Belltech 6519 User manual

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

1

INSTALLATION INSTRUCTIONS

----3300 W. Pontiac Way Clovis, CA 93612 toll free: 1-800-445-3767 web: www.belltech.com----

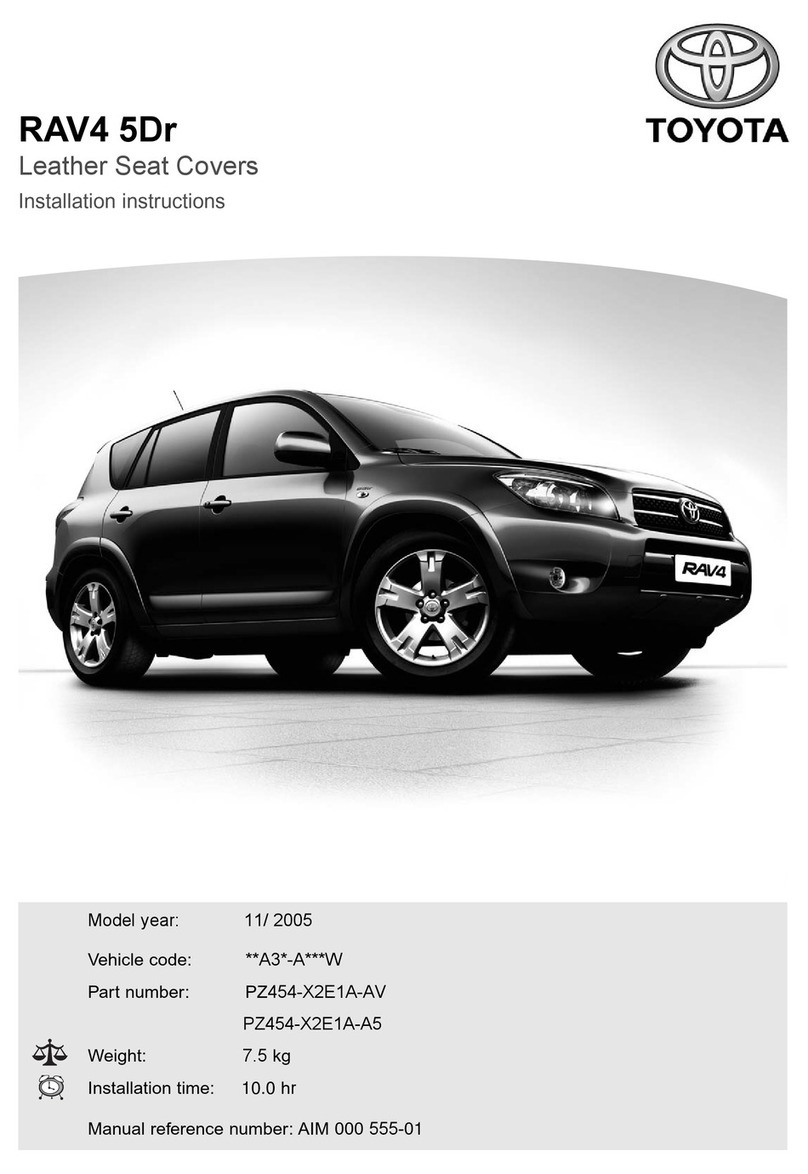

6519

REAR AXLE FLIP & HANGER KIT

04-UP CHEVROLET 1500 QUAD CAB

Thank you for being selective enough to choose our high quality BELLTECH PRODUCT. We

have spent many hours developing our line of products so that you will receive maximum

performance with minimum difficulty during installation.

Note: Confirm that all of the hardware listed in the parts list is in the kit. Do not begin installation if

any part is missing. Read the instructions thoroughly before beginning this installation.

Warning: DO NOT work under a vehicle supported by only a jack. Place support stands securely under

the vehicle in the manufacturer’s specified locations unless otherwise instructed.

Warning: DO NOT drive vehicle until all work has been completed and checked. Torque all hardware to

values specified.

Reminder: Proper use of safety equipment and eye/face/hand protection is absolutely necessary when

using these tools to perform procedures!

Note: It is very helpful to have an assistant available during installation.

