3

Unterzeichnet vo: Generaldirektor – Im auftrag von BELLE GROUP (SHEEN) UK.

Firmato da: Amministratore Delegato – Per conto di BELLE GROUP (SHEEN) UK.

Undertecknat: V.D. – På vägnar av BELLE GROUP (SHEEN) UK.

Signatur: Managing Director - På vegne av SOCIETE BELLE GROUP (SHEEN) UK.

Allekirjoitus: Toimitusjohtaja - BELLE GROUP (SHEEN) UK: n puolesta.

Podpisa³: Dyrektor Zarządzający – w imieniu BELLE GROUP (SHEEN) UK

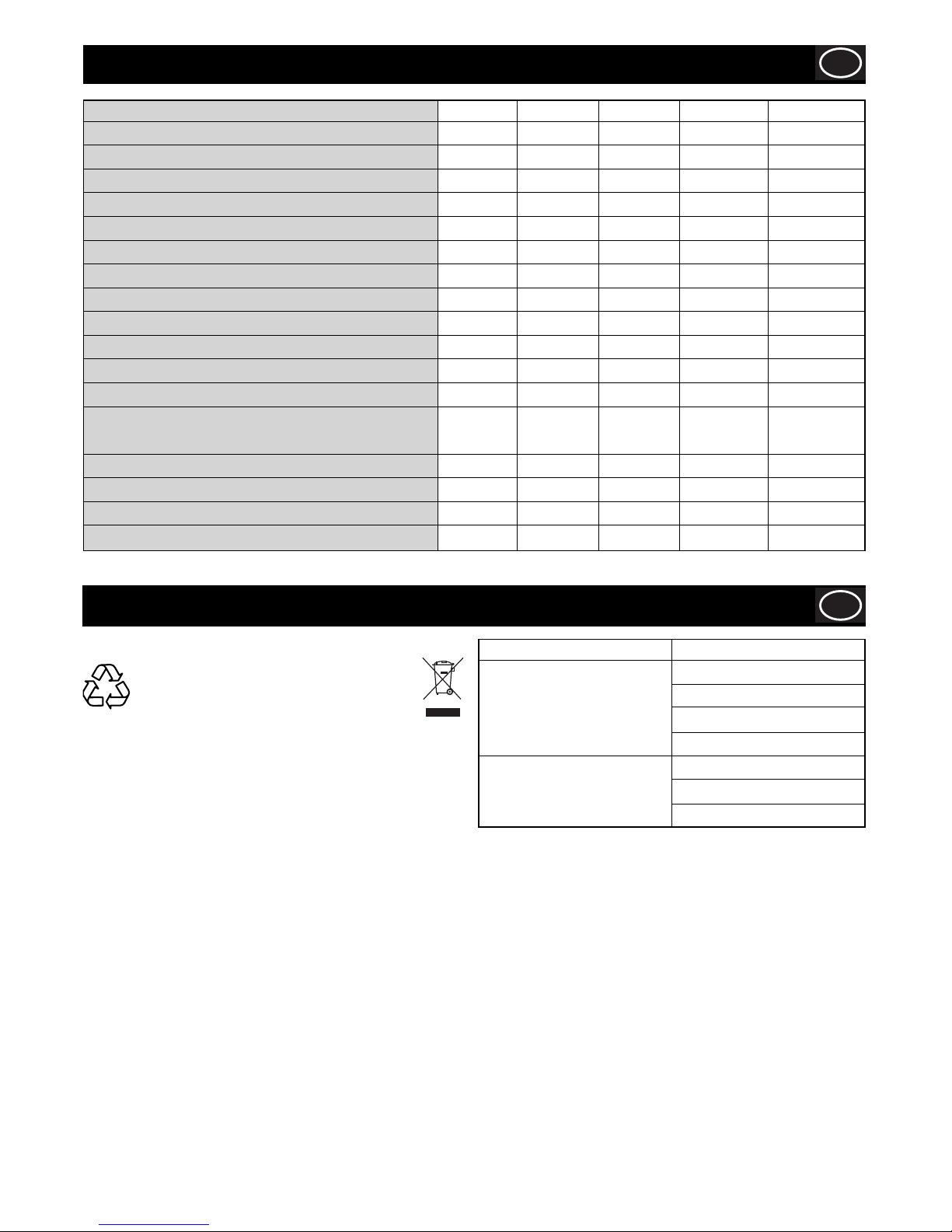

PRODUKTTYP..................... TIPO PRODOTTO ................ PRODUKTTYP..................... PRODUKTTYP.....................

