Electromagnética 89/336/EEC (conforme corrigido pelas 92/31/EEC & 93/68 EEC). A directiva de baixa voltagem 73/23/EEC, EN 292 Segurança

da maquinaria e às normas harmonizadas afins se aplicáveis. As emissões acústicas estão em conformidade com a directiva 2000/14/EC Anexo VI, sendo o organismo notificador a AV

Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Ondergetekende, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 OEU, GB,verklaren hierbij dat als het product zoals beschreven in dit certificaat is gekocht van een erkende Belle

Group dealer binnen de EEG, het voldoet aan de volgende EEG richtlijnen: 98/37/EC (Deze richtlijn is een opvolger van de orginele Machinerichtlijn 89/392/EEG), Electromagnetische Compatability

Richtlijn 89/336/EEG ( geamendeerd door 92/31/EEG & 93/68 EEG). De Laagspannings Richtlijn 72/23/EEG, EN 292 Veiligheid van Machines en hieraan gekoppelde geharmoniseerde

Standaarden, waar deze van toepassing is. Geluidsemissies volgens richtlijn 2000/14/EC Bijlage Vl. Het contactorgaan is AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire,

SK3 OXU, GB

La Sociedad, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK 17 OEU, GB, por el presente documento certifica que si el producto descrito en este certificado es comprado a un

distribuidor autorizado de Belle Group en la CEE, este es conforme a las siguientes directivas: 98/37/CE de la CEE (Esta directiva consolida la directiva inicial sobre maquinaria 89/392/CEE),

Directiva 89/336 CEE sobre Compatibilidad Electromagnética (según enmiendas 92/31/CEE y 93/68 CEE), Directiva sobre Bajo Voltaje 73/23/CEE, EN 292 de Seguridad de Maquinaria y Niveles

armonizados estándares asociados donde sean aplicables. Emisiones Acústicas conformes a la Directiva 2000/14/EC Apéndice VI, siendo notificado el organismo AV Technology Limited, AVTECH

House, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 OXU, GB

.

Nous soussignons, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, certifions que si le produit décrit dans ce certificat est acheté chez un distributeur autorisé Belle Group

au sein de la CEE, il est conforme aux normes CEE ci-après: 98/37/CE (Cette norme est une codification des normes de la machine d'origine 89/392/CEE), Norme compatible pour

l'électromagnisme 89/336/CEE (modifié par 92/31/CEE et 93/68/CEE). Caractéristiques basse tension 73/23/CEE, EN 292, Norme de sécurité des machines et des critères associés et configurés,

si applicable. Niveau sonnore conforme à la norme 2000/14/CE Annex VI, l'état avisé étant AV Technology Mimited, AVTECH House,

Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.