RECOMMENDED TOOLS:

Properly rated floor jack and six (6) support stands

Wheel chocks

Die grinder equipped with abrasive cut-off wheel

½” drive torque wrench

Standard socket wrench set

Air powered ½” drive impact wrench

Flat bladed screw driver

Safety glasses

Air powered chisel

KIT INSTALLATION

As this is a relatively involved installation, we recommend that a qualified mechanic at a properly equipped

facility perform it. We also recommend that the installation be performed on a firm, flat and level surface,

such as seasoned asphalt or concrete. The use of safe and properly maintained equipment is very important!

In order to document any possible irregularities in the factory ride height of your vehicle, please take a few

moments to fill out the Belltech Vehicle Inspection Record included with these instructions. We also

recommend measuring and recording all stock driveline angles prior to installing this kit. This information may

be helpful if vibration problems arise after installation.

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

2

1. JACKING, SUPPORTING AND PREPARING THE VEHICLE

1a) Block the front wheels of the vehicle with appropriate wheel chocks. Make sure the

vehicle’s transmission is in “Park”(automatic) or 1st gear(manual. Activate the parking

brake.

1b) Loosen, but DO NOT REMOVE the rear lug nuts.

1c) Using a properly rated floor jack, lift the rear of the vehicle off the ground. Lift the

vehicle so that the rear tires are approximately 6-8 inches off the ground surface.

1d) Support the vehicle using four (4) support stands, rated for the vehicle’s weight. The

stands should be positioned, two on each of the frame rails, just forward of the front leaf

spring hangers and just below the rear leaf spring shackle hangers. Prior to lowering

the vehicle onto the stands, make sure the supports will securely contact the straight,

flat portions of the frame area.

!It is very important that the vehicle is properly supported during this installation to

prevent frame damage and personal injury! Make sure that the support stands are

properly placed prior to performing the following procedures.

1e) Slowly lower the vehicle onto the stands and, before placing the vehicle’s weight on

them, again check that they properly and securely contact the frame rails described

above. Check for possible interference with any lines, wires or cables.

!SAFETY REMINDER: Check for safe vehicle stability before proceeding under

the vehicle to begin the following procedures. Never work under a vehicle supported by

only a jack. Always use properly rated support stands to support the vehicle.

2. TRAILER HITCH REMOVAL (IF APPLICABLE)

2a) If your vehicle has come equipped with a Trailer Hitch, more than likely, this will

interfere with the installation process. This will need to be removed. This makes

access easier when mounting the REAR SHACKLE hardware.