MODELL .............................. MODELLO ............................ MODELL............................... MODELL ..............................

SERIENNR........................... SERIE N°.............................. SERIE NR. ........................... SERIE NR. ..........................

HERSTELLUNGSDATU ...... DATA DI FABBRICAZIONE.. TILLVERKNINGSDATUM..... PRODUKSJONSDATO........

SCHALLLEISTUNGSPEGEL LIVELLO POTENZA LJUDSTYRKA LYDKRAFTNIVÅ

GEMESSEN ......................... SONORA MISURATA ........... UPPMÄTT............................. MÅLT ...................................

(GARANTIERT).................... (GARANTITA)....................... (GARANTERAD) .................. (GARANTERT) ....................

GEWICHT............................. PESO.................................... VIKT...................................... VEKT....................................

Wir, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Großbritannien, bestätigen hiermit, dass das in diesem Zertifikat beschriebene Produkt,

wenn es von einem autorisierten Belle Group Händler innerhalb der europäischen Gemeinschaft gekauft wurde, folgenden EG-Richtlinien entspricht: 98/37/EG, 73/23/EG

(geändert durch 93/68/EG), 89/336/EG (geändert durch 92/31/EG), 93/68/EG und, wenn zutreffend, den harmonisierten Normen. Geräuschemissionen entsprechen der

Richtlinie 2000/14/EG, Anhang VI, für Maschinen unter Artikel 12: die benannte Stelle ist AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle Heath,

Stockport, Cheshire, SK3 0XU, GB.

Geräuschtechnische Dokumente stehen in unserer Zentrale unter obig angegebener Adresse zur Verfügung.

Il Gruppo Belle Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, certifica che il prodotto descritto nel presente certificato è acquistato da un concessionario

autorizzato del gruppo Belle nell'ambito CEE e che è pienamente conforme alle seguenti direttive CEE: 98/37/EC, 73/23/EEC (emendamento 93/68/CEE), 89/336/EEC

(emendamento 92/31/CEE), 93/68/CEE e relativi standard armonizzati. Livelli acustici sono in conformità con la direttiva 2000/14/EC Annex VI per macchine coperte dall’

articolo 12. L’ente di riferimento è AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Dati tecnici relativi ai livelli acustici sono disponibili su richiesta dalla sede madre Belle Group al sopra citato indirizzo.

Undertecknade, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, Storbritannien, intygar härmed att en produkt beskriven i detta certifikat som

köps från en godkänd Belle Group återförsäljare inom EU stämmer överens med följande EG-direktiv: 98/37/EG, 73/23/EG (ändrat genom 93/68/EEC), 89/336/EG

(ändrat genom 92/31/EG), 93/68/EG och tillhörande harmoniserade standarder i tillämpliga fall. Buller nivån överensstämmer med Direktiv 2000/14/EC Bilaga VI gällande

maskiner under artikel 12, den aviserade organisationen är AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU,

Storbritannien.

Teknisk dokumentation vad gäller test av maskiners ljud/bullernivå finns dokumenterad hos Belle-Groups huvudkontor i Sheen, England.