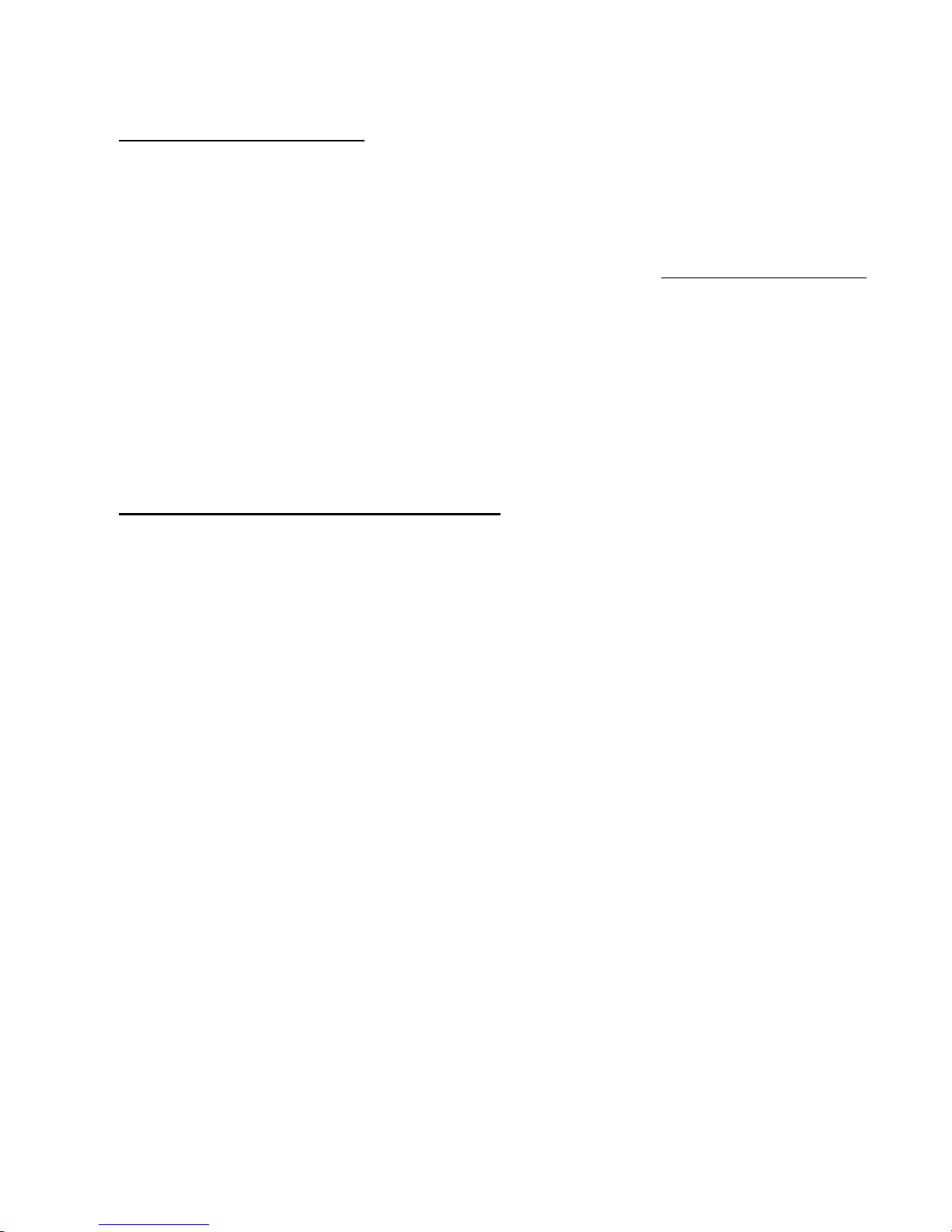

2b) Disconnect the wire plug, as shown below in (Photo 1)

2c) Using a 21mm wrench, remove all the mounting hardware for the Trailer Hitch. There is

a total of six bolts, three (3) per side.

2d) Lower and remove the Trailer Hitch and place out of the way, along with the hardware.

3. GAS TANK PROTECTIVE SHIELD AND GAS TANK REMOVAL

3a) In order to get to the front mounting hardware that mounts the leaf spring(driver’s side),

the GAS TANK will need to be lowered to get access to the bolt head.

3b) First, support the GAS TANK from underneath. NOTE: This step would be easier to do

if the GAS TANK was near empty. Otherwise, moving a half-full or a full tank of gas is

going to be more laborious.

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

3

3c) The PROTECTIVE SHIELD that shrouds the GAS TANK is mounted with three (3)

mounting bolts on one side(driver’s side), that mount directly to the frame. (Photo 2).

Using a 13mm wrench, remove the bolts completely and set aside. On the inside

(opposite of driver’s side), the SHIELD hangs on four (4) rectangular hooks.(Photo 3)

Lift this side up above the hooks. You should now be able to wiggle the PROTECTIVE

SHIELD down and out. Set this aside. Put the three (3) mounting hardware back in

their respective mounting holes for safe keeping.

3d) Holding the GAS TANK in place are two (2) straps that are mounted at each end of the

TANK (Photo 4). Each strap is mounted directly to the frame on one end only. The

opposite end is attached primarily by a hook attachment.

3e) Remove the two mounting bolts completely. These are located on the driver’s side of

the TANK itself and the inside part of the frame chassis.

3f) Pull the straps down from the driver’s side and un-hook the straps from the other end.

3g) Next locate the three (3) mounting hardware that bolts the GAS NOZZLE INTAKE,

behind the gas door (Photo 5). Remove the three (3) bolts completely.

3h) With the GAS TANK supported from underneath, slowly lower the GAS TANK six(6”) to

(12”) inches, pulling the rubber gas neck down as the GAS TANK travels down.

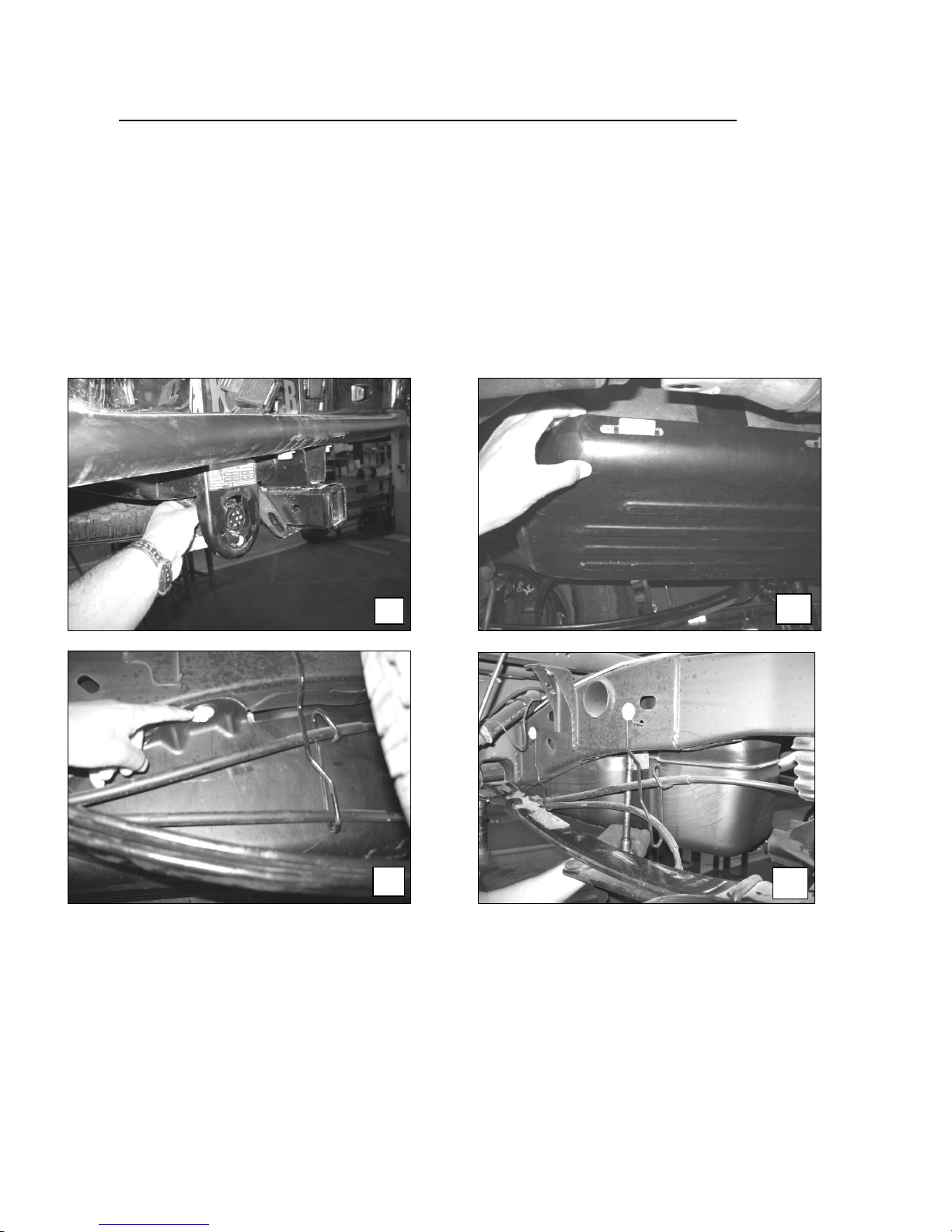

4. U-BOLT REMOVAL

4a) There are two(2) sets of U-BOLTS, two per each LEAF SPRING, that is attached to the

rear axle. Using a 21mm wrench, (Photo 6) un-bolt all mounting hardware (nuts and

washers) on each U-BOLT. Remove all four (4) stock U-BOLTS completely.

The LEAF SPRING not becomes detached from the rear axle.

5. LEAF SPRING REMOVAL

! CAUTION: LEAF SPRINGS may be under tension. SPRINGS under tension store a great

amount of energy. Use caution during the following steps to avoid personal injury

and/or damage to the vehicle. BE CAREFUL not to damage the brake hoses/and or

driveline when re-locating the rear axle assembly.

5a) With the vehicle raised and the chassis supported with stands, raise the rear axle to

remove the load from the shackle.

5b) Starting with the front end of the LEAF SPRING towards the engine (front), using a

21mm wrench, un-bolt the hardware and remove completely. (Photo7) With the GAS

TANK lowered slightly, you should be able to get to this hardware. Once the bolt is

removed, the LEAF SPRING should be able to sit atop the rear axle.