Vi, Belle Group Sheen UK, Sheen, Nr Buxton, Derbyshire, SK17 0EU, GB, bekrefter med dette at det produktet som står beskrevet i denne erklæringen er kjøpt fra en

autorisert Belle Group forhandler innen EØF, og at det oppfyller følgende direktiver: 98/37/CE dette direktivet er et sammendrag av det opprinnelige maskindirektivet

89/392/EØF), Det elektromagnetisk kompatabiltets-direktivet 89/336/EØF (som endret av 92/31/EØF og 93/68/EØF). Lavspenningsdirektivet 73/23/EØF, BS EN ISO

12100-1:2003, Sikkerhet til maskineri og tilhørende harmoniserte standarder, hvor atuelt. Støyemisjon er i samsvar med direktiv 2000/14/EC, vedlegg VI, for maskiner.

Organet som skal informeres under artikkel 12 er

AV Technology Limited, AVTECH House, Birhall Lane, Cheadle Heath, Stockport, Cheshire, SK3 0XU, GB.

Lydtekniske filer er arkivert hos Bell Group Hovedkontor med adresse som nevnt ovenfor.

Me, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, GB, ilmoitamme täten, että jos tässä todistuksessa kuvattu tuote on ostettu valtuutetulta Belle

Groupin myyjältä ETY:n alueella, se on yhdenmukainen seuraavien ETY-direktiivien kanssa: 98(37/EY (Tämä direktiivi on yhdistelmä alkuperäisestä konedirektiivistä

89/392/ETY, sähkömagneettisen yhteensopivuuden direktiivistä 89/336/ETY, korjauksineen 92/31/ETY ja 93/68/ETY), matalajännitedirektiivistä 73/23/ETY,

koneturvallisuusstandardista BS EN ISO 12100-1:2003 ja siihen liittyvistä yhdenmukaistetuista standardeista, tapauksen mukaan. Melumittaus mittaus on laadittu

direktiivin 2000/14/EC Kohdan VI artiklan 12 mukaisille koneille mukaan. Mittauksen suorittaja on AV Technology Limited, AVTECH House, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, GB.

Melumittausten teknilliset arvot ovat saatavana Belle Group pääkonttorin ylläolevasta osoitteesta.

My, Belle Group Sheen UK, Sheen, Nr. Buxton, Derbyshire, SK17 0EU, Wielka Brytania, niniejszym poświadczamy, iż produkt opisany w tym świadectwie został

zakupiony od autoryzowanej Belle Group w UE i jest zgodny z następującymi dyrektywami EU: 98/37/EC (ta dyrektywa to konsolidacja oryginalnej dyrektywy na temat

maszyn 89/392/EEC), Dyrektywą zgodności elektromagnetycznej 89/336/EEC (z poprawkami wniesionymi przez 92/31/EEC oraz 93/68/EEC), Dyrektywą w sprawie

niskich napięć 73/23/EEC, BS EN ISO 12100-1:2003 Bezpieczeństwo maszyn i związane normy harmonizacyjne, tam gdzie to ma zastosowanie. Poziom hałasu jest

zgodny z Dyrektywą 2000/14/EC Zalącznik VI, organizacja zawiadamiana (odnośnie zgodności) to AV Technology Limited, AVTECH house, Birdhall Lane, Cheadle

Heath, Stockport, Cheshire, SK3 0XU, Wielka Brytania.

Informacje Techniczne dotyczące poziomu hałasu są przechowywane w Belle Group – adres powyżej.

EGKONFORMITÄTSERKLÄRUNG / DICHIARAZIONE CE DI CONFORMITÁ /

EG-VERKLARING VAN OVEREENSTEMMING /

EC SAMSVARSERKLÆRING / EY-YHDENMUKAISUUSILMOITUS / DEKLARACJA

ZGODNOSCI Z PRZEPISAMI UE

Ray Neilson

TUOTETYYPPI..................... TYP PRODUKTO..................

MALLI................................... MODEL .................................

VALMISTUSNRO................. Nr SERII................................

VALMISTUSPÄIVÄ.............. DATAPRODUKCJI ...............

ÄÄNENVOIMAKKUUDEN POZIOM MOCY

TASO MITATTU...................

DŹ

WI

Ę

KU ZMIERZONY ......

(TAATTU) ............................. (GWARANTOWANY)............

MASSA................................. WAGA...................................

D

I

S

NO

SF

PL