5c) With the LEAF SPRING sitting atop the rear axle, move back to the REAR SHACKLE

HANGER. (Photo 8) Using a 21mm wrench, un-bolt the hardware and remove

completely.

IMPORTANT NOTE: Once the LEAF SPRINGS have been removed, keep them in tack. Once you

lay them on the ground, keep them in tact by using c-clamps.

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

4

Also, for ease of re-installation, mark each LEAF SPRING left and right, to insure that

the same ones go back on the same side as they were removed.

6. REAR SHACKLE(STOCK) REMOVAL

6a) With the LEAF SPRING removed and set aside, you now have easy access to the

REAR SHACKLE. (one on each side of the vehicle) Below are the steps to follow to

remove the stock REAR SHACKLE from the chassis frame;

6b) Using a cut-off wheel or a type of abrasive cutting tool, makes a slot thru the heads of

the rivets, three (3) each on each REAR SHACKLE HANGER. (Photo 9) There are

three (3) rivets on each side that need to be removed. The slots should be straight thru

the rivet heads and flush with the surface they are mounted to

6c) With a pneumatic hammer and chisel attachment, remove the rivet heads. (Photo 10).

It should take no more than a few seconds to chisel each head off. Once all rivet heads

have been removed, it is helpful to use a punch and hammer or a punch with the air

hammer to push the rivets thru the chassis.

6d) Also located here on the REAR SHACKLE HANGER is a single bolt, that mounts, along

with the rivets, to the chassis. Using a 15mm wrench, un-bolt the hardware and remove

completely.

6e) Remove the entire REAR SHACKLE HANGER completely off the chassis.

6f) Also located in this area is the REAR SHACKLE HANGER SUPPORT BRACKET. This

is a stock piece that is no longer needed and more than likely will interfere with the new

BELLTECH HANGER. Mounted by a small weld to the chassis frame, it is also

mounted with a heavy-duty rivet. Using a cut-off wheel or type of abrasive cutting tool,

make a slot straight (PHOTO 11) thru the rivet head and flush with surface they are

mount to.

Using a hammer, channel-locks or vice-grips, pull and push the SUPPORT BRACKET

upwards towards the spare tire. Repeat procedure back and forth until it breaks free.

(Photo 12)

7. REAR SHACKLE INSTALLATION

7a) Prior to installing the REAR SHACKLE, our R & D Techs have found it easier to pre-

assemble the REAR SHACKLE HANGER and the SPRING SHACKLE MOUNT.

7b) Using the kit supplied hardware, bolt up the new BELLTECH REAR SHACKLE

HANGER to the existing holes in the chassis. (Photo 13)

IMPORTANT NOTE:

Located on your new REAR SHACKLE HANGER, are four (4) sets of holes, four (4) on each

side of the HANGER. Using the top hole and the third hole from the top, (Photo 13) this lowers

the vehicle 4”. Using the second and fourth holes from the top, lowers the vehicle 5”.

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

5

8. LEAF SPRING INSTALLATION

8a) Start with the front end of the LEAF SPRING (towards the engine) (Photo 14). With the

GAS TANK still slightly lowered, install the original hardware from the GAS TANK side

outward towards the driver’s side of the vehicle, thru the frame and the LEAF SPRING

eye. Start the lock nut, but do not tighten completely.

8b) Swing the LEAF SPRING upward. The LEAF SPRING will now locate underneath the

rear axle.

8c) Swing the rear of the LEAF SPRING upward to the SPRING SHACKLE MOUNT, align

the LEAF SPRING eye with the SPRING SHACKLE MOUNT holes. (Photo 15)

Insert the new hardware and but do not tighten completely. This is to be done once the

vehicle has been lowered and put on the ground.

8d) Using a 21mm wrench, re-tighten the front hardware on the LEAF SPRING.

9. SPRING SADDLE AND U-BOLT INSTALLATION

! Locate the BELLTECH axle ADPATER SADDLES supplied in the kit. Place the

ADPATER SADDLES on top of the springs with the hole over the head of the spring center

bolt. To properly position the axle, the offset holes MUST be oriented toward the front of the

vehicle. Slowly lower the rear axle assembly down onto the saddles. (Photo 16) The ears

should fit into the stock spring perches on the axle tubes. Make sure both ears on each

SADDLE locate completely in the perches.

9a) With the new kit U-BOLTS hanging on the axle, one on each side of the SADDLE, slide

the U-BOLTS up against the SADDLE.

9b) Install the U-BOLT PLATES below (under the LEAF SPRINGS), with the off-set holes

forward, so the U-BOLTS pass through the appropriate slots. (Photo 17)Attach the

PLATES using washers and locknuts. Tighten and torque locknuts to 90 lb ft.

10c) Install the kit supplied shim. Its VERY IMPORTANT to make sure the shim is installed

properly, with the large part facing the rear of the vehicle (Photo 17a). The new

location for the shim is between the top of the leaf spring and the bottom of the rear

axle.

!The AXLE ADAPTER SADDLES have been designed to properly position the rear axle

pinion shaft relative to the driveline so that vibrations are eliminated. If driveline

vibrations are experienced, take the vehicle to a driveline service shop immediately for

driveline angle inspection and necessary adjustments. DO NOT drive vehicles

exhibiting driveline vibrations, as U-joint wear could occur prematurely. Be sure to

lubricate the U-joints if deemed necessary.

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

6

10. SHOCK ABSORBER, SHOCK EXTENSION AND BUMP STOP INSTALLATION

10a) Install SHOCK ABSORBER EXTENSIONS (Photo 18) (P/N 6654) as described in the

6654-88 instructions. (These instructions are included separately in the kit)

10b) Install the appropriate BELLTECH Nitro-Drop® or Nitro-Active® rear shock absorbers

using the original hardware. See the current BELLTECH APPLICATION GUIDE or

contact your nearest BELLTECH Dealer for the appropriate part numbers for your

application. Tighten and torque hardware to 70 lb ft.

10c) The BUMP STOP will also need to be replaced. Locate the BUMP STOP, one per side

and remove. (Photo 19) Here removal of the stock BUMP STOP is shown. In Photo

20, you can see a difference in height from the stock to the BELLTECH BUMP STOP.

2

1

3

4

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

7

5

6

7

8

STOCK

U-BOLTS

8b

8a

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

8

10

14

9

11

12

13

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

9

16

15

19

17

U-BOLT

PLATE

SADDLE

AXLE

SPRING

SHACKLE

MOUNT

REAR

HANGER

MOUNT

20

18

SHOCK

EXTENSIONS

STOCK

6519-888 9/05

A Division of KW AUTOMOTIVE North America, Inc.

10

11. All hardware being fastened to the vehicle’s original fastening points should be torqued to the

proper specifications. To prevent chassis damage, never over-torque the hardware.

12. Check that all components and fasteners have been properly installed, tightened and torqued.

13. Lift vehicle and remove support stands. Carefully lower vehicle to ground.

14. Immediately test-drive the vehicle in a remote location so that you can become accustomed to the

revised driving characteristics and handling. Be aware that the vehicle will handle substantially

different now that it has been modified.

15. Installation is complete. Check all of the hardware and re-torque at intervals for the first 10, 100,

1000 miles.

Parts List: 6519 Axle flip kit

Part #

Description

Quantity

6612-005

Axle Saddle

2

6600-010

U-Bolt Plate

2

6519-010

Rear Leaf Hanger

2

6612-012

Shock Extension Rear

2

7000-880-95

Zinc Plated Spacer Tube

2

110670

Flat Washer A325 9/16"

4

110454

Nylon Insert Lock Nut 9/16"-12

2

110456

HHCS 9/16"-12 X 3.5"

2

6654

Shock Extension 99-00 Chevy

1

4920-001

Bump Stop W/Nylon LN

2

110502

Flat Washer A325 5/8"

8

110505

Nylon Insert Lock Nut 5/8"-18

8

110645

Flat Washer A325 7/16"

12

110303

Stover Lock Nut 7/16"-20

6

110650

HH Cap Screw 7/16"-20 X 1-1/4"

6

6612-015

U-Bolt 99-00 Chevy Flip Kit

4

4977-001

4° Pinion Shim

2

Table of contents

Other Belltech Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Go Rhino

Go Rhino Lightning Series Assembly/installation instructions

Safe Fleet

Safe Fleet RVS-116-W instruction manual

PerTronix

PerTronix 1625S-6 1998 Installation Instructions and Warranty

Clarion

Clarion PP-2538T Service manual

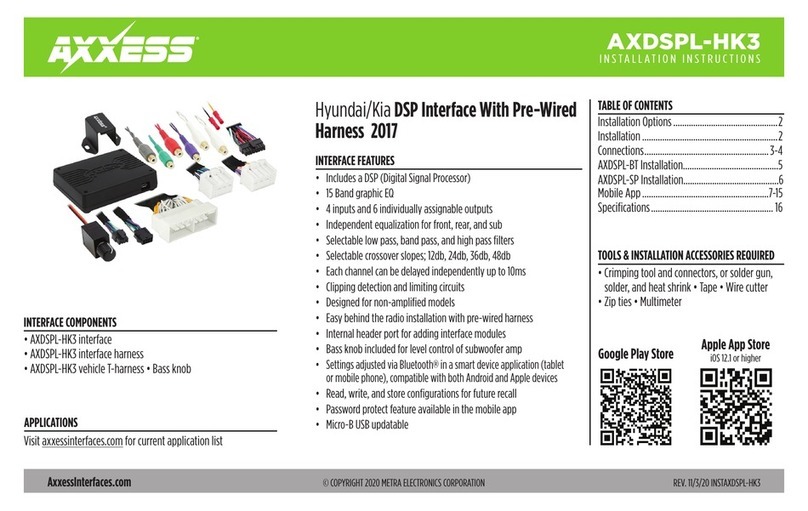

Axxess

Axxess AXDSPL-HK3 installation instructions

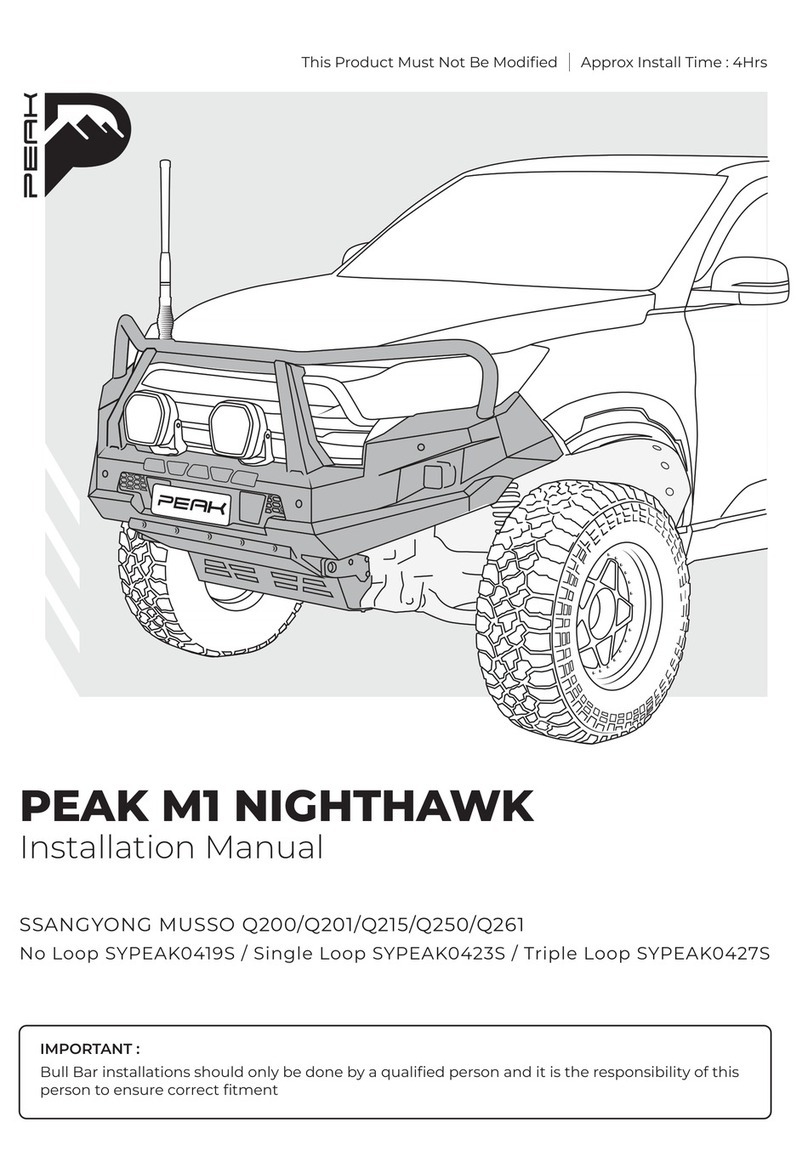

Peak

Peak M1 NIGHTHAWK installation manual